The LS series of GM engines have been around since the late ’90s and over time have found their way into everything from trucks to Corvettes. Why? Because they are simply some of the best engines ever built by the hand of man. But even these engines have their limitations. One is bore size and the other is strength, especially for those wanting to add a little boost to the horsepower equation.

You see, a larger displacement, say 427-cubic-inch, LS is going to be built around an aluminum LS7 block. Aluminum is great for shedding weight, but it doesn’t hold a candle to the strength of iron. That’s where Chevrolet Performance and their line of LSX blocks comes into play. Their aftermarket iron blocks can be bored all the way out to 4.250 inches, and since they are iron, they can take boost levels that would send aluminum blocks to the great beyond. Of course, they have other benefits as well, like billet main caps and priority main oiling, but they really shine in terms of strength.

We knew we wanted to stuff an LSX block full of luscious boost so we just needed to come up with the right formula. We didn’t need huge displacement since we were going to do the heavy lifting with boost, so we settled on a 427 with a 4.000-inch stroke and 4.125-inch bores. Why not go with a bigger bore? Simple, the smaller the bore, the thicker the cylinder walls and the better they will hold up to increased pressure. To add to the overall strength of the engine, we opted for six-bolt Trick Flow LS3 heads. The extra head bolts prevent lifting, which can send things sideways at higher boost levels.

To stuff in atmosphere at a rapid pace we decided on one of the units from ProCharger. At first we were looking at their D-1SC unit, but after doing a little math we figured out that it wouldn’t move enough air to get the engine to our power goal of 1,000 horsepower. With that in mind we went with ProCharger’s F-1A supercharger. (The D-1 would be a great choice on a small-cube engine, something below 400 inches.) The D-1SC and F-1A have similar efficiency up to 850 hp, after that the F-1A has the advantage as it supports more power per psi of boost. In short, a bigger engine with bigger power goals requires a bigger supercharger. Like everything else, the blower needs to be sized properly for the engine.

So with a block, blower, and heads we gathered up the rest of the required parts and headed over to Evod Garage for a build session. Chris Pollock is a stickler for the details, and when your goal is to get somewhere near 1,000 horsepower, he’s just the sort of guy we want putting all those expensive parts together into an engine that won’t go “boom” at the wrong moment … or any moment for that matter.

01. The Chevrolet Performance Parts LSX Bow Tie iron block (PN 19213964) offers quite a few features not found on factory LS blocks. Tidbits like extra head bolt provisions and thicker deck surfaces. Other refinements include improved bay-to-bay breathing, doweled main caps, a seventh transmission bolthole, and a priority main oiling system. Plus, for a boosted engine, it’s hard to beat the strength of iron.

02. Chris Pollock went about the task of properly installing the cam bearings and prepping for assembly. For this build we opted to use Clevite main bearings (PN MS-2188HX) and lots of assembly lube. You can also see the LSX block’s doweled billet main caps. The Scat crank (PN 4-LS1-1-4000-6125-58, $996) came micro-polished, nitride-hardened, with gun-drilled mains and lightening holes in all the rod throws. It also came with dual keys on the snout for a damper.

03. Packaged with the crank were eight Scat high-tensile 4340 forged H-beam rods (PN 6612521, $468). They came profiled for stroker clearance; ideal for our boosted application, and in our case they were already fitted with ARP 2000 cap screws.

04. With a boosted engine, it’s always a better idea to drop the engine’s compression and just make more boost. Given this, Chris came up with a target of 9.1:1 compression. To get there we chose Mahle PowerPak inverted-dome +25.00cc pistons (PN L92105125P25, $957). These phosphate-coated (with Grafal anti-friction coating), 4.125 bore pistons are forged from 2618 aluminum and have forced-pin oiling for increased wristpin lubrication. The set came with file-to-fit rings and wire locks.

