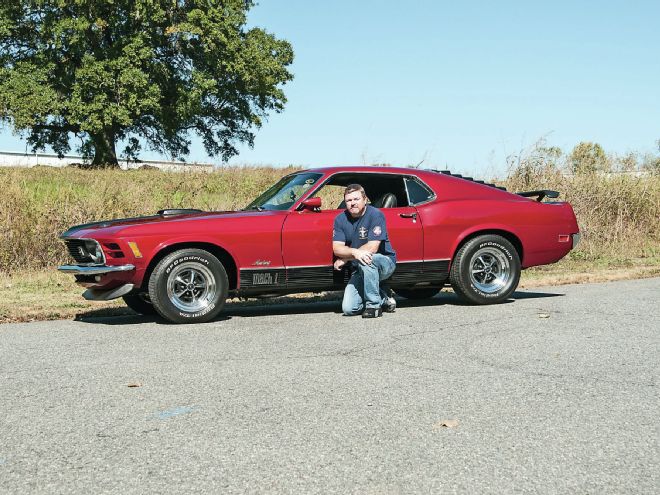

Scott Mays purchased his 1970 Mustang Mach 1 with a 351 Cleveland (351C) engine through Craigslist. “It’s a true Mach 1,” Mays says proudly. “The previous owner had the engine rebuilt but could not recall most of the specs. He told me the original block was bored 0.030 over. I didn’t know the cam specs, but from the way the car ran, it felt pretty huge. Externally, the engine has an Edelbrock Performer intake fed by an Edelbrock 750-cfm carb. A Mallory distributor lights the spark. Exhaust is through FPA headers, dual 2.5-inch pipes, and Flowmasters. The owner claims the compression ratio is around 10:1, and the car runs fine on 93-octane gas.”

The high-option car sports a Shaker hood, slats, louvers, spoilers, and front disc brakes. BFGoodrich Radial T/As ride on Magnum 500 wheels.

The high-option car sports a Shaker hood, slats, louvers, spoilers, and front disc brakes. BFGoodrich Radial T/As ride on Magnum 500 wheels.

When the engine was rebuilt, its original iron 2V heads were replaced with Airflow Dynamics (AFD) 351-2V aluminum castings. A major upgrade for an old Cleveland, these free-flowing, closed-chamber, Australian castings flow enough air to make over 600 flywheel horsepower on an optimized engine, yet their improved intake and exhaust ports remain in the stock 2V location so existing intakes and headers can still bolt on. As installed on the car, Mays says the heads had “huge triple springs and adjustable roller rockers.”

Mays’ problems began soon after purchase. “I noticed excessive valvetrain noise from the beginning. Turns out there was a broken rocker on No. 3 cylinder. I replaced all the rockers with Crane Energizer aluminum rollers, but the car still seemed a little noisy.”

The primary failure was stripped teeth on a succession of soft bronze distributor drive gears, likely due to a high-volume oil pump.

The primary failure was stripped teeth on a succession of soft bronze distributor drive gears, likely due to a high-volume oil pump.

There were also hard-start and driveability problems “that seemed to me to be fuel-related. I tried bigger jets with some success.” Still, “the car has always been hard to start, especially when cold.”

The Mustang originally came off the assembly line with the H-code 351C-2V motor. Mays says, “The original block is still in the car.” The previous owner had the engine rebuilt, but couldn’t recall many specifics about which hot rod parts had been installed. It did have a fairly big cam and free-flowing AFD aluminum heads.

The Mustang originally came off the assembly line with the H-code 351C-2V motor. Mays says, “The original block is still in the car.” The previous owner had the engine rebuilt, but couldn’t recall many specifics about which hot rod parts had been installed. It did have a fairly big cam and free-flowing AFD aluminum heads.

The worst was yet to come. As Mays tells it, “One day I was driving down the freeway. There was a pop and the engine just quit. My mechanic friend, Mike Harvey, put two and two together and saw the distributor wasn’t turning. I cranked it and there was no oil pressure. I was fortunate that the engine just didn’t grenade.”

