Ask any professional racer or engine builder and you’ll hear that cylinder-head airflow is the most important factor in achieving the greatest peak horsepower from any engine. For years Pontiac racers were forced to use heavily ported cast-iron originals, and peak airflow rarely surpassed 300 cfm at 28 inches of pressure. Many new cast-aluminum Pontiac cylinder heads have entered the aftermarket within the past several years, and they have completely revolutionized Pontiac performance.

Some modern aftermarket cylinder heads are intended to be high-performance stock-replacements. Others are specialized castings that boast peak airflow capacity greater than 400 cfm. Kauffman Racing Equipment (KRE) in Glenmont, Ohio, has two very successful Pontiac offerings that cover both markets. Its cast-aluminum D-port offers more than 250 cfm of peak intake airflow as cast, and as much as 375 cfm after porting. Its High Port offers 330 cfm of peak intake airflow as cast, and as much as 455 cfm after porting.

While either KRE cylinder head can sustain great performance on the street or dragstrip, there’s a large market void for those racers looking to compete at the top level, where very large-cube, Pro-Stock–type performance is the norm. KRE has an answer. Its new Warp 6 is a very unique cylinder head that’s designed to deliver 460 cfm as cast and should sustain as much as 1,250 hp with the correct combination of parts.

The new Warp 6 from Kauffman Racing Equipment in Glenmont, Ohio, was designed to take Pontiac performance to the next level. It’s unlike any Pontiac cylinder head ever before. Internal testing at KRE reveals that it won’t disappoint.

The new Warp 6 from Kauffman Racing Equipment in Glenmont, Ohio, was designed to take Pontiac performance to the next level. It’s unlike any Pontiac cylinder head ever before. Internal testing at KRE reveals that it won’t disappoint.

Follow along as we explore the design advantages of a cylinder head that will move Pontiac performance forward at Warp speed!

Intake and exhaust valve size is limited by cylinder-bore diameter in a wedge-type cylinder head, such as a typical Pontiac casting. Shrouding can occur when larger inline valves approach the cylinder wall, and that degrades airflow, subsequently impacting performance. “Our High Port is a great performer, but it has its share of design compromises,” says KRE’s Jeff Kauffman. “It’s a wedge-type casting that accepts conventional intake and round-port-exhaust header packages, and that limits valve sizes and port-to-port consistency.”

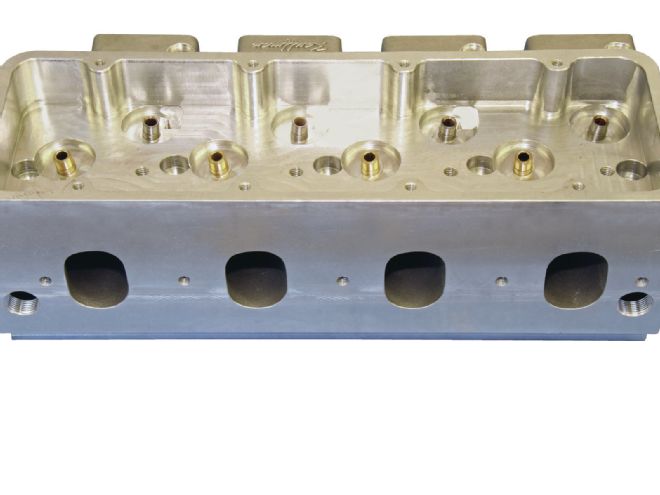

The intake flange features four evenly spaced intake ports. A specific intake manifold available exclusively from KRE is required.

The intake flange features four evenly spaced intake ports. A specific intake manifold available exclusively from KRE is required.

A canted-valve cylinder head features intake and exhaust valves that oppose, with each pointing toward the cylinder centerline. It’s a distinct advantage that allows for larger valves, while lessening the risk of shrouding, thus maximizing airflow. Chevrolet used canted-valve technology when originally developing its big-block, and canted-valve cylinder heads are commonplace in today’s top-performing race engines, regardless of make.

One company already produces a Pontiac-specific canted-valve cylinder head. It retains the conventional Pontiac valve arrangement, however. “The current canted-valve casting is good, but its stock valve layout creates certain limitations,” says Kauffman. “We wanted to create the ultimate Pontiac cylinder head for serious racers. The only restriction we allowed during the development was fitment on a traditional Pontiac block. All other aspects were geared toward maximum performance, and that meant deviating from the original Pontiac design.”

Using the highly successful Drag Racing Competition Engine (DRCE) cylinder heads offered by GM Performance Parts for Pro Stock Racing as its basis, KRE developed its new Warp 6 casting with canted valve angles and a unique symmetrical valve arrangement where the intake and exhaust ports are spaced evenly. “Pontiac used an asymmetrical valve arrangement, where the cylinder head has intake runners share a common port wall, as do the center exhaust ports. That creates a distinctive pair of left and right intake ports, and four uniquely shaped exhaust ports,” explains Kauffman.

