Hemi has always been synonymous with Mopar power, and fortunately the legacy built with the early Hemi and the 426 lives on in today's Gen III. While the first generation of Chrysler Hemi was reserved for higher-end applications, and the 426 served in only the most exotic of muscle machines, the Gen III breaks the mold as everyman's Hemi. Trucks to regular passenger cars, the Gen III is a volume piece that takes the Hemi out of the elitists' realm. Now for the upshot—for brutal street power this latest Hemi is arguably the best of them all.

The massive power potential is inherent in the Hemi's opposed-valve design, allowing space for large, free-breathing ports...

The massive power potential is inherent in the Hemi's opposed-valve design, allowing space for large, free-breathing ports with a direct shot into the cylinder. The production iron 426 Hemi heads were cavernous, and delivered approximately 300 cfm of intake airflow—a stout number for that era. The latest third-generation Hemi heads easily eclipse the stock 426 Hemi's airflow. On top of the airflow, these modern heads come stock with fast-burning twin-plug chambers, a shallower valve angle for greatly reduced combustion chamber volume, and twin active quench pads adjacent to the valves. The engineers did their homework here, taking the two-valve Hemi layout to what may be its optimal form.

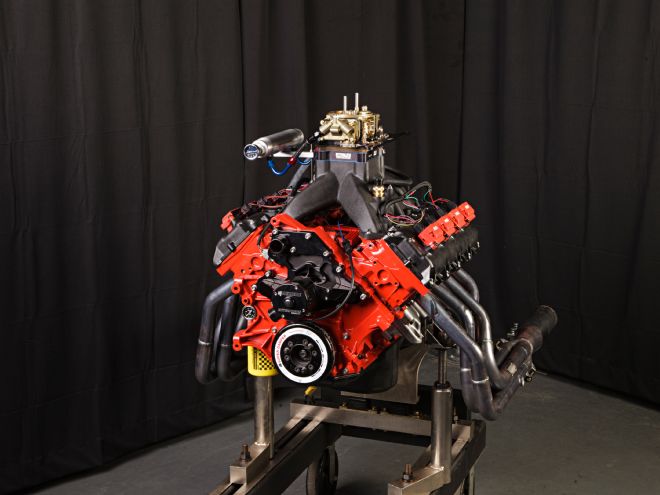

Where the Gen III really breaks new ground is in availability. You won't find a 426 at the local boneyard, but regular mom and pop trucks and passenger cars have been built with the Gen III for over a decade now, making the used pipeline flush with Hemi power. Showing the potential for Hemi power is this 402-cube stroked example built by Daniel Boshears. Starting as nothing more exotic than a common, early-version 5.7-liter pickup truck engine, and using production cylinder head castings, this street beast delivers 570 lb-ft of tire melting torque and 613 horsepower. Here is what went into making it happen.

...regular mom and pop trucks and passenger cars have been built with the Gen III for over a decade now, making the used pipeline flush with Hemi power.

Bottom End Build

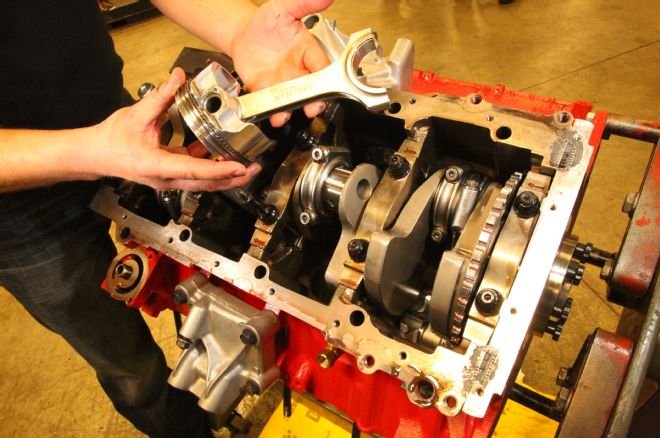

This project actually started with a couple of different complete 5.7 engine cores, a 2006 and a 2010. As Daniel tells us, "I was going to build the 2010 [Eagle] engine because it was a very low mileage salvage yard engine, but the variable valve timing set up made it difficult to get a cam core for this application. I went with the earlier 2006 engine for the block because of this. We just did basic machining to the block, including tightening the mains to the lower side of tolerance, and some minor clearancing to the bottom of the cylinders for the stroker crank. The block required oiling system modifications because of the factory MDS system. We bored the block out .018-inch over, which happens to put it at the same size as a .060-inch overbore 283 Chevy small-block and there are a lot of good rings available at that size. I was able to get a 1mm, 1.2mm, 3mm ring package at that bore size which is a very low-drag set-up. I had Race Tec build a set of custom pistons for this combination with a 4.125-inch stroke."

