Introduced back in 1992, the 5.9L Magnum was the successor to Mopar's successful LA-series 360. With improved cylinder heads, better sealing, higher compression, thinner rings, and an all-new higher ratio valvetrain among the many modifications, the 5.9 Magnum breathed new life in the old small-block V-8. The revision extended the service of the traditional Mopar small-block another 12 years, finally ending production with the 2003 model year. The 5.9 was strictly a truck engine, powering the likes of Durangos, Dakotas, Rams, vans, and Jeeps. Although not a muscle car engine in the traditional sense, power ratings were between 230 and 250 net horsepower depending upon year and application, up from the last LA-series 360's 190 hp.

With a long production run as the last Mopar small-block, these Magnum engines are stacked up like cordwood in boneyards across the country. As pretty much a direct bolt-in for any classic Mopar muscle car or truck, a used 5.9 is an easy and cheap way to up-power your Mopar. We find these truck engines tend to survive very well, often with minimal bore wear owing to the factory 1/16-inch moly compression rings, tall overdrive gears, and the port fuel injection system. The short-blocks more often than not can be freshened with little more than a set of rings, bearings, and gaskets, and sometimes they are good enough to run right out of the boneyard.

Heads You Lose

If there is an Achilles' heel to the Magnum engine, it is actually the Magnum cylinder heads that define the engine. The OEM heads were arguably better than the LA 360 heads in flow, valve size, and combustion chamber configuration, so what's the beef with the Magnum heads? The problem is they crack. Sure, many of these Magnum engines run for years with cracked OEM iron Magnum heads, but once the engine is pulled for a rebuild or to be repurposed, in the vast majority of cases you are going to have to deal with those cracked heads. We have known some engines put back together and run with cracked Magnum heads, but are you going to want to invest in rebuilding a set of cracked iron heads? Not me. Are you going to want to tow your race car or boat knowing a set of cracked heads are under the hood? I wouldn't. Do you want to bolt that Magnum mill into your low-buck street machine, cracked heads and all? Not in my car.

...these Magnum engines are stacked up like cordwood in boneyards across the country.

Now You Win

Fortunately, there is a solution that doesn't take the very low-buck premise out of the Magnum equation, and even adds a few horsepower in the process. The high rate of failure of Magnum heads has created a strong aftermarket demand for low-cost replacement-style heads. EngineQuest (EQ) has answered that need with two cylinder head offerings. The EQ-CH318A heads are direct stock replacements for the Magnum engine, and can be retrofitted to earlier LA engines. The other choice is the EQ-CH318B. This head is identical to the 318A, and has all of the same Magnum features such as the ten-bolt valve cover rail and Magnum valvetrain, but is machined with the LA series intake manifold bolt pattern, rather than the vertical bolt pattern of the Magnum. This allows the use of standard LA-series intake manifolds, broadening the selection of compatible manifolds. The specs on both versions of the EQ heads show 172cc intake runners, 62cc chambers, with machining for 1.92/1.624-inch valves.

Cast in Australia, the EQ Magnum heads put extra iron where it counts, with stiffer decks and more meat in the chamber, effectively engineering out the cracking problem associated with the production factory heads. That would be enough, but EQ revised the already good Magnum port configuration, resulting in a meaningful improvement in flow (see table, "On The Bench"). The better flow makes the EQ Magnum more than a replacement head—it qualifies as a performance piece. How good are they? We went to the dyno with an out-of-the-box set of CH318B castings to find out.

...the EQ Magnum heads put extra iron where it counts ... That would be enough, but EQ revised the already good Magnum port configuration...

