Depending upon specific racing rules, there are often limits placed on the type and extent of allowable engine modifications. Such changes are often confined to re-mapping ignition spark timing, carburetor recalibration, the configuration of exhaust systems, and possible changes of spark plugs since engines in these categories of rules are either "sealed" or of the crate variety for which no other modification are allowed. Consequently, it is by the accumulation of incremental power improvements that net gains are worth the effort. Plus, as on-track fuel "mileage" also plays both strategic and economic roles, these two objectives can become optimized by overall improvements in combustion efficiency.

As frequent readers of this magazine have previously noted, a fair amount of discussion has been directed to ways overall "burn" efficiency can be improved in the combustion space. Whether this is accomplished by an efficiency level that converts more of the fuel delivered into useable cylinder pressure (power) or improves upon the quality of air/fuel charges, the target objective is to waste less fuel by turning more of it into on-track power. However, largely because combustion time intervals are so brief during which flame characteristics can be studied, collecting meaningful burn data becomes a bit problematic.

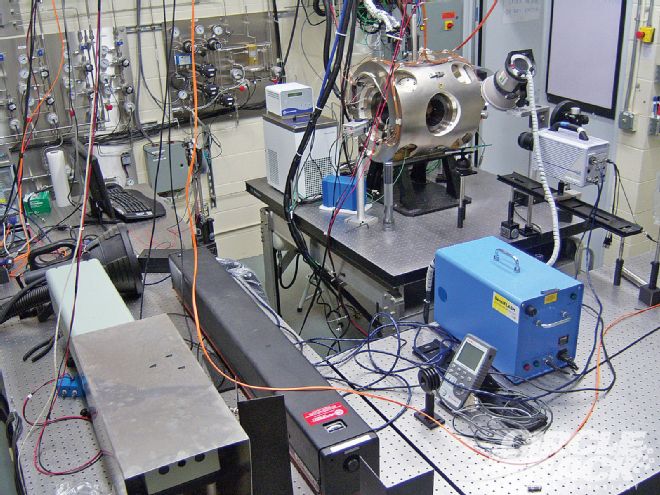

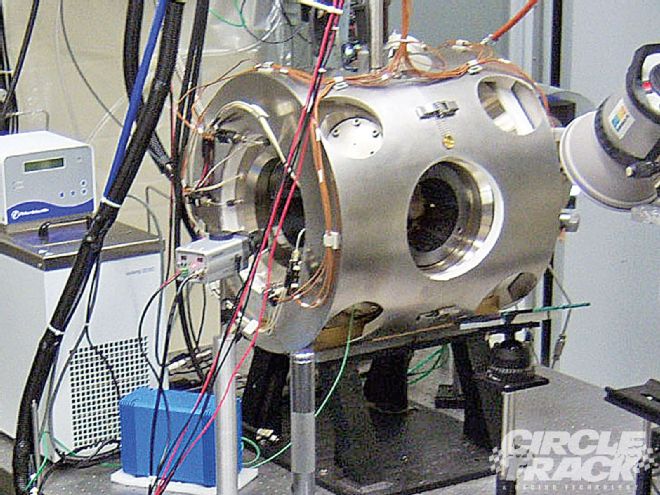

One method for analyzing changes in flame rate involves what is called a "combustion vessel" where a controlled combustion environment and very high speed imaging enables a visual, time-based view and study of the burn process. A version of this equipment resides in the engineering laboratories at Michigan Technological University. Jeremy Worm, a research engineer and instructor at MTU provided us a look at their combustion vessel during the analysis of current spark plug technology used in E3 plugs. The company had recently performed some engine dynamometer testing, observed results favorable to both power increase and emissions reductions, and wanted a more precise and quantifiable analysis performed in an academic environment. MTU conducted that investigation. Our first order of business for this article was to discuss the equipment with Jeremy.

