Chrysler cut new ground while echoing past success when the Gen III Hemi was introduced in 2003. Here we have a thoroughly modern engine design that takes advantage of the exceptional flow of the Hemi cylinder head layout. The engineers took the basic opposed-valve layout, and updated it with modern technology, including a shallower valve angle and filled-in chambers, bringing new tech to the famous Hemi configuration. No one can argue that Chrysler's modern Hemi works, offering serious power even in OEM form. With over a decade of production, these engines are a ready source of affordable Mopar power, with the more common 5.7L displacement being the most readily available. Stepping up the displacement with a stroker crank kit will take the torque production of the modern Hemi into big-block territory, while the inherent high flow will dish out the power.

Chuck Keech of KTC Engines in Springfield, Oregon, built a stroker combination that illustrates the point perfectly. Starting with a salvaged 5.7 engine core and retaining much of the OEM engine components, Chuck built a potent Gen III street powerplant by adding a stroker kit and an assortment of second-hand and new aftermarket goodies. As Chuck tells us, "I always liked the Gen I Hemi and I like the design of the new Hemi—the short pushrods, the high camshaft position, and the combustion chamber. I liked all that and I said OK, I'll build one of those. I actually bought an engine a few years before just to have a firsthand look at it, so I had it, and I liked the engine."

The Bottom End

The central feature of the bottom end modifications was replacing the stock internals in the short-block with a complete stroker kit from K1. This takes the OEM stroke of the 5.7 Hemi from 3.578 inches to 4.080 inches, and in the process increases the displacement from 345 ci to 397 with a .030-inch overbore. Chuck tells us, "I wanted a rod stroke ratio in the neighborhood of 1.5:1, and this combination is in the ballpark. K1 actually caters to the Hemi stuff, so I bought their kit. It has a 4.080-inch stroke, and is offered in either standard bore or for a .030-inch overbore. I didn't have to do anything to get the stroker parts to go in the block, no grinding at all. That was pretty good."

The bottom end was finished with a Mopar Performance camshaft with specifications of 229/236 degrees duration at .050, and .547-/.517-inch lift. Chuck continued, "It is the Drag Pack camshaft. I was afraid of using too much cam, and just thought this cam would be safe. The lobe separation angle was 110 degrees, and it was installed at 4 degrees advance."

…these engines are a ready source of affordable Mopar power, with the more common 5.7L displacement being the most readily available.

Chuck Keech began with nothing more exotic than a production 5.7L truck block. Taking the displacement up to 397 cubes is a stroker kit from K1, which includes a 4.080-inch stroke crank. Chuck tells us the entire rotating assembly was a drop-in, requiring no custom grinding or clearancing.

The kit from K1 features their beefy forged H-beam rods, as well as Wiseco forged pistons and nitrided steel rings. The ring pack features .043-inch compression rings, with a Napier-faced second ring, along with a 3mm oil ring assembly for low friction.

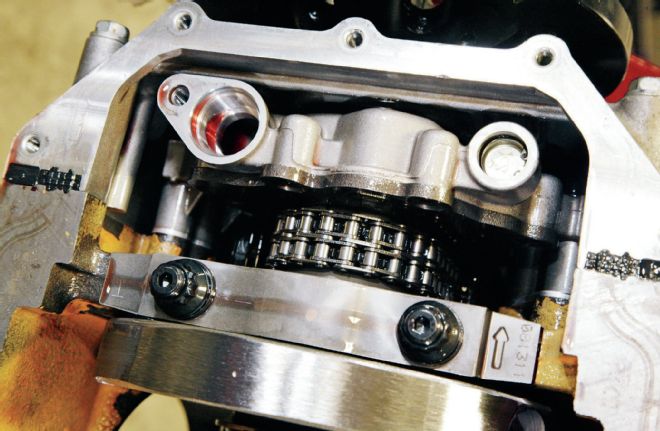

The Gen III Hemi uses an oil pump driven from the front of the crankshaft. Keech found there were no modifications to the stock oiling system necessary at this power and rpm level.

Sealing the bottom end are the excellent OEM windage tray and stock truck oil pan. In a retrofit application into a traditional Mopar muscle car, the pan will need to be swapped to a center sump design, along with the corresponding pick-up tube.

The main feature that makes the Gen III Hemi attractive from a performance standpoint is the Hemi cylinder head configuration. The shallow Hemi chamber and twin-plug arrangement gives this engine an edge in airflow and power. Chuck's modifications to the stock, early 5.7 heads were limited to minor port blending in the bowl area.