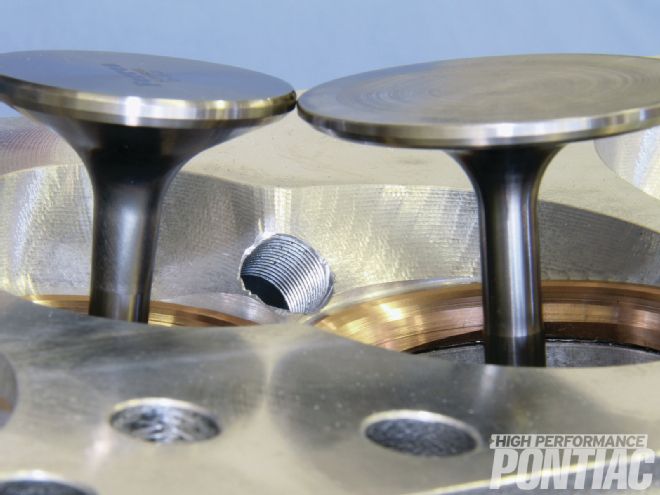

Canted-valve technology places the intake and exhaust valves on opposite sides of a cylinder and points them toward the center. For photographic effect, the valves of the Warp 6 are opened to a lift much greater than 1 inch, and to the point where they contact. This couldn’t occur in a wedge-type casting.

Canted-valve technology places the intake and exhaust valves on opposite sides of a cylinder and points them toward the center. For photographic effect, the valves of the Warp 6 are opened to a lift much greater than 1 inch, and to the point where they contact. This couldn’t occur in a wedge-type casting.

In addition to port-to-port airflow consistency, he says the symmetrical valve arrangement offers another significant advantage that plagues serious performance applications. “As engine power increases, it creates more heat. When dealing with today’s very-high-performance engines, the exhaust gas exiting through the siamesed exhaust ports can create a significant hot spot that burns the head gasket between the center cylinders, and that can cause complete gasket failure. The valve layout of the Warp 6 eliminates this problematic issue.”

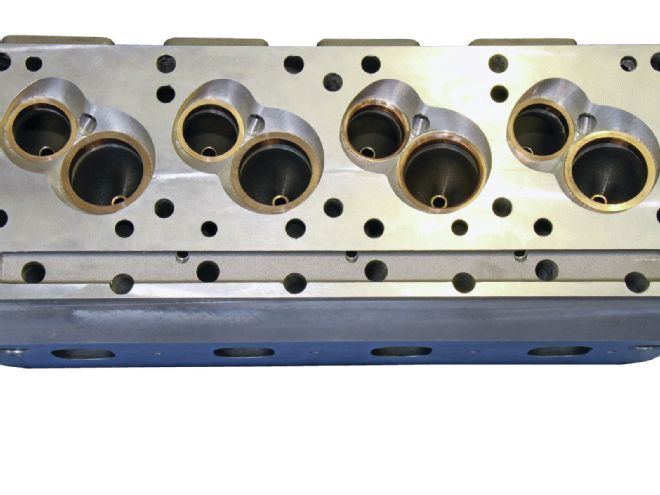

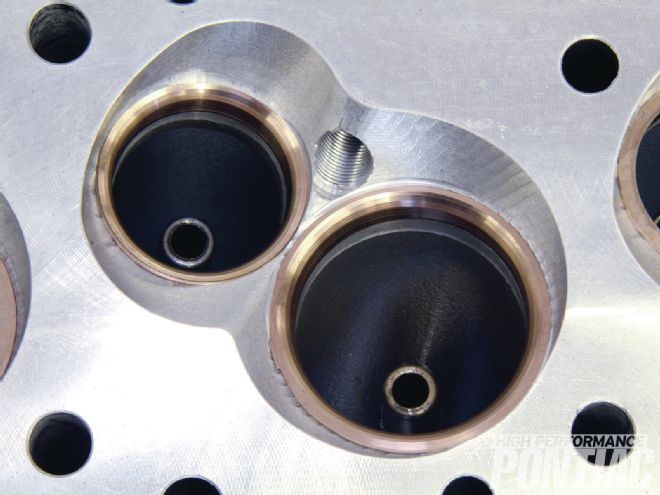

A key feature of the Warp 6 is its symmetrical valve arrangement. It improves and equalizes airflow and combustion efficiency, and eliminates the hot spot between the paired exhaust valves at the center of a traditional Pontiac casting.

A key feature of the Warp 6 is its symmetrical valve arrangement. It improves and equalizes airflow and combustion efficiency, and eliminates the hot spot between the paired exhaust valves at the center of a traditional Pontiac casting.

Kauffman planned for the Warp 6 to be constructed of cast aluminum, but his company’s standard practice is to first create a billet aluminum prototype for testing. “We began developing the Warp 6 about four years ago; the prototype debuted at the Ames Performance Tri-Power Pontiac Nationals in Norwalk, Ohio, in August 2007. The response was astounding. We were very excited to see how well the cast-aluminum production piece, which we manufactured in 2011, turned out.”

As cast, the Warp 6 intake port measures 399 cc’s, or nearly three times that of an original Pontiac D-port. With a standard valve size of 2.25/1.75 inches, intake and exhaust airflow peaks at 460 cfm and 320 cfm, respectively. With the ability to accept larger 2.40/1.85-inch valves, KRE has developed an optional CNC-porting program that increases peak airflow to at least 515 cfm at the present time, and possibly even more in the future.

