Q:

J.D. Ruhlman From Ohio Asks…

I have an ’84 Corvette with a 350ci motor, a 700-R4 transmission, and the factory Cross-Fire fuel injection. I am currently building another engine for it and am planning on using a carburetor instead of the stock Cross-Fire system. I plan on using a Weiand Team G intake manifold, so hood-clearance will be an issue. The engine will have a Comp Cams’ cam (0.525-inch valve lift, 310 degrees advertised duration), and 11:1 pistons with 76cc heads.

What stall-speed converter do you recommend? Who makes a carburetor that will support the 700-R4’s TV cable? Will I have to go to a vacuum-advance distributor, or can I use the stock one? I have also heard I will need to install a fuel-pressure regulator to keep the factory electric fuel pump; could you recommend one if this is true? If anything else needs to be changed to make this switch, could you please let me know?

A:

Besides answering your specific questions, we must first qualify the specific proposed parts combination -- they’re interrelated. The Corvette’s intended usage wasn’t called out, so for the purpose of this response I’ll assume general high-performance street driving with occasional drag or autocross duty. The closest Comp cam I can find to your notional grind is its Magnum 305H flat-tappet hydraulic. This single-pattern cam’s effective 0.050 duration is more than 250 degrees, yielding a 3,000–7,000-rpm operating range. Torque-converter stall speed needs to be at or more than the cam’s minimum operating range on a street car, so you’re looking at about a 3,500-rpm stall; I wouldn’t want to see anything less than 4.56:1 gears out back. That presents two problems: First, the car will be unhappy at cruise in Overdrive with that big of a converter. Second, there are no four- or five-series gears for the spindly, 7.725-inch ring-gear, Dana 36 IRS used in auto-trans-equipped C4 Vettes. Most ’84 models came stock with 3.07:1 gears, although there were a few built with 3.31:1 gears. You can get 3.54:1 or 3.73:1 U.S. Gears for the Model 36 through rearend specialists like Tom’s Rearends, but that doesn’t come close to yielding a matched driveline combo. Regardless, the weak Model 36 won’t last long behind a well-built high-compression engine with a big cam.

It’s possible to move up to the larger Dana 44 IRS (8.5- or 8.537-inch ring-gear diameter) found in ’85–’96 stick-shift Vettes. That adds strength: up to 500 hp (assuming some tire slip) on a stocker packed with U.S.-made internals; as high as 650–700 hp on a unit built to the max by an expert like Tom’s. Gear ratios up to 5.89:1 are available for the Dana 44 (although some sets may require an adapter kit to work in the particular Dana 44 variant used in the Corvette IRS).

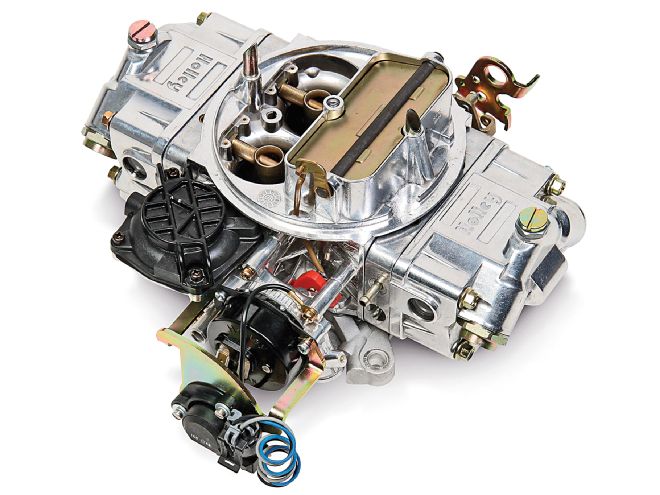

To attach a GM TV cable to most modern 4150/4160 Holley carbs (except some race-only models with cut-down throttle linkage), use Holley cable mounting bracket PN 20-95 (A) plus throttle-arm extension PN 20-121 (B). Both must be used to obtain correct cable geometry. Equivalent TCI parts include PN 376705 (bracket) and PN 376715 (throttle-linkage adapter).

To attach a GM TV cable to most modern 4150/4160 Holley carbs (except some race-only models with cut-down throttle linkage), use Holley cable mounting bracket PN 20-95 (A) plus throttle-arm extension PN 20-121 (B). Both must be used to obtain correct cable geometry. Equivalent TCI parts include PN 376705 (bracket) and PN 376715 (throttle-linkage adapter).

