Can I use a three- or four-speed manual tranny with the new 5.3L LS-style blocks? Do they have the same bellhousing as an older small-block?

- S.C. Griffith

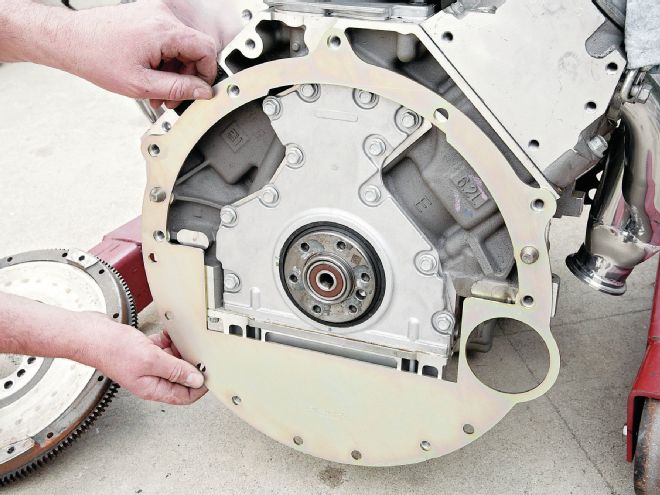

On any LS-type engine (not just the 5.3L), there are two ways to make this work: mechanical clutch linkage or hydraulic linkage. A traditional Chevy V8 bellhousing going all the way back to 1955 more or less bolts up. “More or less” because the LS block’s rear-face (bellhousing) bolt pattern is close, but not 100 percent identical, to the old pattern. Locating dowels are effectively the same size and remain in the same location, as are five out of six bellhousing-to-block mounting holes. Using just five holes to attach a traditional Chevy V8 bellhousing is fine. On the all-metric LS engines, you must attach the ’housing using M10 x 1.5 x 35 (metric) bolts (such as ARP PN 134-0901) in place of the original 3⁄8-16 x 13⁄8 U.S. fasteners.

Compared to the traditional Chevy V8 bellhousing bolt-pattern, LS blocks lack one upper passenger-side bolt hole, but add a hole at the 12 o’clock position. You can safely attach a classic V8 bell using the five holes that line up using metric bolts. Trivia: Some rare OE 409 Chevy bellhousings had the “extra” seventh 12 o’clock hole, but good luck finding one!

Compared to the traditional Chevy V8 bellhousing bolt-pattern, LS blocks lack one upper passenger-side bolt hole, but add a hole at the 12 o’clock position. You can safely attach a classic V8 bell using the five holes that line up using metric bolts. Trivia: Some rare OE 409 Chevy bellhousings had the “extra” seventh 12 o’clock hole, but good luck finding one!

Just because a traditional bellhousing “bolts up” doesn’t mean the longitudinal stack-up is correct. Except for a few rare truck LS engines circa 1999–2000, LS cranks are 0.400-inch shorter relative to the block’s bellhousing mounting face compared to a traditional Chevy V8. A special GM pilot bearing (PN 12557583) is available, which compensates for the difference and allows the use of a standard-length transmission input shaft. McLeod offers a functionally similar bearing under its PN 1094-4. GM has an LS-type flywheel (PN 12561680) suitable for use with traditional four-speeds. This flywheel has an LS six-bolt metric mounting pattern and flywheel dowel-hole location. McLeod offers a special thick LS flywheel (PN 460535) that, combined with the extended pilot bearing, allow the transmission’s relative location to remain in the same location, allowing the use of a GM factory or aftermarket traditional V8 bellhousing. Unlike the GM ’wheel, McLeod’s version is dual-drilled for both the LS 10mm metric mounting bolts as well as the traditional 3⁄8-16 U.S. fasteners. (The metric bolt threads extend all the way to the top of the bolt hole, while the U.S. threads are recessed about 0.200 inch below the surface.) Note that some performance passenger-car LS engines use cranks that require eight- or even nine-bolt flywheels.

An alternative is a shorter aftermarket bellhousing that moves the trans forward to properly mate with the LS’s shorter crank without the need for a special thick flywheel or extended pilot bearing. QuickTime by Lakewood bellhousing PN RM-6036 is designed to achieve the proper “stack” with traditional Chevy V8 manual trans input shaft lengths (as well as aftermarket analogues), but there are potential issues with using this ’housing on an early Chevy II with mechanical clutch linkage.

