Hot Rod To The Rescue

The Original Combo

Jeff Blitz purchased his ’66 Chevy II Nova four years ago, complete with a carbureted 10.5:1 355ci small-block Chevy, a TH350 automatic with a 3,000-rpm stall-speed converter, a 3.55:1 12-bolt rearend, and a manual front disc-brake conversion. Although built up using a factory roller-cam–style block, as received the engine ran a hydraulic flat-tappet cam and GM Vortec cylinder heads modified for close-tolerance pushrod guideplates and cut-down valveguide bosses compatible with high-lift cams.

Imlay City, Michigan’s Jeff Blitz likes to go cruising and hit the local Detroit-area car shows, but valvetrain reliability issues held him back.

Imlay City, Michigan’s Jeff Blitz likes to go cruising and hit the local Detroit-area car shows, but valvetrain reliability issues held him back.

The Problem

Blitz was continuously plagued by noisy lifters. “They tick at all times,” explained a frustrated Blitz. “It’s very slight during cold-start, but after it’s fully warmed up there’s a large and audible ticking. Only some of the lifters tick, generally on the driver-side bank.” A rocker-stud on the driver-side bank also broke.

The Modified Combo

Initially, Blitz tried to resolve the issues himself and gain some power at the same time via a cam and head swap. He replaced the flat-tappet cam with a healthy Lunati hydraulic roller cam (Cam Specs chart, page 130). The roller-cam–style block accepted affordable GM production roller lifters retained by the factory spider. Aluminum, early production, Air Flow Research (AFR), 190cc intake-runner heads purchased from a friend were reconditioned by a local shop with a new valve job, valve guides, valve seals, and hydraulic roller-cam–compatible valvesprings. The heads already had large (7/16-inch threads top and bottom) rocker studs, but were missing guideplates, so the shop installed guideplates it claimed would work on the AFR heads. New 5/16-inch-od hardened pushrods of the right length for the roller cam block with factory roller lifters plus Scorpion 1.6:1 roller-rockers completed the upgraded valvetrain.

Although the engine definitely ran stronger, Blitz still had the same complaint. The new lifters still ticked. Rocker-arm studs still failed randomly. “One stud broke near the top where the nut hits the rocker under normal, freeway-cruise speeds -- 70–75 mph -- with no warning on the way to work,” complained a still-frustrated Blitz. “I’d like to go cruising with my 2½-year-old triplet girls, but it’s got to the point I’m afraid to drive the car.”

The Shop

HOT ROD couldn’t bear to see daddy’s little gals disappointed, so we sent Blitz to Motor City Speed. Founded by veteran LS engine builder Billy Briggs, the shop is located just northwest of Detroit and routinely builds everything from naturally aspirated, 500hp, streetable LS engines all the way up to 3,000hp single-turbo drag LS V8 world-record-holding drivetrains. Yes, we said “drivetrains,” because Motor City can build and tune complete integrated cars and drivetrains. Although its bread-and-butter work is on late-model LS high-tech wonders, Motor City’s more than capable of working on an old-school, carbureted, Gen I small-block like Blitz’s car. It’s kind of like bringing a bazooka to a knife fight, but we knew the car would be fixed right the first time.

The cure: Install quality AFR rocker studs and adjustable guideplates, plus short-travel Lunati guidebar-type lifters.

The cure: Install quality AFR rocker studs and adjustable guideplates, plus short-travel Lunati guidebar-type lifters.

The Diagnosis

To initially rule out any serious internal short-block issues, Motor City first drove the Nova around the block at low speeds and then let the engine idle for a while to make sure no cylinders had lost compression due to a bent or leaking valve or a lifted piston ring land. It ran pretty well and sounded good. “It was smooth, with no spitting or popping. However, the average guy would probably want to run a compression or cylinder leak-down test,” Briggs explained. Blitz had dodged a serious bullet; fortunately, the broken studs hadn’t bent any valves or damaged a piston.

Blitz had OE-style, hydraulic roller lifters retained by the factory-style dogbones and spider in his late-model block. This affordable solution is suitable for the vast majority of street engines, but sometimes—due to inconsistent bleed-down and excessive plunger travel—they can cause problems with aggressive, high-lift cam profiles.

Blitz had OE-style, hydraulic roller lifters retained by the factory-style dogbones and spider in his late-model block. This affordable solution is suitable for the vast majority of street engines, but sometimes—due to inconsistent bleed-down and excessive plunger travel—they can cause problems with aggressive, high-lift cam profiles.

