The controversy between carburetors and EFI has always been about complexity and price. Carburetors are simple—EFI is not. Carburetors are cheap—or at least cheaper than EFI. Those points have not really changed, but the lines are blurring slightly over the complexity issue. It used to be that you had to be a knowledgeable tuner capable of building a fuel and spark map to make a fuel-injected engine run. That part of the EFI game is no longer of concern. The new wave of self-learning EFI systems has made tuning really a non-issue, making aftermarket EFI much less complex.

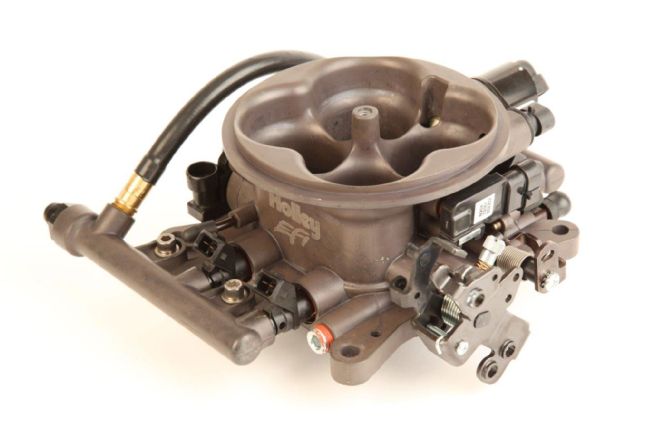

Let's take Holley's Terminator throttle body system as an example. This is a relatively simple EFI system where you remove the carburetor and replace it with a throttle body. It flows 950 cfm and integrates four 80 lb/hr injectors that are capable of delivering enough fuel to feed up to 600 hp. The most difficult part of this installation isn't really the throttle body or even the electronics. The most challenging part is also the one that is most often overlooked—the fuel delivery system. All EFI systems demand a high-pressure (typically 45 to 58 psi) fuel system. This means the system must supply constant pressure, requiring a reservoir inside the tank where fuel always surrounds the fuel pump. The most common system employs an in-tank pump, which is also how the OEs do it. This keeps the pump cool with a constant supply of fuel. We call this out because many problems that rodders experience with EFI can be traced to fuel delivery issues, so it's important that a well-designed fuel system be an integral part of your EFI plan—rather than an afterthought. When it comes to street-driven EFI systems—engines run much better and with far less drama if the fuel delivery system is not an afterthought.

The self-learning part of the Terminator EFI system is based on feedback from a wide-band oxygen sensor located in the exhaust system. The sensor reads the free oxygen in the exhaust and calculates the air/fuel ratio from these readings, which gives direction to the computer to calculate changes to the amount of fuel delivered by the injectors. All this happens very quickly with the result that after you have answered some simple engine data questions, the computer does the rest. We've tested this Holley Terminator on a 590 hp 496ci Rat motor and we were impressed with how well it performed.

Among the inputs the system requires from you are engine displacement, fuel pressure, and the air/fuel (A/F) ratios you desire for idle, cruise, and wide-open throttle (WOT). We input 496ci for displacement, 43 psi for fuel pressure, and 13.8:1 for idle, 14:1 for cruise, and 12.8:1 A/F for WOT. We then calibrated the TPS—which is so easy your 10-year-old granddaughter can do it. With that, the engine fired immediately and ran great. Within a few minutes, the system had learned enough that we were out spinning the tires on our first testdrive. Sometimes these self-learning systems can have difficulty with cold start by delivering an overly rich A/F during warm-up. This didn't happen on our test of the Terminator, but we would need to test the Terminator on several different engines of varying displacements and cold start temperatures to speak with complete certainty.

One distinct advantage offered by the Holley system is that it is easily upgradable. This means that if you at some point in the future want to make some changes, Holley offers easy add-on options that do not require purchasing a new computer. For example, it's really easy to integrate electronic spark control. For our big-block, all we would need would be an additional harness, a free software upgrade, and a simple small-cap HEI distributor. If that sounds easy, you're catching on. If at some point you would want to change to a multi-point fuel-injection system with eight separate injectors, that's merely a matter of upgrading this same ECU to HP status with a simple software swap. If you begin to see the possibilities with this system that perhaps some of the other basic TBI systems don't offer, then you now know why we wanted to try the Terminator. In today's world, having more options is a good thing.

