Electric water pumps for automotive use have been around for a while but for the most part they've been used for racing applications. Self-contained electric pumps are often found on drag cars and are used for between rounds cooling. In some applications an electric motor is used to spin an OEM-style water pump to provide the necessary, though minimal, cooling on a racer. Obviously the emphasis with both methods is reducing the engine's parasitic loss due to driving a mechanical water pump, not cooling efficiency.

While some attempts have been made to use race-style electric water pumps on the street the results have never been very satisfactory—but all that has changed. Electric pumps do have a place on street-driven cars, in fact BMW began using electric water pumps around 2007 and several other manufacturers are working on similar versions. And now there is also an aftermarket version that is suitable for regular use.

In 1971 Australian engineers Daryl Davies and Bill Craig formed their company, Davies Craig, to manufacture electric engine cooling fans. Eventually their fans were being used as original equipment in several American cars and the company grew. Due to their efforts to build quality products in 1995 Siemens Electric Limited, suppliers of air-conditioning equipment to GM and Chrysler, awarded Davies Craig its highest supplier rating when it received 350,000 perfect units, on time, with zero rejects.

Over the years the Davies Craig product line has grown and now includes electric fans, viscous fan clutches, oil coolers, low coolant indicators, tire pressure monitors and their revolutionary electric water pump, or EWP. Still produced in Australia, Davies Craig products are distributed in the U.S. by 3PConnect.

According to Davies Craig, an electric water pump has a number of advantages over the engine-driven variety. They point out an EWP will increase power sent to the drive wheels because the power the mechanical pump takes from the engine increases dramatically with its speed—when the pump speed doubles from idle, say 600 rpm to 1,200 rpm, the power it takes increases by eight times, then eight times going to 2,400 rpm and so on. This extra power and torque released by disabling the mechanical pump now goes to the drive wheels. Additional benefits of an electric pump are improved cooling capacity and fuel economy along with the elimination of engine heat soak after a hot shut down. Engine cooling is improved with an EWP thanks to a higher flow rate at idle and low engine speeds when there is little or no ram air, and when the engine is switched off.

These water pumps from Down Under intrigued us, so we posed a few questions to Davies Craig and 3PConnect to find out more about them:

SRM: What do you consider normal engine-operating temperature?

DC/3PC: The ideal operating engine temperature is dependent on the type, size, capacity, workload, and environment the engine is working in. However the best engine temperature is usually between 185 degrees F to 221 degrees F. Remember, the manufacturer recommends an optimum operating temperature by allocating the desired thermostat to the engine when it’s being built. This is the exact temperature setting that’s recommended when the Digital Controller is installed.

SRM: How does the pump accommodate varying engine speeds?

DC/3PC: The EWP operates independently of the engine's speed. This is a major benefit over traditional mechanically operated water pumps that are only able to circulate coolant while the motor is running. When used with the Davies Craig Digital EWP and Fan Controller (PN DC-8000), the pump speed is increased and decreased based on the engines operating temperature, instead of rpm. This means that the engine's temperature will determine whether the pump circulates coolant. If the motor is cold, it will run the pump at a slower speed to allow a faster warm-up time. Once the engine temperature begins to climb, it will increase the pump's speed accordingly. At the moment when the engine's temperature reaches 5 degrees below the targeted/set operating temperature, the EWP will run at 100 percent flow rate to control the temperature within the desired temperature range. When the temperature rises +3 degrees above the set/targeted temperature, the EWP/Fan Digital Controller will activate the electric fans to help keep the engine at the desired temperature.

SRM: How does the EWP's pump volume compare to engine-driven pumps?

DC/3PC: We offer EWPs in different sizes and outputs, depending on the application.

EWP 80 (DC-8150) 20 gallons per minute

EWP 115 (DC-8125) 30 gallons per minute

EWP 115 (DC-8040) 30 gallons per minute (Alloy Housing)

EWP 130 (brand new to market) 35 gallon per minute.

EWP 150 (DC-8160) 40 gallons per minute (Alloy Housing)

The volume of a mechanical pump will vary depending on engine rpm. Our EWP flows up to 40 gallons per minute, regardless of engine rpm. Also, due to our EWP's efficient design the pump will flow engine coolant without any cavitation (a major drawback with high-rpm mechanical water pumps).

SRM: What is the difference between a EWP Alloy and Nylon plastic pump?

DC/3PC: There is no performance difference between our EWP115 Nylon and EWP115 Alloy pumps. Only the outer housing is in different material and is slightly lighter. The 66/Nylon glass EWPs are good for 266 degrees F (130 degrees C) and is material used by Mercedes-Benz, BMW, Audi, and Volkswagen in the construction of their header and side tanks for radiators so the product is well proven.

SRM: What is done with the engine's existing thermostat?

DC/3PC: If you choose to use the Davies Craig Digital Controller you should remove the engine's thermostat–the controller is the new "thermostat." The Digital Controller allows you to electronically set the engine target temperature and it adjusts the rate of coolant flow, hunting for, and then locking onto the temperature you set.

SRM: Are the pumps reliable—what is the life expectancy?

DC/3PC: We designed the EWP for everyday street use. Our EWP's efficient electric motor has been proven to live past 7,000 hours, when used with our EWP/Fan Digital Controller. The EWP is designed and manufactured at our Headquarters in Melbourne, Australia.

SRM: Are the pumps rebuildable?

DC/3PC: Yes, we do offer spare parts for the EWP. Every EWP is also backed by our two-year/24,000-mile warranty.

SRM: How much current do the pumps require?

