Trevor Flus Asks…

Q:

I purchased a set of what I believed to be Pro Comp PN 3021 rectangular intake-port heads for my 454, but after cc’ing them my machine shop said that although the intake runner volumes were close at 324 cc, the chamber volumes are a huge 134 cc! I was shocked because they were advertised at 115 cc. The heads are new and in great condition otherwise, so I was planning to remove and replace the pistons to make up for chamber volume, as this is a budget build.

The machine shop recommended a 0.060-inch overbore to put in a set of Keith Black KB245-060 pistons to get me 10.5:1 compression, assuming a 0.020-inch “down” piston block deck height and a 0.020-inch compressed head-gasket thickness. Is this a good direction to go in pistons?

With this combo, what would you recommend in a camshaft: lift, duration, and LSA? My intention is to put this in my ’87 Grand National and drive it to cruise nights and bracket race it occasionally. I would like to run pump gas but want it to be an 11-second car without spray.

In case you need to know the rest of my combo, I have a Holley Strip Dominator single-plane intake manifold, a Holley 870-cfm Street Avenger vacuum-secondary carburetor, a TH350 trans with a 2,200-rpm converter stall-speed, and 3.42:1 posi rearend.

I’m retired and trying hard to build on a budget, so I can’t afford to make mistakes!

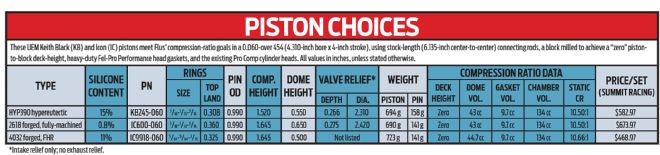

Forged shelf-piston prices are now competitive with hypereutectics. UEM offers both hypereutectic KB pistons and two different forged Icon pistons that meet Flus’ compression-ratio goal with a quench-happy, zero-decked block and premium Fel-Pro head gaskets. From left: KB245 hypereutectic ($582.97/set at Summit Racing); dimensionally similar Icon premium 2618-alloy, fully-machined, IC600 forged piston ($673.97); and budget, 4032-alloy, Icon IC9918 FHR forging ($468.97).

Forged shelf-piston prices are now competitive with hypereutectics. UEM offers both hypereutectic KB pistons and two different forged Icon pistons that meet Flus’ compression-ratio goal with a quench-happy, zero-decked block and premium Fel-Pro head gaskets. From left: KB245 hypereutectic ($582.97/set at Summit Racing); dimensionally similar Icon premium 2618-alloy, fully-machined, IC600 forged piston ($673.97); and budget, 4032-alloy, Icon IC9918 FHR forging ($468.97).

A:

Frankly, if you really want to break into the 11s with a relatively heavy, dual-purpose car with an average chassis, this combination is poorly matched. I also have issues with your piston selection.

Aluminum-headed motors need premium composition-style head gaskets to seal reliably. The only 0.020-inch compressed-thickness head gaskets I’m aware of are old-school steel-shim designs that—although OK for mild iron-headed, factory-style engines—aren’t recommended for sealing aluminum heads. You could get the block and heads O-ringed and use a racing-style copper-shim gasket, but that clearly doesn’t fit the budget concept. The smallest-volume Fel-Pro performance-series Mark IV big-block Chevy composition head gasket is PN 1027. It has a 4.370-inch gasket bore and 0.039-inch compressed thickness, which yields a published 9.7cc gasket volume. With your 0.020-inch piston deck height and 134cc chambers, this puts compression in at 10.07:1. Achieving a true 10.5:1 requires zero-decking the block (not a big deal if everything’s apart anyway). You could also make up some of the difference by milling the heads to reduce chamber volume. In any event, with the thick-composition head gasket and 0.020 deck, quench would be marginal; that could actually increase detonation tendencies, particularly with big, lazy combustion chambers.

As for the KB pistons, such hypereutectic, HYP390-alloy pistons were a popular choice in the past on budget performance builds because they delivered reasonable durability and were more affordable than most forged pistons. Hypereutectic performance pistons contain around 17 percent silicon for improved thermal properties, meaning less heat transfer and less expansion under changing temperature conditions. But they also have lower ductility—think of it like the ability to “roll with the punches.” On the plus side, this yields a more stable piston, minimizing piston-slap under cold-start conditions, while providing good piston-to-cylinder-wall sealing. The downside to a hypereutectic is that if the piston does fail, it can fail catastrophically, shattering and taking the rest of the engine with it.

Forged pistons contain less silicon. As silicon content decreases, ductility increases, making forged pistons more forgiving under detonation and more durable with power-adders (a forging’s superior grain structure helps in this regard as well). Forged pistons may not have as high a theoretical temperature rating as hypereutectics, but at the limit, a forging tends to plasticize instead of shatter outright. In other words, when a forged piston does fail, it tends to fail “soft”: Good-bye piston, but it doesn’t usually take out the entire engine along with it.

