William Pica Asks…

Q: Can I take a naturally aspirated 231 Buick V6 block and use it to build a turbo engine with 16 to 20 psi of boost? I know I would need to upgrade the internals. My main concern is the block itself. The engine is going in a ’69 Cutlass, not a later Grand National.

Boost is merely one means to an end: making power. What you really need to ask is, “How much horsepower can a stock Buick V6 block withstand?” The consensus of Buick V6 experts such as Ken Duttweiler (Duttweiler Engineering) and Mike Tomaszewski (TA Performance) is around 550 to 600 hp. “They’ll take that amount for a good while,” Duttweiler says. “A street guy I know put 80,000 miles on one before a main cap broke, but usually it’s the crank that goes first. There are some guys making 1,000 hp on the stock block with billet main caps and stud girdles. But, ultimately, the deck isn’t thick enough to survive at that level for long; it’ll crack around the head bolts.”

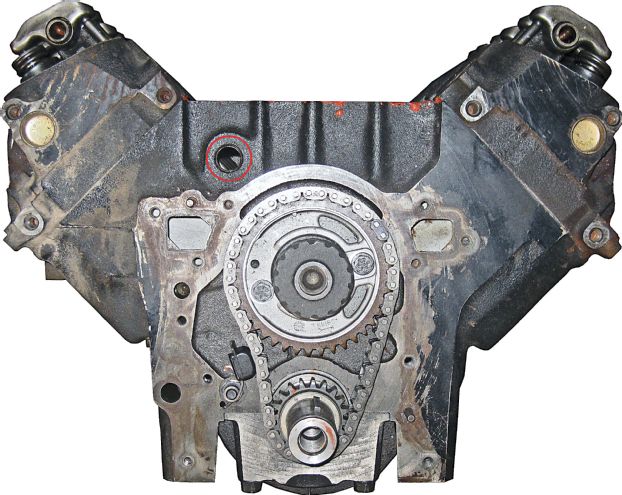

All Buick 231 V6 production blocks can take about 600 hp. However, so-called turbo 231 blocks—used on ’86–’87 turbo cars, ’88 turbo Trans Ams, and even many non-turbo rear-wheel-drive 231 engines made in the same timeframe—have a turbo-oil drain-back boss (red circle). On NA cars equipped with the turbo block, the boss may be present but not drilled and tapped.

All Buick 231 V6 production blocks can take about 600 hp. However, so-called turbo 231 blocks—used on ’86–’87 turbo cars, ’88 turbo Trans Ams, and even many non-turbo rear-wheel-drive 231 engines made in the same timeframe—have a turbo-oil drain-back boss (red circle). On NA cars equipped with the turbo block, the boss may be present but not drilled and tapped.

This advice applies both to blocks used in naturally aspirated (NA) engines as well as those used in factory turbo applications. Although there are some minor differences in the lifter valley and lifter bosses, Tomaszewski says “they’re not structurally relevant.” Adds Duttweiler, “There’s no real difference in strength between the blocks—and I’ve looked at a lot of them!”

Although it has nothing to do with strength capability, there is one obvious difference between earlier 231 V6 NA blocks and many '86-and-later castings: These late, so-called turbo blocks have a turbo oil-return drain-back boss on the block’s front surface. It’s really only needed if using a stock—or direct-replacement for stock—Buick factory turbo setup. Otherwise, just run a drain line directly back to the oil pan.

Turbo blocks with the front oil-return boss are cast “25526109.” The casting number is located at the rear of the block on the passenger side just forward of the bellhousing mounting flange.

Turbo blocks with the front oil-return boss are cast “25526109.” The casting number is located at the rear of the block on the passenger side just forward of the bellhousing mounting flange.

Speaking of oil, the factory Buick oiling system is definitely a weak link. At the street/strip level, the basic fix is TA Performance’s blueprinted, close-tolerance front cover and oil-pump assembly (PN TA 1533B). TA holds its internal pump clearances within 0.001 inch, tighter than original GM factory specs, and light years ahead of sloppy replacement, made-in-China covers. The pump itself puts out more pressure and volume, and the assembly’s internal oil transfer passages are enlarged over stock. This raises overall oil pressure, even after initial warm up, when internal clearances increase and the hot oil thins out.

Be sure to install an antiwalk cam-thrust button. Using a good-quality single-link timing chain instead of a double-roller will permit retaining the factory chain-tensioner, helping to control harmonics by dampening the slack-side of the chain. Tomaszewski says, “It’s not easy to find a replacement tensioner on the outside, but we carry one under PN TA V1394R.”

