You've spent more money on your engine than any other single component of your race car. And if you are like most racers, you're fine with that as long as your engine makes good power and doesn't grenade on you unexpectedly.

Engine builder Keith Dorton of Automotive Specialists shares a few of his tricks for optimizing valve lash gained over years of building winning race engines.

Engine builder Keith Dorton of Automotive Specialists shares a few of his tricks for optimizing valve lash gained over years of building winning race engines.

After all, spending your hard-earned cash on repairs you didn't plan on making is never fun. Thankfully, you can avoid many engine problems with a few regular checks, and, if you're running mechanical (not hydraulic) lifters, one of the most important is checking and setting your valve lash.

By sticking to a regular schedule for checking your valve lash, you can potentially save yourself a lot of money by catching small problems-with easy fixes-before they become big ones. After all, replacing a lifter or a rocker arm that is in the process of going bad is a lot cheaper than the results of a broken valve chewing up a piston and combustion chamber, or lots of metal shavings from the camshaft getting flushed into the oil.

Valve lash is the available gap between the rocker arm and the tip of the valve stem when the lifter for that valve is sitting on the base circle of the cam lobe. In other words, when the valve is intended to be fully closed. Sometimes, it can be difficult to tell by feeling the rocker arm when the lifter is on the cam lobe's base circle. The easiest way to make sure you are checking lash at the right time is to use the "EOIC" method.

EOIC stands for Exhaust Opening, Intake Closing when working with the intake and exhaust valves in a single combustion chamber. To use this method, pull the valve cover so that you can see the rockers and valve stems and turn the engine over by hand. (You can also use a bump starter if you choose.) Work with only one pair of valves from a single combustion chamber at a time. When you see the exhaust valve beginning to open-you will see the rocker begin to push the valve stem down-you will know that the corresponding intake valve is fully closed with the lifter on the base circle of the cam lobe. Likewise, when you see the intake valve fully open and then start to close (Intake Closing), you will know the corresponding exhaust valve is ready to be checked. Repeat the process with each pair of valves on the engine.

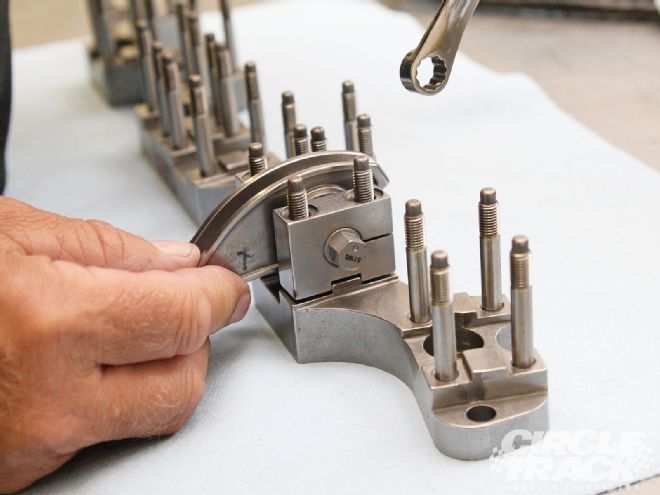

You can set your lash with an Allen wrench and a standard crescent wrench, but a dedicated torque wrench like this can help your precision.

You can set your lash with an Allen wrench and a standard crescent wrench, but a dedicated torque wrench like this can help your precision.

Remember, lash is only an issue with mechanical lifters, either flat-tappet or roller. Hydraulic lifters are designed to pump up the lifter cup and get rid of any lash in the system. Typically, in a race application the lash adjuster in the rocker arm is tightened until all the lash is taken out and then tightened down an additional quarter turn before locking everything down. After a hydraulic cam and lifter set is properly installed, no further maintenance-at least in terms of lash-is typically needed.

