Idle or wide-open throttle, there’s no in-between. Great horsepower or horrible driveability, your only options. Since its ’40s conception, mechanical fuel injection (MFI) was strictly reserved for race cars. Street cars need not apply. Yet we found four guys who break the norm with street-driven, mechanical-fuel-injected gassers. It isn’t easy to operate on the street, but it’s possible with careful tuning and patience.

“You’re putting fuel in and you’re getting fuel out,” says Augie Delgado about the basics of mechanical fuel injection. “It’s a controlled leak.” MFI is crude, simple, and known for being rich in low-rpm operation (below 3,000) partly because there’s no accelerator pump like you’d find in a carb. Being rich on the low end means there’s fuel on tap for quick throttle response and added power. Pete Jackson has said that a little smoke at idle is fine for an MFI system. Making MFI work well in the entire rpm range adds complexity, however.

Today, most carbs-in-a-box can simply be installed and run good enough without any tweaking. A fuel-injection system has fewer parts than a carburetor, but every piece is vital and sensitive to its function. If something isn’t perfect, it can alter the way the rest of the system works. “If things are just a little bit off, it’s not going to run right,” says Augie, who owns a ’66 straight-axle Nova with Pete Jackson mechanical fuel injection.

One technique many guys without pill selectors use is called trimming the throttle. Similar to a technique pilots used in older aircraft, at a steady throttle they slowly close the cut-off until they feel the car speed up, leaning out the system. But don’t try this at home; it takes a knowledgeable ear to get it right.

One technique many guys without pill selectors use is called trimming the throttle. Similar to a technique pilots used in older aircraft, at a steady throttle they slowly close the cut-off until they feel the car speed up, leaning out the system. But don’t try this at home; it takes a knowledgeable ear to get it right.

MFI is a constant-flow fuel system that uses a belt-driven pump to spray fuel through individual nozzles into each cylinder. The pump runs at half the speed of the crank pulley, and fuel pressure increases in sync with rpm. The butterflies control only the airflow, which controls engine speed. When you turn the throttle, engine speed increases, which increases pump pressure into the nozzles.

MFI fuel pumps push approximately three times the necessary amount of fuel. The 66 percent of the fuel that’s recycled back to the tank returns through restrictive “pills,” similar to jets, that alter the pressure of the nozzles. Change to a bigger pill to allow more fuel back to the tank to lean out the nozzles, or restrict fuel from returning and it enriches the mixture—the opposite of a carburetor.

When baselining the system, nozzle size is extremely important for street driving. The pump is set first, then the nozzles, and then the rest of the bypasses are tuned as driving gets better or worse. Engine vacuum pulls air through those tiny holes, helping to atomize the fuel.

When baselining the system, nozzle size is extremely important for street driving. The pump is set first, then the nozzles, and then the rest of the bypasses are tuned as driving gets better or worse. Engine vacuum pulls air through those tiny holes, helping to atomize the fuel.

Most of the street-driven cars use a reservoir tank mounted behind the radiator and above the pump. The tank is filled using an electric pump and filter from a large (usually the factory) rear-mounted tank, with Holley float bowls monitoring the level of the reservoir tank. The gas is gravity fed to the pump, which makes for easier start-ups without the need for priming. If it’s hard to crank, one trick is to flat-foot the throttle as you would with a carb. This will empty the fuel lines of air. Shut-off valves are mounted on the feed line on the pump. This quickly stops fuel flow and is the best way to cut off a mechanically fuel-injected car and keep fuel from entering the cylinders while it’s off. It also keeps fuel close enough for a quick start-up.

Most of the street-driven cars use a reservoir tank mounted behind the radiator and above the pump. The tank is filled using an electric pump and filter from a large (usually the factory) rear-mounted tank, with Holley float bowls monitoring the level of the reservoir tank. The gas is gravity fed to the pump, which makes for easier start-ups without the need for priming. If it’s hard to crank, one trick is to flat-foot the throttle as you would with a carb. This will empty the fuel lines of air. Shut-off valves are mounted on the feed line on the pump. This quickly stops fuel flow and is the best way to cut off a mechanically fuel-injected car and keep fuel from entering the cylinders while it’s off. It also keeps fuel close enough for a quick start-up.

All systems use the same components like pills, bypasses, nozzles, and return lines, but different brands use them in different ways: in-line, screw-in, built-in, and so on. For their ’55 Chevy gasser, Augie and Gary Smith use a Pete Jackson MFI with a screw-in pill and circuits built into the barrel valve. Paul Soliz uses Hilborn MFI in his ’41 Willys, where the pill is mounted in the return line on the mechanical pump. It’s debatable, but some believe the Jackson system to be more street friendly.

