Robert Stefanik from Corning, New York asks...

Can I stroke an AMC 290 V8 using parts from larger AMC engines?

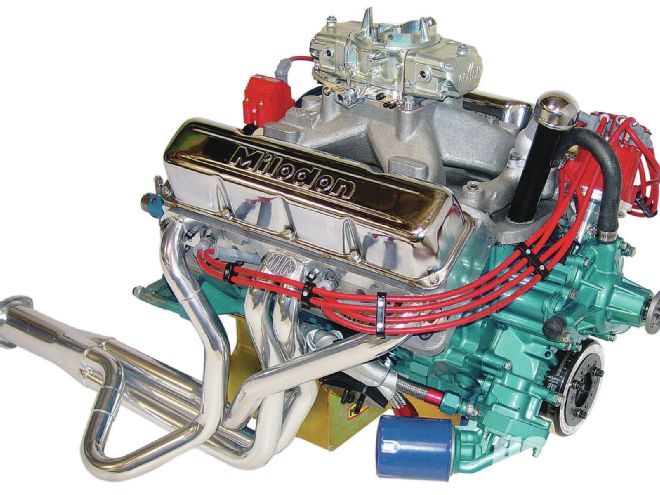

Only big-bore blocks can fully utilize modern heads and big valves, so consider dropping in an AMC 360, 390, or 401 in place of a small-bore 290 or 304. With Indy SR aluminum heads and a custom Comp Cams solid cam, Westech Automotive’s 11.5:1 AMC 390 made 515.3 lb-ft and 541.5 hp on pump premium unleaded. For details, see our Aug. ’04 print edition or sister pub JP Magazine’s website, JPMagazine.com.

Only big-bore blocks can fully utilize modern heads and big valves, so consider dropping in an AMC 360, 390, or 401 in place of a small-bore 290 or 304. With Indy SR aluminum heads and a custom Comp Cams solid cam, Westech Automotive’s 11.5:1 AMC 390 made 515.3 lb-ft and 541.5 hp on pump premium unleaded. For details, see our Aug. ’04 print edition or sister pub JP Magazine’s website, JPMagazine.com.

Q: I am looking to buy a 1969 AMC Rebel with the 290. Parts are hard to find for the motor and car. Can I put 304 parts in the motor to stroke it and give me more horsepower? Where can I get body parts like panels, brake and gas lines, and other parts needed to restore the car? Are there any EFI kits for the engine?

A: As the accompanying tables indicate, there are lots of mix-and-match possibilities for American Motors Corporation (AMC)—but there are also some subtile differences that can really bite you on the posterior if you’re not careful. Also don’t overlook the fact that you can still get 290 replacement pistons from Egge under PN L2247. Pistons, complete overhaul kits, and comprehensive suspension parts are also available from Kanter.

Let’s look at AMC interchange from the bottom up, starting with the basic cylinder block.

Block: Externally, AMC 290 through 401 blocks share the same basic design. The major differences are in deck height (crank centerline to top of block) and cylinder-bore diameters. The ’66–’69 engines had a blueprint deck height of 9.175 inches; later blocks are 9.208. This affects intake-manifold, pushrod, and piston interchange.

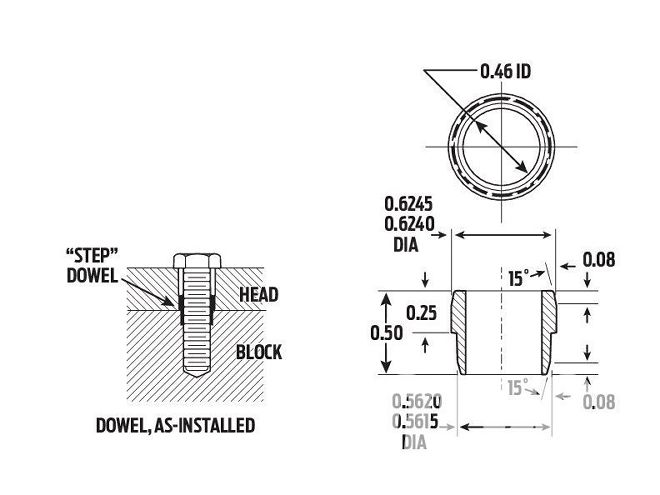

Four special stepped locating dowels are needed to install ’70-and-later heads on earlier blocks. Fabricate from SAE 1112 cold-rolled steel to these dimensions. Use ’70-and-later head gaskets that have larger holes to accommodate the dowels. If your early block is going to the machine-shop anyway, consider having its 7⁄16-inch head bolt holes drilled and tapped to ½ inch.

