There's a new hero hemi on the block. It follows on the coattails of its Street Hemi older brother, but this new hemi is making a name for itself all on its own. Last year's AMSOIL Engine Masters Competition was dominated by a pair of normally aspirated Hemi engines and now the guys at The Supercharger Store have shown us what happens when you put a stroker crank in a 5.7 Hemi and stuff a ProCharger supercharger on top. You've probably already skipped to the results page, but if you haven't, this 395ci Gen III Hemi made nearly 900 hp on pump gas and a squirt of water injection. Let's show you how they did it.

The goal was to build a mid-sized Gen III Hemi for the street that would make as much power as possible on the pump with the help of a ProCharger centrifugal supercharger. Bob and Terry Woods of the Supercharger Store chose the 5.7L Hemi because it is the most numerous and therefore least expensive of the new generation family of Hemi engines. With potential for 400 hp in near-stock trim, stuffing even a mild F1 ProCharger supercharger seemed like an idea whose time has certainly arrived.

The goal was to build a mid-sized Gen III Hemi for the street that would make as much power as possible...

The Foundation

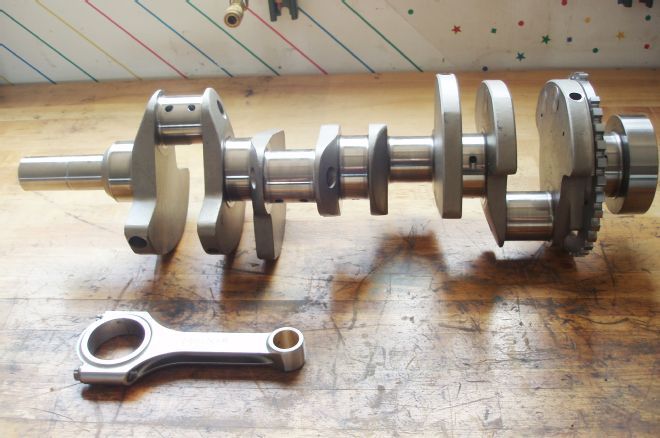

The basis for the engine was a well-used 2005 5.7L truck engine that Bob and Terry obtained out of a wrecked Ram half-ton pickup. Rather than rely strictly on the supercharger for torque, they decided that a longer stroke would both add displacement and low-speed torque at lower engine speeds where the centrifugal supercharger would not be quite as efficient. To that end, Tom Molnar of Molnar Technologies supplied a 4.050-inch longer arm crank to take the place of the original 3.58-inch piece. He also supplied a set of Molnar 6.125-inch long H-beam connecting rods that would be fitted to a set of dished CP pistons that when combined with the stock combustion chambers produced a very reasonable 9.25:1 compression ratio.

All these parts were taken to Larry's Engine & Marine in Tucson for complete machine work including boring and torque-plate honing along with custom-fitting the bearing clearances, crank endplay, and all the other necessary blueprint procedures to ensure the short-block was ready to take on the projected power.

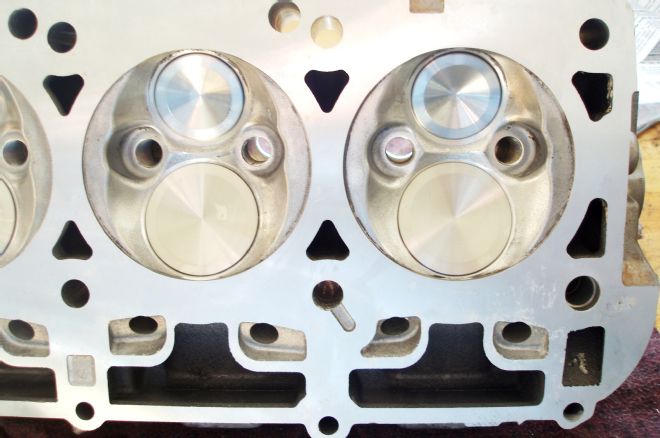

Assuming there are no corks in the intake or exhaust system, the two most critical components for making horsepower are the heads and cam. The Woods brothers contacted long-time Mopar power source Hughes Engines for their assistance. The plan was to use the existing 5.7L heads and valve sizes, yet improve on their performance. Hughes did exactly that with a complete CNC porting effort. The accompanying flow chart shows the improvements that Hughes achieved with the already decent 260-plus cfm stock port with an additional 48 cfm (18 percent) at 0.650 lift while also adding over 45 cfm (a whopping 27 percent) to the exhaust side.