05. Chris then went about the task of mating the Scat rods to the Mahle pistons using the included wire locks. The Mahle rings were then file-fitted to each slug. Since we didn’t want the rings to close up (ring butting), the gaps were opened up a bit. This is important since superchargers make heat, which causes the rings to expand. The top ring was set at 0.028 inch, the second ring was at 0.024 inch, and the oil ring was at 0.025 inch.

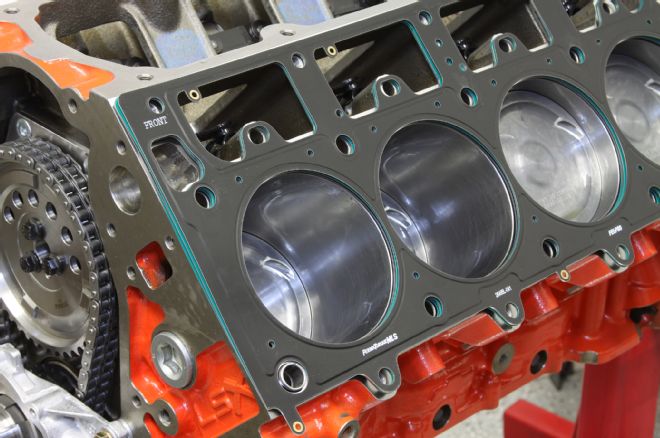

06. The block came with 3.990-inch semi-finished bores that can be taken all the way out to 4.250 inches. In our case, we were looking to build a 427, so Evod Garage had the cylinders knocked out to 4.125 inches. Chris used a Summit compression sleeve to slide each piston/rod into place.

07. Each rod was then torqued to 70 ft-lb. Another nice feature of the LSX block was that Chevrolet Performance had the foresight to notch the cylinder sleeves for rod bolt clearance, which saved us a ton of time.

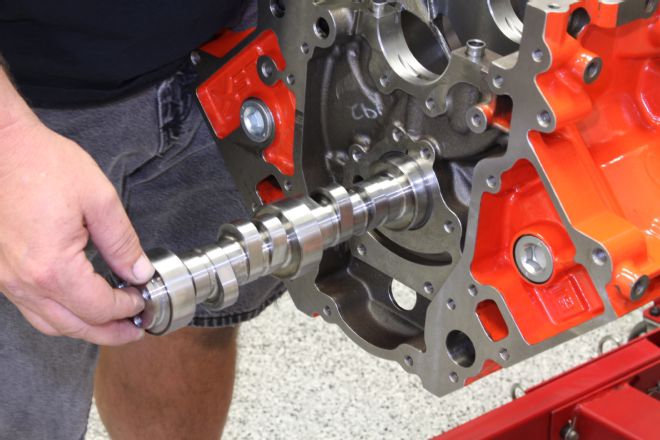

08. Proper camshaft selection is critical in any engine, but even more so in one that will be relying on boost. After consulting with the go-fast guys at COMP, Chris chose a stick with duration (at 0.050-inch) of 243/263, lift of 0.651/0.661, and an LSA of 118. This grind should play nice with both our ProCharged boost as well as our Trick Flow LS3 heads.

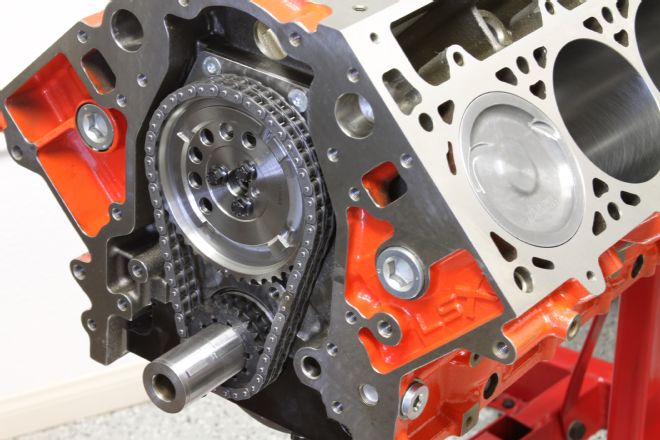

09. One of our favorite timing sets for LS builds is this billet piece from Lunati (PN 95536). Their keyway-adjustable timing set has steel billet gears and a nine-keyway crank sprocket. This allows for one-degree adjustments with a maximum range of four-degree advance/retard. It also has a large-pin, 0.250-inch double roller chain that came pre-stretched and heat-treated. We bolted it to the cam with three ARP fasteners (PN 134-1003).