Chuck also applied some epoxy to the intake runner floors to reduce the runner cross-sectional area in an effort to increase port velocity. In retrospect, Chuck relates that this modification seemed to be unnecessary.

Much of the stock valvetrain was retained, including the OEM lifters, pushrods, and retainers. The springs and titanium rockers are COMP items, while the valves are OEM. The intake valves are lighter weight 6.1 units, cut down to 2.00 inches.

Heads & Induction

To top the stroker bottom end, Chuck used the commonly available early 5.7 production cylinder heads. As Chuck tells it, "I was collecting parts and had quite a few sets of early 5.7 heads. I did a little bit to them with the grinder, just cleaning them up under the valves and around the guide boss. I thought I would increase the velocity and did a little filling to the bottom of the intake port, but it seems to me that it might be better to run it bigger and keep it nice and smooth. These 5.7 heads have a really good port to start with and are not hard to come by. I found the valves used on eBay from a 6.1 and made the change. These valves are lighter with hollow stems, but I didn't go bigger, I just cut them down to 2.00-inch diameter."

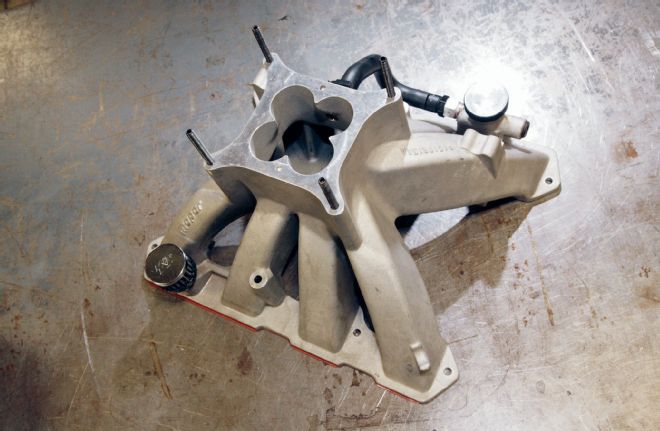

Auction site eBay was also the source for the hard-to-find Mopar Drag Pack intake manifold. As Chuck explained: "This is a very tall intake manifold. What caused me to buy it is that I found a package deal on it along with the MSD ignition controller on eBay. The intake is big, and goes down to a 6.1-sized port at the flange, so that is why the epoxy is in there—to bring the port down to the smaller 5.7 size. The MSD is great; they did a very good job with this product. It is simple, and I had no problem with it. I ran it with a total advance of 25 degrees, and that is where I left it. Since then other engines I have built have required just 21 degrees. These engines need very little timing."

Scouring the classifieds also yielded the unusual EFI system used on this engine. Chuck tells us the vintage Holley Pro-Jection throttle body system was in brand-new condition: "It is a 950-cfm throttle-body injection I found on eBay that was never used. It is an older system from the 1990s. I stuck it on there and set it at the maximum pressure that they recommended and I just ran it like that. I hardly had to fiddle with it, it ran good just like that."

"I didn't have to do anything to get the stroker parts to go in the block, no grinding at all. That was pretty good." —Chuck Keech on his selection of a K-1 assembly

A Mopar Performance "Drag Pack" cam works a set of factory stock rockers to deliver .547/.517-inch lift, with 229/236 degrees duration delivered at .050-inch tappet rise.

The Mopar Performance Drag Pack intake manifold is a very high-flowing, very high-rise, single four-barrel design. The top flange is configured in the common Holley 4150 four-barrel carb pattern.

The Mopar manifold is cast for the larger 6.1L port configuration, so Chuck employed epoxy filler to match the smaller 5.7 cylinder head's intake ports.

Up top we find an unusual fuel delivery system featuring an older eBay-sourced Holley Pro-Jection throttle body fuel injector. This early throttle body system works very much like an electronic carburetor.

The vintage Pro-Jection EFI controller is totally self-contained, with all of the calibration controls incorporated into the control box. Simple adjustments to the dial at the front of the unit allow limited tuning.