"I was going to build the 2010 engine because it was a very low mileage salvage yard engine, but the variable valve timing set up made it difficult..."—Daniel Boshears

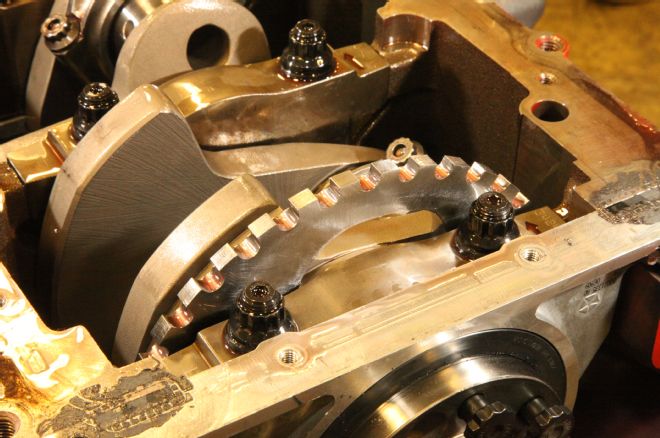

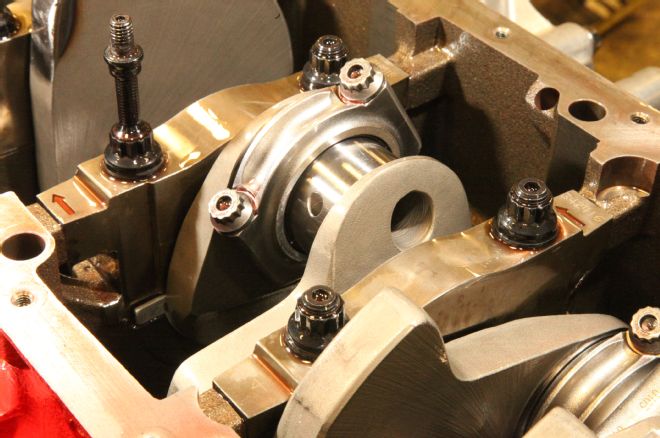

Daniel continued, "The crank is from Molnar, but it started life as their 4.050-inch stroke crank, and I had it offset ground by Adney Brown at Performance Crankshaft to 4.125-inch stroke. We used a Quad Four GM journal size and Molnar offers a rod with that journal size and the Mopar 6.123-inch length. This is a widely used bearing size in endurance racing applications, so good performance bearings are readily available. The final combination ended up with a very light 1,663-gram bobweight. One area where we did run into trouble was clearance with reluctor wheel. With the 4.125-inch stroke, the piston will need to be modified to clear. We grooved the piston and also machined the inside edge of the wheel 0.050-inch to get it to clear."

The oiling system in this engine was very straightforward, relying on stock replacement style parts. Boshears equipped the Hemi with a Melling Select standard-volume oil pump drawing oil from a stock truck pan though a modified stock pickup tube. With the stroker crank, a factory 6.4L windage tray offers improved clearance, requiring only minor modifications to fit. Daniel observed that the factory Gen III is well designed as far as controlling oil drainback, requiring no reworking or improvements to keep excessive oil from the rotating assembly. As an extra measure of friction reduction and insurance, Daniel had all of the moving parts of the engine treated to the proprietary RF85 antifriction process.

Top End, Cam, & Valvetrain

Traditional Mopar small-blocks need high-end race heads to make power in the range of this Hemi. In the case of the Gen III, there is no need to look any further than the production castings. As Daniel described his cylinder head combination, "The cylinder head is the factory production 2009-10 5.7 truck head. What we learned about this particular head is that it has the 6.1L sized intake port, a D-shaped exhaust port, and a 5.7-style combustion chamber with dual quench pads. The heads use a little bit longer valve than what is regularly available, so aftermarket valves choices are limited. We ended up using custom made valves, going up to 2.100- and 1.57-inch diameters to get a good valve job on the heads without having to change out the seats."

