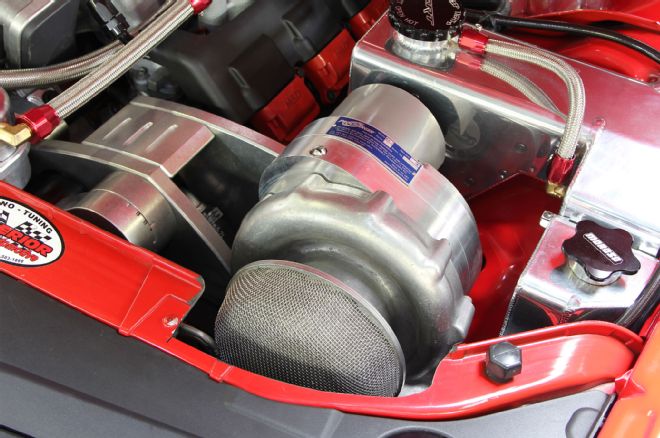

It's a new world and a new generation. Thanks to the new generation Chrysler Hemi, that word is still spoken with reverence in Mopar circles. But Adrian Saavedra decided that even with 6.1L of new Hemi, his engine it needed to be supercharged - but not with a traditional 6-71 Roots blower. That's the old school way. Today's approach means adding a stroker crank that bumps the 6.1L (371ci) motor up to 417ci and a ProCharger centrifugal supercharger that snuggles down under the stock hood of Adrian's '09 Challenger. Combine it with a bazillion electrons making decisions about everything except where to have for lunch and all that power can be harnessed for a daily-driven car that is actually fun to drive – even to work!

Adrian took his blower/stroker idea to Superior Automotive where owner Joe Jill has been perfecting these late model Mopars to both make big power and survive the daily grind of the boulevard gran prix. Superior started with the stock 6.1L block and added a Callies stroker crank, rods, and dished Ross street pistons that all work together with a mild hydraulic roller from Comp Cams. While all the big, romantic parts like a ProCharger F1A centrifugal supercharger and a crank with a long arm make all the power, often it's those littlest details that make the difference betweendetermine if an engine that lives a long, healthy and powerful life, anord one that ends up scattering its guts all over Lincoln Avenue at the top of Second gear. Superior was enthusiastic about showing us how they've developed a couple of simple cures for hemi valvetrain snafus. We'll cover all these goodies along with a few other little tech bits that make the difference between a hacked Hhemi and a professionally-built street engine. Your mother probably warned you that bad girls are fast and easy because they never last. Well, in this case, this fast girl is there for the long run. All you have to do is pay attention to her needs.

The late model Chrysler hemi engines are not difficult to build, but Superior Automotive owner, Joe Jill (left), has learned some interesting tricks that will keep your 5.7 and 6.1L Hhemi alive and thriving. That's engine builder Jorge Jabaz (right) who will accompany us on this hemispherical journey.

Here are the major actors in our Hhemi stroker build. Superior spec'd a Callies 4.00-inch steel crank, and a set of Compstar H-beam 6.125-inch connecting rods, and dished pistons from Ross. to connect to the Ross dished pistons. To complete the power parts there's a Superior-spec Comp hydraulic roller cam designed to make the blower very happy. The tops of the pistons have been coated from by Performance Technology to deflect heat away from the pistons since the oil squirters had to be removed from the block to clear the longer stroke.

