The debate will rage on, which is better,a single-pass radiator or a double-pass radiator?

The debate will rage on, which is better,a single-pass radiator or a double-pass radiator?

Tech Editor John Gibson told me the story of how he was recently at a track in Georgia watching a Street Stock race. During the feature he noticed that several cars would come in under every caution and shoot the radiator with water to cool the engine. Then they would return to the track but wouldn't be able to get their track position back. He said he thought to himself, If these guys had the right radiator and fan they wouldn't have to lose valuable time and positions just trying to keep their engines cool.

In talking with one of these hose-happy Street Stockers after the race, he said that his reasoning for his low-buck radiator was exactly that . . . cost savings. The racer was under the impression that he couldn't afford a "fancy" radiator for his bomber. He didn't recognize the fact that a cracked head thanks to an overheating problem would cost way more than even the nicest double-pass radiator.

John's experience told us that it was time to revisit some critical cooling technology.

So without further ado, let's begin.

This is a worst case scenario. There is significant fin damage, the housing is bent and it's highly likely that the tubes and cores have suffered severe damage. This radiator needs to be replaced.

This is a worst case scenario. There is significant fin damage, the housing is bent and it's highly likely that the tubes and cores have suffered severe damage. This radiator needs to be replaced.

Thermal Transfer

Also known as heat exchange, thermal transfer is the very core of a radiator's function (pun intended). Obviously, radiators are designed to protect your engine from overheating by transfering that thermal energy away from fluid that circulates through the engine via the water jacket-a series of passageways cast into the block. As the fluid passes through the hot engine it absorbs the heat, thereby cooling the engine. Once the fluid leaves the engine, it passes through the radiator which is nothing more than a heat exchanger that transfers the heat from the fluid to the air blowing through the radiator.

That thermal transfer is the key to how the radiator functions, but it can only happen when the fluid is in direct contact with the aluminum of the radiator. Manufacturers achieve maximum thermal transfer through several design methods, one major one being by increasing the surface area of the tubing that carries the fluid through the radiator. Typically these tubes are very wide from front to back and slim from top to bottom. Dozens of these thin tubes can be stacked on top of one another leaving small air gaps between them.

Manufacturers will also make the wall of these tubes extremely thin which further increases thermal transfer. Think of it this way: Heat has to pass through the wall of these aluminum tubes away from the water or coolant. The thinner the tube wall, the quicker that process can take place. But that comes with a price since sealing narrow strips of thin-wall aluminum tubing in position can be a tricky proposition. Manufacturers such as C&R Racing have opted to TIG weld them in place and then follow it by furnace brazing, which essentially fuses all of the parts of the radiator together.

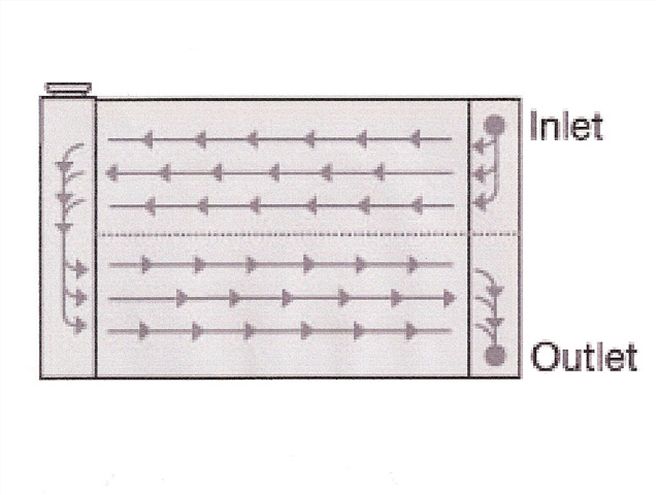

This is your basic design for a double-pass system. Note how the flow of the water crosses the radiator twice.

This is your basic design for a double-pass system. Note how the flow of the water crosses the radiator twice.

Most often these thin-walled tubes are mounted in a parallel arrangement. Separating the tubes are "Z" shaped aluminum fins which help radiate the heat from the tubes. The fins conduct the heat from the tubes and transfer it to the air flowing through the radiator.

In some radiators the tubes will have a type of fin inserted into them called a turbulator, which increases the turbulence of the fluid flowing through the tubes. If the fluid flowed very smoothly through the tubes, only the fluid actually touching the tubes would be cooled directly. The amount of heat transferred to the tubes from the fluid running through them depends on the difference in temperature between the tube and the fluid touching it. So the fluid that is in immediate contact with the tube cools down quicker than the fluid not in contact with the tube and less heat will be transferred. By creating turbulence inside the tube, all of the fluid has the opportunity to come in contact with the tubing wall and lose heat, thereby lowering the temperature of all of the fluid.

