In case you missed the previous installment of the Slick-Built Small-Block (SBSB), we're building this 416ci LA-series stroker to be a fun street driver that can dominate classic and modern muscle cars. Once the stroked small-block is built and dyno tested, it will be implanted into The Slick Challenger, a 1973 Dodge Challenger Rallye 340, with a factory Pistol Grip four-speed.

With today's technology, it's easier now than ever to build an LA with pleasant street manners, yet outperform yesterday's typical high-strung, race-type small-block. For this 93-octane pump-gas street stroker engine, we chose strong, quality components for the rotating/reciprocating assembly (Scat), valvetrain (COMP and Smith Bros.), oiling system, fasteners (Milodon), and gaskets (Cometic). Speaking of the oiling system, we selected Milodon's new Road Race pan that holds six quarts, yet has stock ground clearance to keep our lube supply safe from road hazards.

...it's easier now than ever to build an LA with pleasant street manners, yet outperform yesterday's typical high-strung, race-type small-block.

For the top end, we selected Edelbrock's proven Performer RPM heads and an Air-Gap intake manifold. We couldn't leave them box-stock, so your author performed a street-oriented porting job. After we flow-bench tested our home-ported heads, the gains realized at low, mid, and peak lift should add roughly 50 hp and 50 lb-ft to our combination. All things considered, our combination should have the broad, road-going 2,500- to 6,000-rpm powerband we're aiming for. (If you intend to use RPM heads similar to or better than our ported efforts, check out Hughes Engines. Hughes offers small-block RPM cylinder heads in many stages including their Big Mouth offset-rocker head.) We also massaged our Air-Gap RPM intake to help our induction inhale easier. The carburetor base/plenum area was reworked and we gasket-matched the exits to help get the air moving into and through our ported, high-velocity RPM heads.

For this installment, follow along as we finish up on the long-block assembly. Next time we'll take the 416 to Ray Barton Racing Engines for some dyno testing!

...our combination should have the broad, road-going 2,500- to 6,000-rpm powerband we're aiming for.

We knew the Slick Challenger would benefit from the dependable Edelbrock Performer RPM cylinder heads (PN 60779, each) and Air-Gap intake manifold (PN 7576). Our E-Body's primary purpose is to be a pleasurable street driver that will use its factory air conditioning when blowing away Mustangs and Camaros on the street.

Trial-fitting is always advisable before attempting installation. We needed to make a few adjustments in order to use Milodon's new Road Race oil pan (PN 31590) and windage tray (PN 32230), and the Scat 4.00-inch stroke rotating assembly (PN 1-48013BI).

For the Road Race pan to fit properly, we needed to cut ½ inch from the standoffs on each of the four Milodon main studs that secure the windage tray. A nice feature of the Road Race oil pan is it has the ground clearance of a stock pan. It also has internal baffles and trap doors, and holds six quarts. Once the Slick 340 engine is in place with the Road Race oil pan, the Challenger will be ready for aftermarket suspension upgrades that lower the ride height an inch or two.

Hiding inside the oil pan is a Melling high-volume oil pump (PN M72HV) with the Milodon pickup tube (PN 18343). A stock cap bolt was necessary on the left side of the rear main cap for oil pump clearance. There were enough threads on the four main studs that we cut ½ inch to adjust for the windage tray's clearance with the stroker rotating assembly. The tray's louvers also needed to be tweaked for clearance from the crank's counterweights and connecting rods.

Up front we reused the stock 340 timing case cover, but turned to a new Milodon high-volume water pump (PN 16250), with a TCI Rattler balancer (PN 870012) to smooth out the harmonics of the rotating assembly. Notice the Milodon brass freeze plug kit (PN 34040) and ARP stainless accessory hex bolt kit (PN 544-9601) adding to the engine's attractive color theme.

IDM Speed and Machine's flow bench gave us the numbers on a box-stock RPM head versus our ported version. Both heads were flow-tested with the stock and a back-cut intake valve. We also enlarged the combustion chamber to un-shroud the valve on the ported head to check for flow gains. Flow numbers increased by 5-6 cfm. The clay showed no flow gains on the un-ported head. See the flow charts for our results.

The stock 2.02-inch intake valve on the left has a 45-degree seat. Notice the top half of the seat of the right valve, which received a 23-degree back-cut. Should you decide not to afford the time or money for porting, the flow gains from back-cutting the intake valves are well worth it at only $5 to $6 per valve.

