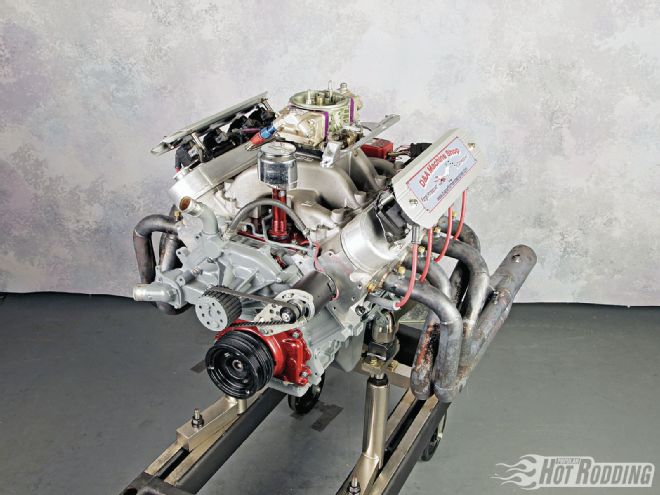

There are many approaches to building engines, but a theme that resonates with practically anyone is maximizing value in terms of power per dollar. Donny and Andy Key of D&A Machine Shop, in Canton, Georgia, quickly concluded that achieving that goal requires a well-thought-out approach. Here the GM LQ4 makes an outstanding starting point. Simply by design, these engines feature loads of inherent power potential. They come through from the factory with ample displacement, and the parts support from the aftermarket means these engines are ripe for modification. The LQ4 version of GM’s LS series of engines has the added advantage of a deep production run in a variety of late-model truck applications. The upshot here is that engine cores are readily available in plentiful numbers, generally at affordable prices.

Adding Muscle

A 4.00-inch stroker crank will drop right into the crankcase of a 6.0L truck block like this LQ4 with no clearance work required. The rotating assembly here consists of a Scat crank, Scat I-beam rods, and Mahle forged pistons. Mahle bearings ensure everything spins as it should, while ARP fasteners lock it all in place.

A 4.00-inch stroker crank will drop right into the crankcase of a 6.0L truck block like this LQ4 with no clearance work required. The rotating assembly here consists of a Scat crank, Scat I-beam rods, and Mahle forged pistons. Mahle bearings ensure everything spins as it should, while ARP fasteners lock it all in place.

Starting with an iron block LQ4 plucked from nothing more exotic than a Chevy Suburban, the engine featured here was built to compete in our annual AMSOIL Engine Masters Challenge engine-building competition. The goals of the event are similar to that of a serious street application: delivering the broadest powerband over an rpm range from 2,500-6,500 rpm, while running on pump gas. While the factory LQ4 comes through with a generous displacement of 366 ci via the stock 4.00x3.62-inch bore and stroke, one of the appeals of these engines is how readily they take to added displacement via a stroker crank. The most common stroker combination for this series of engines is to substitute a 4.00-inch crank, yielding a displacement of over 400 ci with a clean-up overbore. This particular engine spec’d at 409 ci after the bores were machined .030-inch oversize.

Stroker parts for the LQ4 are offered by practically every aftermarket company in the game, meaning the competition is fierce, and prices are reasonable. D&A selected a Scat 4.000-inch crank as the backbone of the combination. As Andy says: “Basically, all we had to do with the crank is balance it. Of course we measured it, and it was right on the numbers. We have never had to return anything to Scat. They are dead on the money, right where they need to be, and they hold up well.”

The Mahle pistons are flat-tops, giving a final compression ratio of 11.4:1, while Total Seal gapless top rings provide the compression seal. The Scat I-beam rods measure 6.125 inches center to center.

The Mahle pistons are flat-tops, giving a final compression ratio of 11.4:1, while Total Seal gapless top rings provide the compression seal. The Scat I-beam rods measure 6.125 inches center to center.

As with the crank, the rest of the rotating assembly consists of readily available, off-the-shelf parts. The rods are also from Scat—their 6.125-inch I-beam units. “We use a lot of this style of rod on our circle track engines, and we are really comfortable with them,” Andy says. “They are a little lighter in weight than an H-beam, and are more than adequate for this application.” Finishing the internal components of the stroker assembly are a set of Mahle forged pistons, wrapped with a Total Seal gapless top ring set in a 1.5/1.5/3mm package. Andy tells us that the factory block readily accepts the long-stroke crank, and it literally dropped right into the main saddles with no custom clearancing or grinding required. It simply doesn’t get any easier than that. The crank spins on King bearings, and was installed with .003-inch clearance at the mains, and .0024 on the rods.