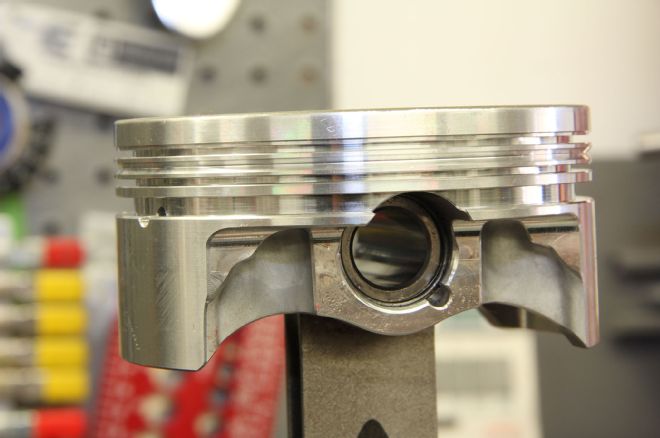

Especially for supercharged engines, Iit's important to check wrist pin clearance to the rods, especially for supercharged engines,. Even with bushed small ends, don't assume the clearance is correct. A good spec is 0.0008 to 0.0010–inch. The Ross dished pistons are forged from a 4032 forged aluminum alloy that uses a greater percentage of silicon that works well for street engines. Note that the top ring is down 0.250 from the top of the piston. This is for supercharged applications.

There are plenty of things happening in this photo. Jorge has already installed the wrist pin clips. Note that the combination of a 4.00 inch stroke and 6.125 inch rod pushes the pin up into oil ring groove. This necessitates a support ring to ensure the oil ring is stable when crossing over the wrist pin hole.

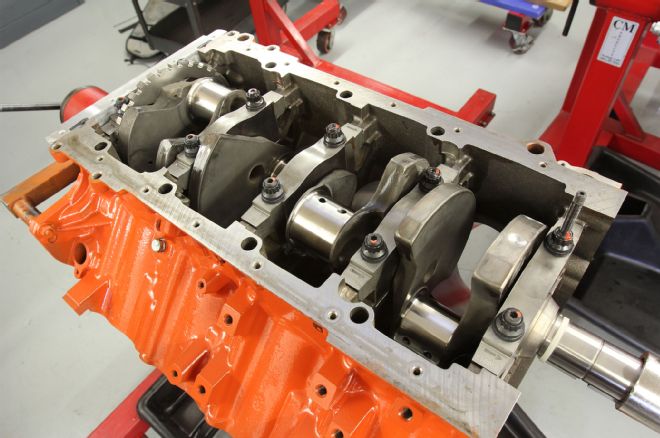

This is the Callies crank with its 58 tooth reluctor wheel that triggers the crank position sensor. Older 5.7L engines use a 32-tooth wheel. Note the 6-bolt crank flange.

After completing machine work that pumped the bores out to 4.070, Jorge dropped the crank in along with the new ARP main cap studs. Note how Superior indicates that all fasteners are torqued with a small dab of orange paint.

The Callies Compstar H-beam rods come with ARP 2000 cap screws and are torqued to their proper stretched length. The big end rides on Clevite 77 tri-metal performance bearings and assembled with Torco assembly lube.

Jorge set the end gaps for both the top and second Total Seal rings before installing them on the pistons. The 1.5mm top ring is a stainless steel top with a 1.5mm Napier second ring.

Joe positions the crank so Jorge could slide each piston in place with the help of an ARP 4.070-inch tapered ring compressor. Note the pistons employ a substantial dish. This keeps the compression down to 8.7:1 in deference to the supercharger and 91 octane pump gas.

Superior's experience with late mode Hhemis has proven that the stock wire retainer clips used in the non-variable valve timing lifters often fail at higher engine speeds. Superior always replaces them with far more robust pieces as shown. The stock clip is on the left with the Superior piece on the right.

This is the layout of the valvetrain parts including the Comp hydraulic roller cam, stock lifters, Manley adjustable steel cam gear, and a stock replacement oil pump.

Gen3 Hemi Displacements

Cam Specs

Hemi Clearances

Torque Specs

All specs using ARP Ultra Lube

6.1L Hemi Head Flow Chart

All tests performed on a SuperFlow 600 flow bench at 28 inches of test depression

Parts List

Before finalizing the cam installation, Jorge also checks its position by degreeing the cam, using a large diameter, professional degree wheel from Comp. The machined, larger diameter wheel offersThis type of degree wheel is much more accuratecy than smaller diameter versions.

Here, the cam is finalized with its intake centerline installed position of 113.5 degrees intake centerlineafter top dead center. This is within a half-degree of Comp's spec on the cam card. Again note how Superior shows that all the fasteners are torqued with an orange paint dot.