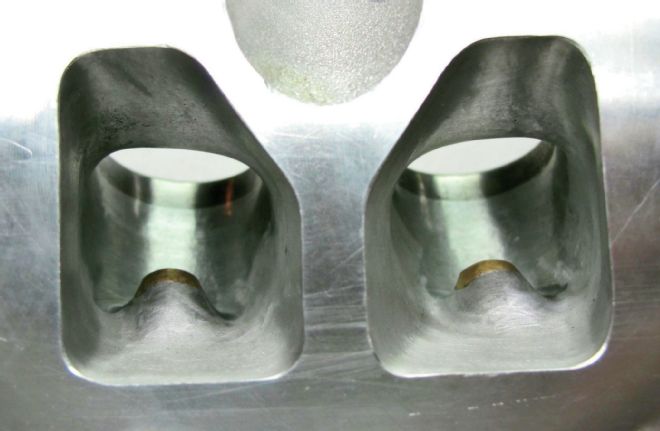

This close-up view of the chamber and port bowls shows some of our handiwork. The combustion chambers were opened up from a width of 3.990 to 4.050 inches to un-shroud the valves. This chamber mod showed a 6- to 8-cfm flow gain on the intake ports. With the chambers enlarged from the box-stock size of 63cc to now 68cc, the compression was reduced a half point to an edgy pump gas compatible 11.2:1. We'll throw in a splash of VP race gas (1 to 2 gallons) into each tankful to be safe from possible detonation should we get a bad batch of pump premium.

The exhaust and intake ports received the same trimming of the valveguide bosses, blending of the bowls, and removal of the sharp edges from the CNC gasket matching that Edelbrock performs on their cylinder heads. We rolled and polished the short-turn radius while blending the bowls. On the intake ports we contoured and safely removed .080-inch from the head bolt bulge. Our porting efforts rewarded us with a 35 and 28 cfm gain at .600-inch lift on the intake and exhaust ports respectively.

After cleanup and reassembly of the RPM heads with the COMP conical springs, we bolted our babies down. We used Milodon head studs (PN 80236) and torque stepped the heads at 35, 55, 75, and 95 lb-ft. Our friends at IDM Speed and Machine shaved the heads .015 inch for the same correct finish as the block to properly seal with Cometic MLS head gaskets (PN C5457-040, 4.125-inch bore, .040 compressed).

Edelbrock provides each cylinder head with a special ARP head bolt to be used next to the oil feed for the rocker shaft and arm lubrication. This special head bolt is roughly .055-inch thinner than a regular head bolt or stud. Here you can see we used the supplied thinner ARP head bolt next to the oil feed to aid in better oil flow to the shaft and rockers.

Completing the valvetrain are high-quality, Smith Brothers 5/16-inch pushrods (PN NH58A-CB). The pushrods were custom-made to an effective length of 7.100 inches for proper pushrod length and rocker arm geometry. We chose to use COMP's 1.6 ratio aluminum rockers (PN 1076, kit) instead of the Pro Magnum's (available only in the 1.5 ratio) because we wanted the valve lift to exceed .600 inch. Note: When using a roller cam in an LA block, clearance grinding will be needed in the lifter valley area where the roller lifter link bars rise up and down. We set the valve lash at .014 inch and .016 cold, (hot lash is .016/.018), on the intake and exhaust respectively.

These before/after shots show the plenum divider under the carburetor. It was profiled (cut down ½ inch) to be similar looking to the divider on a box-stock B-RB Edelbrock RPM intake. We also smoothed out the entire carburetor base/plenum area, short turns, and dividers at the port entrances hoping for additional airflow—but we didn't flow-bench test the intake. The exits of the intake were also gasket-matched and blended 1½ to 2 inches into the port. We're doing all we can for big-block–type torque with our stroker small-block!

For the intake and head ports to line up perfectly, our friends at IDM Speed and Machine removed .040 inch from the mounting surfaces of the intake. We think our 416 looks mean in long-block form. We're hoping for horsepower and torque in the mid 500 range when we dyno test our stroked engine at Ray Barton's. Stay tuned!

On The Bench

The Cone Zone

COMP's new conical valvesprings are the latest breakthrough in valvespring technology since the beehive spring. The cylindrical spring on the left shows each coil is the same diameter making the frequencies and oscillations similar to each other. Notice the decreasing diameter of each coil on the conical spring from the bottom to the top. The conical design reduces mass for improved rpm stability while decreasing spring oscillations. The springs we'll be using (PN 7256-16) have a spring rate of 485 lb/in, with a seat load of 160 pounds at 1.900 inches, and an open load of 495 at 1.210 inches. These springs match up well to the COMP solid street roller stick we chose. It bumps the valves at .616/.622-inch lift with 1.6 rockers, 248/254 duration at .050, and has a 110 LSA. To run these latest springs on our RPM heads, spring seats (PN 4694-16) and steel retainers (PN 787-16) were required.