Good ideas have a habit of not always working exactly as they should. We assembled a 0.040-over 350 small-block Chevy in the Jan. '14 issue that we called the Quick Draw .357. It was intended to showcase all the budget engine parts we had tested in the previous year. The parts bolted together easily enough, but the results were less than impressive. Our cam, head, and intake package ran into valve-control problems that limited the peak horsepower to a mediocre 403 hp at 5,400 rpm. We determined that the Lunati cam uses a rather aggressive lobe design that requires a little more valvespring than the Jegs heads were equipped to deliver.

It appeared this package of camshaft, heads, and intake was capable of much more than 400 hp. So we ordered new valvesprings and, in case you haven't already jumped ahead, we were rewarded with a solid 25hp increase to 430 hp. At this point, we decided that this induction package promised greater potential—all the engine needed was a little more lift and duration. So we added a Lunati hydraulic roller camshaft, lifters, stronger dual springs, and reused the Lunati roller rocker arms from the flat-tappet test. This also worked extremely well, pushing the peak horsepower up to 483 hp. And all this was still with a dual-plane Edelbrock intake and a 750-cfm Holley carburetor. The details are what make this story, so let's get started.

Spring Time for Horsepower

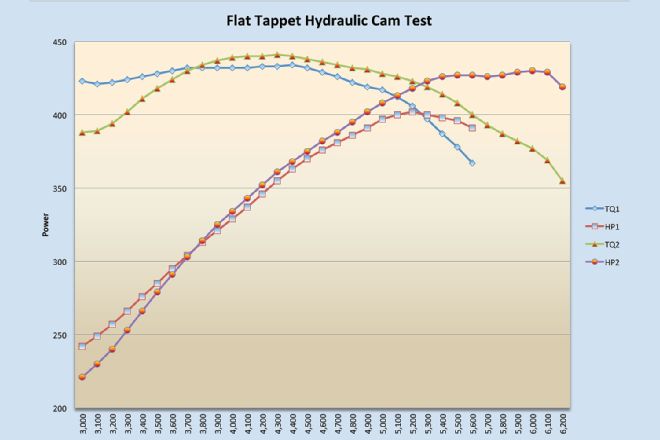

As you can see from the accompanying graph (page 28), just a simple change to new valvesprings made a big difference in power. Note how in the original test, the horsepower peaked at barely 5,200 rpm and then plummeted when the springs could no longer control the valves. With duration numbers of 231/241 degrees at 0.050, we knew we had sufficient cam timing to support the peak horsepower at something close to 6,000 rpm. So we added a set of Lunati conical valvesprings to the Jegs 195cc heads. We've included a spec box of the valvespring seat and open loads. The stock springs that came with the Jegs heads are not weak springs, but it appears that the Lunati cam uses an aggressive lobe design that requires more spring pressure on the seat. It might seem that adding pressure at peak valve lift would be beneficial, but the onset of valve float actually occurs at the point when the valve hits the seat on the closing side. Generally, the valve will bounce at higher engine speeds if there is insufficient seat pressure. So in our case, we raised the seat pressure from 100 to 140 pounds (a 40 percent increase) and the engine responded to this simple swap.

Lunati makes this conical valvespring that bolted right on the existing Jegs heads. The spring-pressure difference is an interesting issue. If you look at our accompanying spring chart, you’ll notice that the stock springs in the Jegs heads offer virtually the same open-load pressure but lower seat pressure. The typical onset of valve “float” is actually where the spring bounces off the seat at closing. This is where the conical spring offers 40 percent more load to keep the valve on the seat.

Lunati makes this conical valvespring that bolted right on the existing Jegs heads. The spring-pressure difference is an interesting issue. If you look at our accompanying spring chart, you’ll notice that the stock springs in the Jegs heads offer virtually the same open-load pressure but lower seat pressure. The typical onset of valve “float” is actually where the spring bounces off the seat at closing. This is where the conical spring offers 40 percent more load to keep the valve on the seat.

If you study the Flat-Tappet Hydraulic Cam Test graph, you can see that above 4,000 rpm the stronger valvesprings added 10-plus lb-ft of torque, which usually means the horsepower will also improve. Note how the weaker springs allow the valves to bounce, which kills the power after 5,200 rpm. But with the better springs, the horsepower curve (HP2) continues to climb right up to 6,000 rpm before it tips over at 6,100 rpm. Peak power stabilized at 430 hp, which equates to a solid 25-plus-horsepower improvement at the reasonable 6,000-rpm peak.

