Air goes in, things go bang, and the air goes out. Sounds simple, doesn’t it? The process of an engine working can actually be broken down to that simple concept. The internal combustion engine is merely an air compressor that moves a given amount of air to create power. So, what happens if you add more air to the engine than it can physically draw in by its own created vacuum?

For years, people have been adding forced induction to just about every style of engine that has been created, and with today’s cars as easily “tunable” as they are, the possibilities are endless. But when it comes to forced induction, what’s right for you? Are you a supercharger or turbocharger kind of guy?

To make that decision, you first need to know what a turbo and supercharger have in common, and what their differences are. Both systems use a centrifugally-driven “compressor” to compress the engine’s incoming air to higher than normal atmospheric pressure, which is 14.7 psi by the way. When the compressor increases engine cylinder pressure, this means that more air is filling the cylinders. If there is more air present in the cylinders, that means that more fuel can also be added. This isn’t an overly technical explanation, but you get the point.

01 For this application, the shophemi.com twin turbo kit uses twin 58 MM Precision turbos. The piping is all handmade in-house, and is designed for the best flow, while not creating any ground clearance issues. All piping is stainless steel and then powdercoated."> <strong>01</strong> For this application, the shophemi.com twin turbo kit uses twin 58 MM Precision turbos. The piping is all handmade in-house, and is designed for the best flow, while not creating any ground clearance issues. All piping is stainless steel and then powdercoated.

02 The connection of the turbo system to stock SRT 8 exhaust manifolds is a very good “shorty” type of manifold/header. Shophemi.com prefers to use these stock manifolds, as they offer better exhaust flow and very good support of the turbo chargers.">

<strong>01</strong> For this application, the shophemi.com twin turbo kit uses twin 58 MM Precision turbos. The piping is all handmade in-house, and is designed for the best flow, while not creating any ground clearance issues. All piping is stainless steel and then powdercoated.

02 The connection of the turbo system to stock SRT 8 exhaust manifolds is a very good “shorty” type of manifold/header. Shophemi.com prefers to use these stock manifolds, as they offer better exhaust flow and very good support of the turbo chargers.">

<strong>02</strong> The connection of the turbo system to stock SRT 8 exhaust manifolds is a very good “shorty” type of manifold/header. Shophemi.com prefers to use these stock manifolds, as they offer better exhaust flow and very good support of the turbo chargers.

03 In this image, you can see that the turbo kit is a direct replacement for the factory intermediate pipe. Keep in mind, this kit does eliminate the factory catalytic converters.">

<strong>02</strong> The connection of the turbo system to stock SRT 8 exhaust manifolds is a very good “shorty” type of manifold/header. Shophemi.com prefers to use these stock manifolds, as they offer better exhaust flow and very good support of the turbo chargers.

03 In this image, you can see that the turbo kit is a direct replacement for the factory intermediate pipe. Keep in mind, this kit does eliminate the factory catalytic converters.">

<strong>03</strong> In this image, you can see that the turbo kit is a direct replacement for the factory intermediate pipe. Keep in mind, this kit does eliminate the factory catalytic converters.

04 In order for turbos to survive, they need oil. Shophemi.com has developed an undercar oiling system that properly feeds the turbos, does not hang below the exhaust. The external pump feeds the turbos and recirculates the oil.">

<strong>03</strong> In this image, you can see that the turbo kit is a direct replacement for the factory intermediate pipe. Keep in mind, this kit does eliminate the factory catalytic converters.

04 In order for turbos to survive, they need oil. Shophemi.com has developed an undercar oiling system that properly feeds the turbos, does not hang below the exhaust. The external pump feeds the turbos and recirculates the oil.">

<strong>04</strong> In order for turbos to survive, they need oil. Shophemi.com has developed an undercar oiling system that properly feeds the turbos, does not hang below the exhaust. The external pump feeds the turbos and recirculates the oil.