John runs a four-core radiator from North Carolina manufacturer ICE. It's design is perfect for his 400-lap weekends on the mile-long tracks of the USAR Pro Cup Series.

John runs a four-core radiator from North Carolina manufacturer ICE. It's design is perfect for his 400-lap weekends on the mile-long tracks of the USAR Pro Cup Series.

Efficiency

Every part of a radiator is designed with the singular purpose of dissipating the heat collected by the water as it flows through the motor. How efficient a radiator accomplishes this task comes down to two specific types of "flow," that being water and air.

Water Flow - Water, or fluid as we have been calling it, flows into a header or large open cavity on one side of the radiator where it then passes through the aluminum tubes before it collects into a header on the other side. This flow of water through your radiator can be influenced a number of ways including through the use of restrictors, the size of the water pump and related pulley system, and the aforementioned inclusion of a turbulator.

Pumps & Pulleys - One of the biggest influences on how efficient your radiator functions is the size of the pulley on the water pump. If the pulley is too big it won't push enough water through the water jacket and radiator to effectively cool the motor. Conversely, if your pulley is too small, water will be pushed through the system so fast it won't have enough time to collect heat from the motor or dissipate that collected heat.

Compounding this problem is the pulley system. Water pumps in many circle track engines are driven off of the crankshaft via a pulley system. If the pulley system doesn't spin the pump fast enough you won't push enough water through the motor/radiator.

After any accident inspect your welds for any cracks or leaks.

After any accident inspect your welds for any cracks or leaks.

Case in point, a friend of the magazine who runs a Dirt Late Model recently had his engine rebuilt. During the rebuild, his engine builder suggested an exotic NASCAR Cup-style pulley system. The builder said the smaller V-belt design of the system would free up horsepower. Now keep in mind that this 550hp motor never had an overheating problem and consistently ran in the 180-190 degree range. It also had a brand-new radiator recently installed. From the first race with the new pulley system, the motor always ran above 220 and would peg the temperature gauge when our racer friend shut it off.

Here's the problem. The smaller pulleys were mismatched to the water pump and ultimately the engine application. They weren't designed for a 5,500-rpm 550hp motor with a stock-style pump and spun the pump too fast, pushing the water too quickly through the cooling system.

Restrictors - In addition to water pumps and pulleys, restrictors are commonly used to regulate the flow of water through the radiator. They're just what their name implies and look like a small funnel engineered to cut down or restrict the flow of water. Usually mounted in the lower radiator hose at the radiator outlet neck, restrictors come in various diameters. Choosing to run a restrictor is a matter of matching it to your system.

Note how the aluminum fins are folded over, bent, and damaged. No doubt the result of flying chunks of dirt, rocks, and mud. Fins bent over in this fashion can't do the job of circulating the air.

Note how the aluminum fins are folded over, bent, and damaged. No doubt the result of flying chunks of dirt, rocks, and mud. Fins bent over in this fashion can't do the job of circulating the air.

"It really depends on the application," says C&R's David Bridges. "With today's water pumps flowing at such high rates, the radiator itself is your biggest restriction and a double-pass is more restrictive than a single-pass."

Bridges says when changing from a double-pass to a single-pass radiator you want to begin with no restriction and then gradually add restriction based on restrictor size until you get the temperatures where you want them. "We always recommend running your water pump at a 1:1 ratio." A 1:1 ratio means that the diameter of your crankshaft pulley is the same as the pulley on the water pump.

Airflow - Like water flow, there are a number of items that affect airflow through the radiator such as fin count, the number of passes, the design of the core, and whether or not it has a shroud.

Cores - Racing radiators come in several different configurations including one-, two-, three-, or four-core/pass systems. This means that once the fluid enters the radiator via the inlet it will make that number of passes through the radiator before it exits back into the engine via the outlet. The most popular short track configurations are one- and two-pass radiators.

Clearly this hose is shot. The crack did not go all the way through, so the system performed fine when it raced last, but without a good inspection this crack would eventually spell disaster.

Clearly this hose is shot. The crack did not go all the way through, so the system performed fine when it raced last, but without a good inspection this crack would eventually spell disaster.