Mays pulled the distributor and found a bronze gear with serious “tooth decay.” Soft bronze gears are usually used with high-end hardened billet-steel mechanical roller cams. In theory, the softer bronze sacrifices itself over time to protect the harder steel. That’s not a problem for racers who expect to periodically inspect, tear down, and replace engine parts, but it’s generally not a good plan for a street-driven car. Not knowing what type of cam was in the motor, Mays replaced it with another bronze gear. Within 500 miles the latest gear also began showing signs of abnormal wear.

Motorsport Connections’ Billy Revis fixed the Mustang. His shop is a complete tune-up and repair facility, complete with chassis dyno.

Motorsport Connections’ Billy Revis fixed the Mustang. His shop is a complete tune-up and repair facility, complete with chassis dyno.

We sent the Mt. Holley, North Carolina–based car to Motorsport Connections in Winston-Salem. Owner Billy Revis has been around forever and can wrench on just about anything—as you’d expect from a facility located in the midst of hardcore NASCAR country.

Revis removed the distributor. He observed “pieces of material coming off its distributor gear.” A bad distributor or incorrectly machined block were initial suspects. To check, Revis put the damaged gear in the lathe and turned it down smooth to eliminate the teeth, then reinstalled it on the distributor and inserted the distributor into the engine. He pushed down on the unit while rotating the engine. “I was looking for excessive drag on the hole inside the block where the distributor gear passes through and picks up the oil pump driveshaft. No problems were observed.”

AFD heads are a great upgrade for a Cleveland, but the rest of the combo must be coordinated to take full advantage of them. Mays’ huge triple valvesprings weren’t a good fit with the engine’s hydraulic flat-tappet cam. Pre-Rescue, Mays broke one of the engine’s as-equipped rocker arms but had fixed that problem himself by upgrading to a set of Crane Energizer roller rockers.

AFD heads are a great upgrade for a Cleveland, but the rest of the combo must be coordinated to take full advantage of them. Mays’ huge triple valvesprings weren’t a good fit with the engine’s hydraulic flat-tappet cam. Pre-Rescue, Mays broke one of the engine’s as-equipped rocker arms but had fixed that problem himself by upgrading to a set of Crane Energizer roller rockers.

Excessive spring pressure likely caused Mays’ rocker arm failure. “There was enough spring to turn 10,000 rpm!” Revis says. “The lifters were adjusted down to almost nothing. In this case, I think it was plain adjuster error. But it does create more cam drag. With excessive oil pressure, this can hold the exhaust valve open too long and eventually burn a valve.”

Excessive spring pressure likely caused Mays’ rocker arm failure. “There was enough spring to turn 10,000 rpm!” Revis says. “The lifters were adjusted down to almost nothing. In this case, I think it was plain adjuster error. But it does create more cam drag. With excessive oil pressure, this can hold the exhaust valve open too long and eventually burn a valve.”

Revis doesn’t think the valvetrain issues caused the distributor gear failure, but they may have overwhelmed the original rockers. At least the engine builder took care to correctly align the pushrod guideplates to the AFD heads’ valve locations: Note how the ’plates were sectioned, then tack-welded back together.

Revis doesn’t think the valvetrain issues caused the distributor gear failure, but they may have overwhelmed the original rockers. At least the engine builder took care to correctly align the pushrod guideplates to the AFD heads’ valve locations: Note how the ’plates were sectioned, then tack-welded back together.

It’s unknown if this particular Mallory Unilite distributor originally came with a bronze gear, or whether the original owner had installed the bronze gear in response to a previous gear issue.

It’s unknown if this particular Mallory Unilite distributor originally came with a bronze gear, or whether the original owner had installed the bronze gear in response to a previous gear issue.

The distance from the distributor housing mount (against the block) to the bottom of the distributor gear on Mays’ Mallory distributor was compared to that on a standard-replacement, parts-store Ford distributor and checked. They were identical. With either distributor bolted in place, the clearance between the bottom of the gear and the top of the internal boss in the block was also within spec.

