When we last discussed our Project Pure Poncho 455-based 467ci stroker engine, Craig Wise at Racecrafters had assembled the bottom end. We will pick up the assembly process in this issue and complete it in preparation for dyno testing.

With the Mr. Gasket high- clearance chrome valve covers (for the roller rockers) and Pontiac silver-blue metallic paint, our mule looks just about ready to challenge the Stuska dyno water brake!

With the Mr. Gasket high- clearance chrome valve covers (for the roller rockers) and Pontiac silver-blue metallic paint, our mule looks just about ready to challenge the Stuska dyno water brake!

To review, this mule engine is being built to test parts combinations in HPP. Bob and Craig Wise at RaceKrafters Automotive Machine have offered their services and will be using their Stuska dyno for future testing. Summit Racing Equipment provided most of the parts for this buildup except for the stroker reciprocating assembly and timing cover and valley pan that Butler Performance contributed.

The whys and hows of the parts choices for the initial combo were discussed in the last issue, which can be found using the keywords Project Pure Poncho in the search. Suffice it to say, we wanted to build a pump-gas engine that readers could relate to. We’ve included the engine buildup worksheet in this installment as well, so you can reacquaint yourself with the combo. Follow along as we complete the assembly, and please keep in mind that photos were taken during pre-assembly and assembly, so there may be instances where installed parts are seen in one photo and not the next.

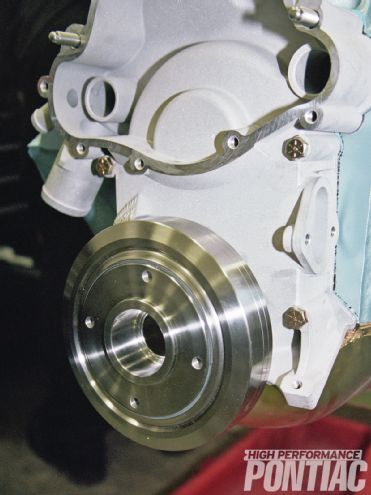

1 This Butler Performance reproduction timing cover was beautifully cast and is a good investment over a worn 40-year-old piece. It fits ’69-’79 engines with the 11-bolt water pump. To mount the Summit Racing Street & Strip Competition steel harmonic damper, Craig used a damper-installer tool and some Sunnen press lube on each side of to reduce the chance of galling, and then he torqued the bolt to the required 160 ft-lb.

1 This Butler Performance reproduction timing cover was beautifully cast and is a good investment over a worn 40-year-old piece. It fits ’69-’79 engines with the 11-bolt water pump. To mount the Summit Racing Street & Strip Competition steel harmonic damper, Craig used a damper-installer tool and some Sunnen press lube on each side of to reduce the chance of galling, and then he torqued the bolt to the required 160 ft-lb.

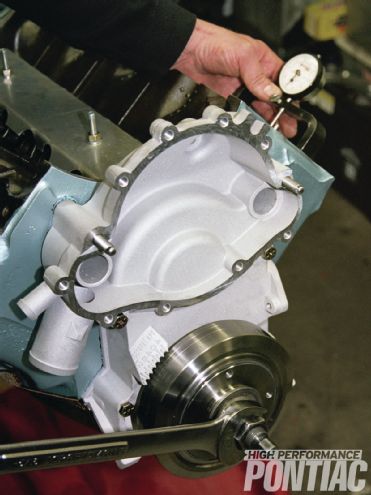

2 The damper is SFI-approved and features engraved timing marks for easy tuning. Summit says that the special bonded elastomer will transfer heat more quickly than a stock damper making it beneficial for high performance applications. Craig then indicated TDC on the No. 1 cylinder to confirm the timing marks. The Summit damper and Butler Performance timing cover were perfect.

2 The damper is SFI-approved and features engraved timing marks for easy tuning. Summit says that the special bonded elastomer will transfer heat more quickly than a stock damper making it beneficial for high performance applications. Craig then indicated TDC on the No. 1 cylinder to confirm the timing marks. The Summit damper and Butler Performance timing cover were perfect.

Correction to the bottom-end story in the last issue: Photo #21 of the oil pan installation is out of order in the story. It should have been placed after the cam degree sequence #22-#23 and short-block photo #24. Sorry for the inconvenience.

HPP Engine Buildup Worksheet

Engine Displacement: 467 ci

Bore/Stroke: 4.185 / 4.250-in

Bore/Stroke ratio: 0.98:1

Rod/Stroke ratio: 1.6:1

Bottom End

Block: Stock ’75 455

Preparation: Cooked, magged, line-bored, line-honed, decks squared with BHJ, bored and honed with torque plates

Deck height: 10.205-in

Crank: Butler/Eagle forged

Preparation: Balanced, polished

Balancer: Summit Street/Strip, steel, elastomer, 6.610-in, SFI 18.1

Rods: Eagle forged H-beam, 6.800-in

Preparation: Pin end honed to proper size, balanced, big end checked for proper size

Bearings: Clevite, plain shell, tri-metal

Preparation: Clean, check for proper clearance in rods

Pistons: Butler/Ross forged flat-top with valve reliefs

Preparation: Pin-fit, check size, clean

Piston-to-deck height: 0.010 below

Piston pins: Ross, 0.990 floating, 0.155-in wall

Method used to retain piston pins in pistons: Spiro Locks

Rings: Total Seal, moly top, ductile second, three-piece oil; 1⁄16, 1⁄16, 3⁄16-in

Preparation: File-fit, clean

Rod bolts and head bolts: ARP

Balancing specs: Internal

Oiling System

Windage tray: Canton in pan

Crank scraper: Canton in pan

Oil pan: Canton Racing Road Race Series 5-quart, wet-sump

Oil pump: Melling M54DS high-volume

Heads

Casting number: 6X

Combustion chamber volume: 96.2 ccs

Maximum flow at 28 inches of pressure

Lift Intake Flow CFM Exhaust Flow CFM 0.100 66 55 0.200 133 106 0.300 191 149 0.400 224 70 0.500 236 182 0.600 250 186

Compression ratio: 9:1

Valves: Manley SS 2.11/1.77-in

Angles used in valve job:

Intake: 45, 60, 75, and 82 deg, 82 is hand-blended into 75 deg.

Exhaust: 45 deg, 12mm radius

Retainers: Comp Cams, steel, 10-deg beehive

Keepers: Comp Cams 10-degee, 11⁄32-in

Valve Guides: K-line bronze liner

Valve Seals: Steel/Viton

Rocker Studs: ARP 7⁄16-in

Rocker Arms: Comp Cams aluminum full roller, 1.65:1

Pushrods: Manley 3⁄8x8.900-in

Cam

Brand: Comp Cams Xtreme Energy hydraulic roller

Duration at 0.050: 224/230-deg

Lift: 0.552/0.561-in

Centerline: 106-deg

Lobe Separation Angle: 110-deg

Installed Position: 106-deg

Lifters: Comp Cams roller

Valvesprings: Comp Cams Beehive

Seat Pressure: 137 lb/in

Open Pressure: 290 lb/in

Timing Chain: Comp Cams double-roller

Induction

Carb: Holley 4150 HP 750-cfm, mechanical secondaries

Intake Manifold: Edelbrock Torker II

Ignition

Distributor: MSD Pro-Billet Ready-to-Run

Exhaust

Headers: Hooker

Primary Tube Diameter: 1.75-in

Primary Tube Length: 32.00-in

Collector Size: 3.00-in

Gaskets

Brand: Fel Pro