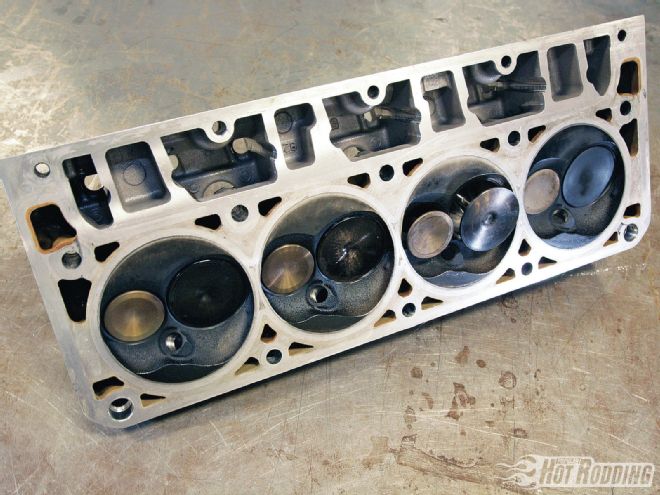

Up top, the engine features a set of GM’s factory big-port L92 cylinder heads. These cylinder heads are right on target to feed a deep-breathing stroker, with plenty of port volume, and substantial intake port flow, even in stock form. Andy tells us the stock ports flow in the range of 330 cfm as delivered, and have the potential for even more with minor modifications. If the heads have a weakness, it is in exhaust flow. Andy says, “On average these heads will flow 190-200 on the exhaust, so the intake to exhaust flow percentages are pretty lopsided.” Once reworked with an emphasis on bringing up the exhaust flow, and breathing though a combination of Ferrea 2.165-inch intake valves and Liberty 1.600-inch exhaust valves, the factory castings delivered 335 cfm on the intake side and 255 cfm on the exhaust at .600-inch lift. High-lift flow like that is power waiting to be had, but what makes it even better is strong airflow right from the bottom of the lift curve. Here D&A worked their magic with a proprietary valve job using seat and valve angles developed from their circle track engine development experience to maximize the flow curve.

Turning the 224/228-degree duration Steve Demos custom hydraulic roller cam is a Liberty billet timing set holding the 108-degree LSA cam to a 102-degree intake centerline angle. Andy Key of D&A tells us the alignment of an LS-engine’s front-mounted oil pump is a critical assembly step.

Turning the 224/228-degree duration Steve Demos custom hydraulic roller cam is a Liberty billet timing set holding the 108-degree LSA cam to a 102-degree intake centerline angle. Andy Key of D&A tells us the alignment of an LS-engine’s front-mounted oil pump is a critical assembly step.

To tap into the airflow of the heads, the camshaft plays a vital role in building a combination that works. Here D&A went with a custom grind from Steve Demos Cams, in Jefferson, Georgia. The resulting hydraulic roller stick features quite conservative numbers in terms of duration, spec’d at 224/228 degrees at .050, with 276/282 degrees of gross duration. While the duration is short, the lift is significant, measuring .607 inch at the valve via a set of Harland Sharp 1.8:1 rocker arms. The short-duration/high-lift combination helps to maximize torque over a broad power range, and ensures plenty of torque down low. The cam was ground on a lobe separation angle of 108 degrees, and installed at 102, or 6 degrees advanced, specifications that also favor strong torque production. The healthy torque numbers showing low in the rpm range add credence to the theory. The ample top end power right up to 6,500 rpm points out that with free-breathing heads it doesn’t take a huge amount of duration to turn the revs.

Sealing off the bottom of the block is an OEM tray and pan, though both were modified. The tray was opened for improved drain-back, while the pan received detail grinding to aid oil flow. Further oiling mods included streamlining the oil passages and defeating the oil bypass.

Sealing off the bottom of the block is an OEM tray and pan, though both were modified. The tray was opened for improved drain-back, while the pan received detail grinding to aid oil flow. Further oiling mods included streamlining the oil passages and defeating the oil bypass.