In a single-pass radiator the fluid flows through the radiator a single time. A double-pass radiator has two separate sets of tubes, sometimes seperated by a baffle, other times with one set stacked behind another set. Radiators with that second setup are known as a two-core setup. In either case, the fluid flows through one set of tubes and then comes back across the other set, essentially flowing through the radiator twice, hence double-pass. Obviously, in a three-pass there are three separate sets (or cores) of tubes sandwiched together while the four has . . . you guessed it, four cores.

The downside to multi-stack radiators is when you stack cores one behind the other you make it harder and harder for air to flow through the radiator. For bigger tracks and higher speeds, three- and four-pass systems are fine, but they just won't flow enough air to cool your engine efficiently in a 20-lap feature on a flat 1/3-mile track.

This housing which holds and protects the radiator has some damage to the bottom side and should be replaced. Housings and shrouds are easy to fabricate and are excellent for directing air to and through the radiator.

This housing which holds and protects the radiator has some damage to the bottom side and should be replaced. Housings and shrouds are easy to fabricate and are excellent for directing air to and through the radiator.

Fins - How tightly packed the fins are in your radiator is known as fin count and is measured in fins per inch. A higher fin count means there is more surface area for the aluminum to radiate the heat it absorbs from the water/fluid into the air. However, if the fin count is too high for your application it can actually form a barrier to the air trying to pass through the radiator. When this happens the air stacks up in front of the radiator or moves around it and doesn't reach the cooling tubes in the second row.

As a general rule, a fast race car can use a higher fin count while slower cars should use a lower fin count. If you're racing on tracks between 3/10- to 1/2-mile in length you should look for 14-18 fins per inch.

Shrouds - Regardless of the type of car you race you should have some type of shroud on the radiator. They are easy to fabricate and will maximize your airflow. Shrouds in front of the radiator direct the high pressure incoming air directly to the fins/core. Shrouds between the radiator and mechanical fans help to increase the airflow through the radiator. Sealing the shroud with duct tape is important to prevent any of the air from escaping.

Air Temp Influences - It's not unheard of, and actually probably more common than any of us realize, for the cooling system that worked like a champ in early spring to give up the ghost come mid-July. Here's why: The radiator works the same regardless of the ambient temperature.

"A good rule of thumb is for every 10 degrees increase in the outdoor temperature, the fluid will be 10 degrees warmer in the motor," says Richard Bailey owner of Innovative Cooling Equipment (ICE) of Concord, N.C.

Ultimately, whether you choose a single or a double-pass will depend on your application.

Ultimately, whether you choose a single or a double-pass will depend on your application.

Based on an outside temperature increase from 80 degrees to 105, you will experience a 25-degree increase in fluid temperature in the motor. Take it a step further, let's say your motor typically runs at 220 degrees. Add 25 degrees to that and you're at 245 and in danger of overheating.

That brings us to radiator selection. Your pick of a radiator should be based on the highest temps you'll see during the racing season. However, you must remember that the radiator is just one part of your overall cooling system. That system should be designed and installed not only based on those high outside temps but also on the number of laps you race, the size of your track, and the horsepower of your motor.

When looking for a new radiator, choosing the right number of passes is crucial. Many racers attribute overheating or running hot problems during the summer months to the increased ambient temperatures in June, July, and August. Often the problem rests within a poorly maintained cooling system, a mismatched radiator for your application, or a system that flows the fluid either too quickly or too slowly through the radiator.

So what exactly determines the proper number of passes? What and where you race is probably the biggest factor.

Let's look at John's car as an example. John runs a four-core system from ICE which may sound like overkill but in USAR Pro Cup racing it's almost a neccessity. On a typical weekend John will turn 300-400 laps on tracks 5/8-mile and bigger. A double-pass system would be inadequate for this environment. But the ICE four-pass system keeps the water temperature at an acceptable level even when he runs tape on the nose, a practice asphalt racers use to add aerodynamic downforce to their cars.

Typical short track racers don't need a four-pass system. They will find single- and double-pass systems will work fine for most situations. But which one to choose? There are advantages to both.

Pros & Cons

The advantage to running a single-pass system is that it's about $30 cheaper than a double-pass.

The down side to a single-pass is that it's less restrictive than a double-pass. And that reduced restriction means that the fluid is going to run through the entire cooling system at a quicker rate.