05 Once bolted together, the exhaust goes in. Our test car is an SRT Challenger with a 392, and a six-speed transmission.">

<strong>04</strong> In order for turbos to survive, they need oil. Shophemi.com has developed an undercar oiling system that properly feeds the turbos, does not hang below the exhaust. The external pump feeds the turbos and recirculates the oil.

05 Once bolted together, the exhaust goes in. Our test car is an SRT Challenger with a 392, and a six-speed transmission.">

<strong>05</strong> Once bolted together, the exhaust goes in. Our test car is an SRT Challenger with a 392, and a six-speed transmission.

<strong>05</strong> Once bolted together, the exhaust goes in. Our test car is an SRT Challenger with a 392, and a six-speed transmission.

When you compress air, a byproduct of this compression is that the temperature of that air increases. When forcing air into an engine, the trick is to not heat the air to a point that power is hampered. That’s why many boosted applications utilize an intercooler to cool the air before it enters the engine. Intercooling plays a huge role in controlling air temperature, but even the efficiency of the turbo or supercharger plays a part. The efficiency of a forced-induction system is rated by how much heat is introduced into the system as compared to the level of air compression that is created.

Since both a turbocharger and supercharger compress air, what’s the difference? The major difference is in the drive of the “charger.” A turbocharger’s compressor is connected directly to a turbine housing that is operated by the exhaust. The turbine takes exhaust energy and converts it to motion. Since the turbine and the compressor are connected by a shaft, when the turbine spins, the compressor spins at the same rate as the turbine. Since powered by the exhaust, a turbocharger does not place a direct mechanical load on the engine. Many feel that this is more efficient, because it uses the exhaust to drive the compressor instead of actual energy supplied by the engine. We also need to mention what is referred to as “turbo lag” or “spool time.” This is the amount of time between the throttle being opened, and the turbocharger actually providing increased intake pressure, thereby increasing horsepower. Turbo lag is inevitable, and occurs because turbochargers rely on the buildup of exhaust pressure to spin the turbine section of the turbocharger. In an automobile engine, the exhaust-gas pressure at idle and/or lower engine speed is not sufficient to drive the turbine fast enough to create boost. Boost (or pressure), is only developed when the engine rpm has reached a sufficient speed that the turbine starts to spin fast enough to produce pressure in the intake.

06 It might be a little hard to tell in this photo, but with the exhaust in place, you can see that nothing about the turbos hangs below the factory engine cradle. Now it’s time to install all of the piping. The piping will run from both turbos, to the intercooler, and then into the engine."> <strong>06</strong> It might be a little hard to tell in this photo, but with the exhaust in place, you can see that nothing about the turbos hangs below the factory engine cradle. Now it’s time to install all of the piping. The piping will run from both turbos, to the intercooler, and then into the engine.

07 With the exhaust in place, it’s time for oil line plumbing.">

<strong>06</strong> It might be a little hard to tell in this photo, but with the exhaust in place, you can see that nothing about the turbos hangs below the factory engine cradle. Now it’s time to install all of the piping. The piping will run from both turbos, to the intercooler, and then into the engine.

07 With the exhaust in place, it’s time for oil line plumbing.">

<strong>07</strong> With the exhaust in place, it’s time for oil line plumbing.

08 Install waste gate, check.">

<strong>07</strong> With the exhaust in place, it’s time for oil line plumbing.

08 Install waste gate, check.">

<strong>08</strong> Install waste gate, check.

09 One thing we were not able to do is take a picture of the intercooler being installed. We left the shop for just a minute, and when we came back, it was in place, and the piping was already being installed. Since compressing air heats the air, it must be cooled before getting to the engine.">

<strong>08</strong> Install waste gate, check.

09 One thing we were not able to do is take a picture of the intercooler being installed. We left the shop for just a minute, and when we came back, it was in place, and the piping was already being installed. Since compressing air heats the air, it must be cooled before getting to the engine.">

<strong>09</strong> One thing we were not able to do is take a picture of the intercooler being installed. We left the shop for just a minute, and when we came back, it was in place, and the piping was already being installed. Since compressing air heats the air, it must be cooled before getting to the engine.