All LS engines use 168-tooth flywheels (including the units referenced above). However, to better clear the early car’s tight floorpan, an original 1963–1967 Chevy II/Nova bellhousing was smaller in diameter and clears only 153-tooth flywheels. The bulkier stock and aftermarket bellhousings capable of accommodating the larger flywheel are a tight fit in a Chevy II, but doable: Since the LS engine installation itself is a custom job, you can fudge a little as needed by slightly repositioning the new adapter mounts in the chassis (forward/backward or higher/lower)—but don’t forget to consider the transmission crossmember location, which in the absence of other critical clearance issues, usually serves as a baseline for engine positioning. And the shifter handle must be properly located relative to the floor or console hole. Additionally, the engine oil pan needs to clear the steering linkage. A Pontiac GTO LS pan works best in an early Chevy II.

No more clutch linkage issues with a hydraulic conversion setup like this McLeod setup in John Kiewicz’s 1966 Chevy Nova. McLeod’s hydraulic conversion kit includes all necessary parts except a hydraulic throwout bearing. The proper bearing will vary according to the combo’s bellhousing, clutch design, and trans.

No more clutch linkage issues with a hydraulic conversion setup like this McLeod setup in John Kiewicz’s 1966 Chevy Nova. McLeod’s hydraulic conversion kit includes all necessary parts except a hydraulic throwout bearing. The proper bearing will vary according to the combo’s bellhousing, clutch design, and trans.

Besides basic larger bellhousing clearance, you also need to deal with the exit location of the mechanical shift fork relative to the bellhousing. On non-Chevy II bellhousings, the fork exits at approximately 9 o’clock, but the correct (and rare) small-diameter Chevy II bellhousing exit is at approximately 7 o’clock and requires a special clutch fork that’s only 6 to 7 inches long, compared to 12 to 13 inches for most other Chevy forks. Installing these parts in a standard 9-o’clock-exit bellhousing requires linkage and clutch fork mods, which tends to screw up the old Chevy’s already marginal mechanical-linkage geometry.

Although an old Ford Top Loader is shown here, the concept is the same for any trans. You need to mock everything up just as if you were measuring pushrods for a custom cam.

Although an old Ford Top Loader is shown here, the concept is the same for any trans. You need to mock everything up just as if you were measuring pushrods for a custom cam.

The previously referenced “short” LS-compatible QuickTime bell also has a 9 o’clock exit. There’s an old-school Lakewood Chevy II scattershield (PN 15050) that accepts large flywheels with the correct fork exit angle, but—as with most old-school heavy steel scattershields that sought to provide more room to accommodate some racing Long and B&B clutches—its 6½-inch length is said to be about ¼ inch longer than an original OE traditional V8 GM bellhousing. With the Lakewood, you’d definitely need that special longer pilot bearing, or maybe even a longer-yet-custom-machined unit, plus a longer mechanical throwout bearing.

An LS has no clutch linkage pivot-ball boss. The owner fabbed a custom bracket from ¼-inch steel plate to mount a factory-style clutch crossbar pivot ball (Classic PN KW201 or equivalent). On an LS block, it mounts to two existing and unused holes, but it’s shown here next to a traditional big-block V8 that lacks these holes.

An LS has no clutch linkage pivot-ball boss. The owner fabbed a custom bracket from ¼-inch steel plate to mount a factory-style clutch crossbar pivot ball (Classic PN KW201 or equivalent). On an LS block, it mounts to two existing and unused holes, but it’s shown here next to a traditional big-block V8 that lacks these holes.

The owner of this Chevy II modified mechanical linkage to try to get the QuickTime, 9 o’clock fork exit, early trans-to-LS block, bellhousing to work. He used a standard-length GM unit sold by Classic Industries listed for a Camaro and later Nova (Classic PN C926321); the heavy-duty throw-out bearing is from Hays (PN 70-101).

The owner of this Chevy II modified mechanical linkage to try to get the QuickTime, 9 o’clock fork exit, early trans-to-LS block, bellhousing to work. He used a standard-length GM unit sold by Classic Industries listed for a Camaro and later Nova (Classic PN C926321); the heavy-duty throw-out bearing is from Hays (PN 70-101).

Yet another complicating issue is that LS-style blocks lack mechanical linkage cross-shaft (aka Z-bar) mounting provisions, which even on an original Chevy II V8 small-block was also located in a different location than on standard, non-Chevy II, traditional V8 blocks. The installer must therefore fabricate a custom mounting bracket using whatever expedient holes are available on the LS block (see the photo on the next page for one owner’s solution).

