In 1995, engine shootouts were big around the office, and staffers struggled to build the most power for the least money. One result of those days was a 351 Windsor engine that squeaked out 447 hp at 6,300 with little couth. It had a set of TFS iron heads ported to 278 cfm at 0.550 valve lift and milled 0.040 to get the compression ratio to around 10:1. Then in a fit of cool, they decided to stab a rowdy Comp Cams 305 solid lifter with 260 degrees at 0.050 and 0.590 lift on a 106 centerline. The bottom end was stock, and the motor demanded to be spun to 6,500, but that's what it took to make cheap power back then.

Nearly 10 years later, Four Wheeler Art Director Greg Smith still has this engine, and he runs it at local tracks in his '67 Mustang, which has accumulated a pile of low 12-second timeslips. He's sure there is an 11-second pass in this car, but he's limited to what he can do at the strip. Times have changed, and now we have affordable handheld A/F meters, chassis dynos, and data acquisition at our disposal, making the final tweaks to get this car into the 11s within our reach. We took the it to Westech Performance for a Mustang dyno tuning session to get him going in the right direction.

Mustang Dyno Preparation

Greg has exchanged the original cam for a Comp Cams 248/254 at 0.050 that has a shorter duration and slightly more lift. He kept the original Victor Jr. intake because it was milled and port-matched to fit the TFS heads on the original combination. It also has a Holley 750-cfm double-pumper and MSD Billet distributor that are very similar to the 750 carb and electronic ignition used on the original, so we knew that the power would be similar. Dyno-operator Tom Habrzyk suggested we bring the original dyno sheet to Westech Performance in Mira Loma, California, along with a list of the static timing, total timing, jets in the carb, gear ratios, stall, and tire height so everything can be entered into the computer when we arrived to save valuable time. He also suggested welding an O2 bung near the collector because it sharpens the air/fuel readings on the dyno and allows for a handheld meter to be installed later if needed. Tom also noted that we should inspect the drivetrain for bad U-joints, fluids, and basic tune-up parts, and if the car is track-only, be sure to have good tires that aren't dry-rotted. The rule of thumb here is if you can't pass tech at the racetrack, you shouldn't be on the chassis dyno. Simple.

Mustang Dyno - Carb Operation

The first thing Tom did was perform a quick visual inspection under the hood. It was immediately clear that the air-cleaner lid was almost resting on the air horn, and when we floored the gas pedal, the secondaries were only opening 75 percent. We readjusted the linkage for WOT and set the float levels so a little fuel would slosh out of the bowl sight when the car was gently rocked. We left the air cleaner on for the baseline, so we could see if there was improvement after we changed it.

Mustang Dyno - Baseline

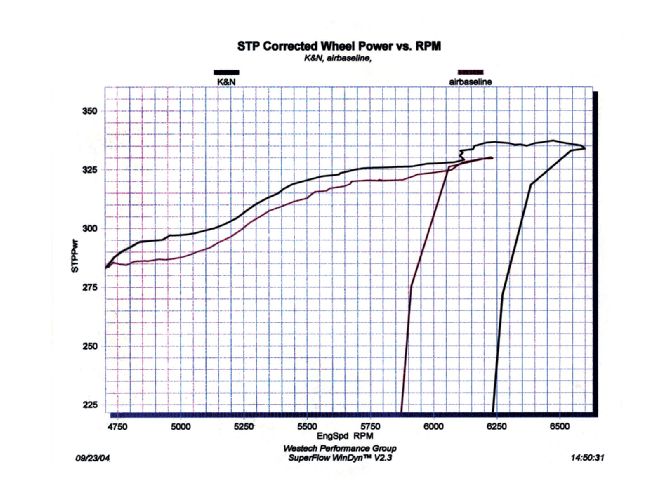

According to the original dyno sheet from the Hot Rod article, the engine made 447 hp at 6,400 and 420 lb-ft at 5,200. The first run on the chassis dyno netted us a maximum 330 hp at 6,200 and 319 lb-ft at 4,600 rpm. Tom told us to expect about a 20 percent loss through the drivetrain, so we calculated that the Windsor was making about 412 hp at the flywheel and 398 lb-ft of torque. We know the smaller cam reduced some of the high-rpm shriek, but we were certain to find some more power during the session.

Mustang Dyno - Air Cleaner Dyno Tuning

We started our dyno tuning with the most obvious problem. The 2-inch air-filter element was causing a restriction between the air-cleaner base and the air horn. We discovered this by marking the position of the wing nut on the carb stud then removing the air-cleaner assembly and reinstalling the lid using the wing nut as a reference. We found that there was only about 11/42 inch of clearance between the two. The solution was to install a drop-base assembly with a K&N 14x3-inch element. We rechecked WOT to make sure the linkage wasn't hitting the base and made a pull. Dyno tuning the air-cleaner change was worth about 7 hp and moved the peak up about 200 rpm. We made another pull without the air cleaner and found no gain so we moved on.

Carb And Air/Fuel Ratio

We were fortunate that Greg hadn't milled the air horn off the carb, because the reference numbers are printed there. Using the numbers, we checked the Holley catalog to find the baseline jets and discharge-nozzle sizes. Dual-metering-block Holley carbs are sent from the factory with "square" jets, meaning the front are smaller, proportional to the power valve, compared to the rear jets. On this example, the front jets were the stock 68s and the rears were 81s. The power valve is worth 13 jet sizes when it opens below 6.5 inches of engine vacuum, making both the front and the rear flow the same at WOT. Tom will occasionally find jets that are unequal and crazy oversized discharge nozzles, so he will set them back to stock before going any further.

