When the Gen III Chevy engine exploded on the scene just over 10 years ago, it seemed that it would take forever for the everyman to afford one of these technological marvels. And back then, if "Joe the plumber" got his hands on a takeout from a salvage yard it would require a computer genius, a cutting torch, a second mortgage, and a good divorce attorney to get one of the LS powerplants hopped up and in your ride. Those days, my friend, are over.

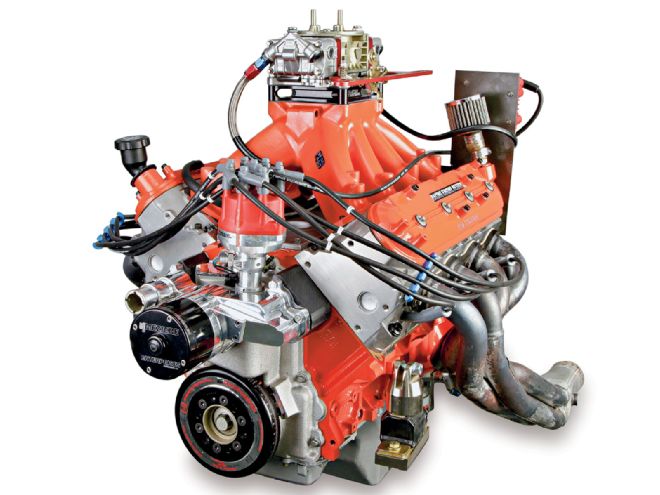

Today, you can buy a complete Gen III core for about the same as a good virgin 350 four-bolt main block, and get it up and running in your hot rod for next to nothing. And thanks to the hard work of engineers at GMPP and MSD, the parts are now readily available to get that high-tech piece of metal making big power with minimal headaches. You can bolt on a distributor and carburetor and spend your nights cruising instead of poring over ECU wiring diagrams or installing a $1,500 high-pressure fuel system. Just how easy is it to make power? Bret Bowers and his team from Racing Engine Design recently built a 370-cube LS for the 2009 Jegs Engine Masters Challenge that made an impressive 579 horses for an even more impressive $6,600.

Our tantalizing tale of Bowers' budget bombshell begins with a journey back in time to when our troops were being welcomed back from Desert Storm (thank goodness that's all over), the Soviet Union imploded, and both Magic Johnson and Freddie Mercury announced that they had AIDS (but not together). That year was 1991, and Tom Stephens, executive director of GM Powertrain, was tasked with laying down the brushstrokes for a completely new multipurpose pushrod V-8. He took advantage of all of GM's resources, most specifically the team he had working with him as well as numerous others contributing to the cause. Weighing a solid 100 pounds lighter than its predecessor, using new casting technologies, Finite Element Analysis, and incredibly powerful cylinder heads designed by the legendary brothers Ron and Ken Sperry, the Gen III 5.7 engine was dubbed the LS1 and finally took life in the '97 Corvette. The Gen III family quickly grew beyond its 5.7L matriarch and expanded to include 4.8-, 5.3-, and 6.0-liter variants as well. Though all are kin and share the Gen III label, only the 5.7L version is designated the LS1 by GM. Somehow as it evolved, the other cube sizes just seemed to inherit the LS designation. Who would have thought that with the overhead cam platforms becoming so popular and efficient GM could create a lowbrow pushrod engine that could not only compete with, but blow away the OHC engines of the time?

With an elevation change of several thousand feet between their home and the University of Northwestern Ohio campus where the EMC takes place, jet changes were the order of the day to make the Racing Engine Design (RED) LS engine perform at its peak.

With an elevation change of several thousand feet between their home and the University of Northwestern Ohio campus where the EMC takes place, jet changes were the order of the day to make the Racing Engine Design (RED) LS engine perform at its peak.

Once that new engine grew out of its toddler phase and took longer strides in the high-performance world, it was only a matter of time before the aftermarket was able to fully realize its potential. Coincidentally, core and takeout prices for the LS were dropping out of the stratosphere and into a more breathable atmosphere. The timing couldn't have been more perfect for Racing Engine Design to undertake this project.

The Harland Sharp rockers and 8.000-inch pushrods gave the heads perfect geometry to free up a little horsepower and reduce side loading on the valveguides. Just a touch of clearancing on the tip of the rockers was all that was needed to clear the OEM valve covers.

The Harland Sharp rockers and 8.000-inch pushrods gave the heads perfect geometry to free up a little horsepower and reduce side loading on the valveguides. Just a touch of clearancing on the tip of the rockers was all that was needed to clear the OEM valve covers.