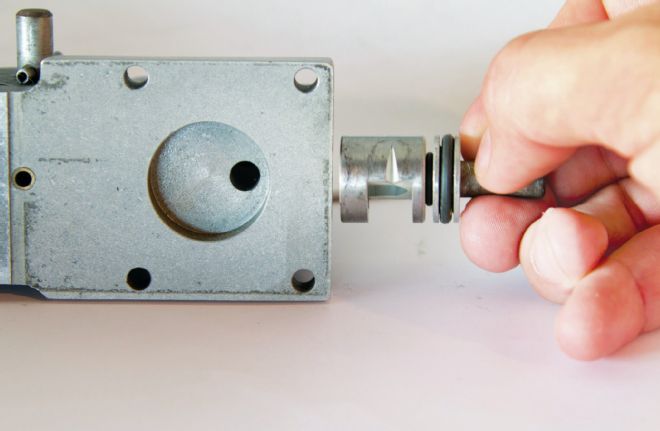

The fuel pump is the foundation of the system and where the rest of the calibration starts. Most gasoline street pumps are PG150-1 (biggest seen on the street) and PG150-0 (smaller). Typically, you’d see a -0 on a small-block and a -1 on a big-block or small-block running alcohol. PG150 refers to the pump, and the -# refers to the impeller. Most brands use identical pumps, and the physical housings are the same size. Only the impeller’s length changes.

MFI is notorious for overloading and fouling plugs because of the constant amount of fuel dumping into the cylinders. Many of the guys use magnetos because they don’t fail. If you lose spark, it can hydrolock the engine, destroying it by filling the cylinders with fuel.

MFI is notorious for overloading and fouling plugs because of the constant amount of fuel dumping into the cylinders. Many of the guys use magnetos because they don’t fail. If you lose spark, it can hydrolock the engine, destroying it by filling the cylinders with fuel.

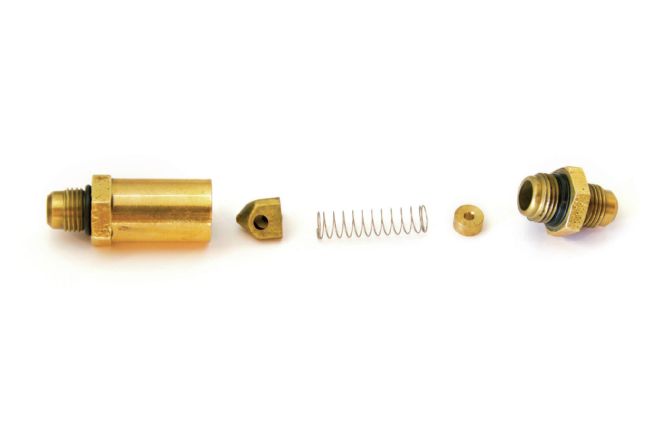

The secondary bypass, as seen here on Paul’s Willys, sometimes called the idle-circuit bypass, doesn’t use a pill, but a poppet and a weak spring. This holds fuel pressure during start-up, so not all of the fuel returns to the tank. Once fuel pressure is established, the spring fully collapses, opening the poppet.

The secondary bypass, as seen here on Paul’s Willys, sometimes called the idle-circuit bypass, doesn’t use a pill, but a poppet and a weak spring. This holds fuel pressure during start-up, so not all of the fuel returns to the tank. Once fuel pressure is established, the spring fully collapses, opening the poppet.

Paul’s ’41 Willys truck originally used a -1 pump on his 283 (enlarged to 301 ci) and then heavily leaned out the rest of the system to compensate. This method is possible, but for Paul it caused problems. Currently, the ’41 Willys uses a PG150-0 pump with a different final calibration.

An MFI fuel curve is linear. As rpm goes up, so does pressure, which is why it works well on race cars. “Below 3,000 rpm, they’re not real friendly,” Augie says. Pumps create roughly 3 pounds of pressure at idle and up to approximately 40 pounds at WOT and feature a return line that’s either built in or needs to be T-ed from the feed line. The fuel is constantly spraying no matter what stroke that cylinder is on, producing horrible gas mileage. Most guys saw 7-15 miles to the gallon.

Augie and Gary in the ’55 both converted to an MSD 6AL ignition, which has much hotter spark on the bottom end. “We had to forgo the nostalgia for performance,” Gary says. They say the cars run better and cleaner. The spark plug gap must change, however, 0.018-0.020 with a magneto and 0.042-0.050 with the MSD. “It starts better and doesn’t burn my eyes,” Augie says. Paul’s magneto causes a weaker start, because the MSD sends hotter sparks and more of them.

Augie and Gary in the ’55 both converted to an MSD 6AL ignition, which has much hotter spark on the bottom end. “We had to forgo the nostalgia for performance,” Gary says. They say the cars run better and cleaner. The spark plug gap must change, however, 0.018-0.020 with a magneto and 0.042-0.050 with the MSD. “It starts better and doesn’t burn my eyes,” Augie says. Paul’s magneto causes a weaker start, because the MSD sends hotter sparks and more of them.

“It’s putting in fuel constantly, even when you don’t need it, blowing out a lot of wasted gas,” Augie says, “but the extra fuel does provide a performance advantage.” The systems are typically richer on the top end, which makes for safer high-rpm operation without risk of blowing up the engine. The extra fuel cools the valves and cylinders, as many of the guys said they’ve never experienced overheating issues. Also, race gas isn’t needed for the higher compression and more timing the engines can run. MFI runs best in supercharged and high compression applications, according to Hilborn and our street guys.