Problem two was the air-cleaner assembly. Using the wing nut as a guide, we found that the air-cleaner lid was restricting the flow to the primaries. Our fix was a 14x3 with a 2-inch drop from K&N.

Problem two was the air-cleaner assembly. Using the wing nut as a guide, we found that the air-cleaner lid was restricting the flow to the primaries. Our fix was a 14x3 with a 2-inch drop from K&N.

On the baseline, the air/fuel ratio was about 10.1:1 and it even dipped into the 9.8:1s for a few thousand rpm. Too rich. Tom kept the jets square by dropped them two sizes front and rear.

Timing

Let's face it, with 4.56:1 gears and a 3,400 stall, this Mustang is more strip than street, so the timing curve can come in hard and fast. There is not going to be any detonation down low, because there is less of a load below the stall speed so our timing curve can have all the timing in by 3,500. In the MSD distributor, we used the largest-diameter bushing (black in the MSD kit) to limit the total centrifugal advance to 18 degrees and used the lightest springs in the kit (two silver). The rule of thumb we were using is this: You'll want 34-38 degrees of total timing without the vacuum advance. With a higher stall speed, more cam, aluminum heads, and a lighter car, you can dial in the timing at a quicker rate than a car with the opposite characteristics and still not detonate. Bigger cams will allow more timing because they tend to bleed off cylinder pressure and need more initial to smooth out the idle. We ended up with 20 degrees of initial for a total of 38 to make best power.

Since the K&N solved the airflow restriction, we didn't end up milling the air horn. If we had, we would have milled the part number with it. A tech tip would have been to stamp it on the body of the carb so future dyno guys can reference it and use the stock jets for a baseline.

Since the K&N solved the airflow restriction, we didn't end up milling the air horn. If we had, we would have milled the part number with it. A tech tip would have been to stamp it on the body of the carb so future dyno guys can reference it and use the stock jets for a baseline.

Revs

After making the timing and air/fuel adjustments, Tom ran it up to 6,600 and recorded a best of 337 hp at 6,400 and 319 lb-ft at 4,800. The air/fuel ratio was at a healthier 11.5:1 average, and we had already found that a leaner jet didn't make a difference. Tom took the engine up a little higher in the rpm range to see if there was any more power there, but it became evident that the engine had quit making power at around 6,400 rpm.

Greg admitted to shifting the C6 at "about 6,800" at the track. Even if the transmission shifted instantly, that's about 400 rpm to high. If you've ever felt an engine lay down, you know that shifting right at peak rpm will often improve the results. This piece of information alone made the trip worthwhile.

We had a theory that if pulling the air cleaner off made no difference, then milling the air horn wouldn't either. For grins we swapped carbs and didn't see any gains. If the larger K&N filter and drop base didn't fit however, the air horn trick would have solved the clearance problem using the old 2-inch filter.

We had a theory that if pulling the air cleaner off made no difference, then milling the air horn wouldn't either. For grins we swapped carbs and didn't see any gains. If the larger K&N filter and drop base didn't fit however, the air horn trick would have solved the clearance problem using the old 2-inch filter.

Ready For The Track

Aside from correcting glaring problems like WOT, air cleaners, and slipping transmissions and such, the primary goal of the chassis dyno is to get the engine making as much power as possible while finding where the peaks and corresponding shift points should be. Greg only had 90 percent of his throttle, was overshifting the engine by about 400-500 rpm, and was a full point rich in the air/fuel ratio. Since his primary goal was about 0.30 at the track, it's easy to see how these problems could compound to cost him at least that much. We shall see. What's important is to have these things out of the way before you tackle the issues between the car and the track that also conspire to slow you down. But that is another tale.

Mustang Tech

Car: '67 Mustang GTA

Owner: Greg Smith

Engine: 351 Windsor with stock crank and rods, TRW forged dished pistons

Induction: Edelbrock Victor Jr. port matched and milled, Holley 750 with mechanical secondaries.

Ignition: MSD Billet distributor and 6AL ignition box

Heads: Iron Trick Flow Specialties with 2.02/1.60-inch intake/exhaust valves

Camshaft: Comp Cams XR286 mechanical flat-tappet, 248/254 degrees duration at 0.050 with 0.614/0.621-inch lift.

Transmission: C6 automatic with a 10-inch Continental 3,400-stall converter

Rearend: 9-inch with Richmond 4.56:1 gears and a Detroit Locker

Front Suspension: Competition engineering 90/10 drag shocks

Rear Suspension: CalTrack (SP) bars, Competition Engineering drag shocks

Wheels and Tires: Fenton slotted mags, 15x3.5 with M/T front runners, front; 15x10 with 28.5x12.5 M/T ET Streets, rear

The 'Stang is as dialed as it is going to get under the hood. With those variables eliminated, track testing can address traction and 60-foot times.

The 'Stang is as dialed as it is going to get under the hood. With those variables eliminated, track testing can address traction and 60-foot times.

Dyno Numbers

The final run with 38 degrees of timing, an 11.5:1 air/fuel ratio, 66/79 jets, and the K&N air cleaner was good for 337 hp at 6,400 rpm and 319 lb-ft of torque at 4,800, up 7 hp from the baseline. We also found the shift points and cleaned up the air/fuel ratio for a little more mileage.

Test 1

Test 1