What a pain! This is why, in my opinion, the smart move is going to hydraulic clutch actuation. Properly engineered, they’re glass-smooth with much less pedal effort. There are many aftermarket hydraulic solutions available. McLeod, for example, offers a direct-fit early Chevy II hydraulic clutch conversion kit (PN 1434003) that includes the new firewall-mounted clutch master cylinder and pedal-adapter parts.

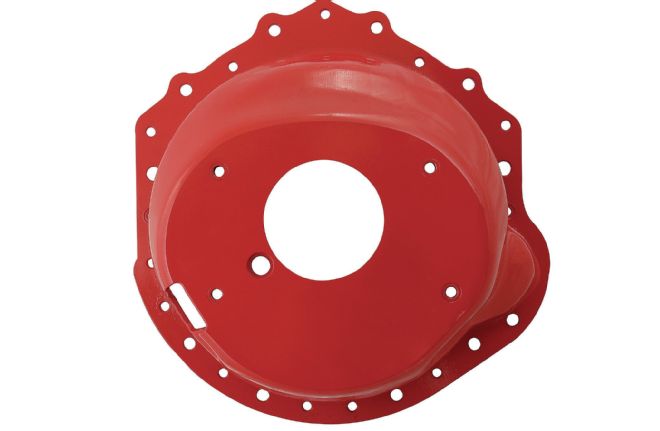

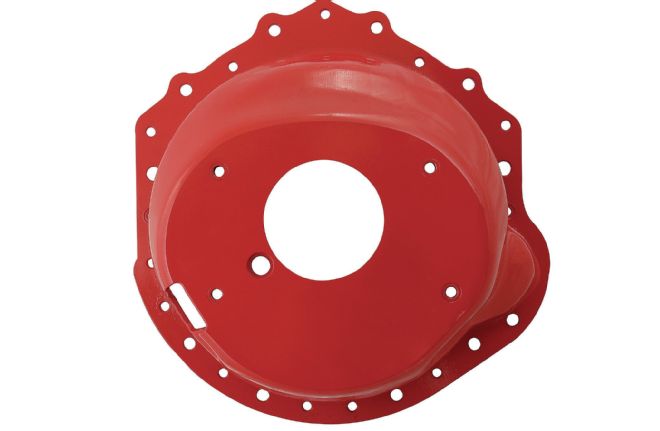

Original early Chevy II bellhousings accommodated only 153-tooth flywheels. LS engines use 168-tooth ’wheels. If you insist on retaining mechanical clutch linkage, the original Chevy II clutch fork exits at 7 o’clock instead of the standard 9 o’clock location. The only large-flywheel bellhousing with a 7 o’clock angle is this old-school Lakewood scattershield (PN 15050).

Original early Chevy II bellhousings accommodated only 153-tooth flywheels. LS engines use 168-tooth ’wheels. If you insist on retaining mechanical clutch linkage, the original Chevy II clutch fork exits at 7 o’clock instead of the standard 9 o’clock location. The only large-flywheel bellhousing with a 7 o’clock angle is this old-school Lakewood scattershield (PN 15050).

QuickTime By Lakewood bellhousing PN RM-6036 is shorter than a traditional Chevy V8 bellhousing. It allows bolting up classic-era GM trannies (including a Muncie) without the need for a special thick flywheel and longer pilot bearing that is otherwise required to compensate for the LS engine’s different crank stick-out dimension.

QuickTime By Lakewood bellhousing PN RM-6036 is shorter than a traditional Chevy V8 bellhousing. It allows bolting up classic-era GM trannies (including a Muncie) without the need for a special thick flywheel and longer pilot bearing that is otherwise required to compensate for the LS engine’s different crank stick-out dimension.

Like other McLeod “direct-fit” hydraulic clutch setups, its early Chevy II conversion kit develops a straight push on the master-cylinder pushrod (no lost motion). It’s engineered to develop the right pedal ratio for the kit’s ¾-inch-od–bore clutch master cylinder. Key in establishing the proper ratio and rod angle is an adapter bracket (arrow) that connects the pushrod to the pedal.