Talking with Bowers at his Fort Campbell, Colorado-based engine shop, he says that the modified Gen III business is now booming and he wanted to showcase what could be done to make good, reliable power with a minimum budget. "I looked at it from a budget aspect, and I looked at the factory parts, the crankshaft and the counterweights and how GM put that engine together. I thought it was way more than adequate to make the power we were going to make. I thought if guys bought a used 6.0-liter, and they wanted to put different heads on it and bore it and they wanted an iron block, that it would be a great deal." Sourcing an iron 6.0L block as a core was easy, since they are turning up at salvage yards and eBay sales by the dozen. Bowers says that with the factory six-bolt main caps, the block would easily handle around 1,000 well-tuned horses, and with aftermarket steel main caps, could possibly handle 1,500. Those are big numbers for a stock block. With a target of around 600 hp, he just kept the factory caps and fasteners, though as they are torque-to-yield, new bolts were a must. Once the caps were mocked up in place and bearing clearance was checked, he found the oil gap in spec but on the tight side, so he just bumped it with a few strokes of his align hone, reducing the bearing crush slightly and opening up the oil clearance to just over two thousandths.

Performance Induction hit a home run with this intake design; the piece that Bowers got was already CNC ported. A little epoxy was added to match the heads, and he just kissed the rest of the runners with a grinder to get the cross-sectional area to his liking.

Performance Induction hit a home run with this intake design; the piece that Bowers got was already CNC ported. A little epoxy was added to match the heads, and he just kissed the rest of the runners with a grinder to get the cross-sectional area to his liking.

Melling's M-Select pump is generally regarded as the pump of choice for LS engines, and that was used on this low-octane 370. Two pump options are available for the Gen III engines. The 10295 pump is a stock-volume pump with 10 percent more pressure than an OE pump, and the 10296 pump offers an 18 percent increase in volume over the stock pump. Both feature hard anodized housings, steel gears, and a phosphate-coated iron rear cover for reduced wear. During the Gen III oiling system development, GM engineers had a tough time with the original oil pan designs because they were so shallow and close to the crank. Fortunately, with the resulting "batwing" pan and the truck pan, the majority of oiling issues were handled. The only major oiling system change that GM made was to enlarge the oil passage crossover at the back of the block from the '99 model year forward. Bowers says the oiling system on his 6.0L block was more than adequate for the task, so no other modifications were necessary. He tells PHR: "I didn't change passageways or restrictions, or anything like that. We used the stock truck oil pan, pickup, and windage tray."

The pistons on a stock Gen III engine stick out of the hole a few thousandths so gasket choice is critical. Using the Fel-Pro 1162 head gaskets and Mahle pistons, there is just the faintest mark where the pistons were touching the heads, indicating tight and efficient quench.

The pistons on a stock Gen III engine stick out of the hole a few thousandths so gasket choice is critical. Using the Fel-Pro 1162 head gaskets and Mahle pistons, there is just the faintest mark where the pistons were touching the heads, indicating tight and efficient quench.

Though some guys jump straight to a forged crankshaft for a high-performance buildup, the RED crew said that for the power levels they were running, a stock cast crank would do the trick just fine. With rolled fillets and lightening holes drilled to help move crankcase pressure between the cylinders, they have been known to hold well over 600 hp. The crankshafts used in Gen III Chevys were all cast iron but there were some minor differences. The 4.8 engine used a 3.268-inch arm but 5.3/5.7/6.0 engines all used the same 3.622-inch stroke. With rebalancing, all of those are interchangeable, similar to dropping a 305 crank in an early 350. The only major variance in cranks is that the 216-casting cranks used in automatic '99-00s had a rear flange that was about .860-inch longer than the more common 215-casting cranks. That could pose a problem for an engine/tranny swap. The factory cast-iron 216-casting crankshaft for this buildup was deburred and balanced, but was otherwise untouched.

Annular boosters in the Quick Fuel 1050 really helped get the fuel atomized at low rpm. The ability of the annular boosters to pull fuel can be a double-edged sword though, as the team really had to work the air bleeds, emulsion jets, and main jets to get the fuel curve straight.

Annular boosters in the Quick Fuel 1050 really helped get the fuel atomized at low rpm. The ability of the annular boosters to pull fuel can be a double-edged sword though, as the team really had to work the air bleeds, emulsion jets, and main jets to get the fuel curve straight.