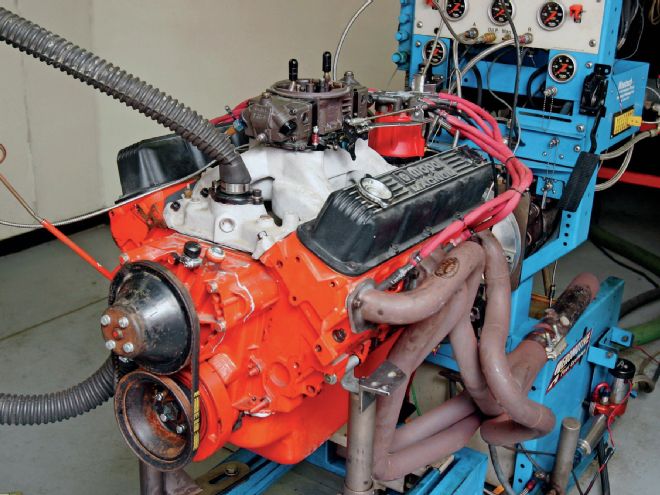

The Engine

Our test unit consists of a standard bore, factory assembled, 5.9 Magnum short-block. This bottom end features the OEM "box" center-dish cast pistons for a compression ratio of 9.0:1. Magnum 5.9 engines commonly carried a rating of 245 horsepower, with the tiny factory hydraulic roller camshafts delivering a hair over .400-inch lift. Our goal was to put together a low-buck hot rod–style engine using the EQ heads and quantify the results. Modifications were kept to just the basics needed to build a respectable street performance engine. Obviously, the OEM truck cam would have to go, and here we opted for the Mopar Performance 380 hp 360 crate engine cam. This hydraulic roller 'shaft comes with specifications of 288/292 gross duration and .501/.513-inch lift on a 108-degree lobe-separation angle. The profile is long in duration but the cam is very easy on the valvetrain and springs, with very good stability and rpm potential. With the long duration and narrow spread, it comes with a healthy sounding performance thump. The cam was teamed with a used stock Magnum valvetrain, including the stock hydraulic roller lifters and retaining system, as well as the stock pushrods and rockers.

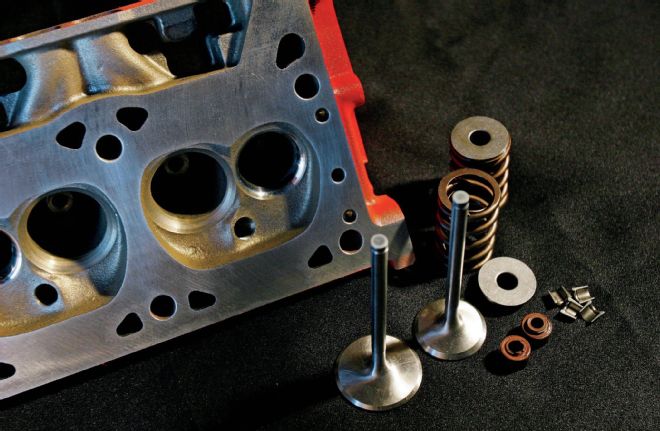

The top end, of course, features the EQ heads, which we assembled with a set of SI valves and COMP springs, using OEM Magnum retainers and locks. The limiting factor here is the installed height, measuring just 1.650-inch with the stock hardware. This represents a limitation on lift, as well as spring selection. Here the Mopar cam helped us on both counts, with the moderate lift providing adequate coil bind clearance, while the gentle profile proved in testing to maintain stability with just 120/300 pounds of spring load. A more aggressive setup will need to take advantage of aftermarket retainers and keepers, which can extend the installed height to 1.800 inch with the same valves, greatly improving the clearances and valvespring options.

Rounding out the breathing combination were the usual performance parts, including an Edelbrock intake, Holley carb, and Hooker headers. The intake we selected was the two-plane Performer RPM Air-Gap, a proven piece that needs no introduction. Topping it was a Holley 950 Ultra HP carb—definitely a state-of-the-art piece and admittedly extravagant in this application, but it was a shelf unit from the dyno facility and we know it works. Substitute a more modest carb such as a basic Holley 750, and we wouldn't expect much of a loss of power in this application. Use a junkyard ThermoQuad on an adapter and you can carb this engine on nothing but your know-how and experience at rock-bottom cost—but hang the results of the execution at your own risk. On the outlet flange, 1 3/4-inch Super Comp headers handle the exhaust, though cheap 1 5/8-inch headers will still be in the zone with this combination.

Given the largely OEM origin of our engine combination, this had to be about the easiest 400 hp we have ever made!

