Since putting my '46 roadster pickup on the street, the cheap aftermarket GM-style starter motor had become more and more lazy, to the point where it would need to cool down for an hour or so before it would start the engine again. Clearly this was unacceptable, and it became apparent that the excessive heat underhood had "cooked" it and the solenoid to the point where they needed to be replaced. But simply replacing it would not cure the problem; I would have to address the heat problem.

When I fabricated the inner fenders I punched louvers in them to let excess heat escape, as well as leaving a 1-inch gap between them and the sides of the firewall in the same manner as stock inner fenders, but this wasn't enough. The small-block Chevy I'd installed has always run at 210 degrees, and a larger radiator with dual electric fans is next on my "to-do" list. But short of cutting vents into the sides of the hood (I'd contemplated louvers in the hood top but didn't want that heat blowing out and back in through the cowl vent). I was at a loss to figure out how to reduce the underhood temperature, which also made the cabin extremely uncomfortable, especially on drives across the desert, which, let's face it, surrounds the Southern California area in which I live!

OK, so I haven't yet installed heat or sound insulation inside the cab, with a bare-metal floor and firewall, but again, this wouldn't cure the heat buildup in the engine compartment. Discussing the problem last year with Jim Henderson from Thermo Tec, he suggested that his company's products may provide the answer. And with the starter motor going AWOL, I figured now was the time to conduct a few heat-mapping tests.

I'd always figured the old plain steel headers I'd found at a swap meet (literally, they were in a dumpster at the end of the day, so I pulled them out to make way for the wheels I wanted to dump!) were part of the reason for the high temperatures. I figured a new set of ceramic-coated headers from Patriot Exhaust Products might help the situation, as well as a high-torque mini starter from Summit Racing (which would take up less room and hence offer more air circulation), plus adding heat insulation products from Thermo Tec, wrapping the starter, wiring, and headers. This would allow me to measure any temperature drop in stages, showing improvements along the way.

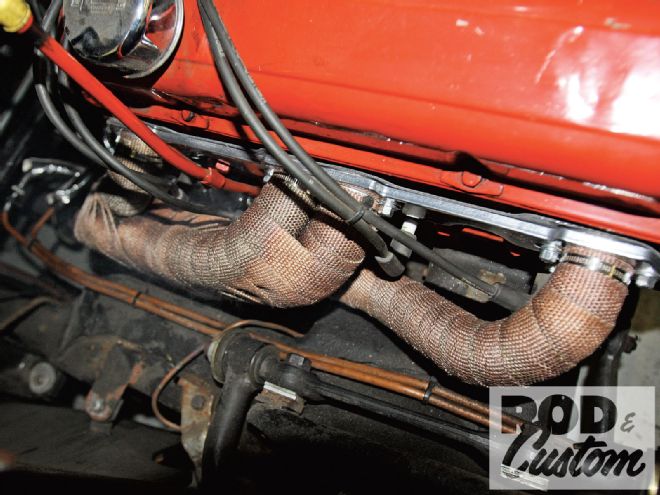

It's not hard to see why my old starter motor suffered from heat absorption, with around an inch of clearance between the old headers and the starter motor body, plus the heat from the block.

It's not hard to see why my old starter motor suffered from heat absorption, with around an inch of clearance between the old headers and the starter motor body, plus the heat from the block.

I first measured the temperature of the starter and headers at various points before any work took place, running the motor for 15 minutes from cold with the hood shut, then replaced the starter and headers and repeated the procedure, finally wrapping the new headers and taking readings once again. I should mention here that most header manufacturers don't recommend wrapping their products, and it will invariably invalidate any warranty. Ceramic-coated headers are already very good at lowering temperatures, as will be seen, but I wanted to experiment and lower the level of heat both underhood, and consequently, inside the cabin, as much as possible, so I ignored this advice!

The table on page 76 charts the differences in temperature at each stage, and makes for interesting observation. All temperatures are in degrees Fahrenheit.

Conclusion

What's immediately obvious is that the ceramic-coated headers reduced the temperatures significantly, while fitting the mini starter saw a temperature drop of around a third. Also obvious is that the temperature of the starter dropped yet again once the heat shield was installed, yet the exhaust temperatures rose to and even beyond the baseline temperatures. I'll explain why but first must mention that despite the high readings, the wrapped headers could be touched by hand (try that with bare steel or coated headers!) and the ambient temperature underhood, as well as inside the car once out on the road, had also dropped significantly.

Wandering 'round my local Harbor Freight Tools emporium, I spied this Cen-Tech infrared thermometer, ideal for measuring the temperatures of individual components underhood. Using a laser, it displays the temperature on a digital display, in either Fahrenheit or Celsius, with a range of -20 degrees C to 520 degrees C.

Wandering 'round my local Harbor Freight Tools emporium, I spied this Cen-Tech infrared thermometer, ideal for measuring the temperatures of individual components underhood. Using a laser, it displays the temperature on a digital display, in either Fahrenheit or Celsius, with a range of -20 degrees C to 520 degrees C.

So just what was going on? Well, it's all down to how the exhaust wrap works. Wrapping the headers maintains exhaust gas heat within the header, the material developed by Thermo Tec having the ability to conduct heat across its surface. The silica-based fabric (not asbestos!) of the Header Wrap , which has a patented inorganic coating, was developed so as not to over insulate the system, as it is important to retain only a specific amount of heat. Maintaining a higher temperature in the headers increases flow and improves the scavenging effect, allowing the gases to escape more quickly, and the engine to breathe more efficiently. While I was concerned with reducing temperatures and protecting electrical components, the improved efficiency and reduction in contamination of gases provides a moderate increase in torque and power. For detailed explanations and dynamometer readings, check out Thermo Tec's website; I'm just pleased my truck is cooler underhood, cooler to drive, and starts every time, even when hot!

PLAIN STEEL FULL-LENGTH HEADERS AND OEM-STYLE STARTER Starter solenoid 192.3 Starter casing 161.6 Header collector 233.4 (right) 232.3 (left) Header flange 234.8 (right) 254.3 (left) Header runners (right, front to rear) 200.1 201.1 210.5 206.4 Header runners (left, front to rear) 198.5 203.7 193.2 197.7

CERAMIC-COATED PATRIOT HEADERS AND SUMMIT MINI STARTER Starter solenoid 110.4 Starter casing 104.5 Header collector (entering extension) 185.6 (right) 186.3 (left) Header flange 195.3 (right) 208.6 (left) Header runners (right, front to rear) 128.8 154.4 171.7 150.9 Header runners (left, front to rear) 164.8 138.7 156.2 147.3

AS ABOVE BUT HEADERS AND STARTER WRAPPED IN THERMO TEC INSULATION Starter solenoid unavailable (though outside of wrap measured 217) Starter casing 93 (measured at end of casing where not wrapped) Header collector (entering extension) 238.1 (right) 234.8 (left) Header flange 269.1 (right) 263.7 (left) Header runners (right, front to rear) 201.3 228.3 228.7 206.2 Header runners (left, front to rear) 212.3 221.4 214.8 202.3