Port work on the cylinder heads was a combination of CNC machining and custom hand porting by Randy Malik. Daniel explains, "The heads were CNC ported by Modern Cylinder Heads to the extent of the runners, and the rest was done by hand. Randy Malik finished the heads by hand doing the bowl work and the tight corner work such as the short turn. In the end we did not get final flow numbers on the heads, but looking at comparable port work that was very close to these in design, we are in about the 350-360 cfm range." To put that flow level in perspective, only the very best of the old Mopar LA-series small-block race heads move a comparable amount of air.Pullquote:

To put that flow level in perspective, only the very best of the old Mopar LA-series small-block race heads move a comparable amount of air.

The camshaft is a custom hydraulic roller from Lunati. As Daniel tells us, "I worked with Lunati because they have been very good to me in the past on all of my business. They have some very good lobes that Harold Brookshire designed, and we looked through those and found the lobes that we really liked. The camshaft is actually a reverse pattern with the intake having slightly more duration than the exhaust. The Hemi tends to like this configuration. The lobe separation is 109 degrees, and that is just because the cam core would not allow anything any tighter than that without risking breaking through the hard case. We installed the cam at 103, and this too was limited by tolerance, since the piston-to-valve clearance wouldn't allow us to go any tighter than that."

"The camshaft is actually a reverse pattern with the intake having slightly more duration than the exhaust. The Hemi tends to like this configuration."—Daniel Boshears

"The rocker arms are custom made from Harland Sharp, with a ratio of 1.7 on the intake and 1.65 on the exhaust. We didn't feel the higher ratio would be beneficial on the exhaust, so we used the split ratio. The pushrods are from Trend and are heavy duty 5/16-inch diameter. The lifters started as tie bar lifters for an LS engine that were modified by Ron Shaver. The reason we used the LS lifter is that the factory lifter for the Hemi does not pump oil. We had to feed the valvetrain through the lifters, so we solved that problem with the GM lifter. The Hemi uses the .842-inch diameter lifters, which is the same as the Chevy, and the height of the lifter body was about right. There was a considerable amount of time put into a set of factory lifter guides to make it work."

Feeding the stroked Hemi is a high-rise single-plane intake manifold and a carburetor. The vertical ports to the Hemi take maximum advantage of these tall manifolds, a design first seen with the Mopar Drag Pack induction. Daniel went with the similar Ritter Racing intake. "The intake is from Ritter Racing, which looks very much like the Mopar Drag Pack manifold. The Mopar intake is very hard to get and was really designed for a smaller fuel-injected application. With a carburetor, the Ritter intake seems to work better. I cut 1 3/8-inch off the top of the manifold, reducing the plenum volume, but otherwise the manifold was run as-cast. I didn't want to increase the volume of the manifold at all, and the runners looked very good as delivered."

"The Mopar intake is very hard to get and was really designed for a smaller fuel-injected application. With a carburetor, the Ritter intake seems to work better."—Danial

Topping the engine is what appears to be a familiar 4150 Holley carb, but this unit is highly modified, as Daniel reveals. "The carburetor is an 850 body, and we modified the venturi diameter and put in a custom booster that is a downleg annular design. We put a third main circuit in the carburetor which helps output in the 4,000-5,000rpm range." Beneath the carb is a unique spacer combination, featuring a short conventional four-hole spacer with an extended segmented spacer from Stealth below. Daniel details, "The spacer actually fits down into the plenum, dividing it into four parts—one for each barrel. We found improved distribution and torque with this arrangement." Another unique aspect of the induction is the normally overlooked fuel log feeding the carb. Daniel and Randy Malik conspired over the design after finding information from the work of Smokey Yunick. The idea is to ensure no aerated fuel enters the bowls, feeding the carbs with nothing but a solid stream of liquid gasoline for improved mixture control.

One of the unique features of the Gen III Hemi is the factory's dual spark plug arrangement, and word is this was done for emissions reduction reasons. The production dual plugs' similarity to the famous Pro-Stock dual-plug race Gen II Hemi heads is unmistakable. Because the Gen III is a distributorless engine, firing the plugs is handled via individual coil packs and a stand-alone ignition controller. Daniel went with MSD components here citing ease of installation and use, as well as reliability for selecting MSD. Daniel remarked about the low timing requirement of the Hemi layout: "We programmed a curve into the ignition system, and in testing found the Hemi wanted very little timing for maximum power. We were in the range of 20 degrees total timing, which shows a very efficient burn. I have to believe there is an advantage in the Hemi's twin-plug design."