Most manufacturers have created tuning charts, which can still be easily found. These charts list sizes for pills, nozzles, and spring rates based on your engine’s displacement and type of fuel. For street use, all guys start one step leaner than recommended.

Tim Avila’s Willys, nicknamed Tequila Sunrise, doesn’t use a reservoir tank in the front. Set up primarily for the track, it’s the least street friendly of the cars we examined.

Tim Avila’s Willys, nicknamed Tequila Sunrise, doesn’t use a reservoir tank in the front. Set up primarily for the track, it’s the least street friendly of the cars we examined.

Possibly the most important part of tuning for the street is finding the proper nozzle size. Some nozzles will drip, some won’t. During start-up, the MFI typically runs rough until the system is pressurized. This is the point where priming the system was once required. One technique is to not work the throttle like a carb, but open the throttle all the way to bleed the system of air and pressurize it. Similar to a carb that you may have flooded, you can flat-foot the throttle while the engine starts. This removes air in the lines and primes the system. Hilborn setups should idle ice cold.

If you do decide to try this for yourself, spend the time to do it right, as some of the guys we talked to were forced to redo their systems several times. Hilborn, Enderle, and Kinsler still deal with MFI, but not all of them offer new systems. Most rebuild originals, sometimes at a heavy cost.

Paul Soliz’s ’41 Willys truck runs a 283 small-block punched out to 301ci. It’s backed by a Turbo 350 with a 3,500-stall converter. He uses a -0 Hilborn pump and Hilborn MFI. He custom-built the surge tank using two Holley carb float bowls with alcohol-style needles to refill the tank faster. Paul sent his system to Don at Hilborn to have it rebuilt, checked, and then bench-flowed and tested. Don set up the intake separate from the car. Then Paul took it to San Dimas Auto (now closed) for dyno runs. The car started with a -0 pump, 114 main bypass pill, 0.014 main bypass spring, and a second bypass (mounted outside of the barrel valve) spring of 0.028 with a 0.187 shim. After a couple of dyno pulls, they determined it to be too rich and replaced the main bypass with a 118 pill, leaning out the system. It now runs great on the street with minimal effort.

Paul Soliz’s ’41 Willys truck runs a 283 small-block punched out to 301ci. It’s backed by a Turbo 350 with a 3,500-stall converter. He uses a -0 Hilborn pump and Hilborn MFI. He custom-built the surge tank using two Holley carb float bowls with alcohol-style needles to refill the tank faster. Paul sent his system to Don at Hilborn to have it rebuilt, checked, and then bench-flowed and tested. Don set up the intake separate from the car. Then Paul took it to San Dimas Auto (now closed) for dyno runs. The car started with a -0 pump, 114 main bypass pill, 0.014 main bypass spring, and a second bypass (mounted outside of the barrel valve) spring of 0.028 with a 0.187 shim. After a couple of dyno pulls, they determined it to be too rich and replaced the main bypass with a 118 pill, leaning out the system. It now runs great on the street with minimal effort.

Tim uses a pill selector, which several brands offer and appears to be the best thing for quick tuning from the driver’s seat. But not everyone believes it works as great as it appears. Originally designed for race cars to save fuel on caution laps, it does help for highway driving. But the weight of the fuel in the fuel line causes the pill to always run slightly richer. The pump is mounted as low as possible on the engine, so the fuel tank can feed fuel to the pump via gravity.

Tim uses a pill selector, which several brands offer and appears to be the best thing for quick tuning from the driver’s seat. But not everyone believes it works as great as it appears. Originally designed for race cars to save fuel on caution laps, it does help for highway driving. But the weight of the fuel in the fuel line causes the pill to always run slightly richer. The pump is mounted as low as possible on the engine, so the fuel tank can feed fuel to the pump via gravity.

Hilborn is adamant about not endorsing street driving. “It’s a pain in the butt, mainly because it’s designed for race applications,” says Hilborn’s Don Enriquez. “But there are customers that’ll do it no matter what.”

If you choose to buy a classic system, be sure to watch out for ones that are worn out. Dirt-track racing systems and those that ran on alcohol are often heavily deteriorated. Hilborn rebuilds systems with 0.015-inch oversized shafts for the butterflies, as the holes in the stacks become worn, and a 0.025-inch overbore for the stacks.

“The geometry of the linkages and barrel valves is often out of whack,” Don says.

When setting up the system for the first time, Augie uses a vacuum gauge like this one. A Uni-Sync tool is designed specifically for such a thing. There’s no exact tuning number, but every cylinder needs to be exactly the same.

When setting up the system for the first time, Augie uses a vacuum gauge like this one. A Uni-Sync tool is designed specifically for such a thing. There’s no exact tuning number, but every cylinder needs to be exactly the same.

These days, Don says, Hilborn strongly recommends using the latest electronic fuel injection that looks almost identical to the early style, but with modern injectors that make for trouble-free street driving. “It costs more to convert an old system than it does to just buy a new one.”

Robert Rey

Royal Pro/Motion

[email protected]