KB Piston’s sister Icon division offers two types of forged pistons. Its premium, high-tech, fully-machined Icon pistons are forged from 2618 aluminum alloy and are for serious hard-core applications; they contain only about 0.8 percent silicon. For some applications, there are also Icon’s budget Formed Head Relief (FHR) forged pistons, that have as-forged (rather than fully-machined) domes; they’re made from 4032 aluminum alloy that contains 11 percent silicone. According to Icon, they fall midway on the ductility curve—in-between the hypereutectic KB line and the high-end fully-machined Icon forgings—making them suitable for a wide variety of applications. The downside is the FHR pistons are heavy and usually use old-school, thick, flutter-prone 5⁄64-5⁄64-3⁄16 ring packs in place of the modern, lightweight 1⁄16-1⁄16-3⁄16 packs found in many of the KB hypereutectic and Icon 2618 forgings.

So which should you choose? Most present-day OE engines run hypereutectic pistons—but they’re all electronically managed: The computer sniffs out detonation and corrects the timing and fuel to allow running hypereutectics with confidence under nearly all conditions. But with old-school engines, the hot rodder is the computer. As the motor goes up in static compression, boost, or horsepower, the tune-up becomes more critical. Realistically, you have to consider: What is your ability to manage the motor?

A solid-lifter cam with 0.050 duration in the 240s like this Comp Cams’ XS282S is recommended to get Flus’ big-block GM G-body into the 11s, but the big cam in turn mandates drivetrain upgrades to place the combo within the cam’s powerband—upgrades that will make the car less street-friendly. Flus must decide just how much streetability he’s willing to sacrifice.

A solid-lifter cam with 0.050 duration in the 240s like this Comp Cams’ XS282S is recommended to get Flus’ big-block GM G-body into the 11s, but the big cam in turn mandates drivetrain upgrades to place the combo within the cam’s powerband—upgrades that will make the car less street-friendly. Flus must decide just how much streetability he’s willing to sacrifice.

Finally, on a budget motor there’s always the cost issue. As is the case nowadays when deciding whether to qualify, blueprint, and rebuild factory connecting rods versus stepping up and just replacing them with now-affordable premium aftermarket rods, in recent years the piston material price gap has narrowed significantly—if not evaporated. Off-the-shelf forged piston prices have declined to the point that even budget performance engine builds can now include them in the short-block at only a slight price penalty, if that. For example, KB Pistons’ sister Icon piston line offers otherwise identical forged 2618-alloy versions of many of KB’s traditional hypereutectic configurations. Icon’s PN IC600-060, the high-end 2618-alloy forged analogue to the KB245-060 hypereutectic casting, is only $91/set more expensive than the KB hypereutectic ($673.97/set for the Icon versus $582.97/set for the KB at Summit Racing). In other words, for less than $100 more, you get a much more robust product with the same 43cc piston dome volume, plus a lighter piston pin.

The ultra-budget move would be the 4032-alloy FHR line. At $468.97/set, Icon FHR PN IC9918-060 is actually $114 cheaper than the KB245-060 hypereutectic. IC9918 has slightly more dome volume (44.7 versus 43 cc for the other two pistons), which (all other parameters remaining the same) would raise compression an additional 0.16 ratio (to 10.66:1 on the zero-deck block example). On the other hand (there’s always another hand), they’re heavier, plus the thicker rings add yet more weight (however, old-school thick rings may be cheaper/set).

Personally, I’d spend the extra $91 and go with the premium piston, but that’s just me. Life is full of trade-offs.

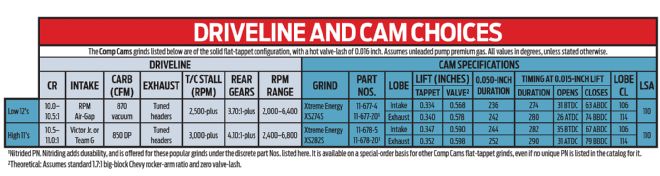

Since this is a budget build, the cam will likely be some sort of flat-tappet grind. An equivalent 0.050-duration roller grind could be worth 15–20 hp and is happier on today’s commonly available motor oils, but it costs about $800–$1,000 more to upgrade a nonroller-cam-equipped motor. Remember that proper cam break-in and oil containing ZDDP (zinc) additive is critical for keeping flat-tappet cams alive. Consider Comp’s extra nitriding option as well, although it will add about $130–$150 to the cam’s cost. Comp Cams and specialty aftermarket oil manufacturers such as Lucas also offer oil additives, break-in oil, and even oil for everyday use that include high amounts of ZDDP and other extreme-pressure additives.

To ensure breaking into the 11’s, camshaft 0.050-inch tappet-lift duration needs to be into the 240s, which means (especially with those big heads), at the drags you’ll be shifting over 7,000 rpm to produce the necessary power without power-adders. Call me old school if you want, but big-block Chevy valvetrains (at least on budget builds) are heavy and really need mechanical lifters to rpm upstairs. So, yes, we are looking at a solid flat-tappet grind such as Comp Cam’s Xtreme Energy XS282S (specs, see “Driveline and Cam Choices” table).