"We were in the range of 20 degrees total timing, which shows a very efficient burn. I have to believe there is an advantage in the Hemi's twin-plug design."—Daniel Boshe

Dyno Time

The engine was completed with a custom set of Schoenfeld headers, a Meziere electric water pump, and an ATI damper, and it was ready to run. Hooked to the DTS/Superflow dyno at Automotive Machine and Performance in Philpot, KY, we could see that the Hemi had evolved considerably from it production pickup truck beginning. The first peak number to cross the dyno display was torque, showing 570 lb-ft at 5,000-5,100 rpm. That, folks, is the twist you might expect from a strong big-block with an extra 40-plus cubic inches. Pulling up the rev range, the horsepower numbers rose steadily until reaching a peak of 613 hp at 6,100 rpm. This street style hydraulic roller Gen III handily crested the 600 horsepower mark, proving that Hemi performance is here to stay.

Fast Facts

402ci Gen III Hemi

Bore: 3.935-inch

Stroke: 4.125-inch

Displacement: 402 cubic inches

Compression ratio: 11.44:1

Camshaft: custom Lunati hydraulic roller

Valve lift: .637/.631-inch

Duration at .050: 249/247

Lobe separation: 109 degrees

Installed centerline: 103 degrees, intake

Rocker arm ratio: Harland Sharp 1.7/1.65:1

Piston rings: Total Seal 1-/1.2-/3mm

Piston: Race Tec forged custom

Block: factory 2006 5.7L Hemi

Crankshaft: Molnar

Bearings: MAHLE Clevite

Rods: Molnar 6.123-inch

Cylinder head: factory 5.7 Eagle casting

Intake valve diameter: 2.100-inch

Exhaust valve diameter: 1.570-inch

Intake manifold: Ritter single-plane

Carburetor: custom Holley 850

Ignition: MSD

Header: Schoenfeld stepped primary

Damper: ATI

Oil Pan: Moroso

Fuel: VP 100 unleaded

Oil: AMSOIL 5w20

1. Daniel Boshears of Red Rocket Engines started with a common 5.7L Gen III Hemi truck block, and upped the cubes to 402ci via a slight overbore to 3.935 inches and a big move in stroke to 4.125 inch. Filling those bores are custom Race Tec pistons swinging from Molnar 6.123-inch rods.

2. The long stroke combination resulted in a tight fit with the factory-sized internal crank trigger wheel. Clearance machining to the piston pin boss as well as the wheel were required to make it all fit.

3. The Molnar crank started life with a stroke of 4.050 inches, and was offset ground to 4.125 inch by Performance Crankshaft. In the process the journal diameter was reduced to the 1.888-inch Olds Quad Four specification.

4. The Race Tec pistons feature a flat top configuration with the required valve clearance notches, producing 11.44:1 compression ratio with the shallow Gen III Hemi head chambers. Fasteners are ARP throughout.

5. A factory truck rear sump pan holds the AMSOIL 5w20 synthetic lube, while a slightly modified factory 6.4L Hemi windage tray controls the oil. The 6.4L tray features more clearance for longer stroke lengths than the production 5.7L piece.

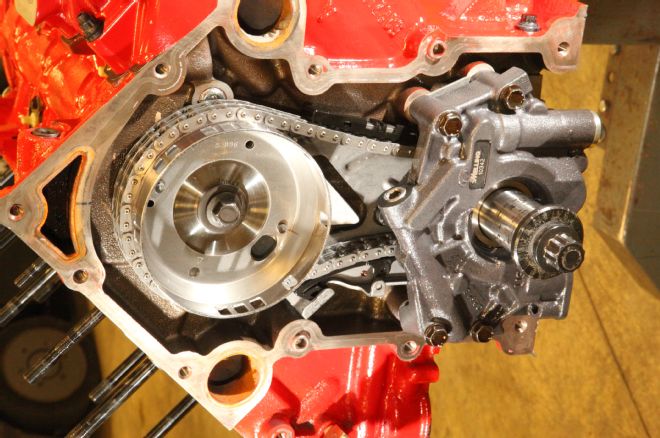

6. Up front a Melling replacement oil pump circulates the vital lubricant, while a Cloyes duplex chain drive spins a custom 249-/247-degree duration-at-.050 Lunati hydraulic roller cam.

7. The production 5.7 "Eagle" head castings were CNC ported by Modern Cylinder Head, and hand finished by Randy Malik. The supporting valvetrain components include .110-inch wall Trend pushrods and Harland Sharp adjustable rockers. To accommodate the required pushrod oiling, GM LS lifters from Morel were reworked by Shaver Specialty Service and run in modified Gen III Hemi alignment guides.

