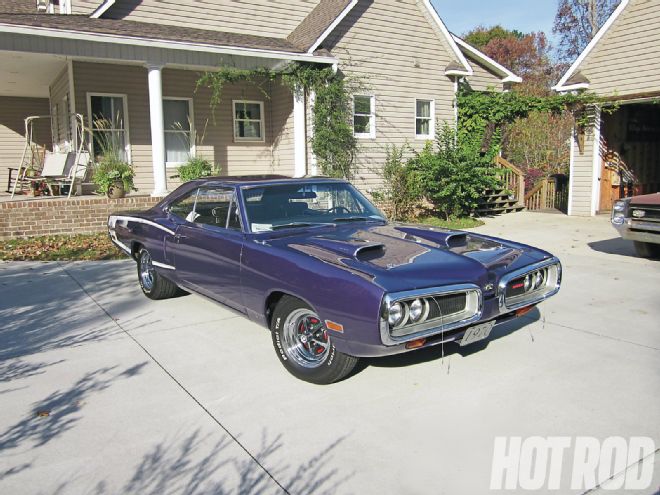

Jim Mooneyhan’s 1970 Dodge Coronet has a pretty stout drivetrain. Motivation is from a built, 11.0:1 440 equipped with a Mopar Performance Purple Shaft cam, Edelbrock aluminum heads, the classic 3x2-barrel Holley Six Pack induction system, headers, and a Chrysler breakerless distributor sparked by Mopar’s Orange Box through an MSD Blaster 2 coil. Shifts are handled by a 727 TorqueFlite equipped with a shift-improvement kit and a 2,800-rpm-stall torque converter that transfers the torque to a 3.73:1-geared Dana 60 rearend. All this should make for a killer muscle car. But the Coronet spent the last seven years on the show circuit, mainly backing on and off the trailer, and has never been regularly driven or really dialed in. When Mooneyhan tried to drive it on the street, it ran terribly. “I can’t get the carbs sorted out at all,” wrote a frustrated Mooneyhan in his rescue request. “I’ve had a couple of ‘Holley guys’ work on it, but to no avail. They say ‘buy some new carbs,’ but they are very pricey now. This should be a great car to drive and enjoy, but it’s just not the case. Help!”

Owner Jim Mooneyhan needed help making his Gray, Tennessee-based ’70 Coronet Super Bee 440 Six Pack street-driveable.

Owner Jim Mooneyhan needed help making his Gray, Tennessee-based ’70 Coronet Super Bee 440 Six Pack street-driveable.

Basically a show car, the Coronet had not been driven regularly for years. Returned to street-duty, it drove Mooneyhan plum crazy.

Basically a show car, the Coronet had not been driven regularly for years. Returned to street-duty, it drove Mooneyhan plum crazy.

Mooneyham’s main complaint: “The car idles too fast. The throttle response is bad. There’s a lean surge at 55 mph, but it may be rich at idle. Turning the idle speed screw and/or idle mixture screws has no affect.”

Was the problem the carbs, the distributor, or the spark plugs? Answer: All of the above—each fed off the other and needed attention.

Was the problem the carbs, the distributor, or the spark plugs? Answer: All of the above—each fed off the other and needed attention.

The two end carbs are still the original factory-installed units, but eight to nine years ago, Mooneyhan installed a new Holley replacement center carb that, he says, “is correct for an auto trans 440 Six-Pack.” When all three carbs were rebuilt two years ago, “vacuum leaks were checked, the timing was adjusted, and the center carb was rejetted several times. Nothing helped. The end carbs have been gone through but not modified in any way. The center carb’s power valve (PV) and accelerator pump circuit were never touched.”

To us, it sounded like the carbs needed a thorough sorting out, and who better than Joe’s Garage owner Joe Kiser, who rescued a 3x2 Rochester installation for this column last year?

When the car arrived and was backed off the trailer, Kiser says “it was idling at about 4,000–5,000 rpm! It was so bad that when Mooneyhan pulled it into the garage, the tires were squealing. The brakes couldn’t hold it. We almost had an accident!” Kiser’s initial inspection quickly found:

We had Mooneyhan trailer the car over the mountains from Tennessee to see Joe Kiser at Joe’s Garage in Winston-Salem, North Carolina.