Because two different distributors had the same dimensional measurements and developed the same within-spec clearances when installed in the block, Revis concluded the block machining was likely to spec.

To aid in checking distributor drag, internal clearances, and free-play, Revis made an expedient checking fixture by turning down the damaged bronze gear teeth in the shop’s lathe to yield a perfectly smooth surface. Installing the distributor back in the block, he found no excessive rotational or clearance drag.

To aid in checking distributor drag, internal clearances, and free-play, Revis made an expedient checking fixture by turning down the damaged bronze gear teeth in the shop’s lathe to yield a perfectly smooth surface. Installing the distributor back in the block, he found no excessive rotational or clearance drag.

Revis next pulled the cam. Its integrally cast distributor drive gear also showed wear, “because the cam had been screwed up from the previous gear failures.” Revis had a local machine shop examine the cam’s wear pattern. According to Revis, “We thought the cam was sitting too far back in the block. Like a rearend ring-and-pinion, you want the wear pattern in the center. The observed cam gear wear started at the center and went all the way back off the teeth.”

Maybe the block or distributor were wrongly machined? To find out, Revis measured the distance from where the distributor housing seats against the block to the bottom of the distributor gear. He checked the Mallory distributor against a standard parts-store replacement distributor. Both measured the same.

Maybe the block or distributor were wrongly machined? To find out, Revis measured the distance from where the distributor housing seats against the block to the bottom of the distributor gear. He checked the Mallory distributor against a standard parts-store replacement distributor. Both measured the same.

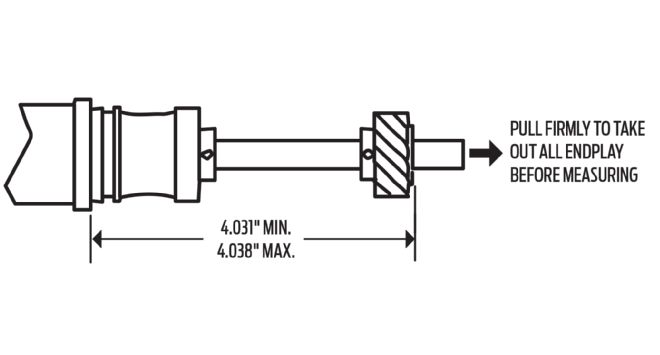

This is Ford Racing’s official gear location dimension. Don’t be shy about drilling an entire new shaft hole rotated 90 degrees from the existing hole if the dimensions are off.

This is Ford Racing’s official gear location dimension. Don’t be shy about drilling an entire new shaft hole rotated 90 degrees from the existing hole if the dimensions are off.

Several decades old, Mays’ existing cam turned out to be an ancient Comp Cams’ flat-tappet hydraulic, that—like any proferal iron flat-tappet cam—is compatible with standard OE-style distributor gears (not the bronze gear that had been installed). We sent the cam back to Comp for analysis, where its quality-control department says total runout was within acceptable parameters for a used cam. It also checked for flutter (tooth-to-tooth error), which, according to Comp engineer Billy Godbold, “Can be a bigger issue than runout as that results from errors in the tooth shape. We limit flutter to 0.002 or 0.003 inch, depending on the application. From its visual appearance, I assumed yours would be very ‘notchy,’ but this was not the case.”

Having observed debris flaking off the damaged gears, Revis checked to see if the rod and main bearings were OK. “We dropped the Milodon replacement oil pan, then pulled the main and rod caps. The bearings looked good with no scouring.” It turns out that due to the previous parts breakage, “Mays had flushed the oil system three times,” which probably saved the motor.

However, with the pan removed, Revis found a high-volume oil pump installed on the motor. That’s not recommended on Ford street engines. Official Ford Racing literature states that “running a high-volume oil pump with production bearing clearances can cause abnormally high oil pressures and possible premature distributor gear wear.” There’s also the possibility that on a Cleveland with its notoriously inefficient stock oiling system, a high-volume pump can suck a stock-sump pan dry. Revis adds that on a Ford, “If the oil pump sucks up any debris inside it, it can jam up the pump and snap the oil pump shaft. If a heavy-duty oil pump shaft is installed in an attempt to crutch the problem [not the case on Mays’ car], it can break the bronze gear to the distributor.”

