The Flathead Ford motor is legendary in many ways, most of them good. But one downfall of this great motor has been cooling. Even in 1932, the first year of the Flathead V-8, Ford was fighting an overheating problem, leading to such rare items as the 25-louver hood. Over the years hot rodders have wrestled with overheating Flathead motors, and in fairness, cooling any hot rod motor was an issue.

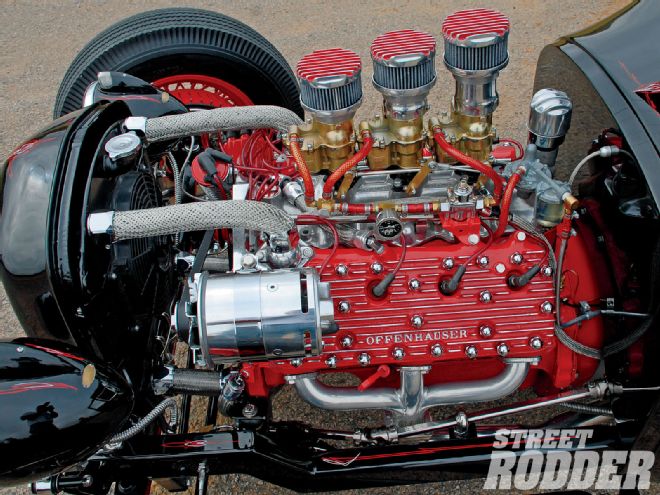

If cooling a normally aspirated Flathead isn't enough of a challenge, step up to a blown version of the venerable Flathead Ford engine. The good news is with today's street rod products the mystery of Flathead cooling is solved.

If cooling a normally aspirated Flathead isn't enough of a challenge, step up to a blown version of the venerable Flathead Ford engine. The good news is with today's street rod products the mystery of Flathead cooling is solved.

Cooling an engine is this simple: The engine is a heat producer while the radiator, coolant, oil, and external surfaces of the engine are heat reducers. The majority of the work is done by the coolant, radiator, and fan, but don't overlook good quality oil and possibly an external oil cooler or finned oil pan for additional heat dissipation.

The Flathead may be notorious for cooling problems, but it is just another motor, except for a couple of unique features. We will be referring to the 8BA (1949-53) and 59AB (1938-48). All Flatheads generate more heat because the exhaust gases spend more time exiting the block. The Ford V-8 employs two water pumps for cooling, so you actually have two cooling systems sharing a common reservoir known as the radiator. This unique cooling system has some interesting traits, let's take a look at them.

Today you can cool a Flathead engine even if the radiator has to fit within the confines of a sectioned Deuce grille, a tribute to the modern design of radiators, fans, and water pumps.

Today you can cool a Flathead engine even if the radiator has to fit within the confines of a sectioned Deuce grille, a tribute to the modern design of radiators, fans, and water pumps.

Treating The Block And Heads

While researching Flatheads we spoke with several engine experts. From Mike Goodman at Honest Charley to longtime Flathead gurus Joe Smith and Joe Abbin, along with several local engine builders, everyone agreed on one concept: To keep the Flathead engine cool the internal block must be clean and free of cracks and remember that boring the block brings with it increased demands on the cooling system.

The newest U.S.-manufactured Flathead engine you can buy is 57 years old-that's 57 years of scale, rust, old sealant, and residue inside the engine. There was also the problem of casting sand leaching out of the castings and residing inside the block. We have heard of everything from sandblasting the inside of the block to "roll it around on the floor" to remove scale, but in the end few things can compare to a chemical bath. "Cooking" a block in a chemical hot stripping tank today removes rust and scale that could not be removed years ago and that's the first step toward cooling a Flathead or any vintage motor. Not only does this scale inhibit uniform water flow through the block, the scale also acts as an insulator, making it more difficult for heat transfer from the block to the coolant. Once the motor is clean, have the machine shop check it thoroughly for cracks using a Magnaflux type of examination.

