We’re excited. We’ve got an engine for our truck. It’s not just any truck. It’s the STREET RODDER Project Shop Truck, the ’47 Chevy being built entirely from new parts at Hot Rods By Dean in Phoenix. It’s not just any engine either. It’s an LS327/327 iron block crate engine from Chevrolet Performance. They call it a “souped up” version (they actually use that term) of their popular 5.3L (iron block) LS small-block built specifically for truck, van, and SUV applications.

While the engine may have been created for trucks, Chevy’s Advance Design pickups weren’t designed for these engines—especially when they’ve got an alternator hanging off one side and an A/C compressor hanging off the other and a power steering reservoir in between. It was time for some problem solving, which on a street rod can be like squeezing a balloon—squeezing it in one place just makes it expand in another place.

This is our Chevrolet Performance LS327/327 crate engine still in its carbureted form. Notice the position of the stock air conditioning compressor on the lower left. There’s no way that was going to clear the framerails in our ’47 Chevy pickup.

This is our Chevrolet Performance LS327/327 crate engine still in its carbureted form. Notice the position of the stock air conditioning compressor on the lower left. There’s no way that was going to clear the framerails in our ’47 Chevy pickup.

Fitting our engine between those fenders took a combination of aftermarket products and custom fabrication. Keep reading to find out how our chain reaction of challenges was met with a chain reaction of solutions.

The first challenge was the stock location of the A/C compressor. It was as low as the crankcase and didn’t stand a chance of clearing the passenger side framerail. The solution was a complete serpentine accessory bracket package from Kwik Performance.

There are three varieties of Gen III/IV LS engines: Corvette, F-body (Camaro), and truck. Each is different in terms of the spacing between the block and the serpentine belts and requires a specific bracket kit. We knew we had the truck version, but if we didn’t know, we would have had to figure it out by measuring from the front of the crank pulley to the front of the engine cover. Place a straightedge across the front of the pulley and extend a tape measure through one of the openings in the pulley to get this measurement. For a Corvette, it’s 2-1/8 inch; for an F-body, it’s 2-15/16 inch; for a truck, it’s 3-11/16 inch.

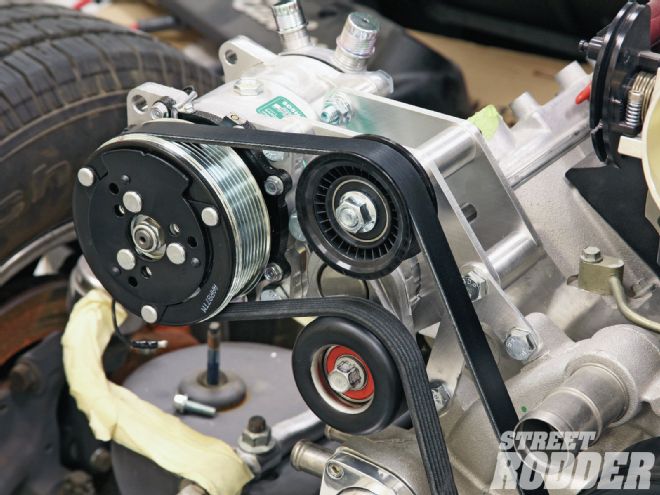

An A/C compressor bracket from Kwik Performance relocated the compressor far from the frame. Note the relocation of the idler pulley (red center) from down low to up high as well.

An A/C compressor bracket from Kwik Performance relocated the compressor far from the frame. Note the relocation of the idler pulley (red center) from down low to up high as well.

In addition to the A/C compressor bracket, our Kwik Performance system included a Sanden compressor to replace the stock GM unit. Kwik includes the compressor to ensure that it is compatible with the rest of the system. Kwik also has alternator brackets.

The new Kwik bracket hoisted the compressor far from the framerail; however, the compressor now ran up against the inner fender. Over on the driver side, we encountered the same problem with the alternator. Fortunately, that’s easily remedied by slicing a notch in both of the inner fenders with a cut-off tool.

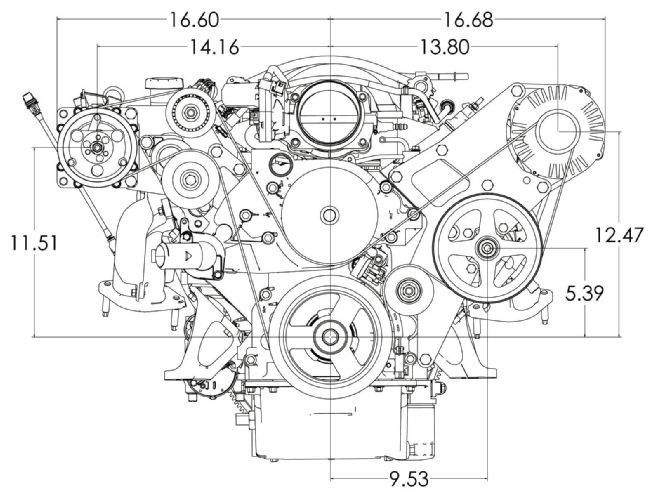

This illustration from the Kwik Performance installation instructions lists the dimensions of its drive and bracket system for the LS1, which includes the A/C compressor bracket as well as an alternator/power steering pump bracket.