The center of the gear’s roll-pin hole to the bottom edge where it contacts the block’s internal support boss measured the same for both the destroyed bronze gear, the gear from the parts-store distributor, and the new Hi-Tec polymer gear.

The center of the gear’s roll-pin hole to the bottom edge where it contacts the block’s internal support boss measured the same for both the destroyed bronze gear, the gear from the parts-store distributor, and the new Hi-Tec polymer gear.

With the distributor bolted down, Revis checked the clearance between the bottom of the gear and the internal block support boss. It came out to 0.010 inch—Revis says anything from 0.010 to 0.020 is OK. You definitely need at least some free play, or the assembly will bind.

With the distributor bolted down, Revis checked the clearance between the bottom of the gear and the internal block support boss. It came out to 0.010 inch—Revis says anything from 0.010 to 0.020 is OK. You definitely need at least some free play, or the assembly will bind.

Moving on to other issues, the huge valvesprings installed in the heads may have been purchased as part of a head-assembly package by the original owner, but they were monstrous overkill for a hydraulic flat-tappet cam. At a minimum, they’ll bleed-down the hydraulic lifters, causing a noisy valvetrain. That can also mess with the lash settings. In extreme cases, too much pressure can wipe out flat-tappet lifters and cam lobes. The pushrod length may also have been wrong for this combo.

Nevertheless, in Revis’s opinion, Mays’ “rocker arm failure and the distributor gear problems aren’t related.” The rocker failure was most likely from the excessive valvespring pressure and improper valvetrain geometry; the gear problems—whenever they first started—were likely initiated by the high-volume oil pump.

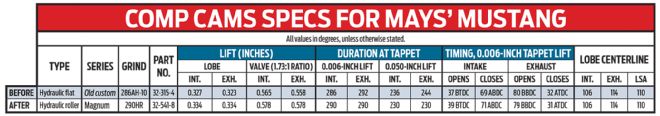

Revis attacked the problem from three axes: installing a modern, coordinated camshaft and valvetrain, changing to a composite distributor gear, and replacing the high-volume oil pump with a standard-pressure oil pump. In the valvetrain department, Comp Cams brought Mays’ Mustang into the 21st century, replacing the ancient flat-tappet hydraulic cam with a modern Magnum 290HR retrofit hydraulic-roller grind, beehive springs, and additional coordinated valvetrain components including the correct-length pushrods needed to establish proper valvetrain geometry with AFD’s heads and the new, taller, roller lifters . The new setup has proven much more street-friendly than Mays’ old cam.

Tri-Tec’s new lightweight polymer Cleveland distributor gear is compatible with any cam material. The roll-pin hole comes only partially drilled to permit perfect final alignment on the shaft. Revis checked the original shaft hole to be in the right location, so he merely lined up the gear hole with the shaft-hole, then drilled through to the Mallory’s 3⁄16-inch pin-hole size.

Tri-Tec’s new lightweight polymer Cleveland distributor gear is compatible with any cam material. The roll-pin hole comes only partially drilled to permit perfect final alignment on the shaft. Revis checked the original shaft hole to be in the right location, so he merely lined up the gear hole with the shaft-hole, then drilled through to the Mallory’s 3⁄16-inch pin-hole size.

Although it’s a roller, Comp manufactures the cam from a material compatible with stock distributor gears. However, doing his own research, owner Mays discovered Tri-Tec Motorsports had just released a carbon ultra-poly composite distributor gear that fits the Ford 335-series (Cleveland and Modified) and 385-series (429/460 big-block) distributors. Previously available for more “mainstream” engines, poly-carbon gears have gained a following due to their light weight, no break-in requirement, and—most importantly, in this case—compatibility with any cam billet material. Tri-Tec was happy to contribute one for the Rescue.