Although the 44’s internal parts remain widely available, there are at least three hard-to-find major structural components needed for the Dana 44 swap: the Dana 44-specific cover and mounting member (the big batwing casting that bolts to the rear cradle), the differential housing (which bolts to the cover and houses all the internal rearend parts), and the driveline support (the central longitudinal bridge-girder-like member that runs from the rear of the trans and connects to the IRS out back). Unfortunately, none of these parts are still available new. Highly sought out by street rodders and other custom car builders, you’d have to scour eBay, Craigslist, Corvette specialty parts suppliers like Guldstrand Motorsports, or big swap meets for good used parts -- and be prepared to pay a pretty penny once you locate a decent core. Because the Model 44 rearend only came in stick-shift cars, the front of the driveline support would also require modification to interface with the 700-R4.

Not that your early 700-R4 is up to the job anyway. Compared to later-model 700s, the hard parts are weaker, the fluid flow through the trans isn’t as refined, and the valvebody design is different. Early versions even used a small-diameter, 27-spline input shaft like a TH200 rather than the later 30-spline configuration that’s similar to a TH350/TH400 input shaft strength-wise (and the spline count in turn limits torque-converter interchange). The aftermarket has pretty much given up on the early 700 and you should, too. They can’t be beefed with most of the good parts from the later 700-R4/4L60 series. Also note that Corvette versions don’t have a conventional transmission mounting pad, the extension housing is unique, and the overall length is about 1.125 inches shorter than “normal” 700-R4 transmissions. What you want is a 700-R4 from an ’88–’92 Corvette.

Then there’s the suitability of the engine itself. Although rowdy cams bleed off some dynamic compression down low, permitting the use of higher than normal (for the available fuel quality) static compression ratios, if you will be running a true, blueprinted 11:1 compression ratio with GM factory smog-era cast-iron heads and their lazy 76cc chambers -- well, that’s just asking for trouble.

If using aftermarket aluminum heads, you could probably skate by at a true 11:1 (though I prefer small, quick-burn chambers), but as noted above, the rest of the drivetrain just isn’t well-matched for such a big cam, even if detonation itself doesn’t rear its ugly head.

A good rule of thumb when using pump premium unleaded is to maintain cranking compression pressures of no more than 200 psi and no less than 150 psi -- the higher side of this range with aluminum heads, the lower end with cast-iron heads.

Put bluntly, you need to reevaluate the engine combo in light of real-world street-gas availability, plus take into account the overall characteristics of the driveline downstream of the motor. On the plus side, the 700-R4 has a deep 3.06:1 First gear, and the early C4 Vette comes in at a relatively svelte 3,500 pounds (give or take), including driver. To an extent, this should alleviate severe tip-in ping tendencies, but there could still be a preignition problem near peak torque where cylinder pressures are highest. Running a dual-pattern cam with 6–8 degrees more duration at 0.050-inch tappet lift on the exhaust side compared to the intake lobe to induce some exhaust-side dilution back into the cylinder should help in that regard.

Add in the weak existing Dana 36 axle, the limited gear ratio selection for that carrier, the need to maintain driveability with an Overdrive trans, and assuming for budgetary reasons you want to stay with a flat-tappet cam, I’d take a close look at a Comp Xtreme Energy XE274H, with its much more reasonable 230/236 at 0.050 duration. This assumes full-length tuned headers (15⁄8- or 1¾-inch primaries). Nontuned exhaust systems are more finicky; if using stock manifolds, consider the Xtreme Marine XM270H with its slightly wider lobe-separation angle (112- versus the 274’s 110-degree).

Either way, instead of the 3,500-rpm stall-speed converter recommended to suit your projected big Magnum cam, the milder grinds match up well to a milder converter, resulting in a much friendlier cruise and driveability scenario. TCI offers its 12-inch Breakaway-series converter (PN 243107 for the stouter 30-spline ’88–’92 trans) that should stall around 2,200–2,400 rpm with a 350 small-block. Use it with a beefy TCI StreetFighter trans (PN 37300), which is capable of supporting up to 725 hp. Assuming some tire slip, with an automatic the Dana 36 should be OK, but move up to 3.73:1 gears.

As to true static compression ratio: With either of the milder recommended cams and stock big-chamber iron heads on pump premium gas, keep it between 9.5:1 and 10:1 with cast-iron heads while maintaining 0.040–0.045-inch quench. Achieving desirable tight quench mandates near-zero block deck heights with a typical thick aftermarket heavy-duty head gasket. Speed-Pro’s lightweight forged piston LW2304F-30 (2.4cc dome volume) develops 9.8:1 compression with a zero piston-deck height, a 9.1cc compressed-volume (0.041-inch thick) Fel-Pro head gasket (PN 1003), and a 76cc combustion-chamber volume. The block decks almost certainly will need milling to yield a “zero” piston deck height.

On the induction side, assuming 6,500 rpm full-throttle shifts so the engine “falls back” into the recommended cams’ operating rpm range, use either a Holley 770-cfm vacuum-secondary carb or a 700-cfm double-pumper (you’re on the bubble as to which is better, but traditionally, a double-pumper requires more tuning finesse “to be all it can be”).