Four special stepped locating dowels are needed to install ’70-and-later heads on earlier blocks. Fabricate from SAE 1112 cold-rolled steel to these dimensions. Use ’70-and-later head gaskets that have larger holes to accommodate the dowels. If your early block is going to the machine-shop anyway, consider having its 7⁄16-inch head bolt holes drilled and tapped to ½ inch.

Crank: AMC offered four factory stroke lengths: 3.28-inch for the 290/343, 3.44 inches for the 304/360, 3.574 for the 390, and 3.680 inches for the 401. All have the same 2.747-inch main-journals, so any crank will fit in any ’66-and-later AMC V8 block, though the 290/304 small-bore blocks must have the bottom of their cylinder bores clearance-ground to clear a 390 or 401 crank’s larger counterweights.

Although the main journals are all the same, there are two rod-journal sizes: 290/304/343/360 nodular-iron cranks have 2.09-inch rod journals, while forged-steel 390/401 cranks have 2.248-inch journals.

Connecting rods: There are three factory rod lengths. The 290/304/343/360 iron rods measure 5.875 inches center-to-center and were only available in relatively weak malleable iron. Like their cranks, 390/401 rods were forged steel. The ’68–’69 390 rods are 5.790 inches, but when the deck height was raised in ’70, the 390 went to 5.8558-inch rods, the same as all 401s. Note that ’72-and-later 401 rods have smaller weight pads on the small end and should only be interchanged as a matching set. Modern, forged, H-beam, AMC-style rods are available from Scat and Wiseco.

AMC V8s have used three different rod lengths: 290/304/343/360, early 390, and late 390/401. Only 390 and 401 rods are forged, and they also have larger journals and piston pin diameters. Early and late 390 rods are shown here: ’68-’69 (left) is 5.790-inch center-to-center; the ’70 design (right) is 5.858 inches.

AMC V8s have used three different rod lengths: 290/304/343/360, early 390, and late 390/401. Only 390 and 401 rods are forged, and they also have larger journals and piston pin diameters. Early and late 390 rods are shown here: ’68-’69 (left) is 5.790-inch center-to-center; the ’70 design (right) is 5.858 inches.

Pistons and pins: Piston compression heights (the distance from the pin hole centerline to the top of the piston flat) can vary by stroke and deck-height. Currently available stock-replacement aftermarket pistons are sometimes slightly shorter than originals, apparently to compensate for typical rebuilt, decked blocks.

Assuming the same bore and stroke, pistons listed for the later high-deck engines can sometimes be used in the earlier low-deck blocks to obtain near zero deck-heights, which is good for compression and quench (in some cases, minor piston top shaving may be necessary). Watch out for piston-pin-diameter differences: It’s 0.9306 inch for 290/304/343/360 engines, but 1.0006 inch for the 390/401. Many aftermarket pistons are machined for 0.927-inch small-block Chevy pins, which would mandate bushing the stock AMC rods to obtain proper clearance.

Crank rear-flange difference: From what we’ve reported so far, you’d think it would be a no-brainer to install a 3.44-inch-stroke 304/360-style crank in a 290 using 304 pistons and 290/304/343/360 rods to obtain a near-zero deck-height. That would solve your parts availability problem because 304s and 360s are by far the most common AMC V8s out there. Wait, not so fast: Starting in ’72, AMC changed the rear crank-flange configuration. An early manual trans would simply require a later flywheel, but with the earlier automatic, either the crank flange must be modified or an adapter fabricated. In other words, what started out as a “simple” crank swap has just gotten a lot more complicated. Of course, most consider the late TorqueFlite automatic trans to be a much better piece than the old Borg-Warner automatic you have now—but if going for a late trans, why pour money into an old, small-displacement engine when you can move up to the late trans plus a widely available late-model AMC 360 engine with a large bore that can take advantage of the latest aftermarket cylinder head technology? No replacement for displacement, I say. The 360s are easiest to find in late Jeep Wagoneers.

Engine balance: Yet another hurdle is that all AMC V8 engines are externally balanced, plus (at least as originally built on the production line) were weight-matched to each displacement, model-year, and even individual vehicle. AMC gurus like California Classic AMC’s Tony Zamisch say, when swapping cranks, you need to grab the harmonic damper and the flywheel or flexplate with the crank from the same donor engine—or have a machine-shop rebalance the entire rotating assembly.

