If you have spent any time running your car at the dragstrip, one thing in the overall tune-up becomes quite clear, and quickly: Getting fuel—and enough of it—to the carburetor is pretty important. You might think this is easy, but it's not, especially if you want to get it done with a lone, stock-style mechanical fuel pump.

Here's the scenario. Think of drinking an old-fashioned milkshake, but instead of using the big fat straw the shake normally comes with, substitute it for the itsy-bitsy straw you'd use with soda pop. You'd have a difficult time getting a mouthful of shake with the little straw. The same applies to a fuel system, which is why some performance cars from the muscle car-era were factory fitted with fuel lines larger in diameter than on more pedestrian cars (for example, a ⅜-inch line instead of a more common 5⁄16-inch job). But lines aren't the only part of the fuel delivery equation. To feed a hungry big-block, you have to take each and every part of the fuel system into consideration. Making it work with stock-style or stock-appearing pieces is another story.

Fuel Tank: There are a number different OE-style replacement gas tanks available for muscle cars today. Some are very close to stock in looks (and quality). Some aren't. You can get them tern-plated (as per original) or bare. You can also get them manufactured in stainless steel.

Ground Up has stainless tanks for Camaros and Chevelles, with Nova tanks in the works. You can order them with or without evaporative emission (EEC) fittings. One thing you should be aware of is the need for a vented or nonvented cap. It depends on the car and the application. Some tanks with EEC provisions are not vented. Plugged vents on a tank or cap can lead to all sorts of freaky fuel delivery issues. We've seen tanks actually collapse when not vented properly.

Fuel Tank Pickup: This is where things become more critical, as the stock pickup can be a big restriction in the fuel delivery system. If you're building a high-flow arrangement, you have two choices: Use a ⅜-inch replacement pickup and sending unit, or do what plenty of guys who race the F.A.S.T. drags do: Replace the factory pickup with a custom job from RobbMC Performance Products. This setup is based upon a huge ½-inch-diameter pickup, and it does away with the troublesome sock filter the OE replacements use. The dilemma with the sock is that it can become plugged and you don't know it. Fuel flow goes down and, obviously, so does performance. The custom pickup requires an external fuel filter (not a bad idea for any muscle car) but otherwise bolts into place as stock. It's a slick piece. And if you're searching for maximum fuel flow from a stock appearing system, this is the place to begin.

Fuel Line: After upgrading the tank and the pickup, you'll need a high-flow line. There are a couple of options available from Ground Up and Right Stuff Detailing. If you're searching for dead-nuts stock, then specify a ⅜-inch high-performance line in either conventional steel or stainless. Additionally, you can special-order ½-inch line, though it's available custom formed in stainless only. It has all of the same bends as the stock line and fits into the stock location, but obviously it's a lot bigger. This line, coupled with the high-flow pickup, is the key to providing (and maintaining) ample fuel flow in a stock appearing, drag muscle car.

Fuel Filter: A lot of different fuel filters are available today. You can even track down filters that are pure vintage in the looks department. Unfortunately from a flow perspective, some of those vintage fuel filters don't work so well. A good alternative is Holley's latest billet inline filter. It's a huge-capacity job machined for -8 AN hose ends, and it can easily accept ½-inch (or larger) conventional fittings. Holley's filter easily disassembles, allowing you to access the internal 100-micron wire mesh filter. Essentially, this filter will not act as a restriction in the system.

Fuel Pumps: Like fuel filters, plenty of stock-appearing mechanical fuel pumps are out there. Some are perfect for a high-flow application; plenty are not. Three examples to consider are Holley's High Output pumps (with or without an external fuel pressure regulator) or Holley's HP series pump. The basic High Output pump has a gallon per hour (gph) rating of 110. The High Output pump with the external regulator is rated at 130 gph. And the HP pump flows a whopping 170 gph. While the 130-gph pump requires an external fuel pressure regulator, the other two do not. In addition, the big HP pump is manufactured from billet aluminum, while the high-output models are cast. On a similar note, RobbMC Performance also offers a comprehensive line of high-flow mechanical fuel pumps.