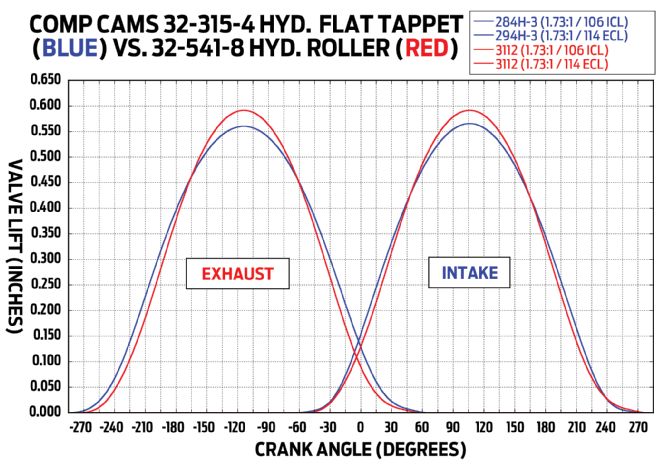

Mays’ existing cam turned out to be an old custom Comp Cams dual-pattern hydraulic flat-tappet 286AH-10 custom grind originally developed to crutch the flow mismatch between an old 4V Cleveland head’s huge intake ports and poor exhaust ports. It wasn’t really the right fit for the better-balanced AFD heads and Mays’ otherwise mild intake and exhaust setup.

Mays’ existing cam turned out to be an old custom Comp Cams dual-pattern hydraulic flat-tappet 286AH-10 custom grind originally developed to crutch the flow mismatch between an old 4V Cleveland head’s huge intake ports and poor exhaust ports. It wasn’t really the right fit for the better-balanced AFD heads and Mays’ otherwise mild intake and exhaust setup.

Perhaps the cam had excessive endplay? Revis checked the clearance between the timing sprocket boss plate and first cam journal. At 0.004 inch +0.001 inch, “it miked identical to sample Ford production cams.” Different thrust plates and cam sprockets also checked within spec. At this point, we mailed the cam to Comp Cams for analysis.

Perhaps the cam had excessive endplay? Revis checked the clearance between the timing sprocket boss plate and first cam journal. At 0.004 inch +0.001 inch, “it miked identical to sample Ford production cams.” Different thrust plates and cam sprockets also checked within spec. At this point, we mailed the cam to Comp Cams for analysis.

Comp checked the old cam with its cumulative gear runout gauge fixture that measures runout, flutter, and cumulative error. Comp shoots for under 0.007 inch total cumulative error on new-manufacture cams; the returned used cam was still under 0.010 inch, the point at which Comp engineer Billy Godbold says, “Durability issues would become evident.” Even with the scoured gears, the observed gear contact pattern—aka “flutter”—was also within spec. Despite Mays’ huge valvesprings, the lobes checked OK, too.

Comp checked the old cam with its cumulative gear runout gauge fixture that measures runout, flutter, and cumulative error. Comp shoots for under 0.007 inch total cumulative error on new-manufacture cams; the returned used cam was still under 0.010 inch, the point at which Comp engineer Billy Godbold says, “Durability issues would become evident.” Even with the scoured gears, the observed gear contact pattern—aka “flutter”—was also within spec. Despite Mays’ huge valvesprings, the lobes checked OK, too.

Comp Cams upgraded the mismatched valvetrain with a modern Magnum 290HR hydraulic-roller grind, retrofit hydraulic-roller lifters, beehive valvesprings with complementary retainers and keys, a three-keyway true-roller timing set, and correct-length Hi-Tech pushrods that develop the proper valvetrain geometry with the splayed-valve Cleveland heads and taller hydraulic roller tappets.

Comp Cams upgraded the mismatched valvetrain with a modern Magnum 290HR hydraulic-roller grind, retrofit hydraulic-roller lifters, beehive valvesprings with complementary retainers and keys, a three-keyway true-roller timing set, and correct-length Hi-Tech pushrods that develop the proper valvetrain geometry with the splayed-valve Cleveland heads and taller hydraulic roller tappets.