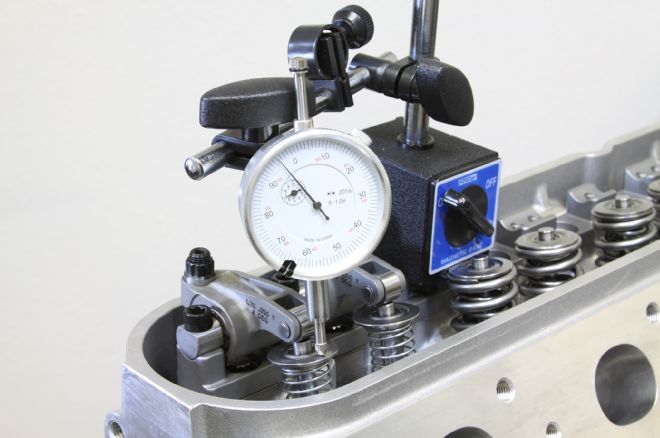

10. The next step was to degree the camshaft. Many LS builders skip this step, but it’s a good idea and takes less time than fixing it later. The cam card specified a 118 centerline and ended up at 17.5 degrees.

11. The next step was to degree the camshaft. Many LS builders skip this step, but it’s a good idea and takes less time than fixing it later. The cam card specified a 118 centerline and ended up at 17.5 degrees.

12. These captured link bar lifters from COMP (PN 15956-16) are a great hydraulic lifter for the money. Link bar style lifters are needed on LSX blocks since there’s no provision for the plastic lifter trays found on OE LS blocks. We chose short-travel style since they cut down on power loss and valvetrain failure by limiting the lifter’s internal piston as they are pumped up.

13. To make big power, you need a killer set of heads. For this build, we went with a set of Trick Flow GenX 255 LS3 cylinder heads (PN TFS-32610002-C01). The big 255cc intake ports should easily feed our supercharged 427, and these square-port heads work on engines with 4.00-inch bores and larger. The heads have 69cc combustion chambers and are completely CNC detailed. This equates to more airflow and better combustion. Trick Flow also altered the valve angles from 15 to 12 degrees to increase piston-to-valve clearance. They came assembled with 2.165-inch intake and 1.600-inch exhaust valves, Viton seals, chromoly-steel retainers, and ductile iron valve seats. For more peace of mind, we opted for the six-bolt offering with an ARP head stud kit (PN234-4319).

14. To be on the safe side, Chris wanted to check the piston-to-valve clearance. So he installed some lightweight springs, the rockers, and set the heads in place. To simulate a head gasket, he used thin shims. We had plenty of clearance due to the wider lobe separation of the camshaft. For the intake there was 0.300-inch and on the exhaust side there was 0.230-inch.

15. To seal the deal between the heads and block, we tossed on a pair of Fel-Pro (0.041-inch thickness) PermaTorque MLS gaskets (PN 26495L/R041).