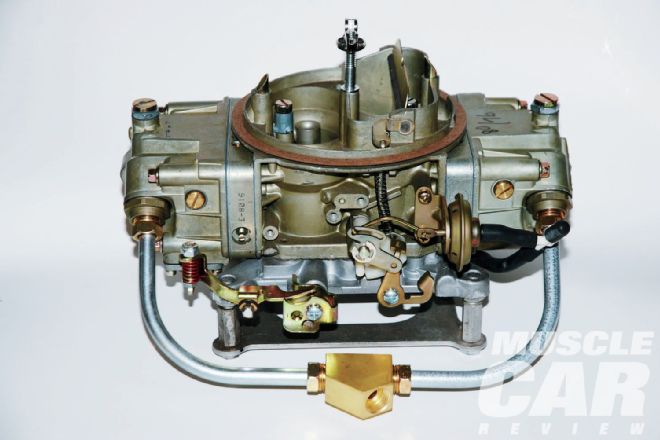

Carburetor Lines: Plenty of OE carburetor fuel lines were 5⁄16 inch. But once the fuel lines lead to the carb bowl fitting, the inlet size (at the fitting) can shrink to 7⁄32 inch! That's tiny. Increasing all the lines to ⅜ inch allows you to use a large high-performance bowl fitting with an actual inlet diameter (at the bowl) of 9⁄32 inch. Ground Up and Right Stuff Detailing can set you up with high-flow, stock-appearing line. You will find, though, that they aren't compatible with OE carb fittings. You'll need the larger bowl fittings found on speed shop–style Holleys.

1.This is the place to begin: Use a quality gas tank. This particular model is a tern-plated exact replacement for a GM fuel tank and is made in Canada and sold by Ground Up."> <strong>1</strong>.This is the place to begin: Use a quality gas tank. This particular model is a tern-plated exact replacement for a GM fuel tank and is made in Canada and sold by Ground Up.

2. You need a gas cap that matches the tank application. Cars with evaporative emissions systems usually have a nonvented cap. Cars without most often mandate a vented cap. Keep in mind that a correct but plugged cap isn’t going to work well. Without adequate venting, a fuel tank can collapse.">

<strong>1</strong>.This is the place to begin: Use a quality gas tank. This particular model is a tern-plated exact replacement for a GM fuel tank and is made in Canada and sold by Ground Up.

2. You need a gas cap that matches the tank application. Cars with evaporative emissions systems usually have a nonvented cap. Cars without most often mandate a vented cap. Keep in mind that a correct but plugged cap isn’t going to work well. Without adequate venting, a fuel tank can collapse.">

<strong>2</strong>. You need a gas cap that matches the tank application. Cars with evaporative emissions systems usually have a nonvented cap. Cars without most often mandate a vented cap. Keep in mind that a correct but plugged cap isn’t going to work well. Without adequate venting, a fuel tank can collapse.

3. While new gas tank straps are readily available, our examples were in good shape. We simply had them powdercoated semigloss black. Ground Up offers nice reproductions if your stock examples are used up.">

<strong>2</strong>. You need a gas cap that matches the tank application. Cars with evaporative emissions systems usually have a nonvented cap. Cars without most often mandate a vented cap. Keep in mind that a correct but plugged cap isn’t going to work well. Without adequate venting, a fuel tank can collapse.

3. While new gas tank straps are readily available, our examples were in good shape. We simply had them powdercoated semigloss black. Ground Up offers nice reproductions if your stock examples are used up.">

<strong>3</strong>. While new gas tank straps are readily available, our examples were in good shape. We simply had them powdercoated semigloss black. Ground Up offers nice reproductions if your stock examples are used up.

<strong>3</strong>. While new gas tank straps are readily available, our examples were in good shape. We simply had them powdercoated semigloss black. Ground Up offers nice reproductions if your stock examples are used up.

4. You may find your tank straps are in good shape, but the strap insulators usually aren’t and will need replacing. This kit is from Ground Up and includes the foam pads that go on top of the tank. These are antisqueak bits that are used to isolate the gas tank from the body.">

4. You may find your tank straps are in good shape, but the strap insulators usually aren’t and will need replacing. This kit is from Ground Up and includes the foam pads that go on top of the tank. These are antisqueak bits that are used to isolate the gas tank from the body.">

<strong>4</strong>. You may find your tank straps are in good shape, but the strap insulators usually aren’t and will need replacing. This kit is from Ground Up and includes the foam pads that go on top of the tank. These are antisqueak bits that are used to isolate the gas tank from the body.

5. Ground Up also offers the hardware you’ll need to install the tank, including new tank strap screws (they install at the forward mount location) and new adjustment bolts, nuts, and washers for the back side of the tank.">

<strong>4</strong>. You may find your tank straps are in good shape, but the strap insulators usually aren’t and will need replacing. This kit is from Ground Up and includes the foam pads that go on top of the tank. These are antisqueak bits that are used to isolate the gas tank from the body.

5. Ground Up also offers the hardware you’ll need to install the tank, including new tank strap screws (they install at the forward mount location) and new adjustment bolts, nuts, and washers for the back side of the tank.">

<strong>5</strong>. Ground Up also offers the hardware you’ll need to install the tank, including new tank strap screws (they install at the forward mount location) and new adjustment bolts, nuts, and washers for the back side of the tank.