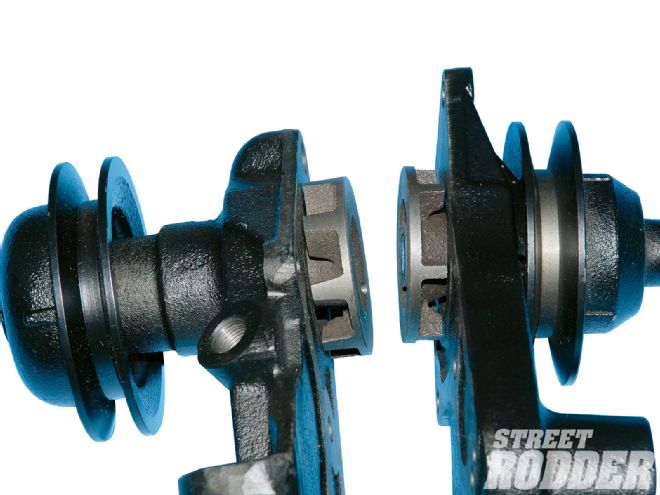

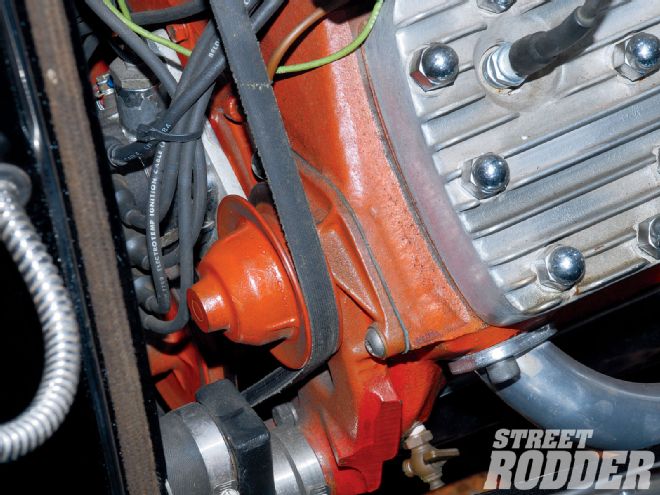

Belt alignment is critical to spinning the water pump, and the early and late pumps have different offsets. Also, note the early pump on the right has fewer vanes on the impeller.

Belt alignment is critical to spinning the water pump, and the early and late pumps have different offsets. Also, note the early pump on the right has fewer vanes on the impeller.

If you're experiencing an overheating problem consider two things. First is a simple block test to see if you have a blown head gasket or worse, a cracked block. Cracked blocks account for a high number of the "impossible to cool" Flatheads because you may be introducing 1,100-degree combustion gases into the coolant, thereby super heating the coolant and introducing gases that cause additional hot spots. The test is a simple kit available from your NAPA store. Generally it's a blue liquid in a tube. The coolant is drawn into the tube with a bulb and the blue fluid turns green or yellow in the presence of exhaust gases. This is done with the engine at full operating temperature. If your engine runs cool at idle but gathers heat as speed increases, a block test should be performed. Remember it's entirely possible to have a cracked block, head, or bad head gasket and not have cross contamination between the coolant and oil.

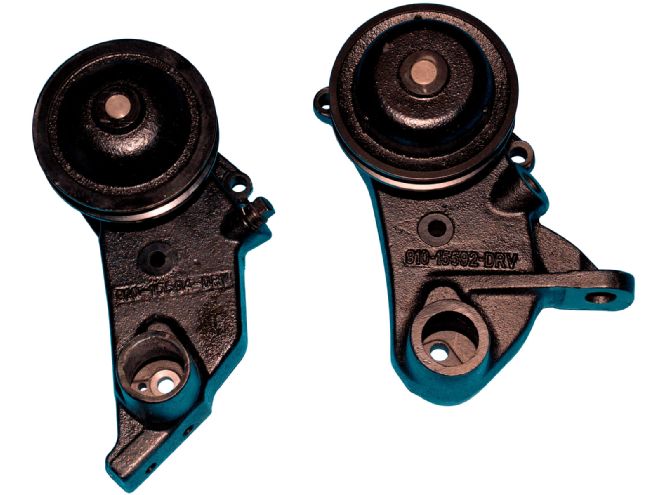

Externally, the all-new Speedway water pumps look like stock Ford items, but even the casting is a stronger high nickel cast iron. The more popular pump for hot rods is on the right, used for ease of mounting the motor.

Externally, the all-new Speedway water pumps look like stock Ford items, but even the casting is a stronger high nickel cast iron. The more popular pump for hot rods is on the right, used for ease of mounting the motor.

Most hot rodders opt for high-compression finned aluminum heads. There is an ample supply of used heads, but inspect them carefully as electrolysis between dissimilar metals (aluminum and cast iron) can cause scaling and flaking in the water passages. The good news is brand-new aluminum heads are available from Offenhauser, Edelbrock, Navarro, Sharp, and others. While the higher compression brings with it horsepower and heat increases, the finned aluminum heads largely offset the heat gain through larger water passages and the improved heat transfer of aluminum.

