Q: I am building a 1976 Chevy Vega. When completed, it should weigh about 2,900 pounds, driver included. My intention is for it to be a high-revvin' street car. It has a Vortec 350 block, GM LT4 HOT Cam, Dart SHP heads, and an Edelbrock Torker II intake. It is equipped with a 700-R4 trans and 4.10:1 rear gears. I plan on using a 650-cfm carb with an electric choke. Should I go with vacuum or mechanical secondaries? What about the new Street Demon carb that allows for adjusting the secondary?

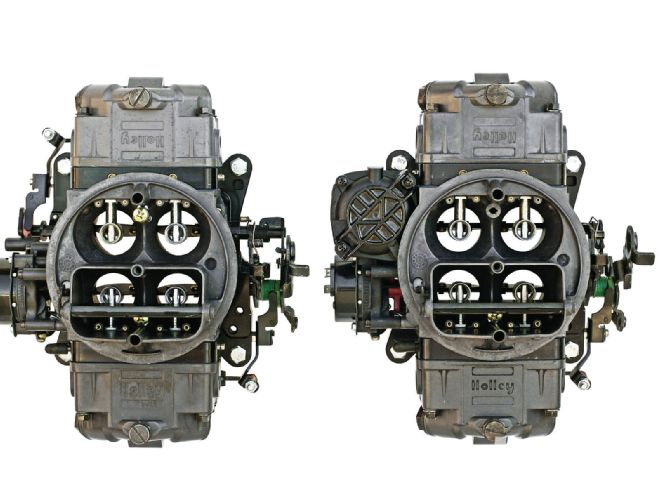

Just what the doctor ordered for Buttrum’s Vega: New Holley aluminum-bodied carbs come with either vacuum secondaries (Ultra Street Avengers) or mechanical secondaries (Ultra Double-Pumpers). Both have four-corner idle circuits, clear fuel-level sight windows, and a factory-installed electric choke (the latter is a first for a double-pumper). Available in red, blue, black, and hard-core gray (shown); the gray 650-cfm double-pumper (left) is PN 76650HB; the 670-cfm vacuum secondary is PN 86670HB.

Just what the doctor ordered for Buttrum’s Vega: New Holley aluminum-bodied carbs come with either vacuum secondaries (Ultra Street Avengers) or mechanical secondaries (Ultra Double-Pumpers). Both have four-corner idle circuits, clear fuel-level sight windows, and a factory-installed electric choke (the latter is a first for a double-pumper). Available in red, blue, black, and hard-core gray (shown); the gray 650-cfm double-pumper (left) is PN 76650HB; the 670-cfm vacuum secondary is PN 86670HB.

A: This question has been debated ever since Holley (and similar-style carbs) gave hot rodders a choice between vacuum or mechanical secondaries. However, regardless of secondary actuation method, virtually any four-barrel carb can be tuned to affect how the secondary-side responds.

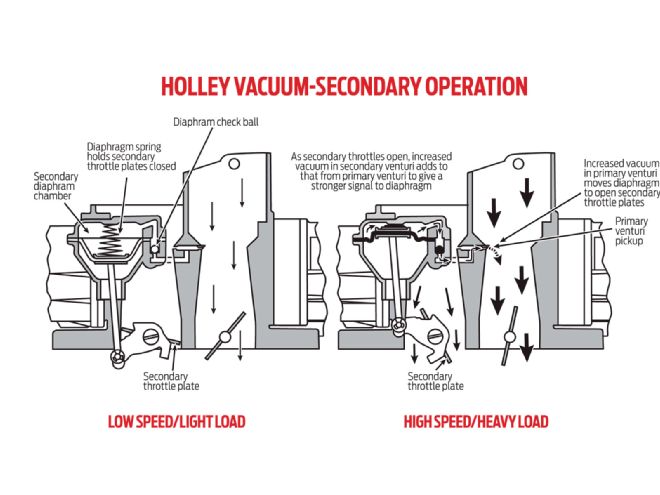

Controlled-secondary carb: The most common four barrel configuration, this type of carb operates only on the primary side until a certain amount of airflow is attained. In the Holley world of controlled-secondary carbs, a vacuum diaphragm plus a diaphragm spring controls secondary throttle-blade opening. Vacuum for the diaphragm is supplied initially from one of the primary venturis. As rpm increase, so does velocity through the primary venturi, resulting in a progressively stronger vacuum signal. Once the signal reaches a certain threshold, suction against the diaphragm overcomes the tension of the diaphragm spring, allowing the secondary throttle plate to begin opening. This in turn establishes flow in the secondary venturis. When this occurs, the primary vacuum signal will be augmented by vacuum from one of the secondary venturis. The rate of secondary opening is therefore regulated by the amount of vacuum through the venturis versus the tension of the diaphragm spring. Up to a point, hot rodders can tune the opening rate via different-tension diaphragm springs.