Lash with a mechanical system is much more precise which can yield increased power, but it also requires more attention. Valve lash can change even if the rocker adjusters are locked down tight and must be checked regularly. If you're using a pedestal-mount rocker system, valve lash should typically be checked after every two or three weekends of racing. Shaft-mount rocker systems are more stable and you can reliably delay checking lash much longer. On a shaft-mount system, most manufacturers say lash should be checked every 500 to 700 laps.

To set the lash on a shaft-mounted rocker system, choose the tab of correct thickness on your feeler gauge and insert it between the valve stem tip and the end of the rocker while using the adjuster on the pushrod side of the rocker to adjust the distance. When it's right, you will just be able to slide the tab into place without any room to spare.

To set the lash on a shaft-mounted rocker system, choose the tab of correct thickness on your feeler gauge and insert it between the valve stem tip and the end of the rocker while using the adjuster on the pushrod side of the rocker to adjust the distance. When it's right, you will just be able to slide the tab into place without any room to spare.

Once you've determined that the valve you are checking is fully closed, actually checking the lash is the easy part. Simply use a feeler gauge and slide the tab of the correct thickness between the tip of the valve stem and the end of the rocker. The camshaft manufacturer or your engine builder will give you the preferred lash range-it's usually between 0.010- and 0.024-inch for a race engine. So let's assume a hot lash spec of 0.017, so you will use the 0.017 tab on the feeler gauge. If the gauge won't fit between the rocker and valve stem tip, loosen up the adjuster nut until it will, then tighten down until the 0.017 tab just fits while a 0.018 tab would be too thick, then tighten down the lock nut.

Be aware, however, that some adjusters will actually change the lash clearance when the lock nut is tightened. On some designs, tightening the nut seems to pull the adjuster up into the body of the rocker and creates a thousandth or so extra lash. So you may need to make some trial adjustments and recheck your lash after tightening the lock nut. If you consistently see more or less lash after locking everything down, you will need to account for this when making your lash adjustment.

Lash on a stud-mounted rocker system is adjusted by turning the adjuster nut on the stud that controls the height of the rocker on the stud.

Lash on a stud-mounted rocker system is adjusted by turning the adjuster nut on the stud that controls the height of the rocker on the stud.

Of course, there's one last curve that we have to throw you before we're done. The lash number that cam manufacturers supply will be the "hot lash," which is the ideal lash after the engine is at operating temperature. The lash can change several thousandths of an inch between when it is at room temperature and when everything is warmed up properly. But lashing valves on a hot engine comes with plenty of difficulties.

The first, and probably most obvious, problem is it's no fun to work on a hot engine. Second, the engine starts cooling off as soon as it is shut down, so it's impossible to lash all 16 valves at a consistent temperature. And third, lots of engine builders are now flooding the valve covers to help control valvespring harmonics, making it impossible to pull the valve covers so that the valves can be lashed for several minutes after the engine has been shut off.

The solution is to determine how much the lash on your particular engine changes as it goes from room temperature to operating temperature. The easiest way to do this is to warm the engine up (getting the oil temp up to around 200 degrees Fahrenheit should do it), lash one intake and exhaust valve properly, allow it to cool and check to see how much the lash has changed. But that's impossible to do if the engine is brand-new and you need to at least get the lash close before cranking it. Keith Dorton of Automotive Specialists has done extensive research in this area and provided us with some guidelines when it comes to lashing a cold engine.

Dorton says it can be difficult to feel with your finger when you have a needle bearing going bad in the tip of a rocker arm. But if you pay attention when lashing your valves, it can be easier to feel a rough spot in the roller when inserting a feeler gauge between the roller and the valve stem tip.

Dorton says it can be difficult to feel with your finger when you have a needle bearing going bad in the tip of a rocker arm. But if you pay attention when lashing your valves, it can be easier to feel a rough spot in the roller when inserting a feeler gauge between the roller and the valve stem tip.

Because different materials expand at different rates as they are heated, you have to take into account your engine's construction when estimating how the lash will change as the engine approaches operating temperature.

For an engine with cast-iron heads and steel valves, you can expect the lash to tighten up a couple of thousandths of an inch as it heats up-so for the cold lash you would set the valve lash a couple thousandths larger than the cam manufacturer's recommended hot lash setting.