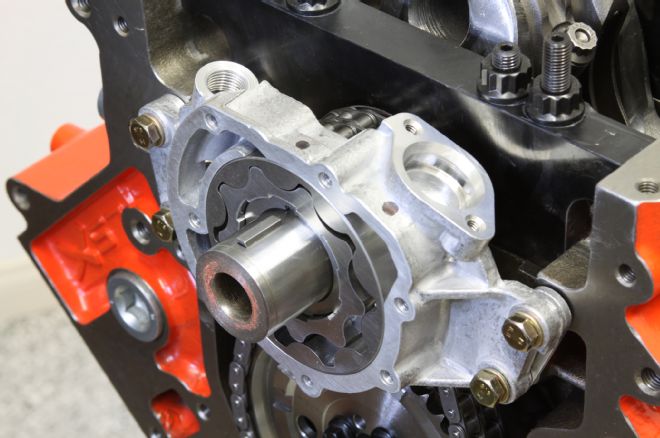

16. We sealed up the front of the engine with COMP’s timing cover (PN 5496). This cover is great on many levels. First, it easily accommodates double-roller timing chains, plus it can work with standard and raised cam blocks. We also picked up the ATI damper from Summit Racing that ProCharger suggested. In addition to the blower drive pulleys, ProCharger also offers complete drive systems with power steering and alternator provisions.

17. According to Trick Flow, our heads were good-to-go with LS3 rockers up to 0.625-inch lift, but our cam was well above that. This meant we needed something a bit more special in terms of rockers. Given this, we picked up some Crower shaft rockers (PN 74173F, $1,400) specifically designed to work with the unique layout of the Trick Flow LS3 heads. These stainless steel 1.7 ratio rockers will stay rock-solid steady at high rpm and are optimized to be as light as possible at the tip. For pushrods, we went with 8.00-inch long, 5/16-inch-diameter chromoly pieces from COMP (PN 7995-16, $140).

18. Our plan was to stuff in a ton of atmosphere, so we wanted an intake that would be up to the task. We chose a FAST 102mm LS3 intake (PN 146102B, $914) and their matching 102mm Big Mouth billet throttle body (PN 54103, $564).

19. To finish off the top of the engine, we ordered a pair of FAST fuel rails (PN 146027-KIT, $196) and a set of FAST low-impedance fuel injectors (PN 30857-8, $375). They have a flow rating of 85 lb/hr and can support over 1,000 horsepower.

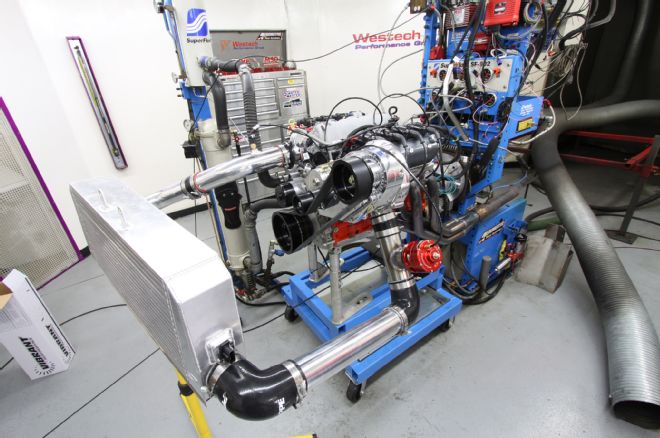

20. With the engine assembled, we hauled it down to Westech Performance for a little fun time on their Superflow 902 dyno. The 427 was fitted with a Meziere electric water pump and filled with Lucas oil. We then bolted on a set of uncoated Doug’s 1 7/8-inch full-length Camaro LS swap headers (PN D-3341R, $548). These mandrel-bent headers feature warp-free 3/8-inch flanges and are designed to reduce backpressure. We could’ve made more power with some huge drag race headers, but we wanted to keep things real and exhale through street pipes.