DC/3PC: The EWP's current draw is one key feature that sets it apart from the other "energy guzzler" electric water pumps in the market. The EWP pulls anywhere from 7-10 amps—10 amps is the most the EWP will ever draw, powered by a 12V automotive electrical system. When using our EWP and Fan Controller the amp draw will fluctuate between 7-10 amps, depending on the temperature of the engine.

SRM: How are the pumps mounted?

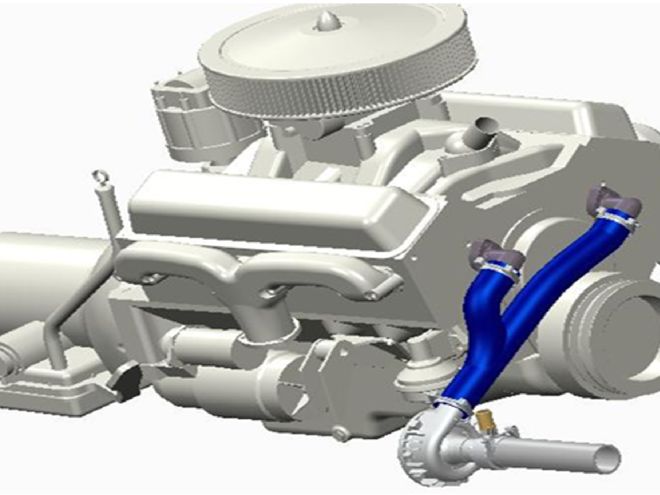

DC/3PC: The EWP is mounted inline and attached directly to the vehicle's lower radiator hose. The ability to mount the EWP inline means that it will not force the installer to modify or manipulate their existing pulley configuration to install the EWP. We also offer Direct Fit kits for the small-block Chevrolet, big-block Chevrolet, and now the bi- block Ford engines. The Direct Fit Kits include everything you would need to properly fit the EWP to your motor: Silicone fitment hose that is trimable for most applications, two 90-degree feeds to the engine block, our heater adapter for the EWP system so the installer can retain use of the vehicles heater. All EWP 150s and the Alloy EWP 115s have threaded AN-16 fittings for easy installation.

SRM: How are pumps rated and how what determines which pump is right for the application?

DC/3PC: We determine proper EWP usage based on engine displacement.

EWP 80 for engines with less than 3.0L of displacement

EWP 115 for engines with less than 5.0L of displacement

EWP 130 for engines with less than 6.0L of displacement

EWP 150 for engines with 6.0-8.0L of displacement.

SRM: How is the original pump dealt with?

DC/3PC: The original water pump can be removed completely, converted into an idler, or left on the engine and used in conjunction with our EWP. To simplify the installation when the mechanical pump is removed Direct Fit Kits are available that free up valuable space and take weight off the front of the engine. When used as an idler the impeller from the OEM water pump is removed and the EWP is installed inline in the lower radiator hose. In this situation, the user will gain all the great benefits of using an electric water pump, while retaining all of the factory pulleys and belt configuration. The EWP can also be installed to work along with the vehicles OEM water pump.

Davies Craig electric water pumps are light, compact, easy to install, and may well be the answer for difficult to cool street rods while offering increased performance at the same time. When used with the DC engine controller engine temperature, pump speed, and electric engine cooling fans are automatically controlled. Certainly the interest the OEMs have in electric water pumps lends credence to the idea and it may be a cool idea for street rods as well.

01 This is a Davies Craig electric water pump kit, model EPW 80. This pump would be applicable to smaller displacement engines.

02 The housing of the EWP 80 is made from glass filled nylon. Note the inlet (to the right) can be positioned as needed.

03 Recently introduced, the EWP 150 was designed to handle large displacement engines up to 8-liters (488 ci). To the right is the Davies Craig controller.

04 Here the EWP 150 has been fitted with AN fittings for the inlet and outlet. The housings of these pumps are made of aluminum.

05 The Davies Craig DC 8000 Controller with digital display adjusts the speed of the water pump and can be used to turn an electric engine cooling fan on and off with adjustable set points.

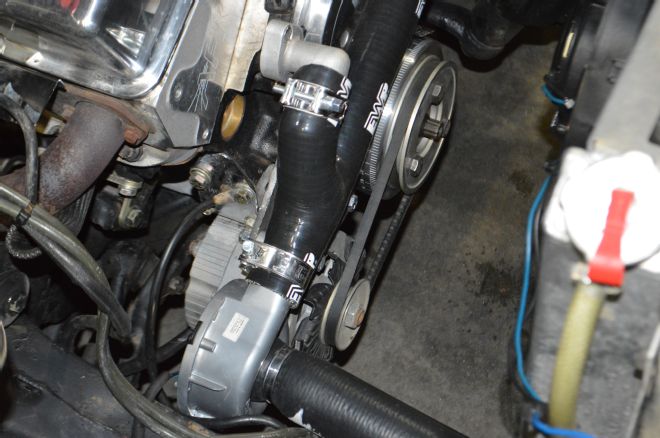

06 Josh Backes has been testing an EWP 150 on his 600hp, 400ci, small-block Chevy. At the dragstrip his Chevelle's e.t.'s have dropped more than two tenths and the engine stays cool even in traffic.

07 Backes eliminated the stock water pump with Davies Craig's adapter kit.

08 The Davies Craig small-block Chevy adapter kit includes fittings and a special hose to eliminate the stock water pump.

09 In addition to their line of engine and transmission cooling products, Davies Craig has been making electric water pumps for over two decades.

10 These are examples of hose adapters for aluminum-bodied pumps. The alloy EWP weights a scant 2.56 pounds.

11 Hose adapters are also available for fiberglass filled nylon pumps. These pumps weigh in at 2.16 pounds.

12 This cutaway of an EWP shows the motor and the highly efficient impeller.