Tuning your engine with the aid of an air/fuel meter can really help you dial in your carburetor. But what numbers should you aim for?

When people talk about the air/fuel ratio of their engine, do you get confused? Do they really know what they’re talking about, or did they just hear someone mention it in another conversation? Another term you might hear mentioned when talking about A/F (air/fuel) ratio is Stoich or Stoichiometric. Stoichiometric mixture is the working point that engines attempt to achieve during different load or cruise situations. Say for instance you want to set your “Stoich” to the proper setting while your car is cruising down the road at approximately 2,400 rpm. While that setting might help you get the best economy from your engine, put the engine under load or at wide open throttle for an extended period of time, and you’ll likely be so economical (lean) that you’ll be walking. In theory, a proper Stoichiometric mixture has just enough air to completely burn the available fuel. In actuality though, this “proper mix” is never completely achieved. This is due primarily because of the very short time available during an engine’s combustion cycle. Most of the actual combustion process is comple.ted in approximately 4 to 5 milliseconds at an engine speed of 6,000 rpm. This is the elapsed time from when the spark plug fires, until the actual burning of the fuel and air mixture is essentially complete.

Like we said, the best mixture or A/F ratio that gives you the best fuel economy is nowhere near ideal for maximum power. A widely-accepted proper A/F ratio number for achieving maximum power is with a Stoichiometric reading between 12.8:1 to 13.2:1. Keep in mind though, that number is for a non-oxygenated pump gas that in order to be efficiently burned, has an ideal ratio of 14.7:1. There is generally a particular ratio of air to fuel that results in all of the oxygen molecules combining chemically with all of the fuel molecules. This ratio is 14.7:1, meaning 14.7 parts of air for every 1 part of fuel. Running an engine at this particular air/fuel ratio helps to minimize emissions and maximize fuel economy, but again, this air/fuel ratio is generally not safe for an engine to run at high rpm and/or heavy engine-load conditions. Since most oxygen sensors produced are only meant to accurately measure a 14.7:1 air/fuel ratio, they shouldn’t be used in applications where much richer or leaner target air/fuel ratios are selected, such as that with fuels like E85, and alcohol. The wide-band oxygen sensor used with those fuels is capable of accurately measuring a much wider range of air/fuel ratios.

Reading the spark plugs can get you really close in regards to tuning, but how many people really understand what they are seeing. An air/fuel meter makes it simple.

Reading the spark plugs can get you really close in regards to tuning, but how many people really understand what they are seeing. An air/fuel meter makes it simple.

Using fuel injection makes achieving Stoich a lot easier than if you’re using a carburetor, as the electronics that control the actual injection requirements, can take into account, the inlet air temperature, the actual air/fuel ratio, engine coolant temperature, and/or a myriad of other readings to adjust the amount of fuel that is delivered.

A concern about reaching a proper Stoichiometric mixture is that it unfortunately burns very hot, and can damage engine components if the engine is placed under high load at this air/fuel ratio. Due to the high temperatures at this mixture, detonation right after maximum cylinder pressure is possible during high load conditions (detonation is often referred to as knocking or pinging). Detonation can cause serious engine damage as the uncontrolled burning of the air/fuel mix can create very high pressures in the cylinder. As a consequence, true Stoichiometric mixtures are only used under light load conditions. For acceleration and high load conditions, a richer mixture (lower air/fuel ratio) is used to produce cooler combustion products and thereby prevent detonation and overheating of the cylinder head.

What happens if you are putting the commonly available E10 mixture of pump gas in your Mopar? E10 is common at gas pumps in many parts of the country, and what about your race car that requires a high octane race fuel?

Installation is fairly simple, and only required a hot and ground wire to be connected in addition to the O2 sensor cables. We welded the O2 sensor bungs onto our dyno’s exhaust system to complete the installation.

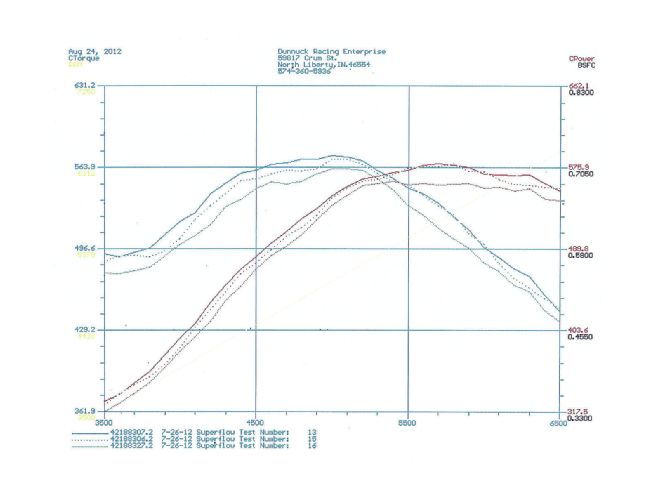

We had our trusty 421-inch small block on our dyno from previous testing, so we filled the dyno’s fuel cell with VP110 race fuel to work with the engine’s 13.0:1 compression ratio. The carburetor is a Quick Fuel Q950. Previous tuning had left us with 88 jets front and rear, with no power valves, and number 30 main air bleeds. We set the fuel pressure at 7 psi and made a full sweep from 3,000 to 7,000 rpm. Our A/F ratio showed our tune to be very rich, with an average of 11.8:1. Reading the spark plugs showed us that the engine was still burning clean.

One thing some tuners don’t pay much attention to is how fuel pressure affects tuning. To show this, we left the rest of the tune the same and dropped our fuel pressure to 6 psi. By dropping pressure 1 psi, our A/F reading went to an average of 12.8:1, and also showed a loss in power throughout the pull.