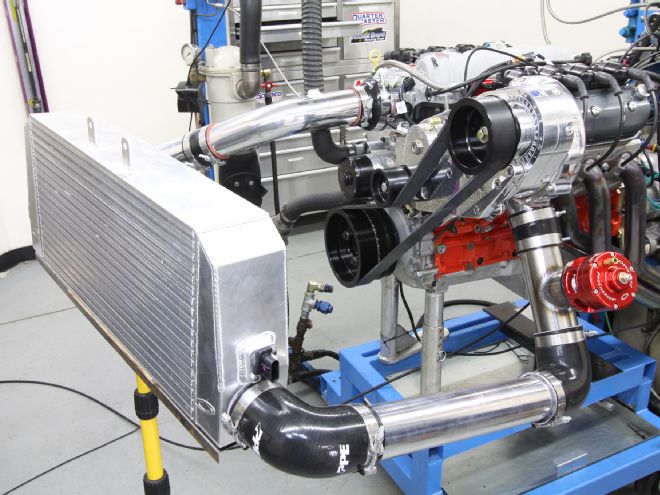

21. For tuning, we decided to roll with the same Holley HP computer that will eventually control the engine in the car.

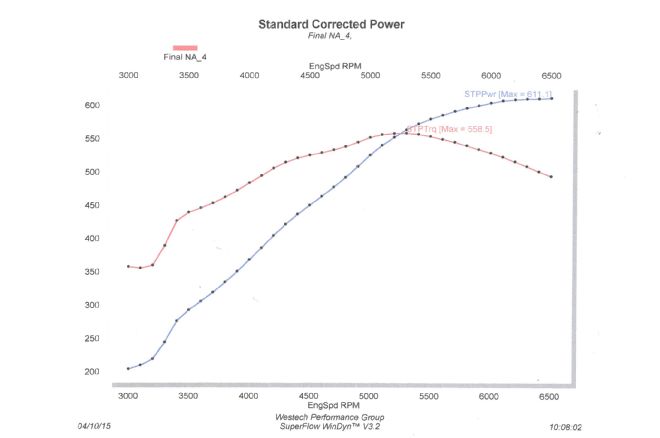

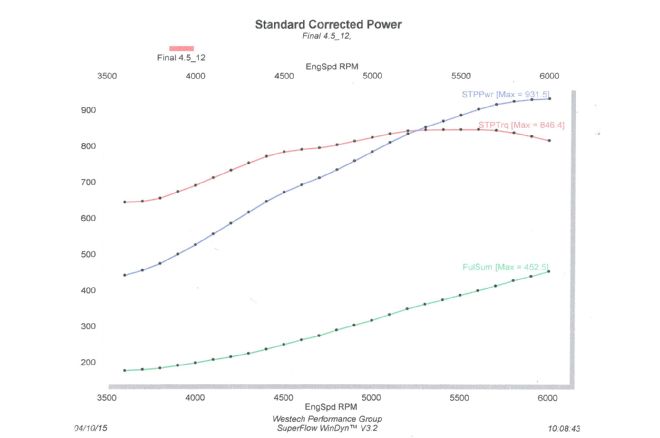

22. On our baseline pull we filled the tank with 91-octane Rocket gas, and after just four pulls it knocked down 611 horsepower and 559 lb-ft. Not bad for a 9.1:1 engine running a camshaft ground for boost.

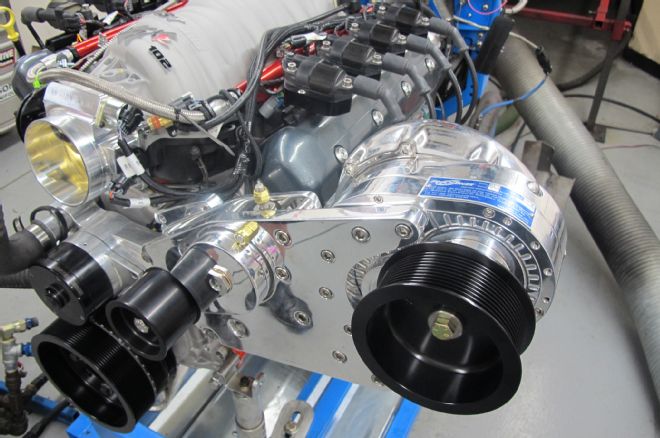

23. Now for the fun part: bolting on the ProCharger F-1A centrifugal supercharger. Given our power goals, we moved up to their F-1 line, and besides, a big blower just looks cool slung on the side of an engine. The supercharger’s design eliminates the need for oil lines and punching a hole in the oil pan. The unit’s internal pump aerates the oil to create oil mist lubrication for the bearings and gears. The entire package makes for a unit that will have amazing longevity and make great power. We decided to start with their 4.50-inch blower pulley, and to be safe we added some 114 Rocket race gas to the tank.