Bolted to the factory crank was a set of Eagle lightweight connecting rods that came equipped with ARP's famous 2000 Series rod bolts. The advanced metal in the 2000 bolts is significantly stronger than the more common 8740 material, and not as susceptible to moisture and oxidation issues as the L19 bolts. With rod clearance at just under two thou, the guys had no problems with their recycled OEM rod bearings.

Mahle has been supplying high-end racers with top-notch pistons for years and since introducing their Power Pak piston/ring packages a few years back at a budget price, they have really taken over in the world of moderately priced street/strip engines. A low-tension metric ring package and short skirts coated with an anti-friction Teflon-based coating were big factors in Bowers' choice of Mahle for their pistons. They were used out of the box, save for some minor valve notch clearancing that was required for the big LS7 intake valves.

The chambers of the LS7 heads were absolutely untouched from the factory. GM engineers worked long and hard to get the design this efficient in a mass produced engine. The double-quench design was an evolution of the heart-shaped wedge. Champion racing spark plugs like these angle-electrode versions were used by a number of competitors at the EMC for the quality and performance they offer.

The chambers of the LS7 heads were absolutely untouched from the factory. GM engineers worked long and hard to get the design this efficient in a mass produced engine. The double-quench design was an evolution of the heart-shaped wedge. Champion racing spark plugs like these angle-electrode versions were used by a number of competitors at the EMC for the quality and performance they offer.

Did we not mention the LS7 heads? Bowers picked them up as bare castings on eBay for just five Bennies. Saving enough from not buying the heads complete, he was able to score a set of big-block sized 2.200-inch Manley intake valves and 1.540-inch exhaust valves to use in the heads. Manley was also the source for the polished Nextek springs, retainers, and locks, keeping those valves in check.

LS7 heads were, of course, available on the Z06 Corvette, and came with giganto CNC-ported runners, Titanium valves, and flow numbers that make 18-degree small-block guys want to throw rocks at their high-dollar engines. Since the RED engine was designed to make big average torque and horsepower numbers from 3,000 all the way to 7,000 rpm, they decided to shrink the runners down from around 250 to 238cc with carefully placed epoxy. Final hand blending of the runners was the only other modification to the heads. They felt that the combustion chamber design was perfect to begin with, so they never even touched them. Fel-Pro MLS head gaskets and ARP head bolts joined the heads to the short-block.

Acting as a mechanical ECM for the engine was a custom Bullet solid-roller cam with aggressive lobes urging the COMP Cams roller lifters. Thanks to the factory location of the runners and offset rocker arms, they were able to use 3/8-inch diameter pushrods to minimize harmonics and maximize ultimate lift. Surprisingly, the Harland Sharp roller rockers fit under a set of stock valve covers with just a touch of clearancing on the tips. With the correct valvetrain geometry set, the crew didn't have any issues on the top end.

The bling under the valve covers shines like a disco ball. Even though they were standard fare for the LS7, Titanium valves were prohibited in the Challenge, so a set of Manley valves were used with RED's custom 52-degree valve job. The only exotic metal allowed was Titanium valvespring retainers, which the team also sourced from Manley.

The bling under the valve covers shines like a disco ball. Even though they were standard fare for the LS7, Titanium valves were prohibited in the Challenge, so a set of Manley valves were used with RED's custom 52-degree valve job. The only exotic metal allowed was Titanium valvespring retainers, which the team also sourced from Manley.

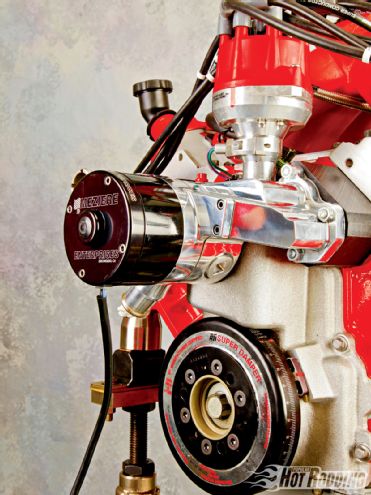

A quick search for GMPP PN 88958679 produced a number of retailers offering the front drive distributor conversion kit for the LS engines. The kit not only includes the timing cover itself but a fuel pump eccentric for use with a mechanical fuel pump, a distributor drive gear, spacers, bolts, and a crankshaft seal. With the conversion kit in place, all that it takes is a small-block Ford distributor (cough, cough), like the MSD Pro Billet dizzy that Bowers scrounged to get fire in the hole. Feeding the flame was an MSD Digital 7 ignition box and HVC II coil.

