Hands On

The whiners can complain all they want about LS engine stories in Car Craft, but when Ken Duttweiler bolted on a Magnuson supercharger on a 390ci LS engine with really good heads and dished up more than 1,000 hp at 6,200 rpm, it would have been a crime to keep the story to ourselves. If you want to complain about something, let's talk about how impossible it will be to hook 900 lb-ft of torque up to the pavement with street tires. That's a good problem to have. It all started when we walked into Kenny Duttweiler's shop on a Friday morning. He had just warmed up this supercharged LS engine after making a small pulley change. He fired it up and ran it through the power curve, and we watched as 1,020 hp blazed up on the computer screen. That was no fluke. For the rest of the day Duttweiler and Left Coast 32 company owner Joe Delano whipped this supercharged LS at least 20 more times, and every time that engine spun past 6,000 the dyno recorded four-digit power numbers. We were witnessing a clinic on how to make epic horsepower. We decided right there we had to know what was inside this beast. Granted, this power was on VP 109 race gas, but that's a small price to pay for this kind of power. And, no, this isn't a race motor. It's going in, of all things, a '32 Ford destined for the standing mile. But enough fluff, let's get down to the easy info on the hard parts.

Start It Up

With supercharged LS engines, you don't shoot for 1,000 hp using a stock aluminum block. In fact, you don't even try it with a stock iron LQ9 block. Duttweiler says you need to head straight for a Chevrolet Performance LSX iron block. Yes, they're heavy and, yes, they're expensive. But that's what you need to do the job right. You may have heard about Duttweiler's recent successes at Bonneville building turbocharged, small-displacement engines for the George Poteet and Ron Main's Speed Demon 400-mph streamliner. Duttweiler took a cue from that effort when building this supercharged LS engine for Delano. Instead of stuffing in a long-stroke crank, Duttweiler went with a stock 3.62-inch stroke only because, "At the time, I couldn't find a shorter stroke crank." He also said he'd like to try building a similar engine with an even shorter 3.30 stroke (355 ci) to see if that would possibly be even more efficient. By pushing the bore out to 4.140, this puts the displacement at 390 inches and leaves room to go larger at a later date if necessary. There is plenty of room since the LSX block is capable of a 4.200-inch maximum bore size. The reason Duttweiler went with the short stroke was an attempt to minimize windage problems inherent with the deep skirt LS block.

The rotating assembly came from Callies in the form of a Dragonslayer 3.62-inch stroke 4340 steel forged crank, and a set of Callies Ultra connecting rods pinned to a set of Diamond dished LS pistons. The pistons, along with a tight quench and Fel-Pro MLS gaskets, put the compression at a very streetable 9.5:1. Next on the list was a camshaft to match this rotating package. For this application, Delano wanted to use a hydraulic roller camshaft from a company in Las Vegas called Leading Edge Performance. He kept the intake duration relatively conservative at 240 degrees (with more on the exhaust) while the lift jumped up 0.738 inch. The key for supercharger use is to widen the lobe- separation angle (LSA) to minimize overlap, which prevents the boost pressure from pushing right out the exhaust valve at lower engine speeds. This cam came in with a 115-degree LSA, which you can see by the power curve does its job very well.

Supercharged LS: Heads and Valvetrain

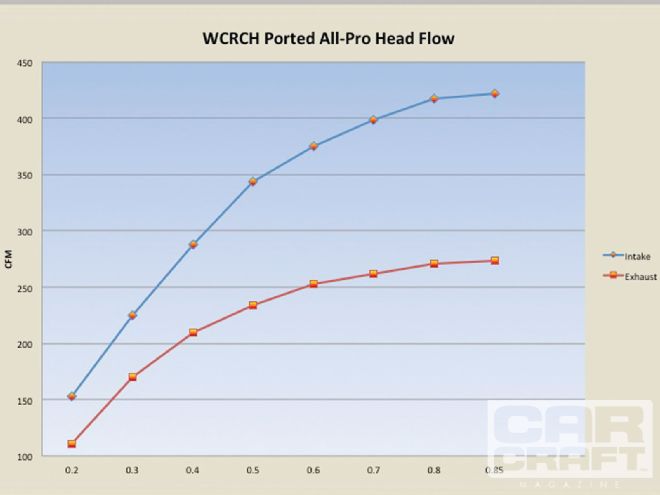

The key to big-time power in any engine is good cylinder heads. Here is where Duttweiler and Delano overachieved. All Pro has been a force in cylinder heads for many years, mostly in the circle track market. They supplied Richard Reyman at West Coast Racing Cylinder Heads (WCRCH) with a set of LS castings that Reyman then placed in his CNC machine for a five-axis rework. The flow numbers are in the accompanying chart (page 18), but with nearly 400 cfm available at max lift, these heads are a rock-'n'-roll dream. Not only are the peak numbers impressive, but the mid- and low-lift numbers are equally good. This is especially important because with good flow numbers comes flow velocity around the valve seat. As the valve approaches the seat on closing, the piston is also nearing TDC and pressure in the chamber is increasing. With good velocity and positive manifold pressure, the blower can push more air and fuel into the cylinder and make more power. Good flow numbers make this job easier. With all these great parts, Duttweiler also wanted to ensure a stable valvetrain, so he opted for a set of Jesel shaft rockers that reduce deflection, which helps on the valve lift side of things. Finally, Delano also added a set of billet LS valve covers and coil covers from Granatelli Motorsports to give the engine a little bit of visual flash.