Revis buttoned the engine up using Fel-Pro performance gaskets, then broke in the new cam and valvetrain on Havoline mineral oil and a WIX oil filter. After break-in, he final-filled the engine with “the good stuff”: Rotella 15W-40 diesel oil that still has lots of anti-scuff ZDP agents (although they’re not strictly needed with a roller cam), plus a premium Motorcraft performance oil filter whose bypass valve opens at a higher pressure than the valve in standard-replacement filters.

The 290HR Magnum retrofit roller profile has less duration but more lift than Mays’ obsolete 290AH-10 flat-tappet hydraulic grind, developing more low-end torque and superior driveability. Today, retrofit hydraulic-roller cams are available for bringing nearly any engine into the 21st century.

The 290HR Magnum retrofit roller profile has less duration but more lift than Mays’ obsolete 290AH-10 flat-tappet hydraulic grind, developing more low-end torque and superior driveability. Today, retrofit hydraulic-roller cams are available for bringing nearly any engine into the 21st century.

Comp’s Hi-Tech roller race timing set has a cast-iron cam gear and an induction-hardened billet steel crank sprocket with three keyways that permit retarding or advancing the cam 4 crank degrees. The true-roller chain is prestretched and heat-treated with large heavy-duty pins. For emissions compliance some stock replacement timing sets for Ford engines retard the cam.

Comp’s Hi-Tech roller race timing set has a cast-iron cam gear and an induction-hardened billet steel crank sprocket with three keyways that permit retarding or advancing the cam 4 crank degrees. The true-roller chain is prestretched and heat-treated with large heavy-duty pins. For emissions compliance some stock replacement timing sets for Ford engines retard the cam.

Comp’s selected Magnum retrofit hydraulic roller is a single-pattern grind: Unlike original stock factory iron Ford heads from the muscle-car era, the improved AFD heads don’t need exhaust-side help. Revis prefers Red Line prelube for all of Motorsports’ new cam installs.

Comp’s selected Magnum retrofit hydraulic roller is a single-pattern grind: Unlike original stock factory iron Ford heads from the muscle-car era, the improved AFD heads don’t need exhaust-side help. Revis prefers Red Line prelube for all of Motorsports’ new cam installs.

Some traditionalists install a street cam 4-degrees advanced from its as-ground phasing to aid bottom-end response and/or compensate for long-term timing chain stretch. But like many Comp street cams, the Magnum’s intake lobe is factory-ground 4 degrees advanced—so Revis degree’d in the new bumpstick on-center.

Some traditionalists install a street cam 4-degrees advanced from its as-ground phasing to aid bottom-end response and/or compensate for long-term timing chain stretch. But like many Comp street cams, the Magnum’s intake lobe is factory-ground 4 degrees advanced—so Revis degree’d in the new bumpstick on-center.

Revis noticed the foldover locating/locking tab was broken off on the inner half of the cam’s bolt-on mechanical fuel-pump eccentric. He later replaced it with a good used piece from the shop’s scrap pile when the new Comp timing set was installed.

Revis noticed the foldover locating/locking tab was broken off on the inner half of the cam’s bolt-on mechanical fuel-pump eccentric. He later replaced it with a good used piece from the shop’s scrap pile when the new Comp timing set was installed.

Final warm-overs included “going over the valve lash twice. We adjusted the rockers to zero-lash, plus ¼ turn. We put in 12 degrees of initial lead at the crank, with a total of 36 degrees centrifugal at 3,600 to 3,800 rpm.”

