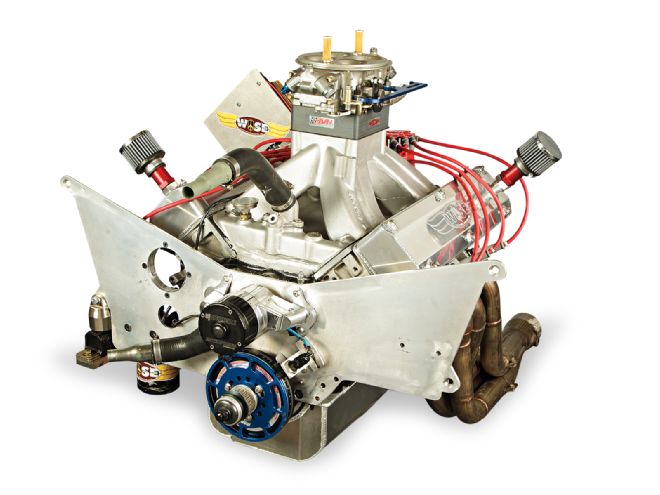

With a production run spanning the years from 1897 through 2004, Oldsmobile is an automobile brand with a strong history and tradition. That historical significance also included some of the finest muscle cars of the performance era, with vehicles like the 442 and Hurst Olds variants punctuating Oldsmobile power. Today, Oldsmobile lives on through a small but dedicated group of enthusiasts determined to keep Olds power alive. One such individual is Brad Wise of Wise Performance Engineering. Wise put Oldsmobile power on display by competing in our annual engine building competition, the AMSOIL Engine Masters Challenge, bringing an incredible 465-cube combination to the Xtreme Street Division of the 2012 event. After witnessing this stock-block Olds produce a peak of 876 hp in competition, we had to find out more about builder Wise, and his secrets to Oldsmobile power.

Building It

The foundation for this powerful build actually originated from what may be considered a footnote in automotive history. In the late 1970s, General Motors was eying the potential of diesel engines for passenger car use. In 1978, GM put into production a diesel V-8 based upon the Oldsmobile architecture, and these engines were installed in large numbers in a variety of General Motors cars and light trucks until production ended in 1985. The Olds diesel V-8 displaced 350 ci and was based upon the small-block Oldsmobile 350. This engine was not simply the gasoline powerplant converted to diesel, but rather an all-new assembly based upon an incredibly beefed engine block just for the purpose. The diesel program ended in what might be considered a failure, with complaints of inadequate reliability and poor power. Ironically, these Olds diesel blocks are just the ticket to massive power on gasoline.

To serve as a foundation for brutal Oldsmobile power Wise selected the production Oldsmobile 350 Diesel block. This massively reinforced version of the Olds V-8 was in production from 1978 to 1985 and is virtually indestructible in a gasoline race application.

To serve as a foundation for brutal Oldsmobile power Wise selected the production Oldsmobile 350 Diesel block. This massively reinforced version of the Olds V-8 was in production from 1978 to 1985 and is virtually indestructible in a gasoline race application.

In building his competition engine, Wise looked no further than the production Olds diesel. "The block is an Olds diesel piece, that's what we use for big power. They are extremely durable. The main webbing on them is about an inch thick, and we put four-bolt mains on them. These blocks all come from the factory with two-bolt mains and we designed a billet main cap for the block. We then do all the machine work to get it down to a 2.500-inch main, which is the standard Olds small-block dimension, since the diesels came with 3.00-inch mains. That's the beginning of the process." While the diesel engines were produced in massive quantities, the blocks are getting a little harder to find. Wise relates: "Surprisingly some guys will even sell them for scrap, but what they don't realize is this block is the basis for making Oldsmobile power."

Elaborating on the block and preparation process, Wise says: "It is a small-block, with a 9.310-inch deck height, which to me is perfect. The stroker combination works out really nice with that deck height. The big-blocks are 10.6250 inches, and that deck is a little too tall, their cranks are way too heavy, and they are just standard production blocks that were never designed for a racing application. They can do well, but considering the money and time you have to put into a block with a girdle and all that, they just don't last when you get the big power out of them. We bush the lifter bores of the diesel block because the factory lifters are 0.921 inch. You really can't find a lifter for that size, so we bush it and bring it down to 0.842 inch. I do a custom lifter and a custom lifter bore for that application. There are specific things that we do to it to make it work and provide for the oiling."