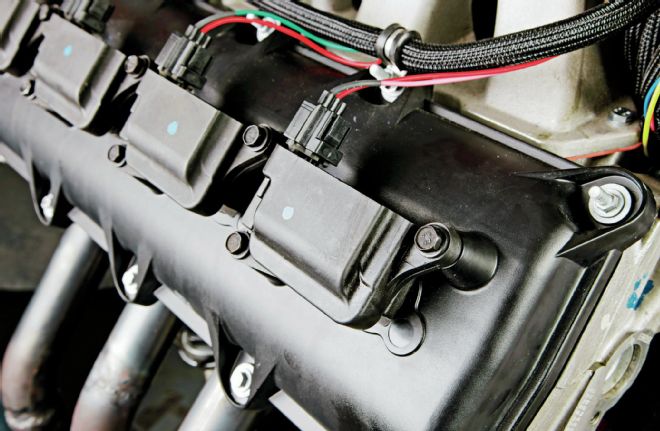

More contemporary electronics are used to control the ignition requirements of the Hemi, in the form of an MSD Timing/RPM Controller. Chuck tells us the MSD unit was simple to install and tune.

The MSD controller works with the stock sensors and coil packs, firing the twin plugs simultaneously. The OEM coil pack ignition has plenty of output for a moderate naturally aspirated engine combination.

With the drive belt system driven directly off the crankshaft damper, an upgrade here is always a good idea. Chuck employed an SFI-certified damper from Professional Products.

Handling the exhaust for dyno duty was a dyno header custom built by Chuck. The header arrangement is a conventional four-into-one design, with stepped 13/4 to 17/8-inch primary tubes.

Dyno Time

Chuck's Hemi combination was not built with the latest and greatest of parts, but just an effective build that resulted from upping the displacement with K1's stroker kit and upgrading the stock Hemi using parts found on a budget. This is the kind of engine an enthusiast can build very affordably, depending upon what kinds of parts can be found in the secondhand market. With the ample increase in displacement fed by the Hemi's high-flowing heads, good power was a sure bet.

Put to the test against the dyno, the output was more than you might expect. Torque, right from the hit at 2,500 rpm was substantial, with more than 440 lb-ft on tap. That would be respectable as a peak torque number for a hot street 360 small-block. From there the torque climbed to record a peak of 516 lb-ft at 4,900 rpm. The strong bottom end torque number combined with the high peak torque rpm is a very good example of the broad power curve that makes a good street combination. In fact, the peak torque number is in the range you might expect from a mild street 440 big-block. On the horsepower side of the calculation, Chuck's Hemi offered up 529 hp at 5,900 rpm. Again, we had output that would not be out of place from a moderately built 440 big-block street engine, and would take a serious street small-block to match. With the Gen III Hemi, the power just seems to be built-in and ready for the taking.

This is the kind of engine an enthusiast can build very affordably, depending upon what kinds of parts can be found in the secondhand market.

With power output recorded at 529 peak horsepower at just 5,900 rpm, and a massive 516 lb-ft of torque coming in at 4,900 rpm, Chuck Keech shows just how easily a street combination can be built from Chrysler's early 5.7L Gen III Hemi.

Fast Facts: 397CI Gen III Hemi Engine

Bore: 3.935 inches Stroke: 4.08 inches Compression ratio: 11.4:1 EFI: Holley Pro-Jection 4 Throttle body: Holley Intake: Mopar Performance P515184 Carb spacer: Mopar Performance Cylinder heads: Chrysler Intake valve: 2.00 inches Exhaust valve: 1.55 inches Block: Chrysler Camshaft: Mopar Performance P5153691 Lift: .547/.517 inch Duration at .050: 229/236 degrees Rocker arms: Chrysler, 1.6 ratio Pushrods: Chrysler Crankshaft: K1 Technologies Rods: K1 Technologies, 6.125 inches Pistons: Wiseco Rings: Wiseco; .043 inch Ignition: MSD Water pump: ProForm Damper: Professional Products Oil: AMSOIL 5w20 Headers: KTC 1¾-inch stepped Mufflers: MagnaFlow Fuel: VP100

On The Dyno: 397CI Gen III Hemi

RPM: TQ: HP: 2,500 442 210 2,600 448 222 2,700 449 231 2,800 443 236 2,900 434 240 3,000 425 243 3,100 414 244 3,200 407 248 3,300 395 248 3,400 393 255 3,500 398 265 3,600 415 284 3,700 439 310 3,800 458 332 3,900 472 350 4,000 483 368 4,100 491 383 4,200 495 396 4,300 498 408 4,400 501 420 4,500 503 431 4,600 507 444 4,700 510 456 4,800 514 470 4,900 516 481 5,000 515 490 5,100 512 497 5,200 510 505 5,300 505 510 5,400 501 515 5,500 496 520 5,600 492 525 5,700 485 526 5,800 477 527 5,900 471 529 6,000 462 528 6,100 453 527 6,200 444 524 6,300 437 524 6,400 429 523 6,500 419 519