One look at this water pump that was removed from a "good" Flathead is a great illustration of just how extensive rust and scale can be in a vintage motor. A good chemical stripper bath will eliminate these problems.

One look at this water pump that was removed from a "good" Flathead is a great illustration of just how extensive rust and scale can be in a vintage motor. A good chemical stripper bath will eliminate these problems.

Assuming you have new or very clean vintage heads be certain you have the head gaskets oriented in the proper manner (they're marked) and then carefully torque the heads. Ford felt the head gaskets were enough of an issue that their service manual includes instructions to re-torque the head bolts with every tune-up as standard procedure. This is a good practice for any Flathead owner.

Finally use a temperature gauge in each head, since the Flathead cools each side of the motor independently twin temperature gauges provide vital information on the health of each bank of cylinders.

In stark contrast to the rust and scale, this new Speedway Motors water pump is superior in every way to the stock Ford piece.

In stark contrast to the rust and scale, this new Speedway Motors water pump is superior in every way to the stock Ford piece.

The Water Pumps

Many myths surrounding cooling the Flathead involve water flow. Flathead water pumps evolved from the original three-vane water pump impeller to the six-vane and finally the eight-vane water pump. While there are three distinctly different water pumps, generally hot rodders use the '49-53 truck water pumps, as these pumps mount to the engine block (earlier water pumps mount to the heads) and have a cast leg that serves as the front motor mount. The later eight-vane pump increased flow by approximately 25 percent, and you can bet Ford's engineers calculated the proper flow rate for the engine. For that reason cutting off impeller vanes, drilling holes in vanes, or grinding the face off vanes makes no sense for street engines. Many old-timers swear cutting off every other vane will cool the motor better, and in a sustained high- rpm race application this might work, but for street motors the eight-vane impeller is the way to go.

Another cause of overheating is a loose fan belt, which allows the belt to slip. Often the belt was too loose because water pump shaft seals in early Fords were weak, and excessive belt tension caused premature seal failure. Mechanics often left the belts loose to save the pump seal and the engine would overheat due to the slipping belt. The overheating problem would then be treated with a high-pressure radiator cap, which in turn blew the carbon seal out of the water pump or split the radiator seams. The good news for Flathead lovers is new water pumps are available from Bob Drake, Speedway Motors, and Dennis Carpenter that cure all the old water pump ills. Today's new water pumps incorporate larger shafts, improved impeller design, and ceramic seals. The larger shaft riding in ball bearings can handle tighter belt tensions and the ceramic seal enables the engine to run a modern 16-pound radiator cap. Armed with a pair of new pumps and proper belt contact on each pulley, your Flathead motor will be well on its way to running cool. Since these pumps are designed to use a belt with a center-mounted generator it is best to mount the generator or alternator close to the stock position to ensure proper belt contact. Powermaster makes an alternator in a generator casing designed just for Flatheads.

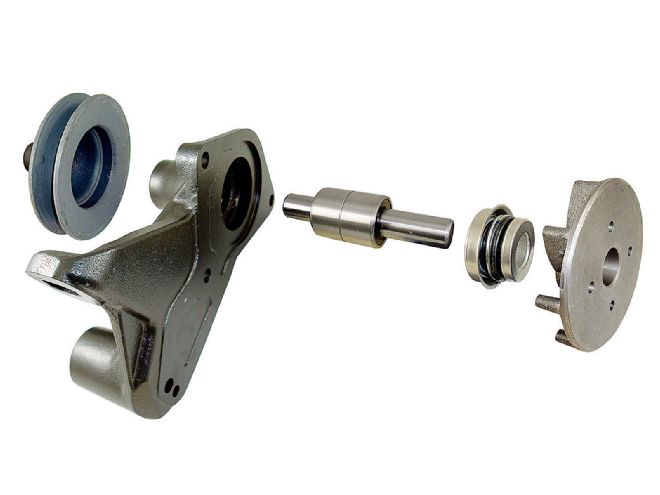

This cutaway view of the new Speedway Motors water pump shows the close tolerance modular impeller that rides on roller and ball bearings. The big 3/4-inch shaft and ceramic seals all ride in a high nickel cast-iron body.