Power to the People

After that quick tour through the internals on this animal, we return to the dyno room to witness the result of all this assembly work. Even though this engine will be used in a '32 Ford, he retained the stock GM ECU, using a copy of HP Tuners to set up the positive manifold pressure fueling. One important aspect of this tuning includes ensuring that the fuel pressure is boost-matched to the manifold pressure. This usually means at least 1 psi of fuel pressure for every 1 psi of positive manifold pressure. This is required to maintain the original fuel pressure in the manifold. Generally, the LS engines run at 58 psi. So at 18 psi of boost, the fuel pressure ascends from 58 psi to 76 psi.

With the fuel and spark maps tuned, Duttweiler landed on 26 degrees of total ignition timing as the peak power number. This may seem like a small number compared to the old days of small-block Chevys requiring 40 degrees of lead. What this really indicates is excellent combustion chamber efficiency. Basically, less ignition timing means the engine can initiate the combustion process later and still maximize cylinder pressure at around 15 degrees after top dead center (ATDC) where the piston can exert maximum leverage on the crankshaft. Lower total timing numbers also reduce negative work because the engine doesn't have to expend energy to overcome increasing cylinder pressure in the combustion space approaching TDC. To reinforce the idea this is a great street engine, Duttweiler also checked the leak-down after two whole days of abuse and dozens of dyno pulls and saw less than 1 percent leakage from the Total Seal Gapless rings.

As you can see from the dyno curve on page 22, this engine makes some astounding power. Let's start with 900 lb-ft at 3,600 rpm. This massive torque means you don't need nearly as much torque converter stall speed to get the car moving or nearly as much rear gear as leverage to accelerate the vehicle. We plugged this power curve into the Quarter, Pro dragstrip simulation, and with a 3,500-pound car with a 3.31:1 rear gear and a TH400 trans with a 3,000-rpm stall speed converter (assuming you can hook it up—our simulation showed tire spin all the way through the 60-foot mark), we saw 9-teens at 151 mph. That is some serious acceleration and fully capable of sub-9-second times. Plus, best of all this combination would fit under all but the lowest hood line and does not demand all the custom plumbing of a pair of turbochargers. Sure, the Magnuson kit is expensive—but look at the power you're making. Folks, the days of a 900hp street engine are here and bangin' on the front door. Better let 'em in!

Often, a big inlet port can suffer from weak flow numbers at lower lifts. But these WCRCH 310cc intake ports are strong, flowing 225 cfm at 0.300-inch valve lift..

Often, a big inlet port can suffer from weak flow numbers at lower lifts. But these WCRCH 310cc intake ports are strong, flowing 225 cfm at 0.300-inch valve lift..

WCRCH-Ported All-Pro Head Flow

Valve Lift Intake CFM Exhaust CFM Exhaust/Intake 0.200 153 111 72% 0.300 225 170 75% 0.400 288 210 73% 0.500 344 234 68% 0.600 375 253 67% 0.700 398 262 66% 0.800 417 271 65% 0.850 422 273 65%

Power Curves

RPM TQ HP Fuel (lb/hr)* BSFC Boost 3,600 907 622 379 0.621 20.6 3,800 912 660 406 0.612 20.8* 4,000 938* 715 429 0.600 20.6 4,200 937 749 448 0.598 20.3 4,400 937 785 461 0.588 20.5 4,600 937 820 486 0.593 19.8 4,800 932 851 505 0.594 20.3 5,000 932 887 523 0.590 20.2 5,200 933 923 542 0.587* 20.0 5,400 925 951 560 0.589 19.8 5,600 912 973 577 0.593 19.8 5,800 901 995 588 0.591 19.9 6,000 885 1,010 594 0.588 19.7 6,200 867 1,023* 607 0.594 19.4 6,400 833 1,015 645 0.636 18.9

*BSFC is an evaluation of how efficiently the engine uses fuel, expressed as pounds of fuel per horsepower per hour, or lbs/hp-hr. Generally, a normally aspirated engine is very efficient at 0.450 lbs/hp-hr. Roots style supercharged engines always exhibit higher BSFC numbers because they require additional fuel to make power to drive the blower. In this case, at 20 psi with a 2.3L supercharger, it requires roughly 150 hp to drive the blower. This means that the engine was actually making around 1,165 gross horsepower. The engine also makes 2.61 hp per cubic inch.