To The Dyno

What we had was a stock 5.9 from the block decks down, just like you'd pull out of a Ram truck or Durango at the local scrap yard. The performance formula consisted of the front line troops of a hot rodder's army: cam, intake, carb, and headers, in addition to the EQ iron heads. Chrysler's Mopar Performance put out a similar piece, a crate engine using the same cam, which makes an interesting comparison. That engine wore the factory Magnum heads instead of the EngineQuest pieces on our engine, but it featured a single-plane intake manifold and a full point more compression ratio via flat-top pistons. That crate was rated at 380 hp, a number we hoped to at least equal with less compression and a dual-plane intake, but better heads.

We actually assembled our 360 from a bare short-block on the dyno. When fired, the long-duration Mopar cam exhibited a noticeable idle lope. The gauge read 8.5 in-hg of manifold vacuum at 800 rpm. We set the timing to 34 degrees, ran it up to operating temperature, and went straight into the power pulls. At the top we recorded 396 hp at 5,600 rpm. Those numbers were encouraging and we were impressed that the hydraulic roller setup easily pulled 6,000-plus rpm. Jetting looked right in the zone from the Lambda numbers, so we went straight into timing adjustments with the theory that the relatively low compression would appreciate more advance. Working in steps we found 38 degrees to be optimal for power production, with horsepower now tagging exactly 400. Given the largely OEM origin of our engine combination, this had to be about the easiest 400 hp we have ever made! Those workhorse 5.9 truck engines are an untapped gold mine of cheap street horsepower.

We began our build with a bare, stock 5.9 Magnum short-block on the dyno. The first step was stabbing in a hot cam to replace the factory truck piece. We went with a Mopar Performance roller featuring 288/292 degrees gross duration and .501/.513-inch lift.

The factory piston in the 5.9 Magnum is a dished cast piece, but with a "box" dish configuration retaining an active quench area.

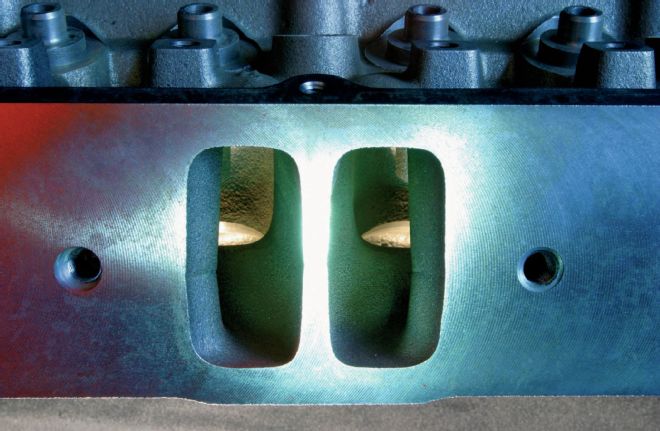

The EngineQuest Magnum heads are available as a direct replacement for the factory Magnum heads, or with an LA-series intake bolt pattern. The heads feature improved ports for increased flow and accept all of the factory Magnum hardware.

Although like all Magnum heads, the intake port runner seems constricted with a large pushrod restriction, port flow is much improved over the OEM Magnum due to an improved port and port bowl area.

Our test heads were filled with SI valves at the OEM 1.92/1.625-inch diameters, along with a COMP single spring with damper assembly. With the stock Magnum retainers and locks yielding an installed height of 1.65 inches, the working loads were 120 pounds on the seat and 300 pounds open.

Magnum exhaust ports were substantially better than those found on any factory LA-series head, and the EngineQuest heads proved much better again on the exhaust side.

The EngineQuest heads were bolted on using Fel-Pro composition head gaskets and the OEM Magnum fasteners. Note that the Magnum heads use a different head bolt set than the standard LA engine.