Like other McLeod “direct-fit” hydraulic clutch setups, its early Chevy II conversion kit develops a straight push on the master-cylinder pushrod (no lost motion). It’s engineered to develop the right pedal ratio for the kit’s ¾-inch-od–bore clutch master cylinder. Key in establishing the proper ratio and rod angle is an adapter bracket (arrow) that connects the pushrod to the pedal.

At the trans end, select a hydraulic release bearing that’s both compatible with the transmission and has the correct travel to correctly interface with the clutch/pressure-plate/flywheel stack height, as well as the bellhousing length. Generally, diaphragm-style clutches work best with hydraulic linkage. The smart move is to go with a clutch-flywheel-hydraulic throwout bearing setup from the same manufacturer. If you are using a Muncie trans (or other classic trans with the same 4.680-inch pilot-collar, input shaft-length, and 11⁄8-inch-od x 10- or 26-spline input shaft), McLeod offers two integral hydraulic throwout bearings: PN 1400-20 (slip-on) or PN 1300-1 (bolt-on). According to McLeod, the slip-on is usually preferred if the measured distance from the bellhousing’s rear trans-mounting face to the top of the pressure plate’s release fingers (photo, middle) is 2.500 inches or less. If the distance is 2.500 inches or greater, the bolt-on bearing usually works better. The bolt-on bearing replaces the transmission’s bearing retainer collar; on the Muncie trans specifically, that tranny’s narrow slinger nut must be modified/ground-down for clearance. With hydraulic linkage, bellhousing fork exit-angle becomes immaterial, although for the case of this installation a shorter bellhousing (like the QuickTime) should be given serious consideration because it would likely permit use of the easier-to-install, slip-on-style bearing.

If running EFI and the computer, there are also vehicle speed sensor (VSS) interface considerations. An old-school trans like a Muncie isn’t set up to run a standard VSS. A functional VSS is more critical for an automatic trans application than it is in a retrofit early manual trans installation, but not having one could still adversely affect idle quality and coast-down to idle smoothness. Normally, an LS computer is set up to accept a “128K” (128,000 pulses/mile) VSS. Dakota Digital offers a 128K VSS that screws into the old speedometer drive cable-hole in the transmission tailshaft (PN SEN-4165), but it has no provisions for a pass-through to permit hooking up the stock speedometer cable required to drive the factory speedometer. One solution is installing an electric speedometer: Auto Meter, Dakota Digital, and other aftermarket gauge manufacturers offer a multitude of styles that can interface directly with the VSS and/or computer. Another workaround available from these outfits are speedos driven by the GPS satellites. Some people have even crutched by with apps available for their Android or Apple mobile phones.

The LS flywheel bolt pattern is similar (but not identical to) the 1986-and-later traditional one-piece, rear-seal, small-block bolt pattern. Also unlike the one-piece seal classic small-block, the LS ’wheel is neutral-balanced and uses ISO bolts (such as ARP PN 330-2802, M11 x 1.5 x 22). With two dowel pins, an LS flywheel can go on only one way.

The LS flywheel bolt pattern is similar (but not identical to) the 1986-and-later traditional one-piece, rear-seal, small-block bolt pattern. Also unlike the one-piece seal classic small-block, the LS ’wheel is neutral-balanced and uses ISO bolts (such as ARP PN 330-2802, M11 x 1.5 x 22). With two dowel pins, an LS flywheel can go on only one way.

The stock Chevy II cross-shaft was too long because an LS block is wider than the traditional small-block. A 1-inch section was cut out and the unit welded back together.

The stock Chevy II cross-shaft was too long because an LS block is wider than the traditional small-block. A 1-inch section was cut out and the unit welded back together.

But if you want to keep that stock speedo, unfortunately, to the best of my knowledge, no one makes a 128K VSS with a cable pass-through. The computer can be reprogrammed to interface with an old 8K (8,000 pulses/mile) VSS as used in early-to-mid-1990s (pre-LS) computers. Since you would need to have the computer reflashed anyway to remove the vehicle antitheft system (VATS) lockout, you could have the VSS signal changed over at the same time. With a manual trans in a retrofit, non-late-model, application, the courser 8K VSS input should be sufficient. Dakota Digital’s 8K VSS with cable hookup provisions is PN SEN-01-4160. Street & Performance is one reprogramming source and it also carries Dakota Digital products, as well as mounts and headers for the LS-into-Chevy II engine swap. You can reflash the GM computer yourself using aftermarket software; HP Tuners is one leading program.

Ask Marlan A Tech Question: [email protected]