There was a time not long ago when if you wanted a really quick street Pontiac, you dropped a Rat motor between the fenderwells. Sure, the purists threw rocks at you, but the simple truth was horsepower was easier and cheaper with the Chevy. Each time this happened, somewhere there was a disturbance in the great cosmic ether of Pontiac karma, and this must have pissed off some rather motivated Pontiac people. They saw each Rat swap as a personal insult and decided to do something about it. The result of this affront is an arsenal of killer Pontiac cylinder heads and cylinder blocks that can lay claim to some serious power numbers. Sure, GM in the fog of forgetting where it came from has scalped the Pontiac logo from the GM family tree, but clearly not everyone intends to forget.

Combine a great set of Roland aftermarket Pontiac cylinder heads with some compression, a solid roller cam, and a 1,050-cfm Holley Dominator carb and you have the ingredients for a stout street Pontiac.

Combine a great set of Roland aftermarket Pontiac cylinder heads with some compression, a solid roller cam, and a 1,050-cfm Holley Dominator carb and you have the ingredients for a stout street Pontiac.

Andy Mitchell, owner of Hardcore Racing, is a low-key engine builder who has constructed a fair number of Pontiac engines that measure up to the company's name. Mitchell has built several big-inch, normally aspirated, real Pontiac engines that have made more than 1,000 hp. There may not be an original GM part to be found in these engines, but they nonetheless pay strict homage to the Pontiac lineage. For this story, we followed along as Mitchell assembled a car-crafty version of a 400 Poncho, block-based, 434ci motor that makes an honest pump gas 650 hp. Here's how he did it.

The Short-Block

The world of Pontiac high performance is rapidly changing. If power is the goal and money is no object, the Indian Adventures II iron block or the Butler aluminum version offer unbelievable strength and large displacement foundations for the born-again Poncho. Mitchell has plenty of experience with these pieces, but this particular customer was looking for a conservative 650 hp, which pointed Mitchell to a stock, '70-vintage, 400 block. It featured a 4.125-inch bore and a 3.750-inch stroke, which is basically a larger-bore version of the 389. Mitchell's combination enlarged the bore to 4.155 inches and stretched the stroke to an even 4.00 inches to produce 434 ci.

According to Mitchell, "In 30 years of building these engines, I've never broken a block, but many other people have. At this power level, we're OK. It's around 750 hp where the stock blocks tend to crack." But this doesn't mean Mitchell didn't inject some beef into this casting. The first upgrade was a full set of Pro-Gram Engineering four-bolt steel main caps. Next, he opened up the main bearing oil feed holes to 3/16 inch and increased the main bearing clearance to 0.003 inch to adjust for the small-journal, 3.00-inch-diameter mains. Rod bearing clearance came in at 0.0028 inch. The only other major requirement for this stock-block buildup was to reinforce the somewhat open lifter bore area on the stock Pontiac blocks. SD Performance makes what it calls the Mega Brace, a series of bolt-in aluminum pieces designed to support the bottom of the lifter bores that tend to crack when subjected to higher engine speeds and greater valvespring pressure. The Mega Brace can even be installed after the short-block is assembled.

Cam Specs

Mitchell custom-spec'd this Comp mechanical roller, so you won't find a part number for this cam in the catalog. Call Mitchell at Hardcore for the details on the lobes.

CAMSHAFT

DURATION AT 0.050 (DEGREES)

LIFT (INCHES)

LOBE SEPARATION (DEGREES)

VALVE LASH (INCHES)

Intake

266

0.675

111

0.020

Exhaust

272

0.675

0.020

Roland Heads

Focus your short attention here. Roland Racing is a small shop that does big things. Casting a cylinder head with the expectation of making a couple of dollars is an achievement unto itself. But doing so for a limited number of Pontiac enthusiasts might well be considered risky. But the results speak for themselves. The Roland CV-1 aluminum cylinder head goes far beyond just replicating a production head by canting the valves to open them into the center of the cylinder and therefore improving flow potential, even on a small-bore engine. This is completely different from typical '60s valve layout technology. This clean-sheet design also demanded changes to the intake port layout to create separation from the pushrods so as not to compromise flow with port intrusions or tunnels. All this equates to some serious flow potential as evidenced by the accompanying flowsheet. While Mitchell did elect to drop extra coin on a T&D shaft rocker system, the Roland CV-1 heads allow the use of more affordable stud-mounted roller rockers. For a made-in-the-USA boutique cylinder head like this, the Roland price of just under $3,000 for a complete pair of heads that flow damn near 350 cfm at 0.700-inch valve lift qualifies for steal-of-the-century status.

Cylinder head flow is the Holy Grail of horsepower. The easiest way to make monster power is with a large-cubic-inch Pontiac fitted with these Roland Racing CV-1 aluminum castings.