If the engine has aluminum heads with a cast-iron block and standard steel valves you can expect lash to loosen up approximately 0.006. If you are running aluminum heads with an iron block and valves with narrow 6mm stems you can expect the lash to loosen up 0.010 to 0.012. And finally, if you are running an all aluminum race engine, the lash can loosen up by as much as 0.015.

Different rocker designs work in different ways. From left to right, the first two rockers are the standard stud-mounted rockers (in aluminum and steel). The center pair are two shaft-mounted rockers. The final pair of rockers is a new design that's hitting the market. They are shaft-mounted but feature an eccentric built into the rocker pivot for adjusting lash.

Different rocker designs work in different ways. From left to right, the first two rockers are the standard stud-mounted rockers (in aluminum and steel). The center pair are two shaft-mounted rockers. The final pair of rockers is a new design that's hitting the market. They are shaft-mounted but feature an eccentric built into the rocker pivot for adjusting lash.

With normal use, you should notice your valve lash slowly decreasing from one check to the next. This is especially true with a new engine. This is because of wear between the valve and the valve seat, which allows the valve to sit slightly deeper in the combustion chamber. You should consider this normal wear and it isn't a reason for concern unless you have one valve move 0.002 or more after a single race, which could be a sign you have a damaged valve or seat.

What is a cause for concern is if you notice the valve lash opening up. The most common reason for this is a failure of the needle bearings in a roller lifter or a wiped cam lobe. "Wiping" a cam is when a lack of lubrication or some other problem causes the crown of the lobe of the cam to be ground away. When this happens the cam, and probably the lifters as well, must be replaced.

The problem is you can only detect damage to the lifter since you check lash with the lifter on the base circle and any damage to the lobe won't show up. You should also check for metal shavings from the damaged cam in the oil and bearings. A broken axle or failed needle bearings in a roller lifter isn't as big of a deal, but the problem lifter should be replaced or rebuilt immediately and the lifter bore checked for wear to avoid further engine damage.

Here's another shot of the new rocker design. The section of the shaft the rocker pivots around is perfectly round and centered, but the portion of the shaft that locks into place on the pedestal is offset by a few thousandths.

Here's another shot of the new rocker design. The section of the shaft the rocker pivots around is perfectly round and centered, but the portion of the shaft that locks into place on the pedestal is offset by a few thousandths.

Finally, lash can also be used sometimes as a tuning tool for your engine. Dorton says you can usually tighten or loosen your lash safely by 0.004. Tightening the lash will cause the cam to engage the valve more quickly, which will result in the valve opening sooner, lifting higher, and closing later. Essentially, it makes the cam act larger. Loosening the lash does the opposite, making the cam act smaller. Running tests with different lash settings on a dyno is a good way to see if your engine could use more or less cam.

But Dorton also gave us one more trick that you might want to consider if you are qualifying poorly and in danger of missing the field. Although he doesn't recommend doing this regularly, he says opening up the lash an extra 0.006 will often pick up qualifying times on a typical half-mile track by around 0.2-second. This is because the first few degrees of the opening and closing ramps on a cam lobe are designed to gently lift the valve off the seat and drop it back into place again without damaging the valvetrain. Opening up the lash by six thousandths effectively removes this part of the cam lobe from the process and makes the valve action much more violent. That delayed opening helps create more compression and power, but it's also very hard on the valvetrain.

Once the rocker is in place on the pedestal, you can raise or lower the rocker (changing the lash) by rotating the shaft.

Once the rocker is in place on the pedestal, you can raise or lower the rocker (changing the lash) by rotating the shaft.

Dorton says he's done it when a team needed to pick up a couple of tenths in qualifying in order to make the race or have a shot at the pole, but only when the track would allow him to re-adjust the valves before the race started. "You can't leave it like that," he explains, "because there's no way it will finish the race without damaging something."

Now grab that feeler gauge and get to work.