A potential pitfall when considering a short duration/high-lift cam—especially with a hydraulic roller—is maintaining valvetrain stability with the aggressive cam action. If the valvetrain can’t keep up, power production is over. To ensure valvetrain performance, D&A used a GM hydraulic roller lifter from the Cadillac CTS-V road race program. These lifters are a direct replacement for stock, using the OEM lifter guides. The rest of the valvetrain consists of COMP 5/16-inch pushrods, the aforementioned Harland Sharp 1.8:1 rocker arms, and Lunati Gold Series springs, PN 73925K2LUN. Andy tells us: “We used the Lunati Gold Series; it’s a dual valvespring and it works really well. It isn’t expensive either, and is really lightweight.”

Providing sufficient airflow capacity is a set of L92 factory GM heads. Known for their ample port size and intake flow, these heads are an excellent choice to meet the demanding airflow needs of a stroker combination.

Providing sufficient airflow capacity is a set of L92 factory GM heads. Known for their ample port size and intake flow, these heads are an excellent choice to meet the demanding airflow needs of a stroker combination.

Carbureted Combination

Modifications to the heads include custom porting, focusing particularly on exhaust port flow. Flow bench testing revealed 335 cfm on the intake side and 255 cfm through the exhaust at .600-inch lift.

Modifications to the heads include custom porting, focusing particularly on exhaust port flow. Flow bench testing revealed 335 cfm on the intake side and 255 cfm through the exhaust at .600-inch lift.

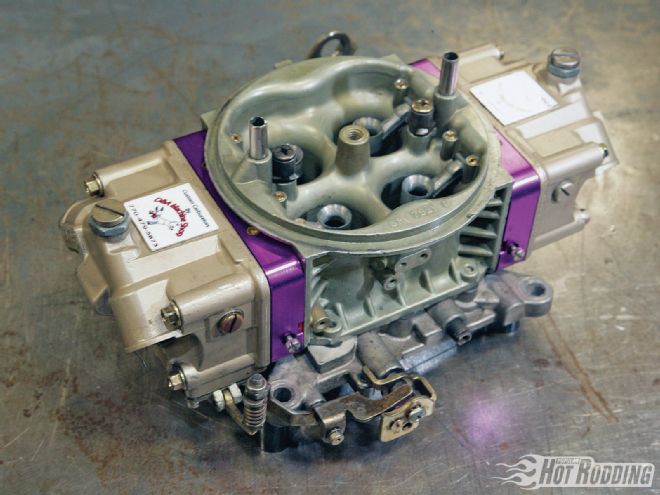

While the LQ4—like all LS-based engines—uses a complicated engine management system and EFI in OEM installations, for general-purpose hot rod use there are simpler alternatives. To handle the induction, the EFI was shelved in favor of a GMPP two-plane intake manifold topped with a D&A-modified Holley 750HP carb. The attraction here is that the fuel system requires no wiring or programming to make it work; just plumb it up and it’s done. Andy was impressed with the manifold: “It’s a really nice piece. There is plenty of room to port on it if need be. I didn’t do any port work on it, and it made for a really nice broad torque curve.”

While the fuel side of the engine management can be readily done away with in favor of good old-fashion mechanicals, the ignition side is another story. Though it is true that a distributor can be adapted, the better solution is to retain the coil-on-plug ignition, but run it via an aftermarket stand-alone ignition control. Here D&A went with the MSD 6LS Ignition Controller, which takes input from the cam and crank sensors to operate the ignition through a fully programmable module. Andy spoke favorably of the unit: “It is a simple setup; it’s easy to play with and easy to tune. It makes setting the ignition timing fun instead of aggravating.”

With a hydraulic roller, the valvetrain is critical. D&A used GM hydraulic roller lifters from the Cadillac CTS-V race program, along with COMP pushrods, Harland Sharp rockers, and Lunati dual springs, retainers, and keepers. Valves measure 2.165 inches on the intake, and 1.600 inches on the exhaust.

With a hydraulic roller, the valvetrain is critical. D&A used GM hydraulic roller lifters from the Cadillac CTS-V race program, along with COMP pushrods, Harland Sharp rockers, and Lunati dual springs, retainers, and keepers. Valves measure 2.165 inches on the intake, and 1.600 inches on the exhaust.