It's also interesting on the graph how at 3,000 rpm we lost as much as 30-plus lb-ft of torque. We realized once we began writing this story that we used a different header in the second test compared to the headers used in the first test session. The original set of Hedman headers use a slightly smaller diameter and longer primary pipe, and this would explain the difference in torque. The other change (other than the valvesprings) was using a 750-cfm HP Holley carb instead of the 0-3310 750-cfm vacuum secondary carburetor we had used in the previous test, although the air/fuel ratio remained similar between the two tests.

More Power

We knew from Jegs' flow numbers that these heads would respond with even more power if we added more valve lift. Adding a 1.6:1 roller rocker arm to increase valve lift on the flat-tappet cam only resulted in lost power, again due to a reoccurrence of valve-control issues. A better solution was to go to a hydraulic roller cam that could add more valve lift. We also decided that with our good crank, rods, and forged pistons, we had the quality parts to allow us to spin the engine a little higher to make more power. This idea comes from the basic premise that if you make the same torque at a higher engine speed, you will make more horsepower. The easiest way to do that is to add a camshaft with more intake and exhaust duration, and this should move the torque curve higher in the engine rpm band. Of course, this almost always also comes at the price of losing power at engine speeds below peak torque.

This is what our small-block looked like after completing testing. While we made 403 hp, we knew we had left lots of power on the table. Our engine was suffering from valvetrain distress. All it needed was some better valvesprings.

This is what our small-block looked like after completing testing. While we made 403 hp, we knew we had left lots of power on the table. Our engine was suffering from valvetrain distress. All it needed was some better valvesprings.

Bolt-On Hydraulic Roller Power

The basic advantage of a hydraulic roller camshaft is that roller followers allow the cam designer to be more aggressive in creating additional valve lift. Without getting into all the differences between a flat tappet and a roller follower, a roller follower allows the cam designer to increase lifter velocity, which increases valve lift for the same amount of duration. We chose to not only add a hydraulic roller cam, but also increase the duration slightly to increase our peak horsepower potential. As you can see from the Cam Specs chart (page 32), we added 10 degrees of duration to both the intake and exhaust lobes, measured at 0.050 tappet lift. This means that the intake and exhaust valves will open slightly sooner and close later. One important key to improved top-end power is to close the intake valve later in the cycle. This increases time (in degrees of duration) for the intake port to fill the cylinder at high engine speeds. Changing to a hydraulic roller camshaft also requires adding a cam button to the end of the cam to prevent the cam from walking forward as engine speed increases. We didn't want to increase the overall cost by adding a custom aluminum front timing cover, so we re-used the original tin cover, using a plastic cam button to create the proper fore-aft 0.010-inch endplay.

All we did was bolt in a hot-load hydraulic roller cam in our 357-inch small-block that resulted in a solid 480-plus horsepower.

All we did was bolt in a hot-load hydraulic roller cam in our 357-inch small-block that resulted in a solid 480-plus horsepower.

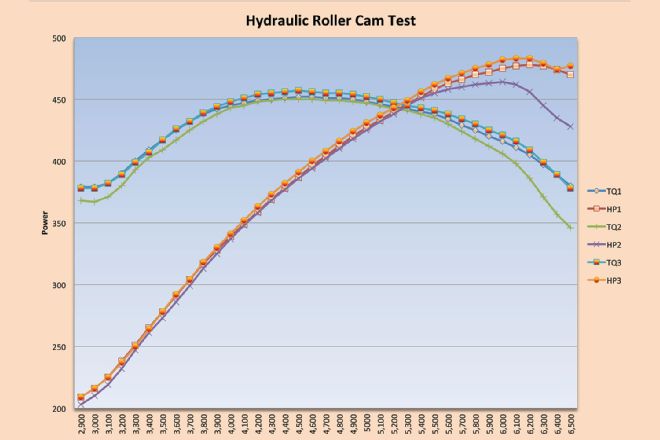

Once we had the roller cam in place, it was time for the power test. To evaluate just the change in the cam, we retained the 1.5:1 roller rockers used with the flat-tappet cam. The first test immediately raised the engine's peak horsepower point to 6,200 rpm from the flat-tappet cam's best horsepower peak of 6,000 rpm. Frankly, we expected the roller's additional 10 degrees of duration to push the rpm peak closer to 6,500 rpm, so 6,200 rpm was mildly disappointing. But the power that we gained was anything but a disappointment with a nice increase to 478 hp. With this simple cam swap, we had just jacked the power by nearly 50 hp. We attributed a majority of the power increase to the roller cam's additional valve lift that bumped the intake lift from the flat tappet's 0.504 to the roller's 0.560 inch, an increase of more than 0.050 inch. Since this added lift really helped the power, we assumed that if some is good, then more is better, so we added a set of 1.6:1 roller rockers to both the intake and exhaust in search of more power.