With compression and ignition taken care of, the final element of the internal combustion triangle was fuel. Shell V-Power 91-octane pump gas entered the Quick Fuel 4150 carb and thanks to our friend Bernoulli, was drawn through the main jets, emulsified with air pulled through the air bleeds, and atomized as it exited the annular boosters. The 1,050-cfm unit uses a three-circuit design that allowed Bowers and teammate Jason Gonzalez to tailor their fuel curve to their liking both at their mile-high shop, and at the near sea-level conditions of the University of Northwestern Ohio-based Challenge. Since tuning is such a big deal in getting the most out of a combination like this, they spent quite a bit of time dialing it in at home. "It had a five-hole emulsion bleed in the metering block, and we were blocking the lower two, then we were blocking just one, and we were trying to straighten out the curve on the top side and we got it pretty good."

An advantage of using the truck oil pan in this competition is that it is deep enough up front to use a full-length windage tray, where the F-body pans only use a 3/4-length tray to clear the crossmember. Also, the truck pan with its deep sump keeps the majority of oil far away from the crank while spinning.

An advantage of using the truck oil pan in this competition is that it is deep enough up front to use a full-length windage tray, where the F-body pans only use a 3/4-length tray to clear the crossmember. Also, the truck pan with its deep sump keeps the majority of oil far away from the crank while spinning.

With the air/fuel mixture perfectly homogenized, it passed through the two-piece intake manifold that is, by itself, a work of mechanical art. The intake was designed by Performance Induction with a large plenum to feed a good-sized engine.

To make it easier to work with it can be split in two for porting, then joined back together with an O-ring seal. Bowers just did a little minor touch-up and port matching to the heads to get the fit right, but the intake was otherwise untouched.

LS engines are different from traditional small-blocks in that their rods are on-center, meaning there is no offset in the rod, it can face either direction. Traditionally though, the engines are assembled with the bearing tangs all facing the driver side. The coated Mahle pistons are right at home in Bowers' engine; Mahle produces the pistons that go into the stock Gen III engine from GM.

LS engines are different from traditional small-blocks in that their rods are on-center, meaning there is no offset in the rod, it can face either direction. Traditionally though, the engines are assembled with the bearing tangs all facing the driver side. The coated Mahle pistons are right at home in Bowers' engine; Mahle produces the pistons that go into the stock Gen III engine from GM.

A turn of the starter and the machinery came to life, ready to embarrass some bucks-up entries that cost two to three times what Bowers' little budget buster set him back. The dyno operator made three back-to-back pulls like he was shifting a Lenco, and as a testament to the efficiency of the engine, it varied by a mere one average horsepower and lb-ft in all three pulls. The torque curve looked like a giant Southwestern mesa. Through a pair of Magnaflow mufflers and 13 feet of pipe, the exhaust note sang crisp and clear. Best of all, with less than $7Gs in his engine, Bret and his crew were able to travel first class all the way back to Colorado.

Six-bolt mains and a strong cast-iron block make the 6.0L block a natural choice for high-horsepower engines. With a reasonable power goal, the crew was comfortable using stock fasters on the bottom end, though they are torque-to-yield so replacement is necessary upon removal. Like many top engine builders, the RED guys marked their fasteners once torqued to eliminate any questions should the engine sit for a few days or weeks before the pan is installed.

Six-bolt mains and a strong cast-iron block make the 6.0L block a natural choice for high-horsepower engines. With a reasonable power goal, the crew was comfortable using stock fasters on the bottom end, though they are torque-to-yield so replacement is necessary upon removal. Like many top engine builders, the RED guys marked their fasteners once torqued to eliminate any questions should the engine sit for a few days or weeks before the pan is installed.

GM's distributor drive adapter kit is a neat way to get an LS up and running without the hassle of deciphering miles of wire. Simplicity is the key: A distributor, ignition box like the MSD Pro Billet, a Digital 7 ignition, and a carb, and it is ready to go.

GM's distributor drive adapter kit is a neat way to get an LS up and running without the hassle of deciphering miles of wire. Simplicity is the key: A distributor, ignition box like the MSD Pro Billet, a Digital 7 ignition, and a carb, and it is ready to go.

