There's a reason the oil pan of the big-block and Hemi Mopar engine seems shallow when compared to other domestic V-8 engines of the muscle car era, and it has nothing to do with the capacity of the pan. In fact, the reason for the oil pan's design is not a function of the pan itself, but rather the design of the block. Instead of stopping the casting at the main cap parting line like most other manufacturers, Chrysler deemed it worth the extra weight to extend the block lower than the main caps, adding angled gussets to the main webbing for strength, as well as affording the opportunity for cross-bolted main caps in the case of the Hemi. And while manufacturing costs prevented the many Chrysler big-blocks from getting factory four-bolt main caps, now thanks to Pro-Gram Engineering you can add cross-bolted billet main caps to any Mopar big-block.

The big-block Mopar engine is known for its tough bottom end. This month we'll show you how we made the bottom end of the big-block we're building for our '71 Road Runner even tougher with billet, four-bolt main caps from Pro-Gram Engineering.

The big-block Mopar engine is known for its tough bottom end. This month we'll show you how we made the bottom end of the big-block we're building for our '71 Road Runner even tougher with billet, four-bolt main caps from Pro-Gram Engineering.

Even though the big-block Chrysler is designed to give the crankshaft maximum support, it is still prone, like all engines, to an anomaly called "main cap walk." Commonly abbreviated to cap walk, the problem is caused by the crankshaft being forced downward, flexing the factory main caps and even stretching the bolts or studs holding the caps in place. The common sign of cap walk is metal transfer between the cap and block of the center three main bearings that can be seen at the mating surfaces only with the main caps removed. Over time, cap walk can affect the main bearing oil clearances, causing premature bearing wear and in the worst cases even bearing and subsequent engine failure. To combat the problems associated with cap walk in a 451-cubic-inch low-deck big-block we're building for our '71 Road Runner, we ordered a set of billet-steel four-bolt main caps from Pro-Gram and had Auto Performance Engines perform the machine work required to install them.

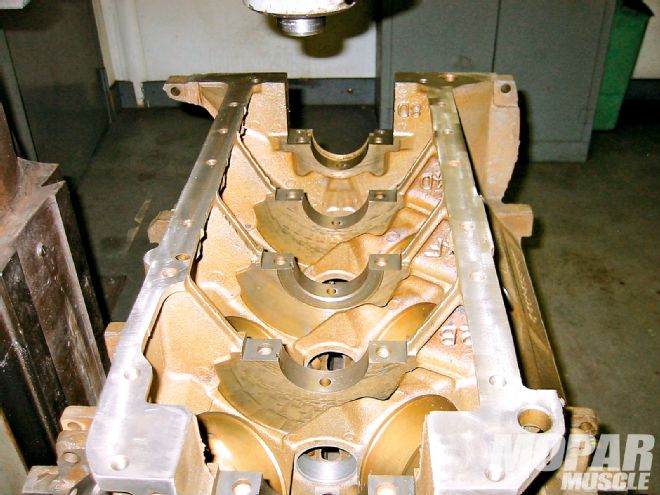

The Chrysler big-block offers more crankshaft support than most domestic V-8 engines, as the block extends past the parting line of the main caps with angled support gussets. Though a good design, we'll make it even better with new four-bolt main caps from Pro-Gram Engineering.

The Chrysler big-block offers more crankshaft support than most domestic V-8 engines, as the block extends past the parting line of the main caps with angled support gussets. Though a good design, we'll make it even better with new four-bolt main caps from Pro-Gram Engineering.

We were impressed with the Pro-Gram main caps when we unpackaged them as they were far beefier than the factory caps, coming with all the hardware necessary for installation. Pro-Gram's main caps are all manufactured from the highest quality materials, and since the center three caps are the most prone to cap walk, they're machined for cross-bolts, just like Chrysler 426 Hemis were from the factory. Since this installation requires precisely machining the block, the best time to perform it is during the rebuild or freshening of your engine. While our 400 block was at Auto Performance Engines, Kevin machined the block for the cross-bolted center caps, then line-honed the mains to the proper tolerances. We're estimating this engine will make well over 600 horsepower and our new main caps will give added strength through superior materials, and even more strength by being cross-bolted on an axis 90 degrees from the main stud. With these main caps in place, we should confidently be able to turn our engine to 7,000 rpm or even higher without worrying about crankshaft stability.