Power Testing

This hot LQ4 combination was put through the wringer on D&A’s dyno, looking to dial in the power. On the dyno, the engine was equipped with a set of Hedman Husler headers with a primary tube diameter of 2.00 inches, and a beltdriven electric water pump arrangement. With the conservative cam duration, the engine idled good enough to be at home in a hot street machine, while the cam’s tight 108-degree lobe separation provided an impressive performance bark. The goal was to dial in the fuel and ignition settings, looking for maximum average power over the entire rpm range. The Holley 750 HP was tested against a Holley 830 carb, and interestingly the smaller carb proved to be better overall. On the other hand, the engine seemed to favor a larger 3.50-inch header collector, in comparison to a 3.00-inch piece. Tuning the ignition timing proved to be critical in getting the best from the engine, and here the MSD ignition controller excelled.

Topping the intake manifold is a Holley 750 HP, a unit that was customized by D&A Machine Shop. The carb proved itself on the dyno, delivering more average power than a larger 830-cfm Holley carburetor.

Topping the intake manifold is a Holley 750 HP, a unit that was customized by D&A Machine Shop. The carb proved itself on the dyno, delivering more average power than a larger 830-cfm Holley carburetor.

With the final dyno printouts in hand and the engine cooling on its stand, the numbers told the story. The short-cammed, big-cube stoker delivered tire-melting torque from the word “go,” showing 530-plus lb-ft right from the jump at 2,500 rpm. From there the torque just ramped upward, peaking at 581 lb-ft at just 3,200 rpm. While the low-rpm torque peak might imply that the engine would quit early, the torque just seemed to plateau, holding over 500 lb-ft all the way up to 6,000 rpm! Peak power was recorded at 588 hp at 5,800 rpm. If you are looking for wild torque, and power that keeps coming, A D&A Machine Shop stroker LQ4 will dish out the numbers.

By the Numbers 409ci LQ4 Iron-Block LS Block: 6.0 LS truck Bore: 4.03 inches Stroke: 4.00 inches Displacement: 409 cid Compression ratio: 11.4:1 Crankshaft: Scat Camshaft: Demos Cams Timing chain: Liberty Lifters: GM CTS-V Pushrods: COMP Cams 7944 7.25 inches long (5/16-inch diameter) Springs: Lunati Gold Series (73925K2LUN) Installed height: 1.810 inches Spring load, closed: 153 pounds Spring load, open: 400 pounds Retainer: Lunati Valve locks: Lunati Duration, intake: 276 degrees Intake lift: .607 inch Duration, exhaust: 282 degrees Exhaust lift: .607 inch Rockers: Harland Sharp, adjustable Rocker ratio: 1.8/1.8 Lobe separation: 108 degrees Installed centerline: 102 degrees Ring pack: Total Seal Ring endgap: gapless Piston: Mahle Piston clearance: 0.005 inch Main studs: ARP Rods: Scat 6.125-inch I-beam Main bearings: King Rod bearings: King Main journal diameter: OEM Rod journal diameter: 2.100 inches Main clearance: .003 inch Rod clearance: .0024 inch Cylinder heads: GM L92 Head bolts: ARP bolts Intake manifold: GM dual-plane Intake port flow: 335 cfm at .600-inch lift Exhaust port flow: 255 cfm at .600-inch lift Intake valve: Ferrea 2.165 inch Exhaust valve: Liberty 1.60 inch Cylinder head gaskets: stock GM Piston/head clearance: 0.051 inch Engine gaskets: OEM Carburetor: D&A-built Holley 750 Headers: Hedman Husler Coils: GM, stock Ignition: MSD 6010 Spark plug wires: MSD Damper: PRW Water pump: stock GM with Moroso drive Oil pan: stock 6.0L truck Oil pump: GM L92 Oil: AMSOIL 10w30

On the Dyno 409ci LQ4 Chevy

RPM TQ HP 2,500 533 257 2,600 534 264 2,700 549 282 2,800 562 300 2,900 570 315 3,000 575 329 3,100 579 342 3,200 581 354 3,300 580 364 3,400 577 374 3,500 578 385 3,600 579 397 3,700 577 406 3,800 572 414 3,900 569 422 4,000 568 432 4,100 566 442 4,200 564 451 4,300 565 463 4,400 567 475 4,500 565 484 4,600 565 494 4,700 566 507 4,800 570 521 4,900 569 531 5,000 565 538 5,100 564 547 5,200 563 558 5,300 559 564 5,400 553 568 5,500 549 575 5,600 545 582 5,700 540 586 5,800 532 588 5,900 520 584 6,000 507 579 6,100 491 571 6,200 479 565 6,300 470 564 6,400 463 564