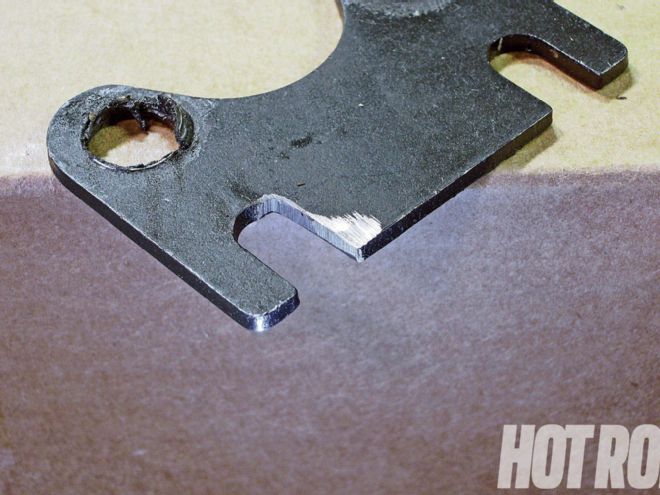

The next step was to pop the valve covers and check-out the valvetrain. Inspection revealed pushrod guideplate slots ground-out for clearance. A good rule of thumb is that with close-tolerance guideplates, there should be about 0.008–0.010-inch clearance between the pushrod and the slot in the guideplate. In this case, clearance was as much as 0.125 inch -- not good for valvetrain stability.

The Nova was also using no-name, poor-quality, offshore rocker arm studs. They might have eventually failed even without the sloppy guideplates, but in this case they certainly couldn’t withstand the added side loads. Briggs explains, “A lot of people look at fasteners as a ‘whatever’ purchase -- they think it doesn’t really matter where they come from; they are all the same. Well, that’s just not true. The studs in this engine were just not good enough for a performance application. Throw on top of that pushrods flapping around in the breeze and you can understand why the studs were breaking.”

Luckily, the rest of the upper valvetrain was OK. The rocker arms exhibited no signs of binding, brinelling, cracking, or general distress; the pushrods weren’t bent; the valvesprings weren’t into coil bind; and the retainers weren’t hitting the seals or guides.

A slight audible ticking sound is normal with hydraulic roller lifters -- but it’s all in the eye of the beholder. Although Blitz found the perceived noise annoying, Motor City’s hands-on inspection didn’t find anything particularly wrong with the stock lifters. Blitz’s noise complaint may just have been caused by the pushrods or guideplate moving around. On the other hand, excessive lifter noise can be indicative of more serious problems -- so it’s not something to take lightly. Stock hydraulic roller lifters may not be up to the job with cams that have higher lift and more duration than the mild cams they were originally designed for. OE GM lifters have lots of lifter plunger-travel, and their bleed-down rates can vary widely between different lifters because of the mass-produced units’ production tolerances. If the lifters bleed down too quickly, they can’t compensate for lash when the lifter plungers return on the lobes’ downside past peak lobe lift -- hence the lifter noise. Long-term, this will accelerate wear. If the vehicle consistently sees high rpm, such valvetrain separation can result in increasingly severe valvetrain problems (for a detailed discussion of this issue, see Pit Stop, Nov. ’13, “Roller-Lifter Noise”).

The Fix: Lifters

To fail-safe the lifter issue, the stockers were replaced with a set of premium Lunati short-travel tie-bar lifters that are manufactured to tighter tolerances than the stockers. This solved Blitz’s perceived noise problem while also enhancing high-rpm stability.

Not every cylinder will necessarily end up with the same slot spacing. You may want to punch the cylinder number and/or scribe alignment lines across the two halves of the scissors in case everything has to come apart someday.

Not every cylinder will necessarily end up with the same slot spacing. You may want to punch the cylinder number and/or scribe alignment lines across the two halves of the scissors in case everything has to come apart someday.

The Fix: Valvetrain

The centerline distances between each intake and exhaust rocker arm stud pair as well as the pushrod slots on a single-piece guideplate must be correct for the cylinder head. Obviously, Blitz had the wrong guideplates for his early AFR heads. Although one-piece guideplates aren’t currently available for its early heads, AFR was able to supply a set of universal adjustable “scissor-style” interlocking plates. It also sent a set of premium rocker arm studs, which -- like all AFR threaded fasteners -- are made in America by ARP.

By pure chance, the distance between the lifter plunger and roller wheel turned out to be the same for both the GM and Lunati lifters, so no pushrod-length changes were needed. Motor City was then able to move on and properly set up the interlocking guideplates, ensuring the rocker arms’ roller tips were centered over the valve stems without putting the pushrods into bind. Briggs says “some old-school people used to tack-weld the two halves together once they were properly adjusted and tightened down, but this ruins the heat-treat and will cause cracks at the weld. Once the studs are torqued, the interlocking plates aren’t moving.”

Tweak the plate halves in or out with a screwdriver or small prybar as needed to center the pushrods in the slots. Ensure the pushrods aren’t binding against the head’s pass-through slot. If there is interference, grind the head (not the guideplate) for clearance. Once everything is lined up and not binding, fully tighten the rocker studs to the proper torque value.

Tweak the plate halves in or out with a screwdriver or small prybar as needed to center the pushrods in the slots. Ensure the pushrods aren’t binding against the head’s pass-through slot. If there is interference, grind the head (not the guideplate) for clearance. Once everything is lined up and not binding, fully tighten the rocker studs to the proper torque value.