BY THE NUMBERS RACING ENGINE DESIGN 370 GEN III CHEVY Bore: 4.030-inch Stroke: 3.622-inch Displacement: 370 actual cubic inches Compression ratio: 11.34:1 Camshaft: Bullet solid roller Cam duration: 247/247 degrees at .050-inch tappet rise Valve lift: .810/.810-inch Rocker ratio: Harland Sharp 1.8 intake / 1.8 exhaust ratio Top ring: 1.5mm Second ring: 1.5mm Oil ring: 3mm Piston: Mahle flat-top Block: OEM cast-iron Crankshaft: OEM cast-iron Rods: Eagle 6.125 H-beam Cylinder head: OEM LS7 Intake valve diameter: 2.20-inch Exhaust valve diameter: 1.54-inch Intake manifold: Performance Induction Carburetor: Quick Fuel 1050 4150 style Header: Pacesetter 13/4-inch primary Ignition: MSD 7

DYNO DATA Best Qualifying Pull RPM TQ HP 3,000 407 232 3,100 410 242 3,200 407 248 3,300 402 252 3,400 398 257 3,500 392 261 3,600 388 266 3,700 386 272 3,800 388 281 3,900 396 296 4,000 414 316 4,100 432 337 4,200 447 358 4,300 460 377 4,400 470 394 4,500 479 410 4,600 487 426 4,700 490 439 4,800 493 451 4,900 499 465 5,000 500 476 5,100 498 484 5,200 499 494 5,300 499 504 5,400 498 512 5,500 498 521 5,600 497 530 5,700 495 537 5,800 492 544 5,900 490 551 6,000 489 559 6,100 487 565 6,200 483 570 6,300 480 576 6,400 474 578 6,500 468 579 6,600 461 579 6,700 452 577 6,800 446 577 6,900 440 578 7,000 433 578

Also, the distributor drive comes setup with a timing pointer that can be used with a harmonic dampener like the ATI piece that Bowers used. A Meziere electric water pump easily cleared the adapter and made it easy to keep the heat down.

Also, the distributor drive comes setup with a timing pointer that can be used with a harmonic dampener like the ATI piece that Bowers used. A Meziere electric water pump easily cleared the adapter and made it easy to keep the heat down.

WHERE THE MONEY WENT 6.0L short-block core $250 Eagle connecting rods $429.99 Mahle pistons $479.99 COMP Cams solid roller lifters $489.99 Fel-Pro MLS head gaskets $188.84 Engine Pro timing chain set $75.42 Melling oil pump $65 ARP head bolt kit $146.88 Engine Pro 3/8x8.1-inch pushrods $116.48 Fel-Pro timing cover gasket $48.44 K&N oil filter $13.99 Intake manifold $1,106.23 Distributor drive kit $456.98 Harland Sharp roller rockers $598.88 Manley springs, retainers, locks $485.23 Total Seal piston rings $259.38 Bullet camshaft $359.99 Manley race-series valves $379.98 LS7 heads (used), eBay $500 Valve covers (used) $30 MSD distributor (used) $125 Total: $6,606.69

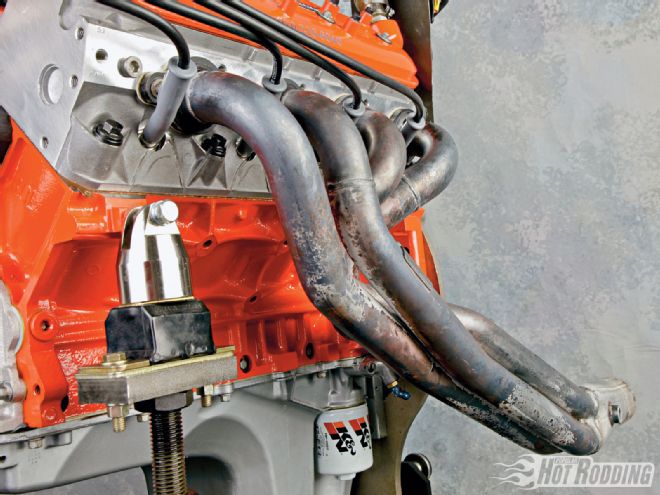

Pacesetter long-tube headers make good power and still fit a normal F-body chassis without much hassle. Built-in O2 bungs are designed for the factory fuel-injected engine, but make tuning with a wideband O2 sensor and a carburetor much easier.

Pacesetter long-tube headers make good power and still fit a normal F-body chassis without much hassle. Built-in O2 bungs are designed for the factory fuel-injected engine, but make tuning with a wideband O2 sensor and a carburetor much easier.