The basically stock 455 H.O. in our ’72 Trans Am had always ran satisfactorily, but when it recently sprung a coolant leak, we yanked it out from under the hood and affixed it to an engine stand for proper assessment.

From its appearance—with the exception of a few corroded frost plugs and maybe a few gaskets—everything appeared issue-free. As you learned in the past two issues of HPP, it was during disassembly to replace those gaskets that we found several areas of concern, and so a full rebuild was underway.

Until that point, the 455 H.O. had given us no indication of any problems. We flogged it on the chassis dyno several months earlier, and it seemingly trotted along like a thoroughbred. After the rebuild, we took the opportunity to measure its performance on the engine dyno, and while we were certain performance had improved considerably, we could only guess at how much since we only had numbers from a chassis dyno.

1 Willard Auto Machine in Omaha, Nebraska, recently rebuilt the 455 H.O. in our ‘72 Trans Am. Owner Chuck Willard treated it to a complete dyno-tuning session. It generated 433 hp at 4,800 rpm and 517 lb-ft at 3,500 rpm on his Land & Sea engine dyno."> <strong>1</strong> Willard Auto Machine in Omaha, Nebraska, recently rebuilt the 455 H.O. in our ‘72 Trans Am. Owner Chuck Willard treated it to a complete dyno-tuning session. It generated 433 hp at 4,800 rpm and 517 lb-ft at 3,500 rpm on his Land & Sea engine dyno.

<strong>1</strong> Willard Auto Machine in Omaha, Nebraska, recently rebuilt the 455 H.O. in our ‘72 Trans Am. Owner Chuck Willard treated it to a complete dyno-tuning session. It generated 433 hp at 4,800 rpm and 517 lb-ft at 3,500 rpm on his Land & Sea engine dyno.

With the 455 H.O. nestled between the framerails again, we found it a completely different animal. Simply stated, it operated significantly better than ever at every speed. It accelerated smoothly and cruised effortlessly in light-throttle conditions. And like any good-running 455 owner can relate, applying throttle too quickly resulted in clouds of tire smoke.

A question still gnawed at us, however. How much power did we actually gain from the rebuild? The only way to determine this answer was with a follow-up chassis dyno session.

HPP Engine Buildup Worksheet

BLOCK

OILING SYSTEM

HEADS

Air Flow Numbers at 28 Inches:

Before Rebuild

After Rebuild

CAMSHAFT

INDUCTION SYSTEM

IGNITION

EXHAUST

GASKETS

VEHICLE SPECIFICATIONS

We regularly tune our Pontiacs using the Mustang Dyno chassis dyno at H.S. Automotive and Dyno in Omaha, Nebraska. The model MD-1750 unit it uses contains a 2,500-pound roller drum and an eddy-current brake that applies a varying amount of resistance that replicates the vehicle weight and load the engine sees accelerating down the street or race track. The power at the tires that spins the roller drum is quite usable when tuning for peak output, but trying to convert that number to actual output at the crank for the sake of discussion can be tricky.

There are a number of power-robbing accessories, as well as driveline components like the transmission and differential, and a full exhaust system, that negatively affect gross engine output. As such, numbers recorded at the tires are generally much lower than those recorded at the crankshaft. Since those components and combinations can vary greatly from one vehicle to the next, it’s difficult to accurately state how much power is lost from equipment that would apply to all vehicles. The owner/operator of this particular Mustang Dyno unit told us that he has previously estimated this parasitic loss at about 25 percent for our particular Firebird, and we would later find at least that and a little more.

2 While retaining a stock appearance and its critical numbers-matching components, the YE-code four-bolt block was bored to a total of 0.040-inch over. It’s filled with forged rods and pistons, and a forged stroker crankshaft, which increased displacement to 468 ci. It’s also equipped with a 224/236-degree hydraulic roller camshaft and oversized Ram Air exhaust manifolds. The 7F6 cylinder heads were milled to produce a 91-octane–friendly compression ratio of 9.2:1. "> <strong>2</strong> While retaining a stock appearance and its critical numbers-matching components, the YE-code four-bolt block was bored to a total of 0.040-inch over. It’s filled with forged rods and pistons, and a forged stroker crankshaft, which increased displacement to 468 ci. It’s also equipped with a 224/236-degree hydraulic roller camshaft and oversized Ram Air exhaust manifolds. The 7F6 cylinder heads were milled to produce a 91-octane–friendly compression ratio of 9.2:1.