Cylinder heads: Well, what about just a head swap? This is slightly more practical, but again, there are some things you need to watch out for. Any ’66-and-up head can be made to fit any ’66-and-up engine. However, ’66–’69 heads (and their original corresponding blocks) use 7⁄16-inch head-bolts; ’70-and-up use ½-inch bolts. To install the later heads on earlier blocks, either fabricate stepped locating dowels and use special stepped washers, or drill and tap the block deck for the later, larger, ½-13 head bolts. To install earlier heads on the later blocks, ream the heads’ 7⁄16-inch head-bolt holes out to ½ Inch.

Normally, you would not want to install earlier heads on the later blocks, because ’70-and-later heads have vastly improved dog-leg exhaust ports that—even in stock form—provide 50 percent better exhaust flow than the ’69-and-earlier rectangular exhaust ports. That’s why AMC engine builders typically go the other way and install the doglegs on earlier engines.

The 343-and-larger engines have bigger valves than the 290/304. Installing big-valve heads on a small-bore 290/304 block is possible by notching the cylinder bores for clearance. The notch depth is contingent on cam profile and final cylinder-bore size (the 290/304 can be bored up to 0.125-inch oversize). Stock 290/304 piston valve-pockets may also require enlargement. When all is said and done, most AMC experts say installing big-valve heads on the small-bore blocks isn’t worth the trouble because the narrow bores excessively shroud the larger valves.

Instead, the best cost-effective head solution for the small-bore engines is a ’70-and-later small-valve, dogleg, 304 head. If you can find a set, the ’70-early-’71 304 doglegs (casting No. 319 9517 for small-bore 290/304) had 52cc chambers (compared with 59 cc for later 304 heads), which offers a little more compression. For those of you running large-bore engines, the equally rare, ’70-early-’71, small-chamber, big-valve, dogleg head is casting No. 319 6291. Any set of heads can be improved with a good three-angle valve job, pocket-porting, and port-matching the intake manifold.

If the cap on this AMC stock points distributor looks like an old GM unit, it’s because it is. Delco supplied AMC’s points distributors, and PerTronix’s bolt-on Igniter electronic ignition conversion kit for an AMC points distributor is the same one PerTronix sells for the common small-block Chevy: PN 1181.

If the cap on this AMC stock points distributor looks like an old GM unit, it’s because it is. Delco supplied AMC’s points distributors, and PerTronix’s bolt-on Igniter electronic ignition conversion kit for an AMC points distributor is the same one PerTronix sells for the common small-block Chevy: PN 1181.

Valvetrain: Starting around ’74, AMC heads are machined for bridge-style rockers. Earlier engines had stud-mounted rockers. Both are nonadjustable in stock form, but the earlier stud-style valvetrain is easier to convert to an adjustable-style configuration.

Intake manifolds: Due to deck-height differences, ’66–’69 intakes differ from ’70-and-later. To prevent attempts at interchange, the spacing of the two center intake-to-head bolt holes on each side is slightly different. The problem is which intake manifold to use if swapping late dogleg heads onto the earlier block. The choices are either filing/elongating the center intake manifold bolt-holes on an early intake to match the later head’s relocated holes, or machining down a late intake manifold’s gasket face to compensate for the cylinder block’s different deck height. Edelbrock and Offenhauser offer early- and late-style AMC intakes.

Exhaust manifolds: Headers or stock exhaust manifolds must match the cylinder heads’ exhaust port configuration: early (rectangular) or late (dogleg). Note that most header companies don’t call out the Rebel specifically in catalog listings. However, AMC engine compartments of the same vintage are pretty similar; for sure, headers listed for a Rambler or Ambassador should fit.

Edelbrock’s Pro-Flo 2 AMC EFI system features fully sequential firing and is tunable via a laptop PC or by its unique handheld calibration module. Systems include everything needed for the conversion, including an intake and distributor. PN 35300 is for ’69-and-earlier; PN 35310 fits ’70–’91. They support up to 450 hp with their included 29-lb/hr injectors.

Edelbrock’s Pro-Flo 2 AMC EFI system features fully sequential firing and is tunable via a laptop PC or by its unique handheld calibration module. Systems include everything needed for the conversion, including an intake and distributor. PN 35300 is for ’69-and-earlier; PN 35310 fits ’70–’91. They support up to 450 hp with their included 29-lb/hr injectors.