8. Here we can see the Gen III Hemi combustion chamber. Note the filled-in quench pads found in the "Eagle" heads, and the twin plugs common to all Gen III Hemi engines. The chambers are filled with oversized 2.100-/1.57-inch valves.

9. The Harland Sharp rocker arrangement multiplies the cam action by 1.7:1 on the intake side and 1.65:1 on the exhaust. Note the clearance notch needed on the plug tube adjacent to the intake rocker. Lift at the valve works out to .637/.631 inch.

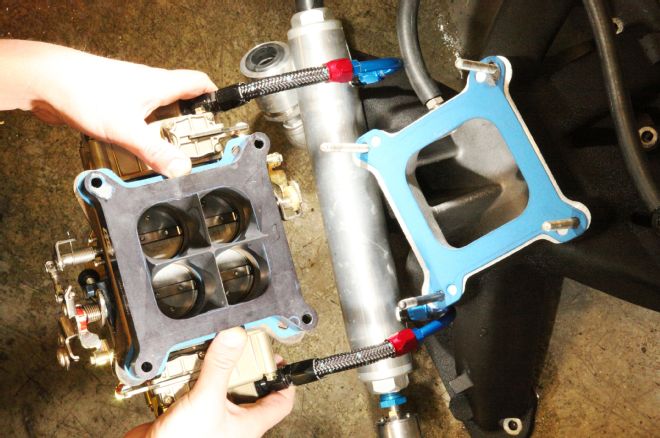

10. Starting with a modified Holley 850 body, the carb was custom built using parts from Stealth. Tricks include oversized venturii, and unique downleg annular boosters.

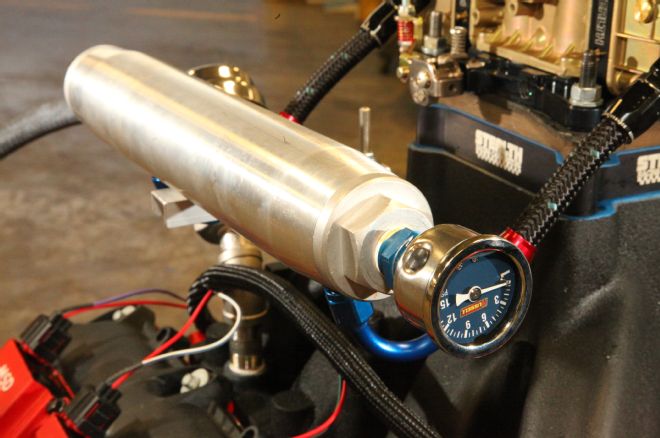

11. The custom oversized fuel log was inspired by the writings of Smokey Yunick, and built by Daniel Boshears. The idea is delivering a steady supply of liquid fuel without aeration.

12. The special carb spacer from Stealth uses a unique extended divider that drops into the plenum. Boshears cites improved distribution as a key benefit here.

13. The Ritter single-plane intake manifold resembles the virtually unavailable Mopar Performance Drag Pack piece. Note the idle vacuum evacuation system plumbed into the far side of the intake, and the evacuation fitting plumbed to the header on the near side.

14. Circulating the coolant is a Meziere electric water pump, while the ATI damper below helps the crankshaft survive. Boshears selected both of these components based upon their impeccable reputations.

15. With the lack of a distributor on the Gen III Hemi, these requirements are handled by an external electronic controller and the factory sensors. Boshears tells us the MSD 6 Hemi timing controller was easy to use and functioned flawlessly.

16. The MSD controller fires a battery of MSD coil modules—one unit per cylinder—to animate the Hemi's dual spark plugs. The plugs are fired simultaneously, and Boshears notes that with total timing requirements in the low 20s, the Hemi is exceptionally efficient.

17. These beautiful headers were created by components from Schoenfeld. The primary tubes feature a 1 ¾ to 1 7/8-inch steps, leading to a Schoenfeld merge collector.

18. On the dyno the long-stroke Gen III delivered outstanding power, no doubt thanks to the deep breathing of the Hemi heads. On tap was a peak output of 612 horsepower, while a massive 570 lb-ft of torque was produced at 5,000-5,100 rpm. It's hard to argue the power potential of the Gen III.

19. Builder Daniel Boshears (L), and his crew of co-conspirators Mike Phillips, Randy Malik and Cory Short can attest to the power-producing capabilities of Mopar's modern Hemi.