Wise reduces the main diameter from the diesel’s 3.00 inch to 2.500 inch, and adds custom four-bolt billet caps to replace the factory two-bolt units. The crank is produced locally from billet steel to Wise’s design specifications.

Wise reduces the main diameter from the diesel’s 3.00 inch to 2.500 inch, and adds custom four-bolt billet caps to replace the factory two-bolt units. The crank is produced locally from billet steel to Wise’s design specifications.

As a specialist company in Oldsmobile engines, Wise Performance Engineering had plenty of experience to draw from in developing this combination: "We designed this engine based upon a lot of the other engines we build. We had a solid engine combination that we knew made power. This was our first Engine Masters competition, and at 465 ci I think the engine was too big to be ideal under the competition rules, but it was a learning experience for us. We knew we had a great combo, and it makes big power."

Filling the Oldsmobile diesel block, Wise relies on parts that have been proven in years of building racing Olds engines, "I have been using the GRP rods forever. We buy the blanks and then machine them up to whatever configuration we want. We use pro-material aluminum rods. It keeps the weight down; these are only around 497 grams, and you can really zing them up. This engine is actually good for 9,300 rpm, and I did some things to bring the rpm range down to the rpm range of the competition. In the high-rpm configuration, the engine is capable of 943 hp on our dyno. Likewise, I've been using Ross pistons forever. They are really good to work with; their turnaround time is very quick, and I've been very happy with the product. Each piston is a little different, and with the cylinder heads in this particular application we had a little bit of a dish in the pistons for a compression ratio of 15:1. The rings are Speed-Pro .043 inch with a 3mm oil ring, running with gas ports in the pistons."

Even with a stroke of 4.085-inch replacing the factory 3.385-inch specification, and adding aluminum rods, clearance modifications to the Olds block are minimal.

Even with a stroke of 4.085-inch replacing the factory 3.385-inch specification, and adding aluminum rods, clearance modifications to the Olds block are minimal.

The crankshaft is actually a billet steel unit developed by Wise Performance Engineering, "There are no forgings for Oldsmobiles. None. There used to be, but those days are gone, and no one wants to put the money into doing a forging. I can get a billet crank done at a reasonable cost. We designed our own billet crankshaft, and I have them made locally using all American-made materials. For this engine we wanted to keep the stroke under 4.100 inches. Most of our cranks are 4.00-inch stroke, that is our standard deal. On this particular engine we tried a little more stroke in it and the engine really liked it. We were impressed with the torque when we dyno'd the engine. We do back-to-back dyno'ing, and when we added that little bit of stroke to 4.085 inches, it really like it, and in down-track performance it was killer. It was one of those things we tried, and it really worked out well."