We had Mooneyhan trailer the car over the mountains from Tennessee to see Joe Kiser at Joe’s Garage in Winston-Salem, North Carolina.

At least the engine was internally sound, with a cranking compression test yielding 175 psi on average with only 2–3 pounds difference between the cylinders.

Apparently, bending the divorced-choke linkage’s arm against the cam was someone’s crude attempt to crutch the choke. However, a standard divorced choke with its intake manifold–mounted stove won’t ever function correctly because the Edelbrock heads have no heat-riser passages. Converting to an electric choke is often a viable option, but in this case, the round electric choke housing would hit the factory Air Grabber air cleaner, ruining the car’s original appearance. After consulting with the owner, Kiser disabled the choke.

Kiser fully rebuilt all three carbs. Based on guidance provided by Holley technical services, Kiser determined that the replacement center carb was really for a ’70 340 small-block Six-Pack with a manual transmission, not a 440 as stated by the owner. Functionally, this meant that in stock form, the entire carb’s calibration would be way too lean for even a stock 440 Six-Pack, let alone Mooneyhan’s built motor with its big cam and higher compression. Previous tuners had tried to crutch it by installing No. 90 main jets plus the giant accelerator pump rather than considering more sophisticated mods to the IAB, high-speed air bleeds (HSAB), or power-valve channel restrictions (PVCR). This produced a calibration way too rich for proper idle quality and part-throttle/cruise driveability. As suggested by Holley, Kiser enlarged the PVCRs and installed No. 64 jets as a baseline. Holley felt that the IAB and HSAB wouldn’t need any mods, and ultimately this proved to be correct.

Kiser temporarily replaced the blown 6.5 PV with a new high-flow, window-style PV that opened at a lower 4.5 in-hg. The new valve’s lower actuation point kept it from opening prematurely until the low-vacuum condition could be diagnosed and corrected.

Kiser sanded the outboard carbs’ throttle blades and bores to eliminate the binding condition, blew out the IABs, replaced the damaged plug wires, swapped out the fouled plugs for a fresh set of Champion RC12YC spark plugs, installed a new center-carb manifold gasket, and set the ignition timing to stock specs. The car was then highway-driven for 20 minutes to clean it out.

The root problem: running a 340 carb on a 440. Making it work on a 100ci-larger motor required enlarging the PVCR passages, plus other mods.

The root problem: running a 340 carb on a 440. Making it work on a 100ci-larger motor required enlarging the PVCR passages, plus other mods.

At this point, Kiser says the motor now “cranked and ran pretty good, but the vacuum was still way low,” and the idle-mixture screws were still minimally responsive. Kiser temporarily blocked off both outboard (secondary) carbs so he could concentrate on diagnosing the center (primary) carb’s idle system. Adjustments yielded a reasonably stable, 1,200-rpm idle with reasonable mixture quality.

But when he reinstalled the outboard carbs, Kiser says “the car went back to running like junk, the rpm was up and down, and again the engine wouldn’t idle. You could tell it was starving for air. I tried readjusting the idle-mixture screws on the center carb again, but running them in and out made no difference. It seemed to me that the outboard carbs were now the main issue.”

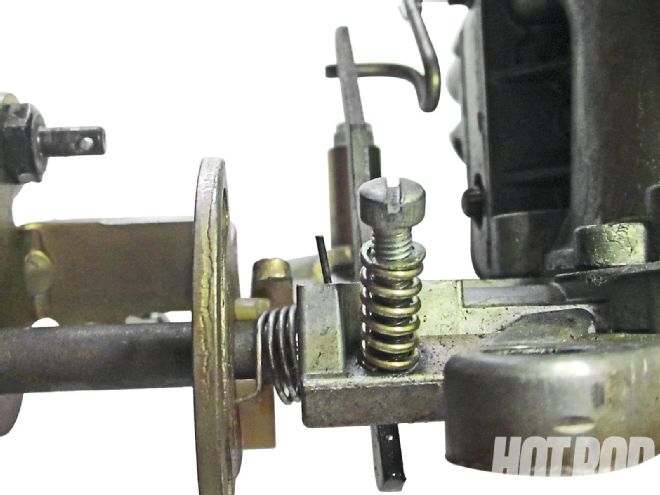

Given all the problems, it was no surprise that adjusting the idle fuel mixture and idle speed screws were ineffective. As received, the idle-speed screw was backed all the way out, yet Kiser says the car idled at more than 4,000 rpm!