Looking at the rotating assembly, a turbo-engine crank is stronger with rolled fillets, but even it won’t last long over 600 hp. Forget the stock pistons—go to forgings, shooting for about an 8.5:1 compression-ratio on a boosted engine. Scat and TA offer quality stock-length rods.

At around $1,800/set, as-delivered TA Performance Street Intimidator heads (PN TA V3850 SI) outflow the best stock ported-iron castings, save weight over those heavy iron slugs, have a beefy 1-inch-thick deck, and permit higher compression or more boost without detonation. TA heads use up to 1.94/1.60-inch valves, compared with just 1.770/1.50-inch for stock heads.

At around $1,800/set, as-delivered TA Performance Street Intimidator heads (PN TA V3850 SI) outflow the best stock ported-iron castings, save weight over those heavy iron slugs, have a beefy 1-inch-thick deck, and permit higher compression or more boost without detonation. TA heads use up to 1.94/1.60-inch valves, compared with just 1.770/1.50-inch for stock heads.

But why worry about stock-length rods if you’ll be replacing the crank anyway? Once committed to a stouter aftermarket crank, it makes sense to put in a stroker and gain some cubes. TA Performance sells an integrated stroker kit (PN TA V1613) that includes a 3.625-inch-stroke billet crank (the stock iron crank stroke is 3.400 inches), 6.350-inch center-to-center con-rods, forged pistons in the compression ratio of your choice, and wider-than-stock bearings. On a 231 bored 0.030-over to 3.830 inches, this yields 251 ci.

As for the cam, I lean toward a very mild hydraulic roller grind. There’s just too many issues with flat-tappet cams with today’s mainline motor oils, even on an engine with inherently good oiling like a small-block Chevy, let alone on the problematic Buick. Current turbo technology is so improved in terms of minimizing exhaust backpressure issues that, other than slightly wider lobe separation, there’s not all that much difference any more in raw specs between an NA cam and a so-called turbo cam. One remaining difference when specing a custom cam for a turbo engine is that with many modern cams, there are quick-acting intake-lobe profiles as well as “softer”-closing exhaust profiles. With a turbo, you don’t really need a different-closing-rate, exhaust-specific lobe profile because exhaust-wave tuning characteristics are not that critical. Still, you want to minimize any through-chamber blow-by to quickly build boost. Hence, the lobe-profile experts at Comp Cams maintain that the modern fast-closing intake lobes also work quite well on a turbo engine’s exhaust-side.

Another Buick oiling problem is keeping the small cam journals alive. TA offers hardened, wider, dual-feed/dual-groove, cam bearings (left). One-hole factory bearings (right) can starve the bottom half of the bearing, especially with higher spring pressure. TA’s groove and extra holes provide 360-degree oiling.

Another Buick oiling problem is keeping the small cam journals alive. TA offers hardened, wider, dual-feed/dual-groove, cam bearings (left). One-hole factory bearings (right) can starve the bottom half of the bearing, especially with higher spring pressure. TA’s groove and extra holes provide 360-degree oiling.

Bearing this in mind, Comp recommends a custom hydraulic roller grind based on its Xtreme Energy XFI hydraulic roller series: intake lobe profile No. 3013 for the intake side, and intake lobe profile No. 3014 for use on the exhaust. The complete ordering information is as follows:

Comp Buick V6 Custom Hydraulic Roller Cam Custom Buick V6 Basic PN 69-000-8 (Spec - 22127312) Core No. C99 Grind No. BV69 30135S / 3014S HR 113.0 Vale lift, 1.55:1 rockers (intake/exhaust) 0.548/0.553 inches Duration at 0.050 (intake/exhaust) 214/218 degrees Lobe-separation angle 113.0 degrees Intake centerline (installed) 111.0 degrees

Small-block Chevy, retrofit-style, paired, link-bar-type hydraulic roller lifters will fit a Buick V6. The Buick No. 3 cylinder’s lifter-boss spacing is about 0.060 inch wider than the Chevy, but the Chevy lifter’s link-bar slot is long enough to accommodate this slight difference without issues. Nevertheless,TA has “real” Buick V6 hydraulic roller lifters if you want them. Bearing this in mind, use the above cam with the following valvetrain parts:

There are strength and reliability differences among factory heads. Buick V6 heads are typically ID’ed by the last four digits of the casting number. Most ’85-and-earlier heads (such as No. 6293, left) are weaker than the later No. 8445 casting (right) that has a strengthening bridge across the end coolant-transfer slots (arrow).This is critical for boosted engines.

