So, we've reached the end of our regular series of BIDBI write-ups, and it only seems appropriate to end with a "greatest hits" of sorts. We'll show you a quick nip/tuck we did to an ill-fitting oil pan, dip into the mail bag, and fondly recall some bits of the highlight reel from the last several months.

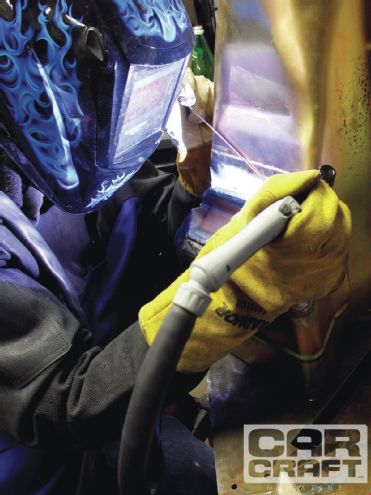

You could have done this whole job with a MIG welder, but we ran out of wire in our machine and had to switch to our Diversion 180 TIG welder and ER70-S2 filler wire. Note the use of a heavier MIG glove on the hand holding the TIG torch. The torch gets hot, and so does the work surface. The heavy glove allowed us to hold the torch very close to the tip while bracing our hands on the hot oil pan without getting burned. After fully welding the patch panel, we filled the pan with water to check for leaks. This oil pan is now on a V8-swapped S-10 Blazer street-racer truck.

You could have done this whole job with a MIG welder, but we ran out of wire in our machine and had to switch to our Diversion 180 TIG welder and ER70-S2 filler wire. Note the use of a heavier MIG glove on the hand holding the TIG torch. The torch gets hot, and so does the work surface. The heavy glove allowed us to hold the torch very close to the tip while bracing our hands on the hot oil pan without getting burned. After fully welding the patch panel, we filled the pan with water to check for leaks. This oil pan is now on a V8-swapped S-10 Blazer street-racer truck.

Reader William Baer of Braidwood, Illinois, emailed to show us his homemade transmission stand. He cut sections of 11⁄4-inch square tubing in a shape that fits a Chevrolet bellhousing bolt pattern and welded them to a piece that fits the rotating head of his engine stand. Thanks, William! We always say we have the smartest readers in the business.