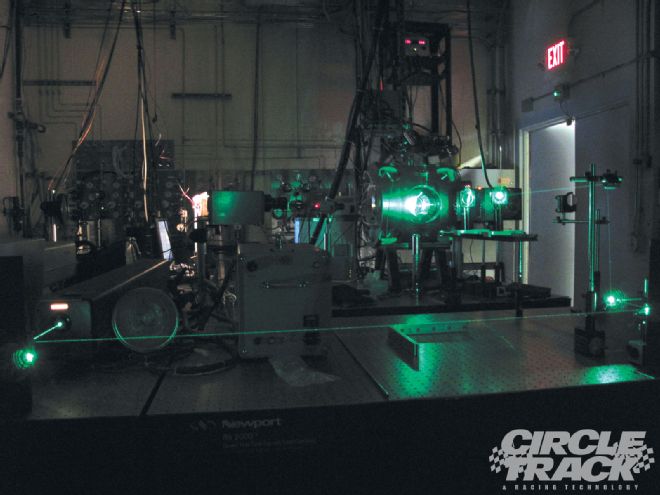

Inside the Alternative Energy Research Building at Michigan Technological University in Houghton, Michigan is a lab that contains an advanced combustion vessel. The lab is just one of several that is under the control of the Advanced Power Systems Research Center at the school which celebrates its 125th birthday this year.

Inside the Alternative Energy Research Building at Michigan Technological University in Houghton, Michigan is a lab that contains an advanced combustion vessel. The lab is just one of several that is under the control of the Advanced Power Systems Research Center at the school which celebrates its 125th birthday this year.

"The process involves a stable and controlled method to study and relate to what's really going on in the combustion space of a running engine. It's a specific volume in which we can introduce air and a fuel, ignite the mixture and then examine the ensuing combustion process without variables that can distract from a specific focus on the 'burn' that follows. For example, there's no moving piston or valves opening and closing, leaking piston rings, or other variables that we can eliminate for the study of something as complex as combustion."

Of course, the relatively brief time spans during which a combustion cycle occurs presents another challenge to recording the process for a visual, time-based look at flame development. "There are eight sapphire crystal windows in the vessel through which we can record high-speed photographs and augment them with laser diagnostic techniques to produce some very descriptive images that display what is going on inside the vessel when ignition occurs, and throughout the burn process. Interestingly, we've developed ways to link data taken from the vessel with a running engine to round out a rather comprehensive analysis of the overall combustion process, including ways to evaluate emissions produced by the burn."

While all this may seem more academic-based than practical, there's more that Jeremy shared which helps peel away some of that perspective. "One of the things we can do is run an engine at a certain speed and load where we have an interest in studying its combustion characteristics. For example, if we wanted to look at full load power, we'd create those conditions on the engine dynamometer, measuring combustion pressures and reverse-calculate for the associated temperatures inside the running engine's cylinders. Then, knowing these actual pressures and temperatures, we can set up the combustion vessel to duplicate them in a more stable environment. So from a thermodynamic standpoint, at least in terms of gas pressures and temperatures inside the vessel, conditions in the vessel are the same as those in the running engine."