<strong>2</strong> While retaining a stock appearance and its critical numbers-matching components, the YE-code four-bolt block was bored to a total of 0.040-inch over. It’s filled with forged rods and pistons, and a forged stroker crankshaft, which increased displacement to 468 ci. It’s also equipped with a 224/236-degree hydraulic roller camshaft and oversized Ram Air exhaust manifolds. The 7F6 cylinder heads were milled to produce a 91-octane–friendly compression ratio of 9.2:1.

Pontiac offered its Round-Port 455 H.O. for ’71 and ’72. While there were a few subtle differences between the model years, Pontiac published a gross power rating of 335 hp and 480 lb-ft for ’71, and it’s safe to say that number is reasonably close for ’72. (From ’72 forward, Pontiac published brake horsepower, not gross horsepower!)

The 455 H.O. in our ’72 Trans Am was essentially nothing more than a stock rebuilt engine fitted with a larger-than-stock hydraulic flat-tappet camshaft. Our initial dyno session yielded a maximum of 262 hp at 4,600 rpm and 327 lb-ft at 3,700 rpm at the rear tires. Doing the math, our relatively stock 455 H.O. was likely generating around 350 hp and 440 lb-ft at the crankshaft, numbers that seemed reasonable for the combination.

The rebuild gave us a chance to freshen up many areas, and add components such as a forged rotating assembly with a stroker crankshaft and a hydraulic roller camshaft. The details of the build were thoroughly covered in the two preceding issues of HPP; the current combination with complete specs is outlined elsewhere in this story.

Machine shop owner Chuck Willard used his Land & Sea engine dyno to break in the newly rebuilt 455 H.O. and measure its output, which after a lengthy tuning session peaked at 433 hp at 4,800 rpm and 517 lb-ft at 3,500 rpm. Quite pleased with the results, we were extremely excited to find the rebuild added what seemed to be about 100 additional hp and 75 lb-ft of torque!

Once reinstalled in the vehicle, the 455 H.O. performed much better at every speed and operating condition. The improvement in full-throttle performance at mid- and high-rpm was dramatic. Measuring just how much we gained was just a chassis dyno session away, and with our 455 H.O. tuned for optimal performance on the engine dyno, we were confident we’d see the maximum result within a handful of pulls. We scheduled an appointment with H.S. Automotive & Dyno, strapped the Trans Am to the roller drum, and let the 455 H.O. sing out the tailpipes.

3 Prior to the engine rebuild, we used the Mustang Dyno at H.S Automotive & Dyno in Omaha, Nebraska to ensure the 455 H.O. was running optimally. It generated 262 hp at 4,600 rpm and 327 lb-ft at 3,700 rpm in its previous configuration. A follow up dyno session would reveal just how much additional power we gained from the rebuild and modifications."> <strong>3</strong> Prior to the engine rebuild, we used the Mustang Dyno at H.S Automotive & Dyno in Omaha, Nebraska to ensure the 455 H.O. was running optimally. It generated 262 hp at 4,600 rpm and 327 lb-ft at 3,700 rpm in its previous configuration. A follow up dyno session would reveal just how much additional power we gained from the rebuild and modifications.

<strong>3</strong> Prior to the engine rebuild, we used the Mustang Dyno at H.S Automotive & Dyno in Omaha, Nebraska to ensure the 455 H.O. was running optimally. It generated 262 hp at 4,600 rpm and 327 lb-ft at 3,700 rpm in its previous configuration. A follow up dyno session would reveal just how much additional power we gained from the rebuild and modifications.

