“Coil bind” occurs when a spring’s coils stack solid at or before full camshaft lift. This develops an infinite load on the valvetrain, causing its weakest link to fail. If you’re lucky, the result is just a bent pushrod; otherwise, you’re looking at a broken spring, a dropped valve, or worse.

When installed at the correct height to develop the right seat and open pressures for the application, a spring needs to have a safety margin before coil-bind occurs. The formula used to determine whether a spring has sufficient coil-bind clearance is: valvespring installed height on the seat – (cam lobe lift × rocker arm ratio) + valve lash – safety margin = remaining open spring length, which should be equal to or greater than the spring manufacturer’s published coil bind height.

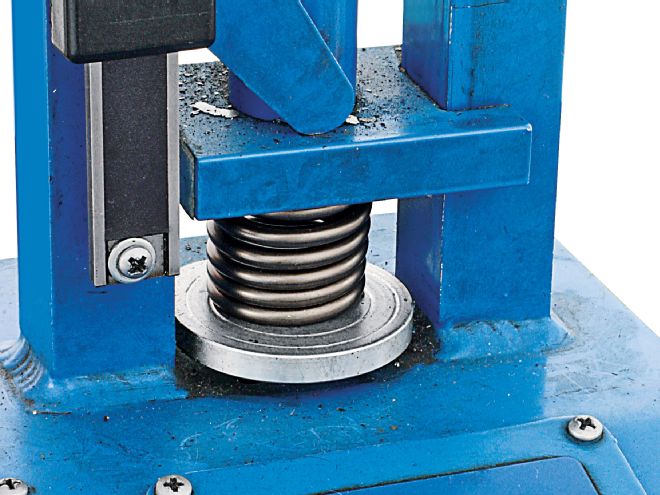

Don’t take published spring coil-bind height data as gospel. Verify using a feeler gauge and a ruler on the assembled engine or in a vise, or with a spring tester (shown). Check multi-element springs with their corresponding retainer.

Don’t take published spring coil-bind height data as gospel. Verify using a feeler gauge and a ruler on the assembled engine or in a vise, or with a spring tester (shown). Check multi-element springs with their corresponding retainer.

About 0.060 inch used to be the textbook safety margin, with more OK and even desirable. That’s still an acceptable standard for everyday performance use, but for cutting-edge setups the “correct” safety margin can vary up or down. Comp Cam’s Billy Godbold notes that “from high-speed video and testing, it is clear that adjacent coils contact as you approach the valvetrain-limiting speed (this is known as spring surge). Hence, modern springs are designed to run near coil bind and use the coil-to-coil interaction for improved damping at or near max lift. This interaction is one of the most effective means of dampening spring surge, but the spring must be properly designed in terms of solid stress to safely use this interaction.” Depending on the intended use and the spring and cam-lobe design, coil-bind safety margins can now vary from 0.015 to 0.120 inch, with tighter numbers predominating on very stiff valvetrains. Anything more than 0.150 inch may cause spring surge, which can greatly reduce the available spring load needed to close the valve.