9. Here’s how the RobbMC pickup looks installed in the Ground Up tank. The installation is easy: Drop the O-ring into the tank bung (be sure to use the proper O-ring; the RobbMC piece is smaller than stock), line up the pickup, and tighten the lock ring. As far as wiring for the gas gauge is concerned, the black wire is the ground. Not shown is the positive red wire that goes to the factory wiring harness connector.">

<strong>5</strong>. Ground Up also offers the hardware you’ll need to install the tank, including new tank strap screws (they install at the forward mount location) and new adjustment bolts, nuts, and washers for the back side of the tank.

9. Here’s how the RobbMC pickup looks installed in the Ground Up tank. The installation is easy: Drop the O-ring into the tank bung (be sure to use the proper O-ring; the RobbMC piece is smaller than stock), line up the pickup, and tighten the lock ring. As far as wiring for the gas gauge is concerned, the black wire is the ground. Not shown is the positive red wire that goes to the factory wiring harness connector.">

<strong>9</strong>. Here’s how the RobbMC pickup looks installed in the Ground Up tank. The installation is easy: Drop the O-ring into the tank bung (be sure to use the proper O-ring; the RobbMC piece is smaller than stock), line up the pickup, and tighten the lock ring. As far as wiring for the gas gauge is concerned, the black wire is the ground. Not shown is the positive red wire that goes to the factory wiring harness connector.

10. Holley offers a new billet inline fuel filter, which offers high flow and good filtering in a relatively small size. Internally, it makes use of a replaceable metal 100-micron filter element.">

<strong>9</strong>. Here’s how the RobbMC pickup looks installed in the Ground Up tank. The installation is easy: Drop the O-ring into the tank bung (be sure to use the proper O-ring; the RobbMC piece is smaller than stock), line up the pickup, and tighten the lock ring. As far as wiring for the gas gauge is concerned, the black wire is the ground. Not shown is the positive red wire that goes to the factory wiring harness connector.

10. Holley offers a new billet inline fuel filter, which offers high flow and good filtering in a relatively small size. Internally, it makes use of a replaceable metal 100-micron filter element.">

<strong>10</strong>. Holley offers a new billet inline fuel filter, which offers high flow and good filtering in a relatively small size. Internally, it makes use of a replaceable metal 100-micron filter element.

14. Here’s the larger-than-stock, ⅜-inch carb fuel line manufactured by Right Stuff Detailing. Aside from the facts that it’s larger and the Y-block doesn’t have a mount tab, it looks OE.">

<strong>10</strong>. Holley offers a new billet inline fuel filter, which offers high flow and good filtering in a relatively small size. Internally, it makes use of a replaceable metal 100-micron filter element.

14. Here’s the larger-than-stock, ⅜-inch carb fuel line manufactured by Right Stuff Detailing. Aside from the facts that it’s larger and the Y-block doesn’t have a mount tab, it looks OE.">

<strong>14</strong>. Here’s the larger-than-stock, ⅜-inch carb fuel line manufactured by Right Stuff Detailing. Aside from the facts that it’s larger and the Y-block doesn’t have a mount tab, it looks OE.

15. Drill bits slipped in the carb inlet nut openings tell the story. The little bit on the right is 7⁄32 inch, while the big one on the left is 9⁄32. That’s the difference in fuel restriction at the fitting.">

<strong>14</strong>. Here’s the larger-than-stock, ⅜-inch carb fuel line manufactured by Right Stuff Detailing. Aside from the facts that it’s larger and the Y-block doesn’t have a mount tab, it looks OE.

15. Drill bits slipped in the carb inlet nut openings tell the story. The little bit on the right is 7⁄32 inch, while the big one on the left is 9⁄32. That’s the difference in fuel restriction at the fitting.">

<strong>15</strong>. Drill bits slipped in the carb inlet nut openings tell the story. The little bit on the right is 7⁄32 inch, while the big one on the left is 9⁄32. That’s the difference in fuel restriction at the fitting.

16. You’ll need to clamp the lines during the installation. Ground Up stocks a wide variety of clamps and mount hardware as shown here. The gold-colored clamps actually fit over a ½-inch line.">

<strong>15</strong>. Drill bits slipped in the carb inlet nut openings tell the story. The little bit on the right is 7⁄32 inch, while the big one on the left is 9⁄32. That’s the difference in fuel restriction at the fitting.

16. You’ll need to clamp the lines during the installation. Ground Up stocks a wide variety of clamps and mount hardware as shown here. The gold-colored clamps actually fit over a ½-inch line.">

<strong>16</strong>. You’ll need to clamp the lines during the installation. Ground Up stocks a wide variety of clamps and mount hardware as shown here. The gold-colored clamps actually fit over a ½-inch line.

<strong>16</strong>. You’ll need to clamp the lines during the installation. Ground Up stocks a wide variety of clamps and mount hardware as shown here. The gold-colored clamps actually fit over a ½-inch line.