I have a question about the small hose going from the front of the intake manifold to the water pump on a big-block Chevy. I have a Dart manifold that has no provision for that water hose. I’ve heard different opinions about this hose: Some say plug off the hole on the top of the water pump and forget it. Others say Chevy put it there for a reason and it should be there. I’ve also seen manifolds with water lines running from front to rear on both sides of the manifold. I’d like to get your opinion.

All engines that run a thermostat need to have some type of bypass provision to avoid localized hot spots, minimize the chance of steam pockets developing, promote even and rapid warm-up, and prevent water-pump cavitation. On some engines, such as classic Chevy small-blocks, the bypass is internal; on others, such as your big-block Chevy, the bypass is external.

You have a number of options that run the gamut from simple to complex:

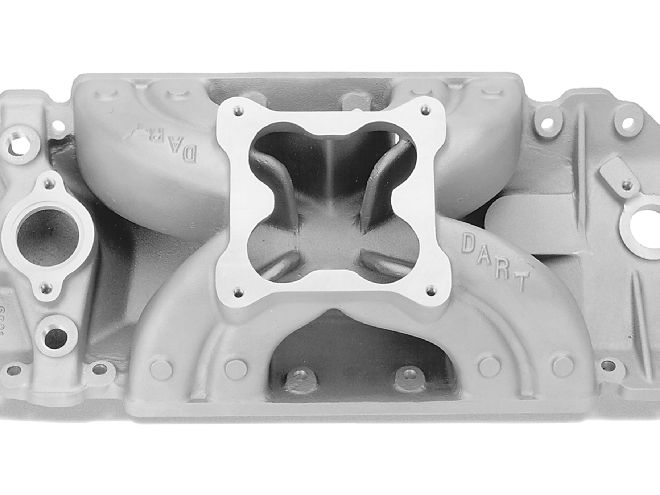

B A B [Most Dart intakes still have a bypass boss provision--it just isn’t machined (A). To add a boss for a stock-size 3/4-inch hose, use a 23⁄32-inch drill bit plus a ½-NPT pipe tap. Another alternative is to just use an existing 1/2-NPT boss (B). Although you could get trick and tee both bosses together to theoretically achieve more equal flow, using only one is more than sufficient.

B A B [Most Dart intakes still have a bypass boss provision--it just isn’t machined (A). To add a boss for a stock-size 3/4-inch hose, use a 23⁄32-inch drill bit plus a ½-NPT pipe tap. Another alternative is to just use an existing 1/2-NPT boss (B). Although you could get trick and tee both bosses together to theoretically achieve more equal flow, using only one is more than sufficient.

Don’t confuse a normal coolant bypass with plumbing “water lines running from front to rear on both sides of the manifold”-- they’re not the same thing. Typically only used on race engines, this is an attempt to promote even cooling on cylinders 7 and 8, which tend to run hotter because they’re at the back of the block. On a maximum-effort engine with aftermarket heads, this may reduce detonation tendencies and help fight steam pockets. On a street engine, you might consider this scheme if the radiator fill-point is not the highest point in the coolant system. Better, however, is a separate surge tank, with the filler cap on the tank, located so that it is the highest point in the cooling system.

Can you run a rectangular-port big-block Chevy (BBC) intake on a large oval-port BBC cylinder-head? I think that BBC square gaskets will be fine and seal the ovals up. Airflow won’t be an issue as engines are pumps and, in the case of a normally aspirated engine, will suck in the air. A supercharged engine will push the air in and pressurize the intake regardless.

Glenn Cattani - Via email

Can you bolt a BBC rectangular-port intake to large oval-port heads? Yes. Should you? Only if there’s no dedicated oval-port intake available for the application. For example, back in the day tunnel-rams were only available for rectangular-port heads. Oval-port racers who needed a tunnel-ram had no other choice but to run a rectangular-port tunnel-ram; in that case, it proved to be a significant improvement over a conventional non-tunnel-ram, oval-port intake in high-rpm racing applications. But when they finally became available, a dedicated oval-port tunnel-ram would prove even better, because there was no longer a port mismatch. In any case, today there’s a manifold available for nearly every big-block head and application out there, so this sort of “crutch” isn’t usually needed.