Power Parts

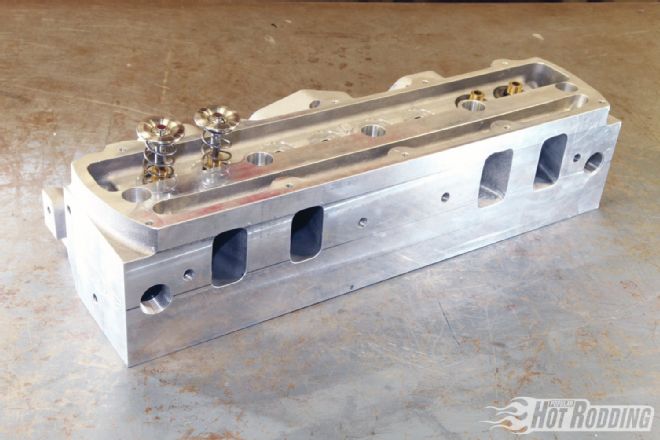

The custom roller cam from Cam Motion is proprietary. Wise explains: "It is a specific cam that we have been working with for 15 years. I have several of them and they are very similar. When we have the cylinder head, intake manifold, and compression, the cam gets matched to that. Our cams specs are very private—I don't like to give that away. Lift is around .800 inch. Those particular cylinder heads, the way they flowed, and where, and all the other parameters, that cam worked really well with those. I was very happy with the cam." [Wise was obligated under competition rules to disclose cam specs for publishing, and his official spec sheet listed .849-inch lift, and 262/300 degrees duration at .050-inch lift. -ed.] The custom camshaft is linked to the valves via a set of Manley pushrods operating a custom set of T&D rockers with a ratio of 1.8/1.7:1. The rockers are actually custom made for the Wise-modified Batten aluminum heads, and are specific for that application.

Elaborating on the cylinder heads, Wise explains, "The heads are Batten Olds cylinder heads from back in the 1980s. We have a CNC program for these cylinder heads and they do very well. We don't mess around with the factory valve angle because the 6-degree angle is almost optimal. There is a reason why the Chevys and Fords go with a flatter valve angle—they found they make more power with a flatter valve. We go with that and just make a good port design and a good chamber.

With a valve angle of just 6 degrees, the Oldsmobile chamber is very shallow and compact. Filling the chambers are Victory titanium valves measuring 2.250 inches (intake), and 1.600 inches (exhaust).

With a valve angle of just 6 degrees, the Oldsmobile chamber is very shallow and compact. Filling the chambers are Victory titanium valves measuring 2.250 inches (intake), and 1.600 inches (exhaust).

"There is nothing to like about these antique 1980s cylinder head castings. The material is not that great, and it's soft, and they move around. By contemporary standards, the actual design is not very good. What we do is take raw castings and weld them up and put our own chamber and our own ports in them. To solve this problem we have designed and manufacture a brand-new cylinder head. When we went into this with a clean sheet of paper, I looked at it and had to decide what we wanted to do with it. I wanted inline valves, just like stock. I wanted the stock valve angle and bolthole location. I wanted all that to be stock Oldsmobile so everything will bolt up. From there we looked at the port design, and we straightened everything up on CAD. We will debut these new heads at the 2013 AMSOIL Engine Masters Challenge."

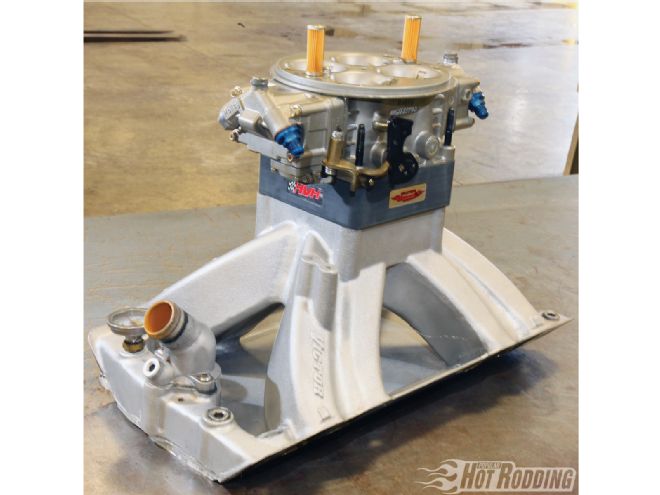

Feeding the reworked heads is an induction featuring Edelbrock's Victor manifold and a Dominator carb. Wise explains that the induction has a dramatic influence on the power curve: "We've done a lot of testing and with this intake and its long runners we have found a tremendous amount of torque. I manipulate the powerband with certain things I do inside the intake manifold and the carburetor spacing. That is what dictates our rpm range. The carb is a 1050 Holley Dominator. It is one of our dyno carburetors and is a one-off piece. It is something we do."

To replace the long out-of-production Batten head castings, Wise has developed an all-new Oldsmobile racing cylinder head. The clean-sheet design will offer Olds fans a modern cylinder head compatible with traditional Oldsmobile engines.

To replace the long out-of-production Batten head castings, Wise has developed an all-new Oldsmobile racing cylinder head. The clean-sheet design will offer Olds fans a modern cylinder head compatible with traditional Oldsmobile engines.