The other popular style of controlled-secondary actuation is by means of an air valve (also known as an auxiliary throttle valve). You can find variations of air-valve actuation on the Rochester Quadrajet, as well as on Carter carburetors and their descendents such as the Edelbrock (AFB and AVS clones) and the Street Demon (an evolution of the old ThermoQuad).

A vacuum signal from the primary venturi initiates secondary actuation. As the secondary throttle blades open, the initial signal is augmented by an increasing signal from the secondary venturi until the secondaries fully open. When rpm decrease to the point at which secondary airflow isn't needed, the check ball in the diaphragm's vacuum-supply passage blows off its seat, instantly releasing vacuum from the diaphragm and allowing the return spring behind the diaphragm, plus airflow acting against the throttle blades that are offset on the throttle shaft to close the throttle. There's also a mechanical override link that ensures postivie secondary closure whenever the primaries close.

As used on Carter-style carburetors, manifold vacuum and air velocity regulate the secondary opening rate instead of venturi bleed vacuum. The air valve is located above the throttle plates and is held closed by either a spring (on a ThermoQuad) or a counterweight (on original AFB carbs). In this design, mechanical linkage starts the secondary opening process, which induces manifold vacuum to start pulling airflow through the venturis. The manifold vacuum signal in turn starts to open the air valve. At this point, ever-increasing airflow through the venturi progressively opens the air valve even more. Theoretically—assuming the rest of the carb is properly tuned—this makes for very smooth-opening secondaries. On a ThermoQuad-style carb and its descendents, you can tune the opening rate by increasing or decreasing the secondary throttle-valve spring pressure.

A lighter secondary vacuum diaphragm spring allows the secondary throttle plates to open more quickly. Use Holley’s spring assortment kit (PN 20-13) to tailor the secondary opening rate. Avengers come with a quick-change diaphragm-cover kit (available separately under PN 20-59) that cuts in half the time required to change the secondary spring.

A lighter secondary vacuum diaphragm spring allows the secondary throttle plates to open more quickly. Use Holley’s spring assortment kit (PN 20-13) to tailor the secondary opening rate. Avengers come with a quick-change diaphragm-cover kit (available separately under PN 20-59) that cuts in half the time required to change the secondary spring.

Controlled-secondary carbs may offer more flexibility in a setup where airflow velocity through the boosters is insufficient for good throttle response. Because it feeds the engine only as much air and fuel as it will accept at different rpm and load ranges, a controlled-secondary carb has the ability—within reason—to self-adjust to engine size and offer more tuning flexibility on mild engine and drivetrain combos. This type of carb can provide a broader operating range than would normally be practical for a given-size carburetor.

Properly tuned, controlled secondaries should deliver superior fuel economy compared with a mechanical-secondary configuration—which is one reason most OE-application Holley carbs back in the muscle-car days had vacuum secondaries. Their broad adaptability for a wide range of engine sizes also means Holley doesn't need to offer a large variety of vacuum-secondary carbs with different cfm ratings. For example, if you use a 750-cfm vacuum-secondary carb on an engine that only needs 650 cfm, the vacuum secondaries probably won't open fully (even with the softest diaphragm spring), so it's pretty hard to over-carburete a controlled-secondary configuration.

Mechanical-secondary carb: On this configuration, the secondary throttles are operated exclusively by a direct mechanical link from the primaries. Most of the mechanical-secondary Holley-type carbs we're familiar with have progressive linkage that delays the secondary opening until the primaries have opened about 40 percent. In addition to the typical primary-side accelerator-pump circuit, most mechanical-secondary carbs have an additional accelerator-pump circuit for the secondary venturis that ensures adequate fuel supply when the throttle slams open (hence the “double-pumper" moniker). Without such additional fuel enrichment, a bog could result at low rpm due to insufficient signal for initiating main-system fuel flow.

A mechanical-secondary carb's enrichment characteristics are regulated by the accelerator-pump capacity, the accelerator-pump cam configuration, and (most important) the accelerator-pump nozzle-size (aka the pump “shooter" or “squirter"). All can be tailored to fine-tune the fuel curve, developing smooth linearity with no bog or hesitation in a performance motor. However, dialing in a double-pumper requires more effort and know-how than the more forgiving controlled secondary design. In summary, mechanical-secondary carbs are much more sensitive to engine size, drivetrain gearing, vehicle weight, and rpm range compared with the controlled secondary configuration, which is why the double-pumpers are offered in many more cfm ratings than the vacuum-secondary carbs.