5 Valve seats are constructed of copper for use with titanium valves. The intake ports measure 399 cc’s and flow 460 cfm at 28 inches of pressure. The exhaust flows 320 cfm.

5 Valve seats are constructed of copper for use with titanium valves. The intake ports measure 399 cc’s and flow 460 cfm at 28 inches of pressure. The exhaust flows 320 cfm.

The Warp 6 is available bare but with valve seats and guides installed. Jeff says, “Unlike a cylinder head for a street engine where hardened valve seats and steel valves are used, the Warp 6 is a full race casting and requires titanium valves, so non-beryllium copper seats are used. Bronze guides are used on the intake side, but steel valve guides with a bronze liner are used on the exhaust for longevity and stability to prevent deflection with aggressive high-lift cams.”

Requiring professional finishing, a pair of bare Warp 6 castings starts at $3,600. A complete pair starts at $6,000 and includes 2.25/1.75-inch titanium valves, a five-angle valve job, roller-spec valvesprings for valve lift up to 0.900-inch, and various other high-quality valvetrain components. Additional CNC-porting adds $2,200 to the cost of either.

The Warp 6 is unique and requires some specialized accessory equipment that’s only available from KRE. These include an ARP head-stud kit, gaskets, one-piece individual T&D rocker arms designed by KRE, a sheetmetal intake manifold and valve covers, custom- fabricated headers, and a specific coolant neck that draws coolant from the front and rear of each cylinder head.

6 Titanium valves measuring 2.25/1.75 inches are standard equipment on the complete casting. The Warp 6 contains enough material to fit 2.40-/1.85-inch valves. The modern fast-burn combustion chamber is CNC-machined and measures 60 cc’s.

6 Titanium valves measuring 2.25/1.75 inches are standard equipment on the complete casting. The Warp 6 contains enough material to fit 2.40-/1.85-inch valves. The modern fast-burn combustion chamber is CNC-machined and measures 60 cc’s.

Due to the Warp 6’s symmetrical valve arrangement, a typical Pontiac camshaft can’t be used. Instead, a specific cam with revised lobe placement is required. “Camshaft specifications are application driven, but we’re commonly seeing peak performance with more than 280 degrees at 0.050-inch and valve lift between 0.750- and 1.00-inch. Because the Warp 6 requires an aggressive, full race cam for greatest performance, we have correct 55mm cores readily available and can custom-grind any specification.”

Kauffman suggests a minimum bore diameter of 4.25 inches for the Warp 6. “I feel that it’s best suited for producing high horsepower from engines displacing at least 500 inches. It would probably perform suitably on a smaller engine, but the engine would have to be capable of operating at very high rpms to take advantage of the available airflow. If you’re building a smaller engine, I believe more sensible options are available.”

7 High-quality valvetrain pieces are included in the complete casting. The valvesprings are equipped to handle 0.900-inch lift of solid-roller spring pressure.

7 High-quality valvetrain pieces are included in the complete casting. The valvesprings are equipped to handle 0.900-inch lift of solid-roller spring pressure.

When developing the Warp 6, Kauffman says, “I wanted to create a cylinder head with identical intake and exhaust ports—I felt it was important in achieving maximum performance. After seeing the results of our dyno testing, I believe the symmetry is even more important than I initially thought. Making each individual cylinder as equal as possible has revealed a distinct performance increase.

“During development, our performance goal was 1,250 hp on a 535-inch engine. So far we’ve seen more than 1,100 hp from an as-cast Warp 6 on such an engine. I’m confident that we’ll surpass 1,200 hp using a CNC-ported unit. We hope to see 1,250 hp in the future, and possibly even more, but time will tell just how much performance potential the Warp 6 possesses.”

8 On our modified Superflow SF110 flow bench, the Warp 6 intake port peaks at 452 cfm at a valve lift of 1.00-inch. Airflow was recorded at a lesser pressure and mathematically converted to 28 inches.

8 On our modified Superflow SF110 flow bench, the Warp 6 intake port peaks at 452 cfm at a valve lift of 1.00-inch. Airflow was recorded at a lesser pressure and mathematically converted to 28 inches.

Jeff Kauffman is very proud of his company’s new Warp 6, and understandably so. “I think the level of performance we’re achieving with it speaks for itself. It will allow serious Pontiac racers to compete on the same level as those with other makes.”

While the Warp 6 certainly isn’t for everyone, it gives any Pontiac hobbyist the opportunity to perform at the top level. And that’s something every performance enthusiast should be very excited about!

8 On our modified Superflow SF110 flow bench, the Warp 6 intake port peaks at 452 cfm at a valve lift of 1.00-inch. Airflow was recorded at a lesser pressure and mathematically converted to 28 inches.

8 On our modified Superflow SF110 flow bench, the Warp 6 intake port peaks at 452 cfm at a valve lift of 1.00-inch. Airflow was recorded at a lesser pressure and mathematically converted to 28 inches.