24. The blower shipped dry, so we add one (and just one) bottle of oil to the ProCharger F-1A. Forgetting to do this will ruin your blower. ProCharger specifies that the oil be changed every 6,000 miles. This isn’t just engine oil in a little bottle; it’s specifically engineered for high-speed use and produces very little frictional heat and parasitic load. Since the supercharger has its own oil supply, heat isn’t introduced like it would be if engine oil were used.

25. If you’re planning on anything more than 5 or 6 psi of boost, then an intercooler system falls into the “must have” category. That meant we needed to find a way to hook one up on the dyno. ProCharger sent us an intercooler and we were able to find all of the clamps, couplers, tubing, and fittings at Summit Racing. Being able to find all the parts in one place made life much easier. We also ordered a Holley three-bar MAP sensor.

26. We also pulled the NGK plugs and closed the gap from 0.033-inch to 0.020-inch for the boosted pulls.

27. We were sort of surprised that our biggest pulley churned out just over 12 psi of boost. This yielded power numbers of 932 horsepower at 6,000 rpm and a whopping 846 lb-ft of torque at 5,600 rpm. We did notice that the engine only pulled to just over 6,000 rpm instead of to the nearly 6,500 rpm it did NA. This is because the engine had to overcome the load of the blower.

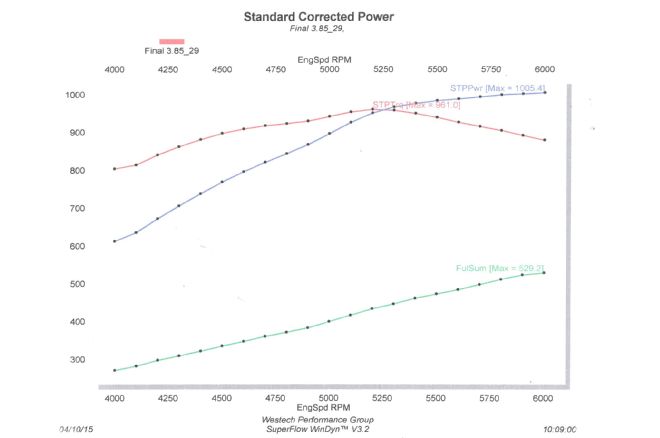

28. It was then time to move to the 3.85-inch pulley on the ProCharger.

29. After battling a little belt slippage, we found that the smaller pulley only netted us another 3 psi of boost (to just over 15 psi). Our power numbers were hovering right around 992 horsepower, but keep in mind that we only had a small fan blowing over the intercooler; nothing close to the amount of air that would be flowing in a moving car. So we let the engine cool down a bit and then went for a “hero pull.” We were rewarded with a best number of 1,005 horsepower and a whopping 961 lb-ft of torque. In terms of torque, the engine made over 800 lb-ft from when we rolled in at 4,000 rpm all the way through the pull.

30. Our main issue at this point was that we were out of pulley. The engine was easily able to handle more than 15 psi of boost, but we didn’t have a way to get there since the smaller pulleys were at ProCharger in Kansas and our engine needed to vacate the dyno cell. The blower’s max spin speed is listed as 74,000 rpm and with a 3.5-inch pulley, we would have been right below that number and well over 1,000 hp. We also feel that at this power level it would be good to move up to ProCharger’s cog system to stop belt slippage. Still, it’s hard to not be happy with a 1,000-horsepower engine.