What do you expect from $19 rocker studs? Buy real parts: You get what you pay for!

Results

The engine sounded healthy when it was fired up, but the Motor City Speed guys felt they needed to run the engine hard to know they solved the problem. First Motor City qualified the repaired Nova on its sophisticated Mustang Eddy-Current all-wheel-drive (AWD) chassis dyno that’s capable of handling more than 2,000 rwhp. With no fine-tuning, a reading of 273 hp was recorded at the rear wheels, using the conservative SAE J1349 “Net” correction factor, the same method Detroit uses to rate its late-model engines. Typically, “Net” ratings are about 4 percent down from the common J607 factor used by most hot rod dynos. Figure another 18 to 20 percent loss through the old-school loose converter, TH350 trans, and 12-bolt ring-and-pinion, and you’re looking at around 340 hp or so at the flywheel. Briggs feels the Nova is being held back by a mismatched converter/cam/cylinder-head combo: “Blitz could easily pick up 75 rwhp with the right parts. The current cam is too small for the AFR heads. He needs a cam with 0.050-inch duration in the high 230s to low 240s. With the larger cam, he should replace his current 650-cfm carb with a larger carb and move up from the current Edelbrock Air Gap dual-plane intake to a single-plane Victor Jr. Those upgrades will better match the characteristics of Blitz’s 3,000-stall converter, which is too loose for the current setup.” Welcome to the upgrade treadmill!

After torturing the engine on the dyno, Motor City extensively drove the car under real-world Street conditions. No further issues were found. Subsequently, owner Blitz confirmed that “although I’m kinda disappointed on what it pulled on the dyno, the car runs great -- better than it ever has. I’m driving the car regularly again -- not just cruising, but jamming through the gears -- and there’s been no problems at all.”

Lessons Learned

Be sure to get the right parts for your combination. If things don’t seem to fit right, find out why before getting out the hammer (or a grinder). Don’t skimp on quality parts, especially when it comes to often-overlooked (until they fail) fasteners.

To ensure the car was really fixed, Motor City ran the car hard on its sophisticated Mustang chassis-dyno. On the dyno, the Motor City team can listen to the engine from multiple angles while it’s running “in anger”—often letting it spot problems not otherwise apparent from just driving the car around on the street.

To ensure the car was really fixed, Motor City ran the car hard on its sophisticated Mustang chassis-dyno. On the dyno, the Motor City team can listen to the engine from multiple angles while it’s running “in anger”—often letting it spot problems not otherwise apparent from just driving the car around on the street.

Need Junk Fixed?

If your car has a gremlin that just won’t quit, you could be chosen for Hot Rod to the Rescue. Email us at [email protected] and put “Rescue” in the subject line. Include a description of your problem, your location, and a daytime phone number.

PARTS AND PRICES Includes the major parts required to fix the problem. Does not include labor or shipping. Priced 10/12/13 and subject to change. All dimensions in linear inches or fractions thereof. BRAND PART DESCRIPTION PN PRICE SOURCE PRICE Air Flow Research Guideplate, adjustable, fits 5/16 pushrods (set of 8 two-piece guideplates) 6103 Summit Racing $33.97 Stud, valve rocker arm, ARP-type, 7/16-20 top × 7/16-14 bottom (set of 16) 6405 Summit Racing $103.79 Fel-Pro Gasket Set, intake manifold, steel-core laminate w/ coating, w/ Printoseal, 1.28 × 2.09 port-size, 0.065 thick 1205 S-3 Summit Racing $29.97 Gasket Set, valve cover, silicone molded rubber w/ steel core, steel compression limiters, 0.250 thick (1 pair) 1628 RockAuto $44.79 Lunati Lifter, Signature Series short-travel hydraulic roller, retrofit-style w/ tie-bars (set of 16 lifters) 72530-16 Summit Racing $729.97 Total $942.49 LUNATI VOODOO HYDRAULIC ROLLER CAM SPECS All values in degrees, unless stated otherwise. Grind Part No.* RPM Range Lift (Inches) Duration At Tappet Timing, 0.050-inch Tappet-lift Lobe Centerline LSA Current Pre-2011 Lobe Valve (1.6:1 Ratio) Advertised 0.050-inch Lift Intake Exhaust Intake Exhaust Intake Exhaust Intake Exhaust Intake Exhaust Opens Closes Opens Closes Intake Exhaust VDSC-282 20080722 60122 2,400–6,400 0.357 0.367 0.571 0.587 282 290 231 239 9.5 BTDC 41.5 ABDC 53.5 BBDC 5.5 ATDC 106 114 110 *Listed Part Nos. are for ’87-and later blocks using bolt-on factory thrust-plates and corresponding timing sets. For conventional timing sets intended for use with a thrust-button or -bearing, order PN 20120712 (formerly PN 60112).