This cutaway view of the new Speedway Motors water pump shows the close tolerance modular impeller that rides on roller and ball bearings. The big 3/4-inch shaft and ceramic seals all ride in a high nickel cast-iron body.

The Coolant

Coolant mix is important for proper cooling, lubrication of the water pumps, and corrosion prevention. Mix the antifreeze to the manufacturer's recommendations, generally around fifty-fifty water to antifreeze. We also like to use a water wetter coolant additive. Most experts agree these additives improve the efficiency of the system by promoting water contact with the heating (motor) and cooling (radiator tubes) surfaces. The use of distilled water helps to minimize minerals in the system and it is available at your local grocery store.

This exploded view shows the oversized shaft, modern design ceramic seal, and it all rides in roller bearings. This water pump is designed for new high-pressure cooling systems and accepts properly tightened belts.

This exploded view shows the oversized shaft, modern design ceramic seal, and it all rides in roller bearings. This water pump is designed for new high-pressure cooling systems and accepts properly tightened belts.

Finally, coolant is only good if it is in your motor, meaning an effective coolant recovery system is needed. If your hot rod tends to "burp" coolant after sitting in traffic, the coolant recovery system holds the coolant and returns it to the radiator as it cools.

Bob Drake didn't stop with the shaft, seals, and bearings, he had a high-performance impeller designed to move more coolant efficiently through the system. Eight curved vanes get the job done.

Bob Drake didn't stop with the shaft, seals, and bearings, he had a high-performance impeller designed to move more coolant efficiently through the system. Eight curved vanes get the job done.

The Radiator

OK, so those new water pumps are pumping fresh coolant through an internally clean engine, now it's time to transfer that heat to the air. Simply put, hot water is pumped into the top of the radiator and drawn down through the tubes into the water pumps, through the motor and back out the upper radiator hoses.

Two things control the flow of coolant in the engine: the water pumps and the thermostats. Once again this is a Flathead engine so that means dual thermostats. The thermostats not only regulate flow through the engine but also enable the engine to reach operating temperature more quickly. Once open it restricts flow and maintains the engine temperature by opening and closing. In a perfect cooling system your temperature gauge will read very close to the thermostat rating, so if you've installed 180-degree thermostats in each upper hose, the temperature gauge should read close to 180 degrees, particularly if you use the port on top of the head as it is close to the thermostat. If you are experiencing overheating problems check the temperature gauges you installed in each head to see if one side of the motor is operating at a higher temperature than the other. Some hot rodders even use two gauge sensors, one in each head and run them through a double throw switch on the dashboard-with the flip of a switch you can monitor head temperatures.

With the thermostats open and coolant freely circulating the temperature should be under control, assuming you have enough cooling capacity in the radiator. A 16-pound pressure radiator cap is standard fare on new radiators and the aforementioned new water pumps can take the pressure.

This is what good belt contact looks like, and keep in mind there are wide and narrow belt pulleys; be sure you are using the proper belt as side contact is what grips the pulley.

This is what good belt contact looks like, and keep in mind there are wide and narrow belt pulleys; be sure you are using the proper belt as side contact is what grips the pulley.

If you are running an original radiator it simply will not stand up to 16 pounds of pressure. We spoke with Vernon Walker at Walker Radiator to learn about new design. The old radiator tanks were formed from 0.025-thick brass, today Walker uses 0.040 brass for their tanks and since converting to lead-free solder the joints are stronger than the old lead base solder. Likewise tubes and fins per square inch have increased over the years. The old continuous fin design is replaced with a modern Z line fin that transfers heat more efficiently. Walker says, "Twenty-five years ago we spent a lot of time working with Flathead guys trying to solve cooling problems, but with today's radiators, fans, and water pumps, we just don't have the problems we once did."

Finally we have the theory of coolant traveling too fast. After polling our panel of experts we may have well asked, "Do you believe in UFOs?" as half the panel was certain coolant could travel too fast, while others scoffed at the thought. Further research seems to support the fact that coolant can travel too fast, but it's not through the radiator that hurts, the consensus is the flow rate is more a function of remaining in the engine long enough to absorb as much heat as possible before entering the radiator. Old-timers sing the praises of restrictor washers rather than thermostats and others say running no thermostat is the solution. The hard part is they all swear they have examples of these things working. So it may be worth trying if you have an overheating problem, but for the most part a good thermostat in a fully functional cooling system that should cool 90 percent of all motors.

Bob Drake offers new water pumps for all popular Flatheads, and are a huge improvement over stock water pumps.