10 Finish installing the air plumbing, and reinstall the bottom engine cover/splash shield.">

<strong>09</strong> One thing we were not able to do is take a picture of the intercooler being installed. We left the shop for just a minute, and when we came back, it was in place, and the piping was already being installed. Since compressing air heats the air, it must be cooled before getting to the engine.

10 Finish installing the air plumbing, and reinstall the bottom engine cover/splash shield.">

<strong>10</strong> Finish installing the air plumbing, and reinstall the bottom engine cover/splash shield.

11 We took this shot just before the bottom splash shield was installed. Here you get a better idea of how well the system tucks up into the car.">

<strong>10</strong> Finish installing the air plumbing, and reinstall the bottom engine cover/splash shield.

11 We took this shot just before the bottom splash shield was installed. Here you get a better idea of how well the system tucks up into the car.">

<strong>11</strong> We took this shot just before the bottom splash shield was installed. Here you get a better idea of how well the system tucks up into the car.

<strong>11</strong> We took this shot just before the bottom splash shield was installed. Here you get a better idea of how well the system tucks up into the car.

A turbo is not entirely “free” horsepower though. The turbine is literally a “blockage” in the exhaust, so some additional back pressure (exhaust flow restriction) is created by the turbine. But once the turbo starts to spin, the “blockage” is minimal. What this means is that the power “robbed” by the extra back pressure is very small.

Unlike a turbocharger, a supercharger is not powered by the exhaust gas, but is mechanically driven by the engine. While belts used to drive a supercharger place a mechanical load on the engine, the power used is more than overcome by the output of the supercharger. We must make note, though, that one disadvantage of supercharging is a lower adiabatic efficiency as compared to turbocharging. Adiabatic efficiency is the measure of a compressors ability to compress air without adding an excessive amount of heat to that air. The most widely used superchargers tend to use compressors that create significantly more heat to the air than their turbocharged counterparts. What this means is that for a given pressure and volume of air, turbocharged air is inherently cooler, which relates to a denser charge. A denser charge has the potential to create more power.

So what does this all mean? In theory, a turbo kit producing 8 psi of boost should produce more overall peak power, because a supercharger is using engine power just to get it spinning. What is more important when discussing a street car application is what’s known as “power under the curve,” or total average horsepower produced. A street car is very seldom driven at full throttle; therefore, the amount of power it creates while at less than full throttle -- or “under the curve” -- will directly affect performance, more so than while the engine is at full throttle. When more power is added to the bottom -- or lower end of the rpm range -- the car will be faster, even if peak power doesn’t change. This is where the turbo outperforms a supercharger, since you can have full boost at a lower rpm.

We decided that since we had covered supercharging in a previous issue (December 2013), we needed to find out if anyone reputable had developed a turbo kit for Mopars. We didn’t have to search very hard, and we found Arrington Performance/Shophemi.com. The guys at Shophemi.com have developed a kit that mounts two Precision turbos directly to the factory exhaust manifolds. Mounting the turbos close to the engine like this virtually eliminates turbo lag, it keeps the turbos well above the scrub line of the car, and when installed, it is virtually undetectable from looking under the car. Now, there are some things to keep in mind when using a turbo kit. Oiling the turbos is a huge concern. Without proper oiling, they will not last. With the turbos mounted low, the guys at shophemi.com developed a proprietary oiling system that keeps the turbos well-oiled and happy. There are different factors that need to be considered when you decide to install a shophemi.com turbo kit, and a single phone call to them will ensure that you get what you need.