There are strength and reliability differences among factory heads. Buick V6 heads are typically ID’ed by the last four digits of the casting number. Most ’85-and-earlier heads (such as No. 6293, left) are weaker than the later No. 8445 casting (right) that has a strengthening bridge across the end coolant-transfer slots (arrow).This is critical for boosted engines.

Additional Valvetrain Parts Except as noted, all parts are made by Comp Cams. Lifters (retrofit-style with paired link bar) TA V11412 (TA Buick V6) or 853-12 (Comp Chevy small-block/V6-90) Valvesprings (beehive-type) 26918-12 Retainers (steel) 1787-12-TS Valve locks, fully machined 648-12 Valve seals 503-12

Unlike the blocks, some late factory turbo heads are stronger than earlier V6 castings. But these days—as is typical with so many other engines—unless it’s a straight restoration or class racer, one has to question whether it’s worth investing in any set of worn-out stock heads when vastly superior yet still reasonably affordable aluminum aftermarket heads are available.

It’s possible to make about 600 hp (the stock block’s safe limit) with a single turbo and a highly efficient intercooler on about 22-psi boost. Exile Turbo’s Rick Head as well as Garrett’s boost advisor recommend a GTX3582R turbo with a 62.5mm compressor inducer. This advanced turbo has a ported shroud compressor housing to increase surge resistance, plus a dual ball-bearing, oil- and water-cooled center-housing rotating assembly (CHRA) for durability.

TA Performance’s nine-keyway, single-link steel chain has billet sprockets and a proven reliability record. Unlike a double-roller chain, it allows retention of the factory chain tensioner. The single-link chain and tensioner combo help fight the Buick V6’s bad valvetrain harmonics issues. PN TA V1522B (shown) fits even-fire engines; PN TA V1522A is for odd-fire motors.

TA Performance’s nine-keyway, single-link steel chain has billet sprockets and a proven reliability record. Unlike a double-roller chain, it allows retention of the factory chain tensioner. The single-link chain and tensioner combo help fight the Buick V6’s bad valvetrain harmonics issues. PN TA V1522B (shown) fits even-fire engines; PN TA V1522A is for odd-fire motors.

Garrett doesn’t sell direct, so you’ll have to purchase the parts through a distributor like Exile Turbo. It’s not available as a single complete unit, either. The compressor housing and CHRA assembly with a No. 58 trim is available under PN 803715-1. The turbine housing must be ordered separately; there are a number of A/R ratio and inlet and outlet flange options. I’d start with a midrange 0.82 turbine A/R ratio with a four-bolt, T4-style inlet flange and a universal V-band coupler outlet flange (Garrett PN 740902-17). The inlet side will mate with TA Performance’s stainless-steel exhaust header set (PN TA V2011CH-SS). Although listed for late-model G-bodies like the Grand National, the tight-fitting set should fit your earlier Olds A-body.

As for an air-to-air intercooler core, if there’s room, you want one measuring at least 18 inches wide x 12 inches high x 3 inches thick (such as Garrett PN 703518-6004). This is the basic core dimensional outline only; side tanks must be custom fabbed. You will probably need water-alcohol injection at full boost on pump gas (Snow Performance is one source).

On the fuel side, consider a larger Accufab 70mm throttle-body (PN 108-20XX-3X) and a programmable aftermarket ECU. According to Tomaszewski, “FAST EFI is where it’s at for the Buick V6.” Duttweiler concurs.

Finally, if you want to go big, check into TA’s aluminum V6 block.

Old Holley Rebuild Kit

Q. I have a 40-year-old, 600-cfm Holley on my 40-year-old truck, and I can’t find a rebuild kit for it. The only numbers I can find are “List 6919” and “2517.” Does any shop have this kit, or should I put the carb on the mantle next to the old shotgun and buy a new one?

Kent M. Williams

Hesperia, CA

“List 6919” on the air horn is the relevant number. And yes, genuine Holley rebuild kits are still available. Holley Renew Kit 37-1536 is the comprehensive straight rebuild kit; Trick Kit PN 37-933 has all the rebuild parts and adds in some additional high-perf tuning upgrades. If you can’t find these kits locally, Summit stocks them.

Ask Marlan a Tech Question: [email protected]