This is the Terminator kit (PN 550-406, $2,049.95, Summit Racing) that does not include a fuel pump but does use the upgraded Hard Core Gray finish throttle body. We've also included the optional color display in the upper righthand corner.

The Terminator throttle body integrates most of the necessary sensors as well as the injectors in an easy-to-install package. The wiring harness uses dedicated connectors so you would have to work really hard to hook it up incorrectly. Connect the sensors, the linkage, and the fuel line and that's about as easy as it gets.

Each throttle body contains most of the system sensors, including the manifold absolute pressure (MAP) sensor (1), inlet air temperature (IAT) sensor (2), idle air control (IAC) motor (3), the injectors (4), and the throttle position sensor (TPS) (5). It might take you 30 seconds to make all these connections

Here is our Terminator system bolted in place on a 496ci big-block Chevy we used for our test. We relied on a Rick's Tank's fuel tank with an integrated in-tank fuel pump and a complete return system with filters. The system operated flawlessly.

The most important installation step is to always connect the main power and ground leads directly to the battery. Do not hook the Terminator main power lead to a common power lead in the wiring. Hooking directly to the battery uses the battery as a capacitor to minimize electrical noise causing driveability problems.

The Holley Terminator uses the exact same throttle body that is also used on all NASCAR engines. Holley employs an interesting annulus around each venturi that improves idle quality and off-idle throttle response.

The basic Terminator kit comes with this small handheld, which is all you need for input into the system to make it work.

If you are into electronic displays, you might consider upgrading to Holley's larger color display screen that is configurable for a cool instrument display screen like this one. We designed ours with (clockwise from upper left) a tach, air/fuel ratio, inlet air temperature, coolant temperature, fuel pressure, and voltage. This display would look cool as a flip-down screen from underneath the dash.

The Terminator throttle body flows 950 cfm and with its four, 80 lb/hr injectors, it has the potential to deliver 640 hp at 43 psi fuel pressure with a 0.50 brake specific fuel consumption efficiency (BSFC). Well-built engines can lower that BSFC number to 0.45, which pushes the potential peak horsepower closer to 700 hp.

Holley offers several options for fuel pumps that can be run in-tank if necessary. Keep in mind that the key to a good install is an in-tank sump that will keep the pump submerged in fuel at all times.

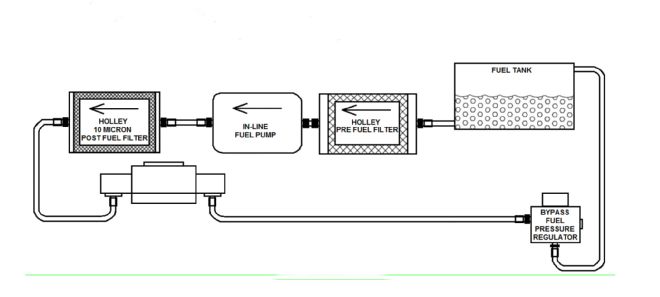

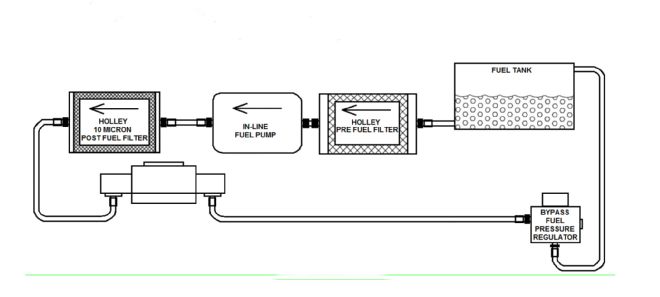

This is Holley's illustration for the fuel delivery system mainly showing filters before and after the pump. This shows the pump outside the tank. If you use a system like this with a carbureted pickup in the tank, the engine will sag whenever the fuel uncovers the pickup. This occurs most often when the fuel level drops below half full.

The kit comes with an oxygen sensor and a weld-in bung. Locate the oxygen sensor as close to the engine as possible within the collector and above the exhaust centerline so that any moisture that might collect in the pipe will not contact the sensor.