So much for the broad brush strokes. With the combo established, we can focus on your detailed questions. Currently, the existing in-tank electric fuel pump, the transmission torque converter clutch (TCC) lockup, the distributor, and the existing Cross-Fire injector throttle-bodies are all computer-managed. There are kits to lockup the TCC without a computer, you could replace the computer-controlled distributor with an earlier conventional HEI with mechanical centrifugal and vacuum advance, and then rewire the fuel pump with ignition-switched analog relays and an oil-pressure safety shutoff switch -- but that’s a lot of rewiring.

Is there an easier way? Yes: Keep the stock electronic control unit (ECU, aka “the computer”), but have an aftermarket chip burner such as McPhail Performance burn a custom chip that shuts off the fuel-related tables and fuel-related diagnostic codes, but retains spark-curve management with a revised advance table that complements the new engine and new rearend gear ratio. The TCC lockup and fuel pump will continue to operate as before without major rewiring. McPhail needs to know the intended application, fuel octane, camshaft, and true “blueprinted” static compression ratio.

Retaining the existing electronically controlled distributor and ECU-controlled TCC lockup still requires a throttle position switch (TPS) and manifold air pressure (MAP) sensor. No problem on the TPS: Holley offers a TPS mounting kit for its modern carburetors that are set up for, or capable of utilizing, an electric choke. Holley carbs with electric-choke capability of the sizes recommended above include the PN 0-4778C 700-cfm double-pumper (purchase electric choke kit separately under PN 45-224) or the PN 0-80670 770-cfm vacuum-secondary Street Avenger that comes with the electric choke already installed.

Both Holley and TCI offer a mounting bracket for the TV-cable retainer and a throttle-lever extension that aids in achieving the correct TV-cable geometry. (Be sure to adjust the cable per your transmission manufacturer’s instructions.) Your existing MAP sensor reference can be hooked to any full-time intake manifold vacuum port.

Like other GM throttle-body injection (TBI) setups, the Vette’s twin Cross-Fire injection typically operates at 12–15 psi. As such, it’s no problem to use a conventional Holley carburetor pressure regulator to step-down the existing stock in-tank pump’s fuel pressure to a Holley carb-friendly 6–8 psi. Use Holley regulator PN 12-803 if not running a return line; use PN 12-803BP with a return line.

If hood clearance is a problem, one comprehensive aftermarket source for a variety of hoods, hoodscoops, louvers, or bulges at varying price-points is Showcars Bodyparts Unlimited.

At the 6,500-rpm performance level, in the Holley-Weiand line, this dual-plane Stealth Air Strike (PN 8501) is a better fit for the rest of your drivetrain combo compared to the single-plane Team G. The dual-plane is also about 0.115-inch lower.

At the 6,500-rpm performance level, in the Holley-Weiand line, this dual-plane Stealth Air Strike (PN 8501) is a better fit for the rest of your drivetrain combo compared to the single-plane Team G. The dual-plane is also about 0.115-inch lower.

Ask Marlan A Tech Question:

[email protected]

DRIVELINE All Comp Cams grinds listed below are of the hydraulic flat-tappet configuration. Assumes unleaded pump premium gas. All values in degrees, unless stated otherwise. CR Intake Carb(CFM) Exhaust T/C Stall(RPM) Rear Gears RPM RANGE Ruhlman’s Choice 11:1 High-rise single-plane 750 DP Tuned headers 3,500-plus 4.56:1-plus 3,000–7,000 Pit Stop Choice 1 9.5–10:1 High-rise dual-plane 700 DP or 770 vacuum Tuned headers 2,200-plus 3.73:1 1,800–6,000 Pit Stop Choice 2 9.5–10:1 High-rise dual-plane 770 vacuum Exhaust manifolds 2,000-plus 3.55:1 1,600–5,800 *Nitrided PN. Nitriding adds durability. Nitriding is available for this popular grind under its own PN. It is available on a special-order basis for other Comp Cams flat-tappet grinds, even if no unique PN is listed in the catalog for it.

CAM COMBOS

Grind

Part No.

Lobe

Lift (Inches)

0.050-Inch Duration

Timing at 0.006-Inch Lift

Lobe CL

LSA

Tappet

Valve

Duration

Opens

Closes

Magnum 305H12-214-4

Intake

0.350

0.525

253

305

40 BTDC

84 ABDC

110

110

Exhaust

0.350

0.525

253

305

44 ATDC

80 BBDC

110

Xtreme Energy XE274H12-246-3

12-246-20*

Intake

0.327

0.490

230

274

30 BTDC

64 ABDC

106

110

Exhaust

0.327

0.490

236

286

30 ATDC

76 BBDC

114

Xtreme Marine XM270H12-240-4 Intake

0.320

0.480

226

270

23 BTDC

66 ABDC

110

110

Exhaust

0.326

0.489

236

286

30 ATDC

75 BBDC

114