We put the fuel pressure back to the previous 7 psi and made a change to the air bleeds, changing them from number 30’s to number 33’s. When tuning with air bleeds, it is important to note that a change in air bleed sizing can often change the shape of the fuel curve and cause an engine to be too rich or lean in a different rpm range than just changing a jet. With the air bleed change, our average A/F reading was now 13.2:1, which is where most people will tell you to run. In our case, our power was down even further than before. Knowing that a dyno loads the engine differently than how it will run at the dragstrip, we looked for a car we could next test our theories on.

To test our theory at the track, we had an opportunity to work with a street/strip car that runs on premium pump fuel. The ‘69 Satellite belonging to Scott Dunnuck has an engine based on a stock 440 bottom end , and is equipped with Edelbrock Performer RPM heads, a Holley Street Dominator intake, a Holley-based 830 carburetor with a Proform main body, and a custom solid flat-tappet camshaft. We brought the Satellite to our local ¼-mile test track filled with 93 octane E10 Fuel, and again hooked up the FAST air/fuel me.ter to both sides of the exhaust.

04] The easy to navigate on screen display makes for an easy setup. The F.A.S.T. Air/Fuel Meter has built-in data logging capability and plays back logged information on the lighted display screen, without requiring downloading to a computer. Additional features include outputs for external data loggers and gauges, and a narrow-band simulator function that allows you to feed your engine’s computer a factory signal, while using the wide-band sensor for air/fuel measurement and adjustments.

04] The easy to navigate on screen display makes for an easy setup. The F.A.S.T. Air/Fuel Meter has built-in data logging capability and plays back logged information on the lighted display screen, without requiring downloading to a computer. Additional features include outputs for external data loggers and gauges, and a narrow-band simulator function that allows you to feed your engine’s computer a factory signal, while using the wide-band sensor for air/fuel measurement and adjustments.

A baseline run showed an average reading of 12.0:1, and the Satellite turned in a ¼-mile e.t. of 12.28 at 109.78 mph. We then jetted the carburetor down from 80’s in the front (with a 6.5 power valve) and 88’s in the rear, to 76’s in the front and 84’s in the rear. This leaned our A/F readings to an average of 13.0:1, and also slowed the car down to the tune of 12.47 at 107.59 mph.

We decided to go back up on our jetting to just slightly leaner than our baseline. We installed 78 jets in the front and 86’s in the rear. This brought our average A/F reading to 12.4:1, and resulted in a ¼-mile e.t of 12.33 at 109.23 mph.

There are many reasons why your engine might want a different A/F ratio than someone else’s. The type of fuel you are using, how efficient your engine is, even air quality can affect it. Our best advice is to try adding a little more fuel and see how your engine responds.

We have noticed through testing that an engine that is slightly lean will lose power faster than the same engine that is slightly rich. We also need to remember that most enthusiasts are measuring these A/F reading in one or two exhaust pipes, after all the cylinders have merged via a set of headers at the collector or exhaust manifolds. Due to fuel distribution issues, you may need to add fuel to the engine to keep one or more cylinders from being too lean. Unless you are measuring each cylinder and making changes that fix these distribution issues, you have to keep the leanest cylinder happy. This can lead to a richer than “ideal” A/F reading.

Although our testing was aimed at maximum horsepower and/or minimum e.t., an A/F meter can also be used to dial in better fuel economy by tuning for a more efficient ratio while at cruising rpm. We can also can it to monitor accelerator pump shot effectiveness, and the point at which fuel enrichment circuits start to come in. Even though both of our combinations wanted similar A/F numbers for best performance, remember that every engine and fuel combination is different and your resulting A/F ratio may be different.

Using an A/F meter and testing is the best way to find out what your combination likes. We have tried the old “jet it for best mph” routine before just to find out our car was running extremely rich through a good portion of the ¼-mile. Achieving an A/F ratio that is correct throughout the entire range may take more than just a simple jet change. Changing the jet/air bleed combination can get you the extra fuel you need at a certain point in the run. A/F readings can definitely help you figure out which direction to go if you let it be your guide and don’t get hung up on the numbers.

If you use one on the street, it is probably best to take a passenger with you to take notes while watching the meter so you can pay attention to the road. Taking readings while going up a steep grade can show where an enrichment circuit adds too much extra fuel.

Cost for F.A.S.T. Dual sensor A/F meter: $481.95

08] Manipulating horsepower is as easy adjusting fuel pressure. With the fuel pressure at 7 psi, our tune was rich, with an average of 11.8:1. We left the rest of the tune the same and dropped our fuel pressure to 6 psi. By dropping pressure 1 psi, our A/F reading went to an average of 12.8:1, and also showed a loss in power throughout the pull. We put the fuel pressure back to 7 psi and changed the air bleeds them from number 30’s to number 33’s. With the air bleed change, our average A/F reading was now 13.2:1, which is where most people will tell you to run. In our case, our power was down even further than before.

08] Manipulating horsepower is as easy adjusting fuel pressure. With the fuel pressure at 7 psi, our tune was rich, with an average of 11.8:1. We left the rest of the tune the same and dropped our fuel pressure to 6 psi. By dropping pressure 1 psi, our A/F reading went to an average of 12.8:1, and also showed a loss in power throughout the pull. We put the fuel pressure back to 7 psi and changed the air bleeds them from number 30’s to number 33’s. With the air bleed change, our average A/F reading was now 13.2:1, which is where most people will tell you to run. In our case, our power was down even further than before.