Tuning the engine combination continues to the exhaust side, as Wise tells us: "The header was designed by dyno testing over and over. The runner length, size, shape, and entry size are all developed by testing. The result is this three-step header, and it made 40 more horsepower than any other header. There is a lot in headers, and a lot of people just don't realize it; we found power just by changing collector length. For this header we used a 1⅞-inch first step, and that is what created the torque we needed for this application. I could have gone with a 2.0-inch and it would make more power, but it would change the rpm level. For the Engine Masters competition, the smaller first primary step was right. The headers use a merge collector with a 2¾-inch choke and goes back out to a 3-inch collector. That choke really makes a difference. In the testing we have done we've found a very small change in the choke can make a quite a bit of difference."

Dyno Time

The engine was dressed with a Meziere electric water pump and an MSD ignition system, including an MSD Digital 7 Plus programmable control box, and a Wise-modified Moroso crank trigger. Bolted to the DTS Powermark engine dyno at the University of Northwestern Ohio, this hot Oldsmobile combination had the opportunity to prove its worth. Running on VP Q16 race fuel, the Olds showed a power curve that was staggering for a production-based Olds small-block. With a healthy 465 ci built into the diesel block, the torque curve displayed massive twist, recording 672 lb-ft at 6,200 rpm. Obtaining peak torque that high in the curve illustrated that breathing and airflow was available in abundance from the extensively modified heads and induction. Where there is giant torque at high rpm, mass quantities of horsepower are sure to follow. In this department the Olds delivered the goods, posting a peak of 876 hp at 7,400 rpm. That is power that will shove an Oldsmobile down track in a real hurry!

Edelbrock’s Victor intake manifold features long runners for strong torque production, and the flow that a radical Oldsmobile needs. Topped with a Wise-modified Holley Dominator, the capacity is available to feed outrageous horsepower.

Edelbrock’s Victor intake manifold features long runners for strong torque production, and the flow that a radical Oldsmobile needs. Topped with a Wise-modified Holley Dominator, the capacity is available to feed outrageous horsepower.

As Wise tells us, "Getting the heads to make serious power with the Oldsmobile engine has always been the difficulty. We put a great deal of effort to get the most of the old castings that were available, and this engine shows the success of that effort. What we are doing now is taking things to a new level of performance and parts availability with our all-new head castings. This will open the door for more horsepower for Oldsmobile fans everywhere." We appreciate the efforts and unwavering enthusiasm of Oldsmobile specialists like Wise Performance Engineering in keeping Olds performance alive and well.

Wise uses internal manifold modifications and spacer height to tune the rpm range and torque for a targeted application. Note the extensive porting to the intake and the tall HVH-tapered carb spacer.

Wise uses internal manifold modifications and spacer height to tune the rpm range and torque for a targeted application. Note the extensive porting to the intake and the tall HVH-tapered carb spacer.

BY THE NUMBERS 465CI OLDSMOBILE Bore: 4.255 inches Stroke: 4.085 inches Displacement 465 ci Compression ratio: 15:1 Camshaft: Cam Motion solid-roller Valve lift: 0.800 inch Rocker and ratio: T&D 1.7/1.8 Piston rings: Speed-Pro .043/.043/3mm Piston: Ross forged Block: OEM Olds diesel production Crankshaft: Wise Billet Rods: GRP aluminum 6.180-inch Cylinder head: Batten Olds Intake valve diameter: 2.250 inches Exhaust valve diameter: 1.600 inches Intake manifold Edelbrock Victor Carburetor: Holley 4500 Header: ARH 1⅞-inch step Ignition: MSD Damper: ATI

ON THE DYNO 465CI OLDSMOBILE RPM: TQ: HP: 4,000 558 425 4,200 583 466 4,400 579 485 4,600 574 503 4,800 597 545 5,000 617 588 5,200 634 628 5,400 652 683 5,600 657 701 5,800 663 733 6,000 669 765 6,200 672 794 6,400 671 817 6,600 667 839 6,800 661 856 7,000 653 870 7,200 637 874 7,400 622 876 7,600 602 871 7,800 580 861 8,000 558 850