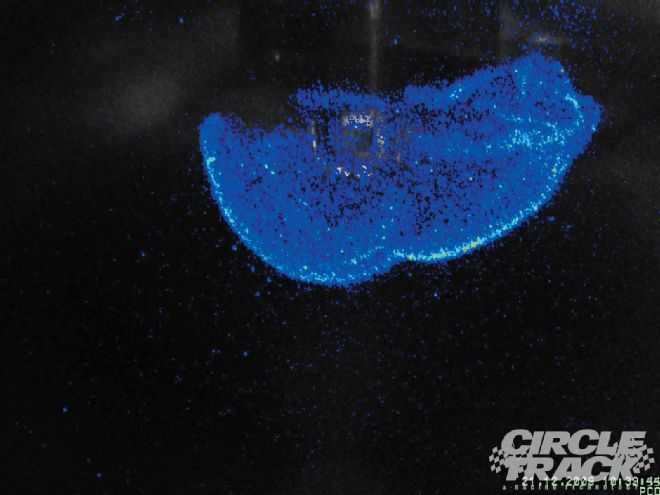

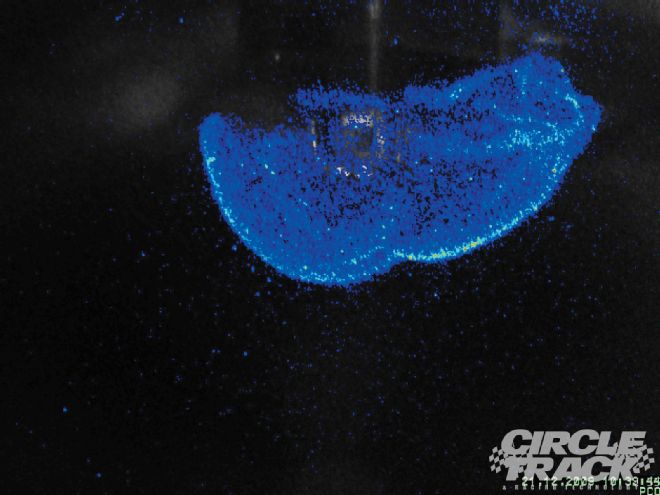

This series of combustion flame images was recorded in Michigan Technological University's "combustion vessel" and compares propagation rates (at the same time intervals) from the use of an ordinary spark plug and the E3 technology. The same homogenous charge mixture was present at the beginning of each test and the same ignition spark energy level was introduced at the plugs. Note the increased rate of growth and activity using the E3 plug, projected to indicate a quicker rise in cylinder pressure and net torque gains. Even though each series of images was recorded in a scant 44 MS (milliseconds), you can still see the effects of the E3 technology.

This series of combustion flame images was recorded in Michigan Technological University's "combustion vessel" and compares propagation rates (at the same time intervals) from the use of an ordinary spark plug and the E3 technology. The same homogenous charge mixture was present at the beginning of each test and the same ignition spark energy level was introduced at the plugs. Note the increased rate of growth and activity using the E3 plug, projected to indicate a quicker rise in cylinder pressure and net torque gains. Even though each series of images was recorded in a scant 44 MS (milliseconds), you can still see the effects of the E3 technology.

Given this environment, the next question was directed to how MTU decided to set up the combustion vessel to evaluate a specific product, in this case the spark plug technology represented in the E3 plug. Specifically, E3 wanted to validate its belief (through comparison testing with a competitor's product) that a more rapid burn is produced by its technique rather than that of another design.

"We set up and 'ran' the combustion vessel under conditions that we knew from prior testing would be representative of a running engine. In this particular case, E3 wanted to compare time-based flame rates among images that showed any differences in speed between their product and that of a competitor's product. Comparing these two designs of spark plugs, we were looking at the flame radius and flame growth as a function of time, all else being equal. By 'being equal' I mean that the same initial or pre-combustion pressure and temperature conditions within the vessel were the same, test to test. Specifically, based on a given time span, we were looking to see if one plug would develop a flame kernel to a larger radius than another under the same conditions, especially equal time intervals. The images we obtained demonstrated the differences E3 was expecting to see."

Although the vessel can be used with a variety of fuel types, combustion involving a gaseous fuel helps assure a homogeneous mixture of air and fuel for further validation of a uniform air/fuel charge during tests. Since it's known that air/fuel mixtures (ratios) do vary within the combustion space of a running engine, the same mixture ratio may or may not be the same in a spark plug's gap from cycle to cycle, and cylinder to cylinder. So in order to remove this variable from the equation, MTU used a gaseous methane and air mixture to ensure uniform mixture homogeneity for these particular tests, again with the intent to remove yet another variable and further improve data integrity.

Here you see the robust, cylindrical vessel with sapphire crystal windows through which ultra-high speed video cameras are able to record combustion events that enables engineers and research staff at MTU to pinpoint and evaluate numerous properties associated with the complex process of combustion. The precision and accuracy by which these studies are conducted is remarkable. Clients include those from the new vehicle manufacturing sector as well as the academic and fuels communities.

Here you see the robust, cylindrical vessel with sapphire crystal windows through which ultra-high speed video cameras are able to record combustion events that enables engineers and research staff at MTU to pinpoint and evaluate numerous properties associated with the complex process of combustion. The precision and accuracy by which these studies are conducted is remarkable. Clients include those from the new vehicle manufacturing sector as well as the academic and fuels communities.

"We didn't want to inject liquid fuel into the vessel, run a test with one spark plug and then inject liquid fuel again for a comparative test, knowing that it would be difficult to verify that the differences we saw were attributable to variations in charge homogeneity or spark plug technology."

Actually, as you will note from the accompanying images, the results produced by MTU are particularly revealing. Since the images were recorded using the same time-based intervals, it's possible to draw direct comparisons between the flame growth rates of the two spark plugs tested. As previously mentioned, E3 had obtained data from tests conducted at other facilities, especially power data showing increases from the installation of their product alone, and wanted to scientifically verify that increases in horsepower and reductions in emissions were linked with the development of a more rapid flame kernel, utilizing their technology. Judging by the results gathered with the combustion vessel at Michigan Technological University, support for that belief is pretty clear. Installing products like this in otherwise "un-modifiable" racing (or street) engines appears to be a sensible consideration.

Ordinary Spark Plug

E3 Technology