This illustration from the Kwik Performance installation instructions lists the dimensions of its drive and bracket system for the LS1, which includes the A/C compressor bracket as well as an alternator/power steering pump bracket.

We recently converted the LS engine from an Edelbrock four-barrel carburetor to FAST fuel injection. Now we needed a way to supply air to the LSXRT intake manifold and Big Mouth throttle body. With EFI, we know that the computer uses the signal from the temperature sensor to determine the correct air/fuel ratio. An aftermarket air intake system is an effective way to provide more air and add power.

For best results, the air needs to be cool and undisturbed. Turbulent air at the Mass Air Flow Sensor can cause an incorrect signal, prompting the engine management system to generate the wrong air/fuel mixture, hurting performance.

Air is especially hot and turbulent right behind the radiator, so the challenge here was to route an air intake system from inside the shroud directly behind the grille on the driver side. We used air intake components from Spectre Performance.

Along with the Kwik Performance compressor bracket came a new Sanden compressor, which is compatible with the revised setup.

Along with the Kwik Performance compressor bracket came a new Sanden compressor, which is compatible with the revised setup.

Spectre offers a lot of model-specific systems, none of which applied to our application—so we selected modular components, including tubing, a non-restrictive P4 cone air filter, and the necessary mounting hardware. Installation required a little more cutting into the driver side inner fender, but was simple and straightforward.

Now that we’d gotten this far, we started wondering about how we could hide the coil packs. The MSD Multi Spark Coils replace stock GM Gen III coils and fire multiple times for improved ignition and performance. That’s what MSD says and that’s what we’re counting on. And they’re good looking, but they didn’t fit the appearance of our engine. Corvette guys use those large coil covers to hide the coils but that wasn’t the right look for Project Shop Truck either, and there’s no way they’d fit with that jumbo-sized FAST intake manifold.

With the compressor in its elevated position, the custom inner fender did not fit without being notched.

With the compressor in its elevated position, the custom inner fender did not fit without being notched.

As with any engine swap, headers (and subsequent exhaust system) can present a real problem—one that can’t be ignored. We tried several different styles of headers, and settled on the Patriot Exhaust Tight Tuck coated headers. Next, we installed a set of Smithy’s mufflers, using an exhaust pipe kit from Patriot. We gained the frame, steering, and spark plug wire clearance that was needed.

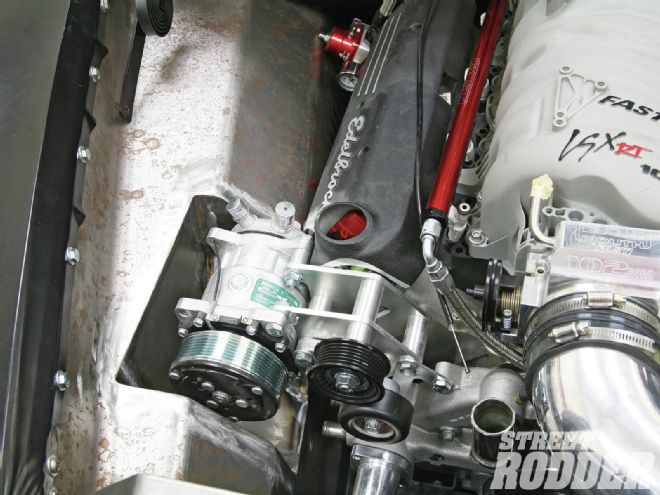

The Kwik serpentine system reduces the number of belts from two to one six-rib belt. Notice that the carb and intake have been replaced with an LSXRT intake manifold and Big Mouth throttle body from Fuel Air Spark Technology (FAST).

The Kwik serpentine system reduces the number of belts from two to one six-rib belt. Notice that the carb and intake have been replaced with an LSXRT intake manifold and Big Mouth throttle body from Fuel Air Spark Technology (FAST).

Edelbrock had just what was needed with its Gen III LS Series Coil Covers. These cast aluminum covers don’t just hide the coils and wiring harness, the coils mount to the underside of the covers instead of to the stock GM mounting brackets. They will work with GM coils as well as our MSD coils (PN 8245).

Once the guys at Hot Rods By Dean started installing the Edelbrock covers, we discovered that the air conditioner compressor and the alternator were going to interfere. It seemed like squeezing that balloon had just come full circle. But once again, the challenge was met with some basic custom fabricating. The Edelbrock covers could be trimmed to fit around the obstacles without affecting them. The necessary trimming didn’t interfere with the coils or with the breather hole on the passenger side cover.

The Kwik serpentine system reduces the number of belts from two to one six-rib belt. Notice that the carb and intake have been replaced with an LSXRT intake manifold and Big Mouth throttle body from Fuel Air Spark Technology (FAST).

The Kwik serpentine system reduces the number of belts from two to one six-rib belt. Notice that the carb and intake have been replaced with an LSXRT intake manifold and Big Mouth throttle body from Fuel Air Spark Technology (FAST).

After some metal finishing and some paint to the inner fenders and the coil covers, this is going to be a good-looking engine compartment.