Ignition system: AMC began using electronic ignitions in ’75, but it was a weird Prestolite setup. The ’78-and-later engines have more reliable Ford-type Duraspark II distributors and modules. Either will work on an earlier engine. MSD also has AMC distributors.

Electronic fuel injection (EFI): AMC never put modern EFI on its factory-built V8s, staying with a carburetor until production ended in 1991. Edelbrock offers turnkey Pro-Flow 2 electronic fuel-injection systems for both early and late AMC engines. You could also use any of the throttle-body-based “self-learning” conversions from MSD, Holley, or FAST.

Restoration parts: Comprehensive AMC restoration parts specialists include American Parts Depot, Blaser Auto, California Classic AMC, Dale Cooper, and Galvin’s. For interior parts you might also try Legendary Auto Interiors. If you can’t find fuel and brake lines at the comprehensive vendors’ sites, contact Classic Tube or Inline Tube; they have patterns for just about everything, even if it’s not listed in the standard catalog. Failing that, the tubing specialists in the Contacts box can fabricate lines off your samples.

AMC Production V8 Engine Specifications

All dimensions in linear inches, except as noted. Advertised CI 290 304 343 360 390 401 Actual CI 289.8 303.9 343.1 359.8 389.6 401.1 Model Years ’66½–’69 ’70–’81 ’67–’69 ’70–’91 ’68–’69 ’70 ’71–’79 Bore 3.75 4.08 4.165 Stroke 3.28 3.44 3.28 3.44 3.574 3.68 Block Deck-Height 9.175 9.208 9.175 9.208 9.175 9.208 9.208 Con-Rod Length 5.875 5.790 5.858 Piston Compression Height* 1.600 1.601 1.600 1.601 1.575 (’69 S/S AMX) 1.553 (others) 1.553 1.508 Deck Clearance 0.060 0.012 0.060 0.012 0.023 (’69 S/S AMX) 0.045 (others) 0.010 0.002 Main Journal Diameter 2.7472 Rod Journal Diameter 2.0944 2.2481 Piston Pin Diameter 0.939 1.0006 Intake Valve 1.787 2.025 2.080 (’69 S/S AMX) 2.025 (others) 2.025 Exhaust Valve 1.406 1.625 1.625 (early ’70) 1.68 (’70½–and up) 1.740 (’69 S/S AMX) 1.625 (others) 1.625 (Early ’70) 1.680 (Late ’70) 1.680 Combustion Chamber Volume 54 cc (’66–’68) 52 cc (’69) 52 cc (’70–early ’71) 59 cc (’71½–and up) 53 cc (’67–’68) 51 cc (’69) 51 cc (’70–early ’71) 58 cc (’71½–and up) 58 cc (’69 S/S AMX) 51 cc (others) 51 cc 51 cc (’71 early) 58 cc (’71½-and up) *Calculated by subtracting from other official published AMC blueprint specs. Currently available replacement piston compression heights can be up to 0.020-inch shorter—which correspondingly increases the deck clearance unless the block is milled to compensate.

AMC V8: Max Overbore Recommendations

All dimensions in linear inches. Block Standard Bore Size Max Overbore Amount Max Overbore Size 290-304 3.75 0.125 3.875 343-360 4.08 0.045 4.125 360 Special* 4.08 0.1075 4.1875 390-401 4.165 0.0225 4.1875 *A limited number of special blocks were reputedly installed in ’70 Javelins to meet SCCA Trans Am race-series homologation requirements. They have thicker walls than standard 360 blocks. The lower main-webs are beefed up and can be drilled and tapped for four-bolt caps (caps not factory-installed).

AMC V8: Engine Combos Using Stock Cranks

Production ci ratings with the stock bore and stroke are shown below in red. Other possible combinations attainable by swapping production parts into stock-bore blocks are shown in blue. Remember, rods and pistons must be compatible with the bore-size, stroke, crankshaft rod-journal diameter, and cylinder-block deck-height. All dimensions are in linear inches. Bore Stroke 3.28 3.44 3.574 3.68 3.75 290 304 316* 325* 4.08 343 360 374 385 4.165 358 375 390 401 *When installing in a 3.75-inch-bore 290/304 block, must notch cylinder bores 0.060–0.090 inch for minimum crank-throw clearance.

Ask Marlan A Tech Question: [email protected]