The other down side to a single-pass is that it's not as efficient as a double-pass. Faster flowing air may not have as much time to pick up heat from the tubes. And that's the point of the radiator in the first place, to dissipate heat. Also since the fluid also runs through the radiator a single time, the air passing through only gets one chance to pull heat from the fluid. If the air only "sees" the fluid one time and the air is passing that fluid at a fast rate of speed, it may not be maximizing the heat extraction. But again, much of this depends on the application. Our Project Dirt Late Model has a single-pass C&R radiator that works perfectly on the 3/8-mile dirt track (Ocala Speedway) that we run weekly.

There's virtually no weight savings between a single- or double-pass system because a double-pass radiator is basically a single-pass radiator with a baffle inserted into it that directs the flow of water through the radiator a second time. They're the same size and virtually the same weight. But where the double-pass shines is in its ability to cool your engine.

"A double-pass radiator will increase your cooling efficiency anywhere from 5-10 percent based on the application," says Bridges.

VP's Cool Down is a cooling system additive that reduces cooling system operating temperatures by up to 50 degrees. It reduces coolant surface tension, allowing better laminar coolant flow for better heat transfer.

VP's Cool Down is a cooling system additive that reduces cooling system operating temperatures by up to 50 degrees. It reduces coolant surface tension, allowing better laminar coolant flow for better heat transfer.

But what about the additional restriction provided by a double-pass? "Today's big water pumps which flow so much more water basically offset the additional restriction you'll find going to a double-pass," says Bridges.

There's another benefit. Say for performance reasons you want to run your motor a little leaner. Any time you lean out the engine, it's going to run warmer; switching to a double-pass gives you that extra needed cooling efficiency at an increased cost of only $30. Finally, the double-pass will move your inlet and outlet hoses to the same side of the radiator, making for a cleaner engine compartment.

The decision of what type of radiator and associated cooling system your race car needs should be based on your series, motor size, and the highest temps you'll see during the summer months.

Wrapping It Up

Ultimately, you need to speak to your engine builder and your chosen radiator manufacturer to ensure that you get the correct cooling system for your race car. Companies like C&R, Afco, ICE, and others are more than happy to help you select the right radiator for your application. However, there are a number of items that you need to pay attention to regardless of the type or make of radiator.

The type of water you're putting into your radiator is important as well. In a passenger vehicle we use anti-freeze, whose active ingredient is Ethylene glycol, nasty stuff. When added to water, anti-freeze drops its freezing point well below the typical 32 degrees F. Obviously race cars don't need anti-freeze, unless you're ice racing in Alaska, but can you do better than just plain tap water?

This flexible radiator ductwork is an alternative to solid ones. In the event of a wreck, it will pop back into shape.

This flexible radiator ductwork is an alternative to solid ones. In the event of a wreck, it will pop back into shape.

The problem with tap water, other than the widely varying quality level, is that it often contains minerals, flouride and other particulates, which can corrode the aluminum in your radiator. Both John and Bobby Clark, driver of our Project Dirt Late Model Team use distilled water in their radiators because it's pure, doesn't have any unwanted chemicals, and will ensure optimal performance of your cooling system. Both teams also use a glycol-free additive in that distilled water. Products such as VP's Cool Down, Water Wetter, or 40 Below will reduce cooling system operating temperatures.

Maintenance

One of the smartest things you can do after each race is pull the radiator out of the car and inspect it even if you weren't in an accident. Check all of the lines, hoses and fins. If any of the fins are bent or closed off, air won't pass through them. Take a pair of needle-nose pliers and carefully straighten them out. Hoses that are cracked or in danger of cracking should be replaced immediately. Also pay close attention to the welds for any small cracks or potential breaks. Don't forget to crawl under the car and look on the shop floor. You just might find a small puddle of water that will lead you to a bigger problem.

Choosing the right cooling system for your application and then keeping a close eye on it throughout the season will allow you to avoid problems that would keep you out of Victory Lane.

Radiator Protectors

Radiator protectors are a good way to add an extra layer of protection for your cooling system. These protectors mount in front of the radiator and absorb the impact from debris, rocks, and dirt instead of those aluminum cooling fins. The one pictured above, the Tru-Kool Radiator Protector, is from Speedway Motors. Its Nomex honeycomb construction is very strong and extremely lightweight offering excellent protection.

The protector is disposable and is designed to be replaced as it absorbs various amounts of damage. Naturally, how often you race, the type of track you race on, and other factors will determine how often you have to replace the protector, but some racers have reported running an entire season on just one honeycomb. The Tru-Kool Radiator Protector comes in four different sized sheets that can be easily trimmed to fit any radiator.