Given all the problems, it was no surprise that adjusting the idle fuel mixture and idle speed screws were ineffective. As received, the idle-speed screw was backed all the way out, yet Kiser says the car idled at more than 4,000 rpm!

It turns out the outboard carbs have their own idle circuits complete with adjustable mixture screws. It’s just not obvious because the screws are hidden under plugs pressed into the baseplate. After carefully chiselling out the block-off plugs to gain access, Kiser found the screws fully bottomed in the idle-adjustment slot. This prevented any fuel from mixing with the outboard carbs’ idle air supply, meaning the outboard carbs’ idle circuit was dead lean.

Supposedly, the hidden mixture screws on original OE outboard Holley carbs should have been factory-set, but obviously these were way off. You could tell they’d never been adjusted in the carbs’ half-century of existence because the screws were practically cemented in place by a factory-applied thread-locking compound. If you are working on your own carbs, you’ll need to carefully apply heat to the screws to break them loose. Be careful! The screws are fragile and can easily break off in the casting. If all else fails, new baseplates can still be special-ordered directly from Holley technical services (they’re not available through the standard retail parts chain).

Kiser set the mixture screws on the outboard carbs to ½-turn out from bottoming, at last permanently solving the idle problems: “The car cranked and idled great. Vacuum went to 12 in-hg. The idle-mixture screws on the center carb became adjustable again. The engine, even with its big cam, idled happily at 1,200 rpm.”

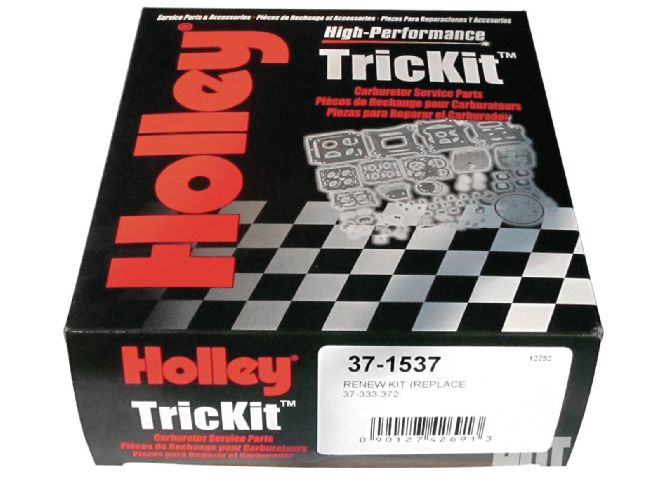

Holley still offers TricKit Renew rebuild kits. One is needed for each carb, for a total of three. If you’re performing a lot of trial-and-error tweaks, Holley also sells several different tuner parts’ assortment kits for its modular carbs.

Holley still offers TricKit Renew rebuild kits. One is needed for each carb, for a total of three. If you’re performing a lot of trial-and-error tweaks, Holley also sells several different tuner parts’ assortment kits for its modular carbs.

At last, the car could be tuned for best performance. With the vacuum stabilized, Kiser tried different PVs, finally settling on a 6.5-rated unit as the best compromise between proper power enrichment and reasonable cruise performance. The center carb’s main jets were slightly richened from Holley’s recommended No. 64 size to No. 68s. Kiser evaluated different accelerator-pump cams and squirters with the existing pump, ultimately settling on the stock 0.031-inch squirter nozzle with the OE white cam. Kiser says “there’s now absolutely no hesitation off-idle” with these parts.

The center carb was wrong—it was off a 340. Someone had really screwed up the calibration trying to make it work on the larger-ci, fully built 440. As received, the center carb had huge No. 90 main jets (top, compared with a No. 66, bottom). This made it way over-rich and virtually undriveable down low. The final tune ended up with No. 68 jets.