On The Bench:Some may question why you would want to spend the cash for porting when the supercharger can just use pressure to feed the same amount of air into the engine. The simple answer is that the amount of air moved by a supercharger is usually measured in pounds per square inch (psi) of boost. But this boost number is actually an indication of resistance to flow. By reducing the restriction to the inlet side by porting the heads, this immediately reduces the restriction to flow. This increases the volume of air the engine can ingest and power improves while at the same time reducing the actual boost in the manifold. Plus, reducing the boost demands on the supercharger also reduces the amount of work the supercharger has to produce, which reduces heat. The net effect is that moving 500 pounds per hour (lb/hr) of air at 10 psi requires less work than moving the same 500 lb/hr at 18 psi. The net result is more power.

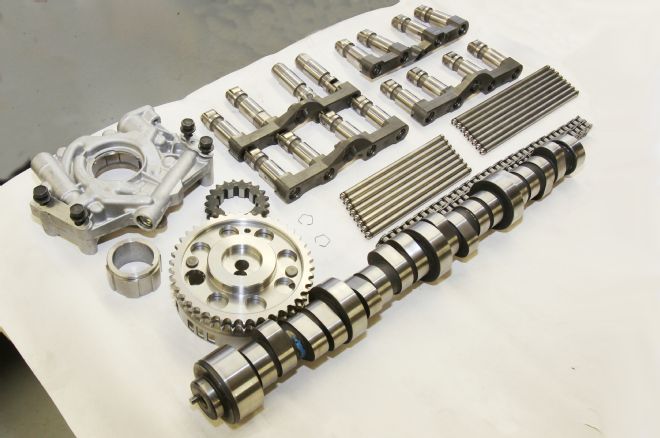

Because this engine was destined for a street car, the Woods brothers wanted to keep the duration relatively conservative. A long-duration camshaft would certainly improve peak power, but it would have reduced the torque output in the under-4,500 rpm portion of the power curve and that's where this engine will likely spend a majority of its time. So Hughes suggested one of its popular hydraulic roller street cams but widened the lobe separation angle to 114 degrees. This reduces the overlap when the intake and exhaust valves are open at the same time. This minimizes blower pressure losses from flowing right out the exhaust. This generally improves the mid-range power, and as you can tell from the dyno runs, this was certainly beneficial. Hughes also matched the cam with a set of its custom-spec'd Manley beehive valve springs and retainers that are precision-matched to the camshaft. The Woods brothers planned to re-use the existing stock hydraulic roller lifters, but added a set of stronger retaining clips for the tops of the lifters from Superior Automotive. This is a simple upgrade over the stock factory retaining clips that tend to pop out under high-rpm operation.

As for the induction side, the Woods decided to keep the budget in line by going with a blow-through carburetor so Hughes also supplied a Ritter carbureted intake manifold that actually comes in two different heights: 8.5- and 7.5-inch. For this engine, the Woods went with the shorter version for more hood clearance, and so it would line up with the ProCharger blow-through carburetor hat for the Competition Carburetors 750cfm carburetor. The Woods have had great success with owner Bob Oliver's blow-through annular discharge carburetors. While it might seem that a larger carburetor would add even more top-end horsepower potential, experience with blow-through carburetors has proven that smaller carburetors with annular discharge boosters produce a much more accurate fuel curve. A larger carburetor will not produce as much signal under boost which will result in a leaner air-fuel ratio.

With the plan calling for 18 psi of boost, and the limitation of 91 to 93 octane pump gas, the water injection is a crucial element.