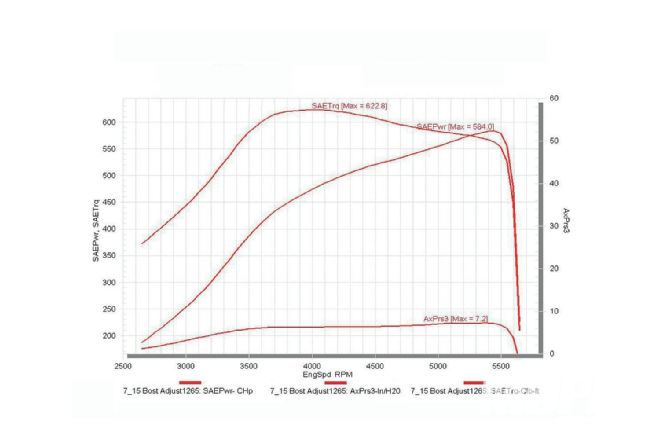

12 622.8 horsepower and 584 lb-ft of torque isn’t too shabby. Keep in mind, that’s with only 7 psi of boost. The guys at Arrington/shophemi.com told us that 6-7 psi is the most boost that they recommend on a stock engine. According to the guys at Shophemi, the system can produce 25 pounds or more on a properly prepped engine."> <strong>12</strong> 622.8 horsepower and 584 lb-ft of torque isn’t too shabby. Keep in mind, that’s with only 7 psi of boost. The guys at Arrington/shophemi.com told us that 6-7 psi is the most boost that they recommend on a stock engine. According to the guys at Shophemi, the system can produce 25 pounds or more on a properly prepped engine.

13 Power numbers will grow exponentially if the engine has the right modifications, and boost can be increased. This graph is from another Challenger that uses a “moderate” increase in boost pressure, but also utilizes an engine that has been built to withstand the pressure (i.e. forged internals). How does 1,098.9 horsepower sound in a daily driver?">

<strong>12</strong> 622.8 horsepower and 584 lb-ft of torque isn’t too shabby. Keep in mind, that’s with only 7 psi of boost. The guys at Arrington/shophemi.com told us that 6-7 psi is the most boost that they recommend on a stock engine. According to the guys at Shophemi, the system can produce 25 pounds or more on a properly prepped engine.

13 Power numbers will grow exponentially if the engine has the right modifications, and boost can be increased. This graph is from another Challenger that uses a “moderate” increase in boost pressure, but also utilizes an engine that has been built to withstand the pressure (i.e. forged internals). How does 1,098.9 horsepower sound in a daily driver?">

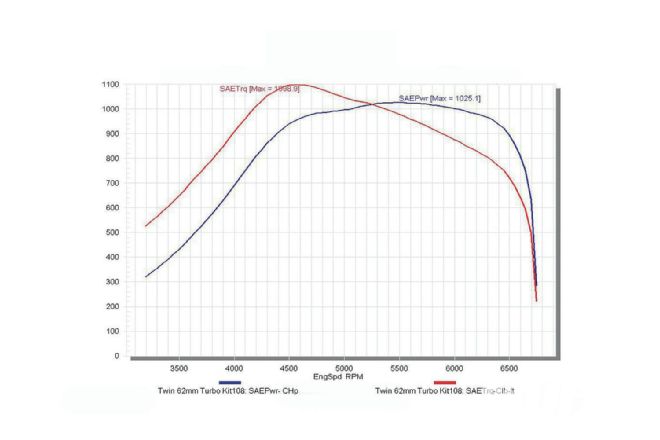

<strong>13</strong> Power numbers will grow exponentially if the engine has the right modifications, and boost can be increased. This graph is from another Challenger that uses a “moderate” increase in boost pressure, but also utilizes an engine that has been built to withstand the pressure (i.e. forged internals). How does 1,098.9 horsepower sound in a daily driver?

<strong>13</strong> Power numbers will grow exponentially if the engine has the right modifications, and boost can be increased. This graph is from another Challenger that uses a “moderate” increase in boost pressure, but also utilizes an engine that has been built to withstand the pressure (i.e. forged internals). How does 1,098.9 horsepower sound in a daily driver?

Costs for PN API-TTK-62: *$10,699.95

* Includes everything required. (Note: at this boost level it does not include a boost controller).