The center carb was wrong—it was off a 340. Someone had really screwed up the calibration trying to make it work on the larger-ci, fully built 440. As received, the center carb had huge No. 90 main jets (top, compared with a No. 66, bottom). This made it way over-rich and virtually undriveable down low. The final tune ended up with No. 68 jets.

Don’t drill the puck holes too deep or you’ll hit the emulsion tubes. An unwrapped paper clip makes for an expedient depth gauge. Insert into the holes until it bottoms, than wrap the clip’s exposed portion above the hole with masking tape. The unwrapped area below the tape is the max hole depth. Transfer that dimension to the drill bit. Be sure to drill the hole at the correct angle.

Don’t drill the puck holes too deep or you’ll hit the emulsion tubes. An unwrapped paper clip makes for an expedient depth gauge. Insert into the holes until it bottoms, than wrap the clip’s exposed portion above the hole with masking tape. The unwrapped area below the tape is the max hole depth. Transfer that dimension to the drill bit. Be sure to drill the hole at the correct angle.

The outboard carbs, with their idle circuits now dialed in, performed flawlessly. The original yellow secondary-diaphragm springs seem to be right for this combo (but it could be that the giant pump is covering up any bog). At any rate, so far there’s no need to redo the still-stock outboard carbs’ main circuits. That’s good, because for clearance reasons, the tightly spaced outboard carbs use metering plates instead of replaceable main jets (and the plate configuration is different from standard 4160-style four-barrel metering plates).

On some ’69–’70 440 six-barrel cars, the outboard carbs may stick closed. Throttle-blades stamped “226” on the bottom may have this problem. If stamped “199,” they should be OK. Yup, Mooneyhan’s plates were “sticky.” Kiser carefully sanded the sticky throttle blades and throttle bores until the throttles opened freely.

On some ’69–’70 440 six-barrel cars, the outboard carbs may stick closed. Throttle-blades stamped “226” on the bottom may have this problem. If stamped “199,” they should be OK. Yup, Mooneyhan’s plates were “sticky.” Kiser carefully sanded the sticky throttle blades and throttle bores until the throttles opened freely.

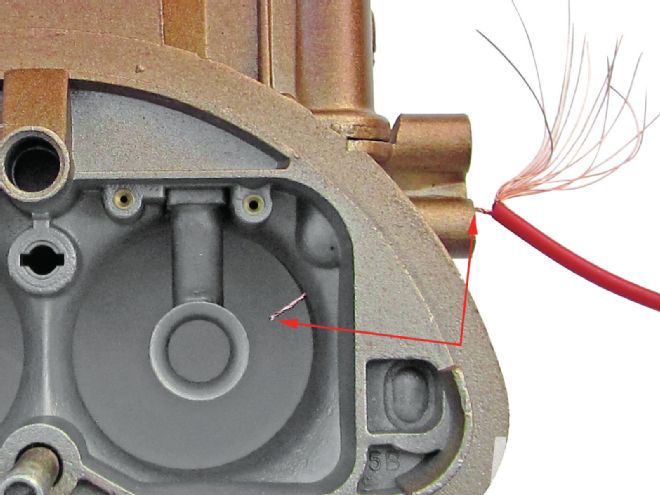

Check or clean out the casting’s various passages by inserting a stripped 18-gauge wire with its strands twisted together through the orifice, as applied here to the venturi vacuum pickup channel.

Check or clean out the casting’s various passages by inserting a stripped 18-gauge wire with its strands twisted together through the orifice, as applied here to the venturi vacuum pickup channel.

One remaining problem needed to be dealt with: a random miss at idle and cruise. Kiser says, “The distributor was just junk; it was sloppy, and the shaft had too much endplay. The reluctor was also wired backward, so it was out of phase.” The orange box’s ignition output may also be marginal for an engine of this caliber. With time growing short, the quick fix was a high-quality new MSD Ready-To-Run distributor. Kiser installed MSD’s supplied 25-degree centrifugal advance stop and dialed in another 11 degrees initial timing, ending up with a total of 36 degrees. “My vacuum gauge helped me put the initial timing where it needed to be for best idle quality.”