Blower Time

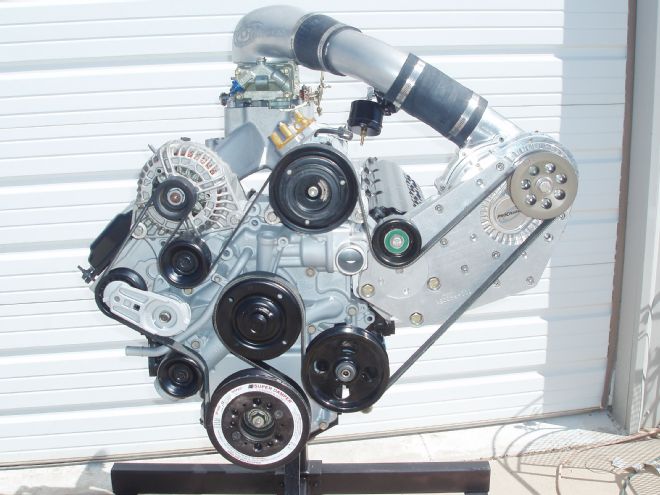

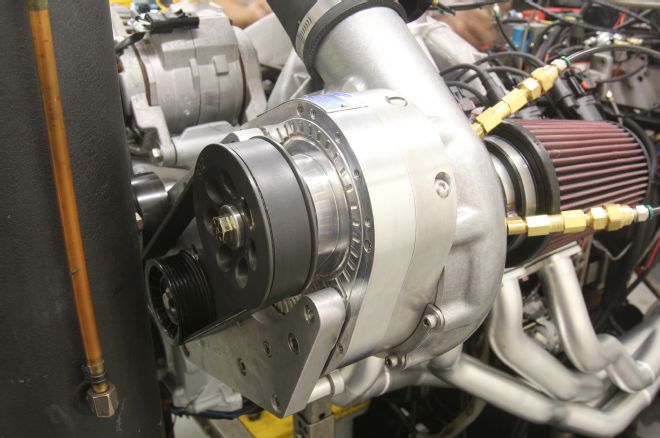

One of the last parts to bolt to the engine was among the most critical: the ProCharger F1 supercharger. The F-1 can supply enough air to make well over 1,000 hp and 35-plus pounds of boost. The Supercharger Store has created an entire line of specially engineered ProCharger centrifugal blower mount packages for the Gen III truck-based Hemi, and the 5.7-, 6.1-, and 6.4L car-based Hemi engines. While this particular application is intended to be bolted into a '74 Plymouth Scamp (yikes!), the Woods brothers decided to retain the standard 7-rib truck serpentine belt system and spin the blower with this same belt. This required using an ATI balancer with its integral serpentine drive pulley. One advantage to using this drive is that it does not require an additional pulley system that extends farther off the end of the crank. As this distance increases, it places a longer bending moment on the crank that can reduce crank durability.

...experience with blow-through carburetors has proven that smaller carburetors with annular discharge boosters produce a much more accurate fuel curve.

Another critical component within this system is the Supercharger Store's own proprietary water injection system. With the plan calling for 18 psi of boost, and the limitation of 91 to 93 octane pump gas, the water injection is a crucial element. Some think that adding water injection to the inlet side of the engine is somehow equivalent to pouring water on an open flame. That's really not a fair analogy. A different way to look at this is to think of water injection system as a high-performance inlet cooler. One of water's more amazing capabilities is a very high latent heat of vaporization. This means that when high temperature air is combined with atomized water, the water tends to pull heat out of the air as the water changes state from a liquid to a gas. This cooling of the inlet air temperature charge is dramatic. And as you know, cooler air is not only denser and more powerful, but it's also worth dramatic reductions in the engine's sensitivity to detonation (see The Octane Game sidebar below).

The Octane Game

There is a direct relationship between inlet air temperature into the engine and the engine's octane requirements, regardless of compression ratio. According to Rockett Brand Racing Gasoline's Tim Wusz, several years ago the OEs did a major study on fuels and octane. The testing involved changing the inlet air temperature to various engines and measuring the octane requirement based on that air temperature. Wusz says they discovered that for every 25 degree F increase in inlet air temperature, the engine required a one full point of increase in octane. As an example, let's use an engine running on 93 octane that did not detonate with an inlet air temperature of 100 degrees. Increasing the inlet air temperature to 125 degrees would then require a 94 octane fuel. Of course, the converse is also true that a decrease of 25 degrees will reduce the engine's octane demands by a full point.

This information holds true for supercharged engines as well. This is why water injection works so well because it first reduces the inlet air temperature by virtue of its latent heat of vaporization before the air ever arrives in the combustion chamber. Plus, this air temperature reduction helps prevent the engine from suffering from uncontrolled combustion and enormous pressure spikes that create that all-too-familiar engine rattle that can break parts and cause all kinds of grief.

Testing

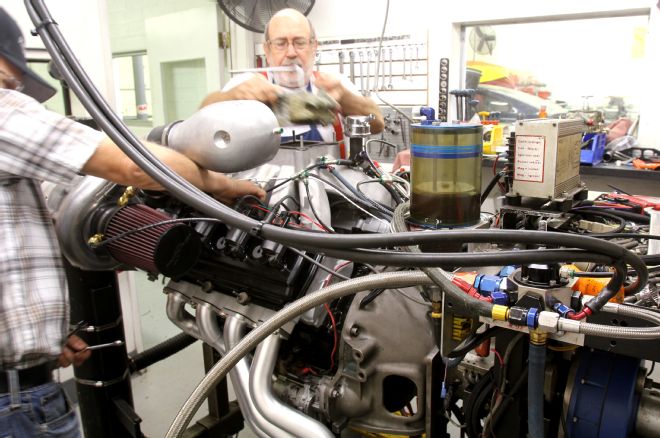

After the Woods assembled the 395ci Hemi, they returned to Larry's Engine & Marine to bolt it up to the SuperFlow dyno. After a short break-in procedure to make sure the rings were fully seated, owner Larry Peto dialed in the carburetor and connected the water injection. The SuperCharger Store's water injection system is designed to deliver two stages of water based on boost pressure. The first stage comes on at 4 psi, and the second stage injects additional water at 11 psi. The jetting nozzles are adjustable, but based on the Woods brothers' experience with literally dozens of these systems, the as-supplied system is generally very close and no adjustments were necessary.