The basic problem is that the rectangular-port intake’s runner exits are larger than the oval-port head’s intake runner entrances. This restricts airflow and promotes reversion. It doesn’t matter if it’s a normally aspirated or supercharged application: A restriction is a restriction. It’s a fallacy to believe that a blown application isn’t subject to the rules of airflow. With a blower, overcoming the restriction requires generating higher boost to make equivalent power compared to an otherwise-identical combination with minimal restriction. Higher boost reduces efficiency, excessively heating the air. If the air gets too hot, it may not produce the expected power at any boost level. That’s because hot air puts the engine into detonation sooner, plus it’s also less dense. To some extent this can be offset with a sufficiently large intercooler (if there’s enough room), but that adds complexity and weight. And of course, given the same size intercooler, an unrestricted combination would make more power yet. Turning up the boost (working the blower harder) also causes the supercharger drive to consume more power (aka “parasitic power loss”). Bottom line: The objective should be to make the most power with the least boost.

You may never realize any of this unless back-to-back tests were conducted with the “wrong” and “right” intakes on a dyno or at the track. Nevertheless, if you go ahead with this anyway, use a rectangular-port intake gasket without an integral sealing bead around the ports. Instead, finger-smear a very light coating of silicone around each port. Pay particular attention to the seal at the port roofs.

I have a ’95 Ford Ranger with a 2.3L single overhead cam (SOHC) four-cylinder. It is my daily driver as well as my do-anything truck. I want to upgrade the cam and various other parts to gain more power. Does any company offer a cam for my truck? Could you recommend any other parts that I could upgrade?

Mike Porter - Via email

Ford 2.3L engines have huge hop-up potential. Noted Ford 2.3L engine-builder and drag-racer Joe Morgan dropped this ’80s Ford 2.3L turbo motor into his ’76 Pinto. Using a bigger turbo but with stock heads, it made 400 hp at the wheels, enough to run 10.70 seconds at 122 mph, shifted by a C4 automatic. It’s said to remain marginally streetable.

Ford 2.3L engines have huge hop-up potential. Noted Ford 2.3L engine-builder and drag-racer Joe Morgan dropped this ’80s Ford 2.3L turbo motor into his ’76 Pinto. Using a bigger turbo but with stock heads, it made 400 hp at the wheels, enough to run 10.70 seconds at 122 mph, shifted by a C4 automatic. It’s said to remain marginally streetable.

The ’74-97 Ford 2.3L SOHC L4 was installed in many Ford cars and trucks, including Mustangs, Pintos, Fairmonts, Rangers, and early Aerostar vans. Factory-turbocharged versions were introduced on the ’79 Mustang. A second-generation, port-fuel-injected turbo package powered the ’83 Thunderbird Turbo Coupe, the Mustang SVO, and later the Merkur XR4Ti. There was even a twin spark-plug head introduced on the ’89 Ranger and ’91 Mustang that featured Ford’s first coil-pack distributorless ignition. Other engines with similar architecture include SOHC 2.0L and 2.5L engines. However, the 2.2L 3V SOHC Probe, the 2.3L/2.5L OHV HSC, and the 2.0L DOHC Zetec engines are not related.

The Ford 2.3L SOHC engine had a long production run, so cores are still widely available. They have huge potential compared to other domestic four-cylinder engines of the day. Even now the engine architecture remains competitive in SCCA F2000-series road-racing, as well as entry-level, Hobby Stock–type, oval-track classes. High-boost turbo versions have proven successful in niche drag-racing and land-speed applications.

Stock 2.3L iron heads are crack-prone. Esslinger offers this bolt-on stock-replacement aluminum head with oversize 1.74/1.47-inch valves and high-flow heart-shaped chambers that joins its stable of all-out raised-port full-race 2.3L heads. For more exotic tastes, it also offers a full lineup of more exotic, full-race, raised-port heads.

Stock 2.3L iron heads are crack-prone. Esslinger offers this bolt-on stock-replacement aluminum head with oversize 1.74/1.47-inch valves and high-flow heart-shaped chambers that joins its stable of all-out raised-port full-race 2.3L heads. For more exotic tastes, it also offers a full lineup of more exotic, full-race, raised-port heads.

Because of the engine’s continuing popularity, there is wide aftermarket support. Literally everything is upgradable. The major cam companies all sell cams. But your one-stop source for anything 2.3L SOHC Ford-related is Esslinger Engineering, which has everything from basic nuts and bolts up to aluminum blocks and heads. Decide how fast you want to go, and Esslinger’s tech-guys will spec-out a combo that meets your goal.