Kiser solved an occasional, pesky engine-miss by replacing the existing worn-out distributor with a modern MSD Ready-to-Run standalone distributor. The drop-in unit requires no separate ignition box or ballast resistor, has a simple three-wire hookup, and is compatible with the car’s existing MSD Blaster 2 coil.

Kiser solved an occasional, pesky engine-miss by replacing the existing worn-out distributor with a modern MSD Ready-to-Run standalone distributor. The drop-in unit requires no separate ignition box or ballast resistor, has a simple three-wire hookup, and is compatible with the car’s existing MSD Blaster 2 coil.

We’ll let a thoroughly satisfied Mooneyhan speak on this one: “It’s absolutely a different car now! It’s fabulous! It’s great! Joe Kiser came up with things no one’s been able to check! It finally does what it’s supposed to do! I’m tickled to death! It’s responsive! When you mash on the gas it does everything it’s supposed to do!” Do you think he’s happy?

From Sick Pack to Six Pack: Cured at last, Mooneyhan’s motor is ready to kick butt and take names.

From Sick Pack to Six Pack: Cured at last, Mooneyhan’s motor is ready to kick butt and take names.

On a roll with its driveability woes cured, the Coronet is ready for many more years of successful street driving.

On a roll with its driveability woes cured, the Coronet is ready for many more years of successful street driving.

The most basic lesson, as Kiser puts it: “Starting with the right stuff in the first place helps!” Don’t let things slide—they’ll only get worse. Isolate a carbureted car’s choke before tuning it. A vacuum gauge should be in everyone’s toolbox. And in this case specifically, it may have been easier to just step up and get the correct center carburetor; Holley still offers a replacement ’69–’70 440 Six Pack center carb (PN 0-4144-1, $540.95 at Summit Racing).

Center Carb¹ List No.: R4791 Flow Rating: 350 CFM OE Application: ’70 Chrysler 340 3x2 w/ manual transmission (incorrect for this car) Main Jets Power Circuit Accelerator Pump Circuit Orifice (Inches)² PN(1 Pair) PVCR(Inches) Power Valve Cam Nozzle Opens (In-Hg) Type PN Color Position PN³ Orifice (Inches) Type PN Before 0.1055 122-90 0.046 6.5 Standard 125-65 White No. 1 41R218 0.031 Straight 121-131 After 0.0685 122-68 0.052 6.5 High-Flow 125-165 White No. 1 41R218 0.031 Straight 121-131

NOTES: ¹Outboard carbs required only an idle mixture adjustment. ²Jet hole sizes provided for reference only. All Holley jets are sized by actual flow and may vary from the listed orifice size. ³Cam PN provided only for reference and is not separately available; included in pump cam kit PN 20-12 that contains eight different cams.

Includes the final major parts required to fix the problem. Does not include labor, shipping, miscellaneous small shop parts, or sales taxes. Priced 03/07/13 and subject to change. Brand Part Description PN AMT. Price Source Price Champion Spark Plug, Copper Plus, gasket seat, 14mm thread, 0.750-inch reach, projected tip, resistor (8/pack) RC12YC 1 RockAuto $13.36 Holley Jets, main metering, No. 68, 0.0685-inch nominal orifice (1 pair) 122-68 1 Summit Racing $6.95 Power Valve, w/ gasket, high-flow “window” design, opens at 6.5 in-hg 125-65 1 Summit Racing $13.95 Renew Kit, carburetor rebuild (1 kit does 1 carburetor) 37-1537 3 Summit Racing $251.85 MSD Distributor, Ready-to-Run, Chrysler 426/440 8387 1 Summit Racing $385.95 Wire Set, Spark Plug, 8.5mm Super Conductor, universal, 90° distributor and multiangle plug terminals, black 31183 1 Summit Racing $84.95 Total $ 757.01

Need Junk Fixed?

If your car has a gremlin that just won’t quit, you could be chosen for Hot Rod to the Rescue. Email us at [email protected] and put “Rescue” in the subject line. Include a description of your problem, your location, and a daytime phone number.