Under full-power runs, one minor issue cropped up. The serpentine drive belt began slipping at over 12 psi. The guys resolved the problem when they discovered they had incorrectly installed a 6-rib serpentine pulley on the ATI balancer. This prevented the 7-rib belt from fully seating, which created the slippage.

After a few other minor tuning tweaks, the engine was ready for a full-boost pull and immediately responded with 883 peak hp. Larry began his timing experiment with 25 degrees and pulled 10 degrees out with boost using the MSD ignition controller, leaving only 15 degrees of lead. Next, he tried adding a few more degrees of lead assuming it might add a little more power, but this immediately cost 95 hp, so they returned the timing to 15 degrees under boost for a third run and the power came right back with 885 hp at the peak at a very conservative 5,900 rpm.

Perhaps almost as impressive is the torque curve. Even at 3,500 rpm the engine is making over 600 lb-ft of torque. Unlike a normally aspirated engine's power curve, torque will continue to rise on a supercharged engine as long as the boost is climbing, which is why the peak torque occurs so close to the peak horsepower level. One advantage to a centrifugal supercharger is that maximum boost does not come in all at once, allowing the car to hook first as the boost builds. We plugged this 885 hp power curve into a 3,600-pound car in the Quarter Pro drag strip simulation program and with a 3.73:1 gear, a 12.5 x 28-inch Mickey Thompson E.T. Street Radial tire, and a relatively mild torque converter the simulation spit out an estimated 9.90 at 140 mph. With more gear, tire, converter, and good traction, this could be a 9.60 combination at roughly 141 mph.

Perhaps almost as impressive is the torque curve. Even at 3,500 rpm the engine is making over 600 lb-ft of torque.

But perhaps the best part is that this package doesn't require race gas or deep gears to be a ton of fun on the street. With 600 lb-ft of torque at 3,500, you can bet that this will be a tire-shredding combination, especially in a light car. The dawn of Gen III performance has arrived. Are you ready?

On The Dyno:*The complete Supercharger Store kit comes with an F1 and all the components to install the blower including the belt drive system, fuel pump, blow-through carburetor, MagnaFuel fuel pump, Aeromotive fuel pressure regulator and their Stage II water injection unit. Call The Supercharger Store for details.

1. Larry's Engine & Marine in Tucson did all the machine work and also performed the dyno testing. Here, the block is finished and the ARP main studs have been installed and are waiting for the crank.

2. Molnar supplied the 4.050-insh stroker forged steel crank and .125-inch and H-beam rods.

3. The CP Bullet forged aluminum pistons are dished to keep the compression down to 9.25:1. Note how the Gen III Hemi uses small quench pads on both sides of the chamber to improve mixture motion in the chamber.

4. To maintain decent street manners, Hughes suggested a relatively short hydraulic roller cam with a wider 114-degree lobe separation angle to use with the supercharger.

5. The Woods Brothers assembled the short-block with a Manley timing set that required a ¼-inch spacer behind the oil pump mount to clear the wider gear and chain. This also affects the oil pump pickup location.

6. Along with the cam, Hughes also CNC ported the cylinder heads while retaining the stock valve sizes of 2.00/1.55 inch, although the valves were upgraded to stronger Manley stainless steel versions.

7. Before they fired the engine for the first time, Bob built a simple pressure luber. It uses a plastic bucket reservoir for the oil, a mechanical fuel pump driven by an electric drill, some fittings, and a few quarts of oil to get oil all the way up to the rocker arms.

8. This is a shot of the valvetrain with the new Manley springs but retaining the stock 5.7L Hemi shaft rocker system.

9. Here's the F-1 ProCharger supercharger installed on the engine. The Supercharger Store has created a mounting system that integrates the supercharger with the stock accessory drive, necessitating only a longer belt to make it work.

10. A critical component to the accessory drive is the ATI balancer. Here, the incorrect pulley was installed which did not allow full contact with the 7-rib belt. Once that problem was rectified, they were able to create full belt contact.

11. The Supercharger Store's water injection system mounts on the inlet side of the ProCharger blower, giving the water the most amount of time to reduce the compressed air temperature. Reducing the inlet air temperature allowed the engine to accommodate as much as 18 psi of boost on pump gas. The two nozzles are for the two stages of water.

12. Ignition was handled by an MSD 6013 Hemi box that allows finite control of ignition timing and boost retard.

13. On the dyno Bob Woods (left) and technician Wade Stocum put the tune on the Competition Carburetor and ignition, and managed to extract an amazing 885 hp out of this 395ci Gen III Hemi.