But now the domino effect comes into play: You need more torque converter stall plus steeper rear-gears to support the cam’s 2,400–6,800-rpm operating range. I’d like to see no less than a 3,000-rpm stall speed and 3.70:1-or-steeper gears; better—if you can live with them on cruise night—would be a 3,500-stall unit (for example, the 10-inch Street Fighter in TCI’s converter lineup) and 4.10:1 (or steeper) gears.

If you were willing to settle for a mid- to low-12-second car, the existing driveline is more suitable. Back down the cam one step to Comp’s Xtreme Energy XS274S, and you can skate by with the existing 2,200-rpm stall converter and 3.42:1 rear gears—although an 11-inch TCI Breakaway converter (2,400–2,600-rpm stall speed in a typical big-block) plus 3.70:1 gears would be better.

With its 4,500–8,500-rpm powerband, the full-race single-plane Holley Strip Dominator intake for rectangular-port heads (PN 300-5) may be a tad too big for either combo. With the XS282S cam, consider Edelbrock’s single-plane Victor Jr. 454-R (PN 2902, 3,500–7,500-rpm operating range) or the Weiand second-generation single-plane Team G for rectangular-port heads (PN 7622, 3,500–8,000-rpm operating range). For more streetability if using the milder XS274S, lean toward the Edelbrock Air-Gap dual-plane (PN 7562) or Weiand Stealth dual-plane (PN 8018). Try a 1-inch open spacer (hood clearance permitting) to get a little more top end out of the dual-planes. The 870-cfm vacuum-secondary carb is OK, but if you’re serious and willing to tune, an 850-cfm double-pumper will perform better at the strip.

Don’t forget to check piston-to-valve (PV), retainer-to-valve guide, and retainer-to-seal clearances with either of these high-lift cams. High-dome pistons and zero-decked blocks can be particularly finicky when it comes to PV clearances.

One more thought: If the existing short-block is in good shape and the engine doesn’t need to be otherwise rebuilt except to install the high-dome pistons to crutch your apparently incorrectly machined set of cylinder heads, have you considered leaving the short-block alone, selling the heads, and getting some mainstream aftermarket heads with the right chamber size for your application? You may save money in the long run if rebuilding is not otherwise necessary.

GM A-Body Interchange

Q.

I recently bought a ’74 Chevy Chevelle Laguna S-3 with a 454, TH400, and front disc brakes. GM ’73–’77 A-bodies were from a forgotten era, an enigma. No one loved them in their time, and few seem to value them today. Forget about finding enough parts, too. There simply weren’t enough of these cars made, because they weren’t very popular for a number of reasons.

My biggest concern is their dumb weight, front and rear. The 5-mph bumpers add plenty of weight. Will a ’72-or-earlier Chevelle or other GM car’s front-end or rear-end with their lighter parts fit my car? It will save me a lot of weight! It seems the frame of the ’72 and ’74 are similar. I would really like to rid my project of its dead weight.

John Ransom - Huntington Beach, CA

A.

No joy, John. Hate to say it, but the lost decade from ’72–’83 was pretty much the “Nader” (pun intended) of automotive performance. Still, although the Laguna S-3 variant is relatively limited, overall production numbers for third-gen A-bodies are competitive in terms of yearly totals for the previous generation. But as to your question specifically, the third-generation A-bodies were completely redesigned and share little in common with the previous generation except for the wheelbases. The frames are totally different, the body mounts are redesigned, the upper rear control arms are shorter, and the front steering and suspension is totally new, the same as a ’70–’81 F-body (Camaro/Firebird) and ’75–’79 X-body (Nova and clones). The bodies are 5 inches longer and 1 inch wider. Wheel track width is wider, too. About the only major parts that interchange more or less directly would be the rear brake drums, front steering boxes (although the stops may be wrong, depending on tire size), and (depending on vehicle weights and ride heights) some of the front and rear springs. Brake calipers are close but not an exact fit—and earlier is rarer because front discs were only an option, not standard as they are on the third-gens. Objectively, the stock third-gen front suspension is arguably much improved with better front camber geometry compared to previous generation A-bodies. The third-gen’s improved perimeter frames are beefier; that makes them heavier, but also more rigid than earlier A-bodies—which most feel is a plus as far as weight transfer for drag racing or stability in a handling application.

The best way to reduce weight is to replace every body part you can with fiberglass or other lightweight materials. Every 100 pounds of weight shaved off a car is conservatively worth about 10 hp. A fiberglass hood alone can save 20–50 pounds over a steel hood. Hundreds more pounds can be saved by replacing everything you can with fiberglass. Showcars Bodyparts Unlimited has most ’glass parts for your Chevelle Laguna and just about any other car out there. If it doesn’t currently have a part you want but you have an original steel part in good shape you’re willing to send them, in many cases Showcars can pull a mold off it and fabricate a ’glass duplicate.

You can also gut the mechanism “behind” the 5-mph bumpers and just replace the parts with simple fabricated brackets. Complete fiberglass-replacement doors won’t have the heavy steel guard beams, either.