Bob Drake offers new water pumps for all popular Flatheads, and are a huge improvement over stock water pumps.

Moving Air

Moving coolant is important, but moving air is equally as important. Even if you had a 30-gallon tank in the trunk, without cooling air moving through the fins the car would eventually overheat. Getting air through the radiator at speed involves using louvers to allow the hot air to escape, creating a low pressure area in the engine bay and inviting cool air to move through the radiator rather than around it. Shrouding, bellypans, and hood sides all play a role in forcing air through the radiator.

Proper belt contact on the water pumps is critical and the best way to ensure good contact is with a center-mounted alternator or generator. Powermaster makes this cool alternator in a generator housing that mounts in the stock position.

Proper belt contact on the water pumps is critical and the best way to ensure good contact is with a center-mounted alternator or generator. Powermaster makes this cool alternator in a generator housing that mounts in the stock position.

However, when you're in traffic the engine fan must draw the air through the radiator. That old four-blade fan might have cooled a stock Flathead but your bored out, 210hp Flattie is putting out more heat than that old fan can manage. Your choices involve an improved design mechanical fan bolted to the engine or one of the new electric fans. We recommend talking to your radiator manufacturer to see which electric fan they recommend, but far and away the best solution to moving air through the radiator is an electric fan and shroud.

Finally, one maintenance item often overlooked is cleaning the radiator fins. Bugs, dirt, and sand can accumulate in the fins of the radiator, effectively blocking the air from passing through the fins. Make it part of your semiannual maintenance to take an air gun and blow compressed air from the back side of the radiator forward. You'll be amazed at the amount of bugs, grit, and dirt you'll dislodge in the process.

Most experts agree that coolant additives, or water wetters as they are often called, improve the performance of any cooling system by enhancing contact with heating and cooling surfaces. Rust inhibitors are an added bonus.

Most experts agree that coolant additives, or water wetters as they are often called, improve the performance of any cooling system by enhancing contact with heating and cooling surfaces. Rust inhibitors are an added bonus.

External Factors

You may have the cooling system dialed in but still have a motor that runs on the hot side. There are several non-cooling items that can affect engine temperature. First be certain the motor is in proper tune, a lean condition or timing that is advanced or retarded can affect engine operating temperatures.

If you're running a Flathead engine there is a good chance you may be running early drum brakes. Those dual adjuster early Ford brakes are notorious for going out of adjustment and something as simple as dragging brake shoes can raise your operating temperature. Likewise check for restricted exhaust systems and collapsed radiator hoses on a routine basis to ensure your motor is not causing its own overheating problem.

Select the right gear; if you're planning on driving your Flathead at sustained highway speeds select a gear that spins the motor around 2,200 rpm at highway speed. High rpm for sustained periods of time can put a strain on the cooling system.

Coolant only works if you keep it in the system and to that end a coolant recovery system is essential in cooling any motor. You can buy a nice stainless version coolant recovery system, or be creative and make one from one the new "aluminum bottles."

Coolant only works if you keep it in the system and to that end a coolant recovery system is essential in cooling any motor. You can buy a nice stainless version coolant recovery system, or be creative and make one from one the new "aluminum bottles."

Keeping Your Cool

Welcome to street rod cooling in the new millennium. Thankfully the automotive aftermarket continues to design products that work efficiently and help solve our problems. Our back to basics approach will cool a Flathead, but for those looking for more there are full serpentine belt systems, Chevy water pump conversions, and the list goes on. With today's cooling products and proper engine assembly there is no reason to fear the Flathead cooling issues any longer.

Books Worth Reading

Flathead Ford V-8 Performance

Handbook by Joe Abbin

Available from Road Runner Engineering

www.roadrunnerengineering.com

(505) 296-7678

Flathead Fever by Mike Davidson

Graffiti Publications

Available from Speedway Motors

www.speedwaymotors.com

(800) 979-0122

Thunder Road Flathead by Bill Sinclair

Published by Thunder Road

Motor Works

Available at www.amazon.com

How to Build Ford Flathead V-8

Horsepower by George McNicholl

Rebuilding the Famous

Ford Flathead

by Ron Bishop

Tex Smith's The Complete Ford

Flathead V8 Engine Manual

by Ron Ceridono

Available from Honest Charley Speed Shop

www.honestcharley.com

(800) 959-4700

Tex Smith Books

www.texsmithbooks.com

(800) 513-8133