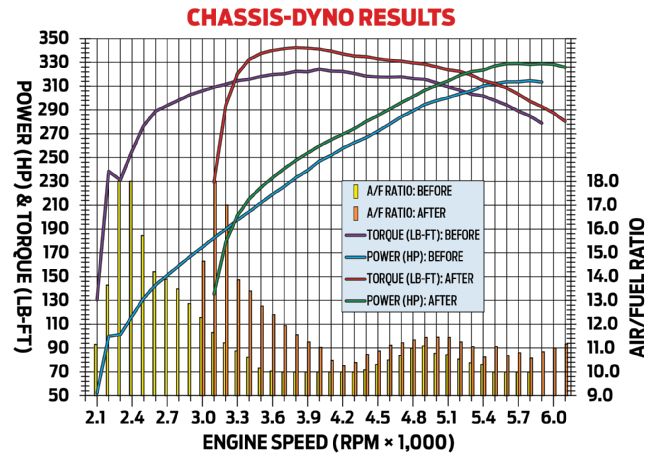

The engine makes more power and torque on Motorsport Connections’ Dynojet chassis dyno. According to Revis, “The roller cam, standard oil pump, and lower-friction springs are all worth real power.” There have been no further distributor-gear issues. A pleased Mays says, “The car is much smoother in power; you can really tell the difference with that roller cam. Cold starts are better. It seems to be a little stronger; it has more torque. It runs hard!”

A Tri-Tec polymer distributor gear, a standard-pressure Melling oil pump, and a new Comp Cams hydraulic roller cam cured Mays’ ills.

A Tri-Tec polymer distributor gear, a standard-pressure Melling oil pump, and a new Comp Cams hydraulic roller cam cured Mays’ ills.

The new springs’ beehive configuration—narrower on top, wider on the bottom—requires less pressure for a given cam profile, reduces spring weight and mass, and permits a smaller, lighter retainer. Beehives are more stable with better harmonics. Their ovate spring-wire configuration increases spring life by handling stress more efficiently and developing better heat dissipation.

The new springs’ beehive configuration—narrower on top, wider on the bottom—requires less pressure for a given cam profile, reduces spring weight and mass, and permits a smaller, lighter retainer. Beehives are more stable with better harmonics. Their ovate spring-wire configuration increases spring life by handling stress more efficiently and developing better heat dissipation.

When you buy a prebuilt hot rod, try to get the car’s complete info and history. If it’s your own car, keep detailed records in the first place: Consider assembling a notebook containing a parts list, build sheets, and problem history. Take care when assembling an engine combo—so that it really performs as a combo. In this case, the springs were wrong for the cam, the original cam wasn’t really a good fit for a regularly driven street car, and a high-volume oil pump was a poor choice for a street-driven Cleveland with a near-stock oil pan and oil system.

On Maximum Motorsports’ Dynojet chassis dyno, at the rear wheels the Mustang’s 351C made 329.0 hp and 342.4 lb-ft of torque, a gain of 14.4 hp and 18.1 lb-ft over its as-received, pre-Rescue, configuration. Mays could use a better induction system to develop his AFD heads’ full potential—but then that Shaker hoodscoop would no longer fit right.

On Maximum Motorsports’ Dynojet chassis dyno, at the rear wheels the Mustang’s 351C made 329.0 hp and 342.4 lb-ft of torque, a gain of 14.4 hp and 18.1 lb-ft over its as-received, pre-Rescue, configuration. Mays could use a better induction system to develop his AFD heads’ full potential—but then that Shaker hoodscoop would no longer fit right.

The Mustang still has the original Ford cold-air induction system. For safety, Revis “left the carb’s calibration a little fat. With Mays’ Shaker hood, on the highway you get a ram-air effect at speed that you won’t see on a chassis dyno. This may cause the engine to lean out on the top end.” He did adjust the choke one notch richer to address the cold-start issue.

The Mustang still has the original Ford cold-air induction system. For safety, Revis “left the carb’s calibration a little fat. With Mays’ Shaker hood, on the highway you get a ram-air effect at speed that you won’t see on a chassis dyno. This may cause the engine to lean out on the top end.” He did adjust the choke one notch richer to address the cold-start issue.

If you’re having problems with your distributor in a Ford engine, the following are the most likely culprits, according to Ford Racing Performance Parts. For more detail on how to check for these problems, see the current Ford Racing parts catalog.