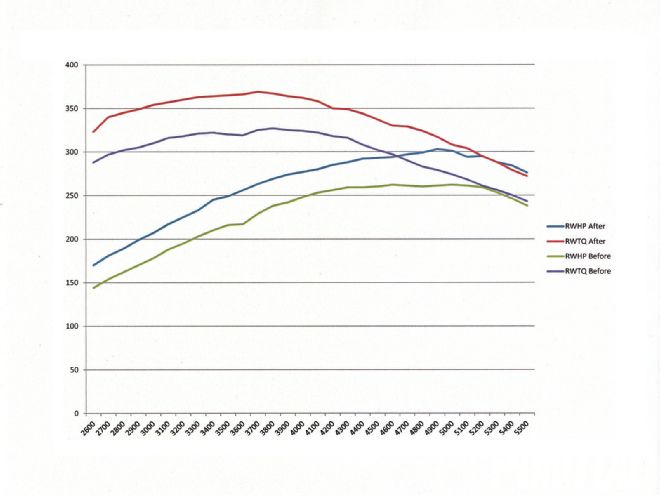

Unlike an engine dyno, which only takes the water-brake resistance into account when tuning, and uses minimal accessories and very little exhaust backpressure, a chassis dyno allows the operator to tune a vehicle for conditions very similar to what the engine will see on the road in normal operating conditions. After leaning out the carburetor slightly, the 455 H.O. peaked at 303 rwhp at 4,900 rpm and 369 rwtq at 3,700 rpm. Compared to our initial dyno session, that’s an increase of more than 40 rwhp and 40 rwtq—a gain of about 14 percent!

DYNO RESULTS Before After Difference RPM RWHP RWTQ RWHP RWTQ RWHP RWTQ 2,600 144 288 170 323 26 35 2,700 154 297 181 340 27 43 2,800 162 302 189 345 27 43 2,900 170 305 199 349 29 44 3,000 178 310 207 354 29 44 3,100 188 316 217 357 29 41 3,200 195 318 225 360 30 42 3,300 203 321 233 363 30 42 3,400 210 322 245 364 35 42 3,500 216 320 249 365 33 45 3,600 217 319 256 366 39 47 3,700 229 325 263 369 34 44 3,800 238 327 269 367 31 40 3,900 242 325 274 364 32 39 4,000 248 324 277 362 29 38 4,100 253 322 280 358 27 36 4,200 256 318 285 350 29 32 4,300 259 316 288 349 29 33 4,400 259 308 292 344 33 36 4,500 260 302 293 337 33 35 4,600 262 297 294 330 32 33 4,700 261 290 297 329 36 39 4,800 260 283 299 324 39 41 4,900 261 279 303 317 42 38 5,000 262 274 301 308 39 34 5,100 261 268 294 304 33 36 5,200 259 261 295 295 36 34 5,300 253 256 288 288 35 32 5,400 246 250 284 279 38 29 5,500 238 243 276 272 38 29 AVG 228 300 261 338 33 38

7 When comparing dyno pulls of the engine before and after the rebuild, it’s evident that the power bands mirror one another, but the engine now makes more power at every RPM point. The flat torque curve gives us an engine that’s responsive at very low speed and willing to fry the tires in an instant."> <strong>7</strong> When comparing dyno pulls of the engine before and after the rebuild, it’s evident that the power bands mirror one another, but the engine now makes more power at every RPM point. The flat torque curve gives us an engine that’s responsive at very low speed and willing to fry the tires in an instant.

<strong>7</strong> When comparing dyno pulls of the engine before and after the rebuild, it’s evident that the power bands mirror one another, but the engine now makes more power at every RPM point. The flat torque curve gives us an engine that’s responsive at very low speed and willing to fry the tires in an instant.

When comparing the numbers our 455 H.O. generated on the engine dyno to those recorded at the rear tires on the chassis dyno, our particular Firebird sees an equipment loss of about 30 percent. A quick call to Mustang Dyno’s technical department revealed that our calculations were correct, and 30 percent is indeed a reasonable number when considering our Trans Am contains a fully contented accessory-drive system, a Turbo 400 automatic transmission, and an exhaust system consisting of 2.5-inch–diameter tubing and a stock-type transverse muffler.

The addition of a more efficient exhaust system and/or removing drivebelts or eliminating such equipment will likely reduce that number. But we’re confident this particular Firebird (and any others we own that are similarly contented) will show about 30 percent less than what we might otherwise see on an engine dyno. This will help us accurately predict just how much power future modifications may give us in crankshaft values.

With the 455 H.O. rebuild complete and the fresh engine tested in two different forms, we can now appreciate the newfound power by driving the Trans Am as often as possible. Not only can we feel more power from the go-pedal under our right foot, we have proven in our own minds that we have 433 hp and 517 lb-ft available at the tip of our toe, and that’s nearly 15 percent better than it was before!