All late model engines drive the oil pump off the crank snout. This is accomplished with help from a mandrel that fits over the crank snout to drive the pump. The pump body uses slotted mounted mounting bolts to center the pump over the mandrel. There is a factory procedure, but the easiest way is to slip the pump over the mandrel, lightly tighten the bolts and then turn the engine six or eight revolutions. This will center the pump and allow you to torque the bolts.

The Manley dual row cam timing gear is slightly deeper than the factory single row chain and gear so the aluminum cover must be lightly machined to provide the necessary clearance.

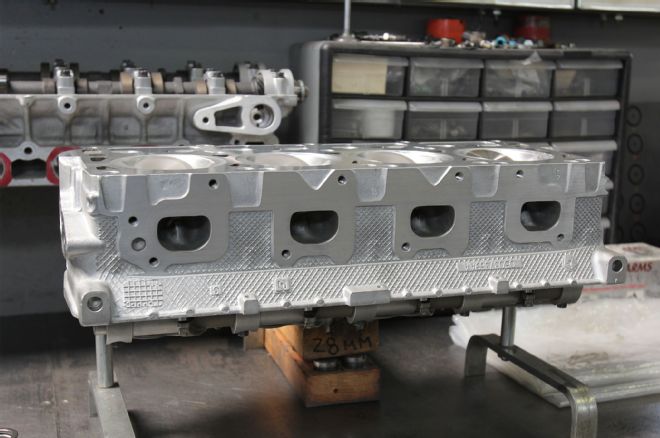

The stock 6.1L heads offer a much larger intake port than the previous 5.7L engines, but Superior still added its own porting work to enhance the flow even more. Superior's port work was worth over more than 50 cfm on the intake side at a couple of different lift points.

The exhaust port is also changed from the 5.7L engines with a wider, almost D-port shape. Superior improved its flow as well.

Superior added a set of Manley stainless 2.08- intake and 1.650 inch.650-inch exhaust valves along with some basic chamber work to optimize combustion by blending any sharp edges and smoothing the surface finish.

The main reason for adding the Manley valves was to move the retainer lock groove slightly lower. This is done to clear the required larger diameter, titanium retainer. If the retainer is not repositioned lower, it will hit the underside of the factory shaft-mount rocker arms. Joe told us they are very close to releasing a new beehive spring that will eliminate the need for a custom valve, which will reduce the cost of this conversion.

With the heads assembled, Jorge used a checking spring to measure piston-to valve clearance and also took the time to set the proper pushrod length to ensure the valvetrain is stable at higher engine speeds.

With the engine assembled using the stock 6.1L intake manifold, Superior used 65 lb/hr SRT injectors to deliver sufficient fuel to feed close to 900 hp.

That's a ProCharger F1A supercharger snuggled into the Challenger's engine compartment. Note that this required some radiator core support modifications to clear the inlet. At 708 rear wheel horsepower, that's some serious power.

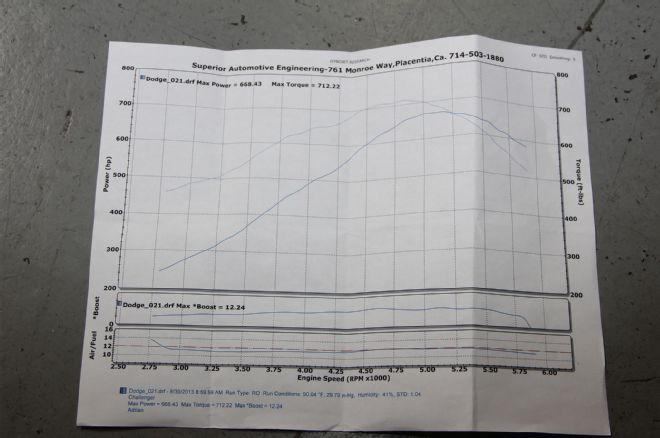

We converted the rear wheel horsepower chassis dyno numbers into this graph. At 4,000 rpm, the rear wheels are seeing almost 630 lb-ft of tire-spinning torque, and yet this beast is all done by 5,000 rpm which means if you don't have to spin this engine real hard, it will live a very long time.