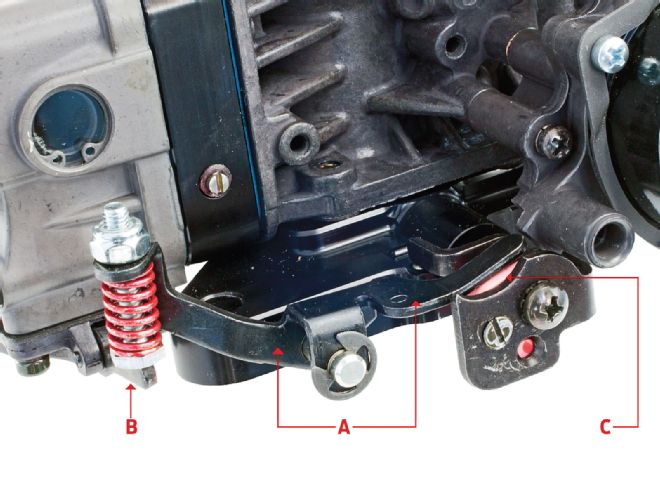

Fine-tuning the secondary accelerator pump is key to avoiding a bog when mechanical secondaries open. The pump arm (A) must move as soon as the throttle blades open; Holley recommends 0.015-inch clearance, measured between the arm and pump lever (B) at WOT. After the proper nozzle size is determined, a different pump cam (C) can further tailor accelerator-pump actuation. Use cam-assortment kit PN 20-12.

Fine-tuning the secondary accelerator pump is key to avoiding a bog when mechanical secondaries open. The pump arm (A) must move as soon as the throttle blades open; Holley recommends 0.015-inch clearance, measured between the arm and pump lever (B) at WOT. After the proper nozzle size is determined, a different pump cam (C) can further tailor accelerator-pump actuation. Use cam-assortment kit PN 20-12.

In a no-holds-barred performance application, a mechanical-secondary carb does have advantages over a controlled-secondary configuration. Assuming it's properly sized and fine-tuned for the application, due to its quicker-opening secondaries, when you slam the throttle full-open, a double-pumper carb has the potential to generate better throttle response and make more power than a controlled-secondary carb with the same airflow (cfm rating). Until its secondaries fully open, a controlled-secondary carburetor has more pressure drop under the throttle plates compared with the mechanical-secondary unit; less pressure drop below the throttle plates translates into the engine receiving a denser air/fuel charge. Greater charge density translates into higher engine output.

That dovetails with the importance of sizing a double-pumper correctly. If intake-manifold vacuum is low, velocities and signals are also low. The only thing to tide you over on a double-pumper is the pump shot—but the larger the carb, the higher the airflow needed to start the main system. If the mechanical-secondary carb is too large for the application, the pump shot gets used up before the main system starts, resulting in hesitation or bog.

Specific recommendations: So how does all this apply specifically to your 350 Vega? From the information provided, you appear to be right on the bubble. Ground with a 112-degree lobe-separation angle, your GM LT4 HOT cam has 218/228 degrees duration at 0.050, and a valve lift of 0.492/0.492 inch with 1.5:1 rockers or 0.525/0.525 inch with the 1.6:1 rockers it's really designed for. In a 350 Chevy, it should make peak power around 5,500 rpm, which means you need to shift around 6,000 rpm to remain in the torque/powerband “groove." That's not really “high revvin'" in the small-block-Chevy scheme of things. I'm also assuming that with a stock 350 Vortec-era short-block, even with the 64cc-combustion-chamber version of Dart's SHP aluminum heads, the static compression ratio still comes in under 10.0:1. You didn't share the auto trans' torque converter stall-speed, so again I'm assuming a stock or near-stock configuration at around 2,000 rpm or lower. A single-plane intake manifold like the Torker II is not as strong down low as a modern high-rise, dual-plane configuration. (I'm guessing you're using it because it clears the stock Vega hood.) Taken as a whole, this fairly mild setup generally calls for a vacuum-secondary carb. On the other hand, the Vega's fairly stout 4.10:1 rear gears, plus its light weight (less than 2,900 pounds with driver and fuel), is a configuration that generally behaves well with a double-pumper.

Changing the nozzle size (arrow) is the primary means for tuning the accelerator pump. Larger nozzles deliver fuel faster than smaller nozzles. Holley says to change them in three-step increments; for example, go from a No. 28 (0.028 inch) to a No. 31 (0.031 inch). Use a hollow pump screw with a No. 40-or-larger nozzle. Consider a 50cc pump if you need a No. 37 or larger pump nozzle.