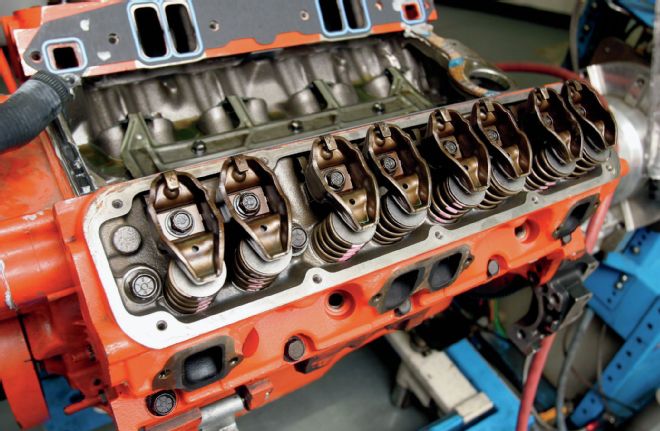

Inside the lifter valley, the factory lifters were reused, guided by the stock alignment yokes and spider. The factory Magnum hydraulic roller lifters are very good and difficult to improve upon.

Likewise, the factory pushrods and rocker arms were retained. With a more radical cam and substantially more spring load, aftermarket pushrods would be recommended, but with our modest springs, the stockers do the job. The stock rockers are not adjustable, however, they are very good in moderate lift applications.

An Edelbrock Performer RPM Air-Gap intake is a proven piece, delivering peak power rivaling a very good single-plane, while adding substantially to the bottom end and midrange torque.

Topping the intake is a Holley 950 Ultra HP carb. This may seem like an extravagant choice given the budget nature of our build, but it was simply a test piece taken from the dyno shop inventory. At the power level we are dealing with here, similar performance can be expected from a more basic Holley carb.

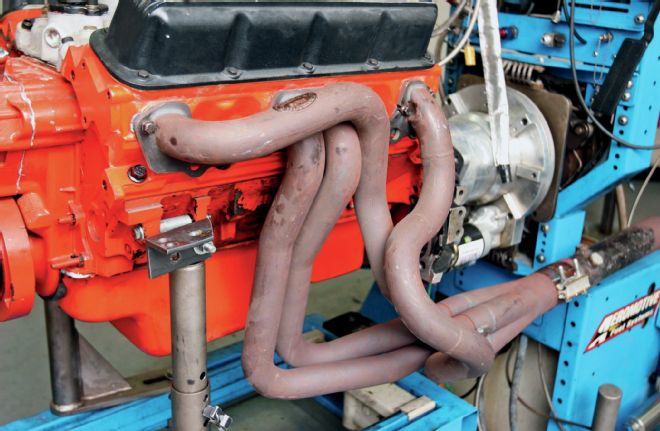

The 1 3/4-inch Hooker Super Comp headers are more of a race-style header, with slip fit pipes and collectors. Common 1 5/8-inch street headers are well within the zone for a street small-block like this.

The all iron 5.9 Magnum proved to be a strong little combination, despite its production short-block. We tagged the 400 hp mark at 5,600 rpm, and watched the engine pull cleanly and make power to over 6,000 rpm.

EngineQuest heads are sold by the manufacturer as bare castings. To hard-core engine guys or performance shops, that is all you are after. For the regular enthusiast, fitting out the cylinder head is another hurdle to overcome. You'll have to find the right size replacement valves and the related hardware. Next, unless you have the required precision measuring tools on hand, you are in the dark on the valve-stem-to-guide clearance. Even if that's covered, you'll need some means of correcting the clearance as required. The springs need to match the camshaft application, with consideration to critical numbers such as installed height, retainer-to-guide clearance, and coil bind. We know a lot of guys would not consider bolting on a set of out-of-the-box heads before having a professional give them a full going over.

Jesse Robinson of SKMFX Engines in Summerstown, Ontario, Canada, has these EQ heads dialed in. Jesse has proven his expertise running the EQ heads in a variety of small-block Mopar engines at the Engine Masters Challenge competition, achieving unbelievable results with these replacement-style parts. SKMFX can supply the EQ heads in a wide range of prep, from basic assembled and ready-to-run units, to fully ported and worked sets. Would you believe 510 hp from a street-spec 417 small-block stroker wearing an all-out set of EQs? SKMFX also offers a version with big valves and the basic pro bowl porting completed. This option is ideal for the home porter, with the portion requiring machining equipment done. This leaves the runner work open to further modification, however, if you want your EngineQuest heads dished up, the dedicated Mopar guys at SKMFX are prepared to serve the Mopar enthusiast!

On The Dyno

On The Dyno On The Bench

On The Bench