Little or no shaft endplay: This has been found with both new and remanufactured distributors. Improper endplay may force the gear against the support in the block or hold it up off the support, causing damage.

Incompatible gear material: The distributor gear must be compatible with your camshaft’s material. Consult your cam grinder if in doubt.

Heavy-duty oil pump driveshaft clearance: Some heavy-duty oil pump driveshafts may not allow an EFI distributor to slide down far enough over the oil pump driveshaft. EFI distributors have a longer shaft below the gear.

High-volume (HV) oil pump: HV pumps can cause abnormally high oil pressure and possible premature distributor gear wear.

Poor finish on camshaft drive-gear: This can cause premature distributor gear wear.

Wrong driven-gear height: Some new and remanufactured distributors may have the gear installed at the wrong height.

Parts and Prices Includes the major parts required to fix the problem. Does not include miscellaneous small parts, labor, tuning, shipping, or sales taxes. Priced 11/13/14 and subject to change. All dimensions are in linear inches or fractions thereof unless otherwise noted. Brand Part Description Part No. Amt. Price Source Cost Havoline OIL, engine, Havoline 10W-30, 1qt bottle (used for break-in) HAV 79630 7 NAPA $34.93 Comp Cams Camshaft, Magnum retrofit hydraulic-roller, 290HR, 2,500–6,000 rpm operating range 32-541-8 1 Summit $274.97 Lifter Set, hydraulic roller, small-block Ford 0.875 od, paired retrofit-type w/ vertical link-bar 8931-16 1 Summit $540.97 Lock Set, retainer-to-valve, Super Lock 10°, 1 groove, 11⁄32 valve stem, +0.050 installed height 614-16 2* Summit $47.94 Pushrod Set, Hi-Tech chrome-moly, heat-treated, seamless, 5⁄16 od x 7.850 ol x 0.080 wall 7974-16 1 Summit $139.97 Retainer Set, valvespring, 10°, 4140 chrome-moly steel, 1.095 od x 0.440 id, for 26120 spring 795-16 1 Summit $54.97 Timing Set, Hi-Tech, double-roller, 3-keyway, +4° advance/retard 3121 1 Summit $66.97 Valvespring Set, single beehive configuration, 370 lb/in rate 26120-16 1 Summit $202.97 Dupli-Color Paint, enamel w/ ceramic resin, gloss Ford blue, 12oz aerosol can (for engine touch-up) DE1601 1 NAPA $6.49 Fel-Pro Gasket Set, exhaust header, 351C-2V, 1.56 x 1.98 ports, perforated steel core w/ antistick coating 1430 1 Summit $19.97 Gasket Set, intake manifold, 351C-2V, 1.50 x 2.12 port size, 0.060 thk, composite w/ Printoseal 1240 1 RockAuto $17.77 Gasket Set, oil pan, 0.094 thk, rubber-coated fiber 1811 1 RockAuto $12.81 Gasket Set, timing cover, blue stripe cork/rubber TCS45061 1 RockAuto $9.57 Ford Eccentric, camshaft mechanical fuel pump drive, inner half w/ locking tab Used 1 Motorsport $10.00 Loctite Sealant, anerobic gasket-maker and flange-filler No. 518 red, 50ml tube 37394 1 NAPA $12.99 Melling Pump, engine oil, standard-pressure/volume M84A 1 Summit $43.97 Motorcraft FILTER, engine oil, performance, 22-psi relief-valve (used after break-in) FL1HP 1 RockAuto $8.71 Red Line LUBRICANT, camshaft break-in and engine assembly, 4oz container 80312 1 Summit $7.95 Shell OIL, engine, Rotella 15W-40, 1qt bottle (used after break-in) SHE 550019905 7 NAPA $37.03 Tri-Tec GEAR, distributor driven, carbon ultra-poly composite, Ford 335-385 series engines PP3734-MB-467 1 Tri-Tec $125.00 Wix FILTER, Engine Oil (used for break-in) 51515 1 RockAuto $4.35 *16/package; 32 required. Total $1,680.30