We decided to test the new conical springs with 1.5:1 roller rockers instead of jumping right into the 1.6:1 ratio. Subsequent testing revealed that the aggressive lobe profile wasn’t compatible with higher ratio rockers, even with the better conical springs.

We decided to test the new conical springs with 1.5:1 roller rockers instead of jumping right into the 1.6:1 ratio. Subsequent testing revealed that the aggressive lobe profile wasn’t compatible with higher ratio rockers, even with the better conical springs.

The problem with adding rocker ratio is that this also increases valve acceleration rate, which makes the valvespring's job more difficult. Most of the time, the spring can handle this increase in valve acceleration. In our case, adding 1.6:1 rocker ratio to both the intake and exhaust resulted in a dramatic loss in power above 5,400 rpm, and the engine suffered serious valve float at about 6,200 rpm when it began popping out of the exhaust. We then experimented by returning to a 1.5:1 rocker on the exhaust side and retaining the 1.6:1 rocker on the intake. This gave us the best power of the session with an excellent 483 hp at 6,200 rpm. While the heavier intake valve usually pushes the intake side into valve float before the exhaust, in this case, our valve control issues might be attributed to a more aggressive lobe design on the exhaust side.

We then tried a Holley Strip Dominator single-plane intake on our hydraulic roller combination, thinking that it might help the peak power, but again, our 357 rejected the single-plane, losing more than 30 lb-ft of torque below peak torque while gaining barely 5 hp at horsepower peak. Clearly, the inconsequential horsepower gain wasn't worth the massive torque loss, so our best power combination remains with the Edelbrock Performer RPM (not the Air-Gap) dual-plane intake. We also tested a 1-inch open plenum spacer on the dual-plane in search of more horsepower, but this attempt also resulted in no additional power.

Overall, we jacked up our 357 small-block with 80 more horsepower while only losing a small amount of torque below 3,500 rpm. In the first story, we plugged the 403hp curve into our Quarter-Pro simulation program which estimated elapsed times for our Chevelle at 12.50s at 104 mph. With the hydraulic flat-tappet cam package, that estimate improved to 12.20s at 111 mph, and when we plugged in the roller cam package, the times improved to an estimated 11.95 at 114 mph. That's a solid 0.50-second and 10-mph gain over our original combination, which is downright excellent for a simple cam swap. The reality is that the heads and intake complement the larger hydraulic roller cam package very nicely, and we now have a very strong small-block that offers 480 normally aspirated horsepower at the flywheel at the touch of the throttle pedal. Not bad for a small-caliber, small-block Chevy.

The next plan was to bolt in a Lunati hydraulic roller cam, so the first thing was to ensure initial lube with a squirt of Lucas Assembly Lube. We didn’t degree this cam but installed it at the same position as the flat-tappet version.

The next plan was to bolt in a Lunati hydraulic roller cam, so the first thing was to ensure initial lube with a squirt of Lucas Assembly Lube. We didn’t degree this cam but installed it at the same position as the flat-tappet version.

Flat-Tappet Cam Test

Test 1: This is the best power test from Part 1.

Test 2: All we added was better conical Lunati valvesprings. This test also used Westech's dyno headers as opposed to the Hedman headers used in Test 1.

The red HP1 curve is with the original valvesprings, while the green line (HP2) is with the stronger, conical springs. Note how the weaker springs gave up at around 5,300 rpm, while the conical springs offer improved valve control, making more power starting down as low as 3,700 rpm. That's a 53hp difference at 6,000 rpm! Do you think you'd feel 50 hp in the seat of your pants? Damn straight.

Valvesprings Specs

Parts List

Cam Specs

The Hydraulic Roller Cam Test

Test 1: This was with the Lunati hydraulic roller cam and 1.5:1 rocker ratios on both the intake and exhaust.

Test 2: Here we added 1.6:1 rockers to both the intake and exhaust. Note how the power dropped off radically.

Test 3: We discovered it was the exhaust that caused the power loss, so this test used 1.6:1 roller rockers on the intake side only. This resulted in the best power.

If you look closely at the Test 2 HP curve (purple), it began experiencing valve float as early as 5,200 rpm and fell off the power curve above 5,900 with the higher ratio rockers on both the intake and exhaust. With more spring pressure, or perhaps a lighter valvespring retainer, we might have been able to use the 1.6:1 rocker ratio on the exhaust. We assumed that the exhaust lobe is quite a bit more aggressive than the intake lobe, causing this problem.

We also swapped in Lunati’s nice, dual spring with a damper that offers quite a bit more spring pressure to accommodate the more aggressive hydraulic roller velocity curve.

We also swapped in Lunati’s nice, dual spring with a damper that offers quite a bit more spring pressure to accommodate the more aggressive hydraulic roller velocity curve.