Cylinder head flow is the Holy Grail of horsepower. The easiest way to make monster power is with a large-cubic-inch Pontiac fitted with these Roland Racing CV-1 aluminum castings.

Flow Numbers

These flow numbers were generated on Westech's SuperFlow 600 bench using a 4.175-inch bore size at 28 inches of water test depression. While Mitchell's cam only lifts the valve to 0.675 inch, note how these heads continue to deliver flow improvements up to a staggering 1 inch of valve lift. These are as-cast flow numbers. Porting could easily push the intakes above 400 cfm.

CFM VALVE LIFT INTAKE EXHAUST E/I (PERCENTAGE) 0.100 72 61 85 0.200 145 114 78 0.300 220 142 64 0.400 273 166 61 0.500 303 186 61 0.600 330 202 61 0.700 349 211 60 0.800 358 220 61 0.900 373 230 62 1.000 385 240 62

The Test

The final assembly included adding the necessary Roland CV-1 single-plane intake manifold along with a 2-inch phenolic spacer topped off with a Holley Ultra Dominator 1,050-cfm three-circuit carburetor. Even though the motor was only 434 inches, the CV-1 heads seem to prefer a larger 2-inch primary header. Bolting up this completed package on Westech's dyno, Mitchell and Westech's Steve Brulé performed some quick jetting and timing exercises and then cranked out an impressive 650 hp at 7,000 rpm. On the other end of the curve, peak torque occurred at 5,500 rpm with 549 lb-ft, which outlined a wide powerband of 1,500 rpm. And there was no race gas here-this was on little more than California-conservative 91-octane. Mitchell says the owner was initially going to stuff this beast into an original '65 GTO but reconsidered, and it now occupies the engine compartment in a '69 Firebird. Just for fun, we plugged the power curve into a simulated 3,000-pound Firebird with a TH400, a 28-inch-tall tire, and a 4.10:1 gear using the Quarter Pro software. The sim reported a 9.90 at 135 mph, which should make any Pontiac owner proud. We certainly do live in the golden age of horsepower.

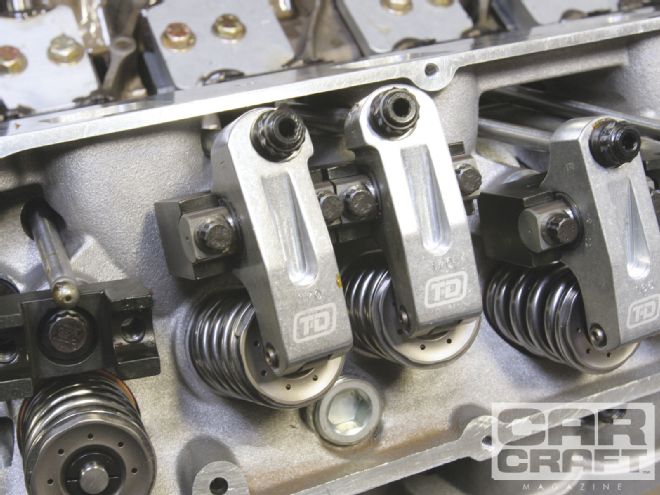

Buttoning up the engine was a complete set of 1.60/1.65:1-ratio T&D shaft rockers actuating Manley mechanical roller valvesprings and retainers.

Buttoning up the engine was a complete set of 1.60/1.65:1-ratio T&D shaft rockers actuating Manley mechanical roller valvesprings and retainers.

PONTIAC POWER RPM TQ HP BSFC 4,600 525 460 0.445 4,700 525 470 0.439 4,800 529 483 0.436 4,900 534 498 0.437 5,000 538 512 0.436 5,100 543 527 0.434 5,200 547 541 0.435 5,300 548 553 0.432 5,400 548 563 0.429 5,500 549 574 0.429 5,600 549 585 0.430 5,700 549 596 0.431 5,800 546 603 0.432 5,900 541 608 0.433 6,000 536 612 0.431 6,100 530 616 0.429 6,200 524 619 0.429 6,300 519 623 0.434 6,400 515 627 0.437 6,500 511 632 0.439 6,600 507 637 0.443 6,700 503 642 0.445 6,800 499 645 0.451 6,900 493 648 0.460 7,000 488 650 0.469 Peak 549 650 0.429 Avg. 527.8 580.9 0.437

The final top-end pieces included the requisite CV-1 Roland single-plane intake that Mitchell merely cleaned up internally along with a Holley 1050 three-circuit Ultra Dominator carburetor that required very little tuning to make 650 hp. Ignition was handled by an MSD billet distributor and BOP Engineering composite gear.

The final top-end pieces included the requisite CV-1 Roland single-plane intake that Mitchell merely cleaned up internally along with a Holley 1050 three-circuit Ultra Dominator carburetor that required very little tuning to make 650 hp. Ignition was handled by an MSD billet distributor and BOP Engineering composite gear.