Changing the nozzle size (arrow) is the primary means for tuning the accelerator pump. Larger nozzles deliver fuel faster than smaller nozzles. Holley says to change them in three-step increments; for example, go from a No. 28 (0.028 inch) to a No. 31 (0.031 inch). Use a hollow pump screw with a No. 40-or-larger nozzle. Consider a 50cc pump if you need a No. 37 or larger pump nozzle.

In this instance, and because the Vega is primarily street-driven, I would say the features that weigh in favor of selecting a vacuum-secondary carb slightly outweigh those in favor of a mechanical-secondary carb. Specifically, I'm concerned about the possible lack of low-end signal on the single-plane Torker II intake, mild torque converter, and low compression ratio. Now if you were willing to install a modern, high-rise, dual-plane intake (which probably calls for a hoodscoop on your car), and the true compression ratio is actually 10.0:1 or higher, in a lightweight car like the Vega, the double-pumper would be the better choice if you are willing to invest the time and effort required to properly dial it in.

In fact, regardless of the carburetor's secondary actuation method, good dual-plane intakes like the Edelbrock Performer RPM (PN 7101) or Air-Gap with isolated runners (PN 7501), and the Weiand Stealth (PN 8150) or Stealth Air Strike with isolated runners (PN 8501) will outperform the Torker II, extending the rpm band both down low as well as on the top end.

On the ThermoQuad or Street Demon carb, the secondary air-valve door is tunable. Using a flat-blade screwdriver, engage the adjusting screw, then loosen the locknut. Turn the screw clockwise to decrease tension and permit the door to open sooner and counterclockwise to increase spring tension and delay opening.

On the ThermoQuad or Street Demon carb, the secondary air-valve door is tunable. Using a flat-blade screwdriver, engage the adjusting screw, then loosen the locknut. Turn the screw clockwise to decrease tension and permit the door to open sooner and counterclockwise to increase spring tension and delay opening.

And yes, a 650-cfrm carb (give or take 25 cfm) would indeed be in the ballpark for your application.

Use a Controlled-Secondary Carb If... Use a Mechanical-Secondary Carb If... A controlled-secondary (vacuum-secondary) carb is probably the best choice if the majority of the following factors apply to your combo: A double-pumper (mechanical-secondary) carb is probably the best choice if the majority of the following factors apply to your combo: Off-road/all-terrain racing Drag racing, road racing, and oval-track racing where allowed by the rules The car is primarily used on the street The car is not a fulltime daily driver Fuel economy is important Fuel economy is not a primary concern Part-throttle driveability and sustained highway cruising at lower rpm is a primary concern Maximum full-throttle performance and top-end power is a primary concern Torque is more important than power Power is more important than torque The camshaft duration at 0.050-inch tappet lift is less than 230 degrees (based on a typical 350ci engine) The camshaft duration at 0.050-inch tappet lift is 230 degrees or higher (based on a typical 350ci engine) Max engine speed is 6,000 rpm or less, especially if using a single-plane intake manifold Max engine speed is 6,500 rpm or higher with any intake or 6,000 rpm or higher with a good dual-plane, high-rise intake The car weighs more than 3,500 pounds (including driver and fuel) The car weighs less than 3,500 pounds (including driver and fuel) The engine has 9.5:1-or-less true static-compression ratio The engine has a 10.0:1 or higher true static-compression ratio The car has a manual transmission with a 2.56:1 or numerically higher First-gear ratio and a 3.55:1 or numerically lower rearend ratio The car has a manual transmission with a 2.56:1 or numerically higher First-gear ratio and a 3.70:1 or numerically higher rearend ratio The car has a manual transmission with a 2.20:1 or numerically lower First-gear ratio and a 4.10:1 or numerically lower rearend ratio The car has a manual transmission with a 2.20:1 or numerically lower First-gear ratio and a 4.56:1 or numerically higher rearend ratio The car has a two-speed automatic transmission with a 2,500-rpm or lower torque-converter stall speed and a 4.10:1 or numerically lower rearend ratio The car has a two-speed automatic transmission with a 2,800-rpm-or-higher torque-converter stall speed and a 4.56:1 or numerically higher rearend ratio The car has a three- or four-speed automatic transmission with a 2,000-rpm or lower torque-converter stall speed and a 3.55:1 or numerically lower rearend ratio The car has a three- or four-speed automatic transmission with a 2,300-rpm-or- higher torque-converter stall speed and a 3.70:1 or numerically higher rearend ratio