This is the age of the stroker motor, and when it comes to cubes, it's pretty much a case of bigger is better. Nevertheless, just how much better is highly dependant on the utilization of those cubes. In essence, there is low-tech cube utilization, which delivers so-so results, and there is high-tech cube utilization, which as we'll see here, delivers dynamite results. Moreover, the cost difference between one and the other may only be marginal. Read on to find out why.

Laz Mesa (the boss at Mesa Balancing in Hialeah, Florida) and I have one thing in common-we both like big-inch motors. A few years ago, we did a successful project on a stroker 351 Windsor, and since then we have shared test data to fine-tune Windsor stroker combinations. This all came to a head when I got a call from Laz telling me that Pro Power had a new budget stroker kit good for street/strip power levels up to 650 hp. I had successfully used a Pro Power budget stroker kit in the past to good effect, but the latest iteration had an upgrade on the rods, and more importantly, the pistons. In addition, Laz had sonic tested a 351 block that was good for .060 over. This, with the 4.10-inch stroke of the Pro Power stroker crank, would give us 425 inches. That's a whole 21 percent increase over a stock 351 Windsor.

Cubes & Efficiency The Pro Power stroker kit used here (including bearings and rings) can be had complete with a damper (tuned to the crank) for $1,399, and for $250 extra, the whole lot can be balanced. But buying the cube-generating parts and installing it all in the block is the easy part. To capitalize on the extra cubes, two factors become super critical. These fall under the heading of volumetric (breathing) efficiency, and combustion efficiency. Maximizing volumetric efficiency means maximizing the combination of airflow capability, and velocity of the carb, intake manifold, heads, and exhaust, such that with the right cam, the maximum amount of air can be passed through the engine. Achieving good combustion efficiency starts with a carb that delivers a mixture with just the right amount of fuel atomization, and assuring that the quality of the mixture does not deteriorate too much by the time it has arrived in the cylinder. Along with this, we need an ignition system that has not only high spark power, but also the right advance characteristics. All this means a substantial number of parts working together in a well-orchestrated fashion. It did not happen overnight, but the final spec of our engine, which came together in total over a period of some two years, was just that, so let's look at the key issues involved.

Cylinder Heads We have lots of cubes to feed, and if any sort of real power is to be had, the heads must be able to feed those cubes. To do so requires good airflow, but that alone is not the answer. If we are looking for high torque over a very wide rpm range, then port velocity becomes a real factor. Not only that, but the wet flow characteristics must also be such as to promote good combustion. We realized that all this is a lot to deal with, so we started with a set of heads with proven performance-namely a set of 200cc intake port RHS heads. The goals here were to increase both flow and velocity. On top of this, we wanted to increase swirl, and refine the wet-flow characteristics.

Pro Power rates its entry-level rods with a 650hp capability. If more power is required from this stroker kit, it has an upgrade to suit.

Pro Power rates its entry-level rods with a 650hp capability. If more power is required from this stroker kit, it has an upgrade to suit.

Let's start with moves to increase flow. Here, the first move was to increase the stock 2.02-inch valve to 2.08 inches in diameter. The seat for this was a trick-radius approach, 45-degree Cup Car profile that was successfully used a few years ago. The port mods had to deal with four issues concurrently-those being flow, velocity, swirl, and wet flow. To achieve these goals, the port was reworked to give it a slight bend, and the approach part of the guide boss was angled to move more of the air onto the cylinder-wall side of the port. This, together with a bowl rework and attention to the short-side turn, measurably moved head characteristics in the right direction. Packing this port rework into a couple of sentences makes it sound like it was all just so easy. The reality is that it was the sum of many hours of tedious flow bench work. The results, though, appear to be worth the effort. Even though these RHS heads flowed very well out of the box, we still managed to tap measurably further into their potential. The wet flow patterns were tidied up, and swirl went up by about 30 percent, which in itself was good, as Ford heads traditionally are low on swirl. The extra flow was achieved with minimal metal removal, and with a final port volume of 208cc, the flow went up more than the port volume, which meant the already excellent port velocity of these heads was further increased.

Cam & Valvetrain For the valvetrain to be as near optimal as possible, it has to do two things effectively. First and foremost, it must open and close the valves at precisely the right time in relation to the crank's rotational position. Secondly, the valvetrain dynamics must accurately transmit the cam profile to the valves. Fail in either respect, and a serious chunk of output is lost. First, let's deal with valve events. Anytime the displacement goes up for a given valve size, the cam's lobe centerline angle needs to be tightened. Most cams are in the 110- to 112-degree LCA range. Whereas this might be handy to what is required for a typical 350, it is not going to be anywhere near best for our 425. Failure to get the LCA where the engine wants it by just 3 degrees too wide, and you can watch 25 lb-ft of torque disappear everywhere from this engine's torque curve. The number-one requirement then was a cam on a 107-degree LCA. Since this is a street engine, we opted for a hydraulic cam. Here, Laz uses custom grinds from Crane, COMP, and Cam Motion. The particular brand we opted to use here was a 252/256-degree hydraulic profile from Cam Motion. That, with the Crane rockers we were going to use, delivered close to .620-inch observed lift. That profile might seem rather on the large side for a street motor, but because we have taken care of business in terms of a high port velocity, this big cam will act smaller at low rpm than would otherwise be the case. That, plus the cubes involved, makes this cam act as if it is about 232/236 degrees in a stock-displacement 351. It doesn't look so big now, does it?

Now that we have the cam spec sorted, it's time to look at the hardware. High-lift hydraulic roller valvetrains are notorious for collapsing typical roller lifters. One of the best hydraulic roller lifters to combat lifter collapse is the Crane alloy-steel-body piece. We have run these lifters to as much as 7,800 rpm, so they should be more than up to the job. But there is more to these lifters than just a high-grade, heat-treated steel body. The internals are such that these lifters, when adjusted to Crane's prescribed one turn in, contain such a small oil reservoir that they not only cannot collapse very far, but also they recover very rapidly from whatever minimal collapse may take place.

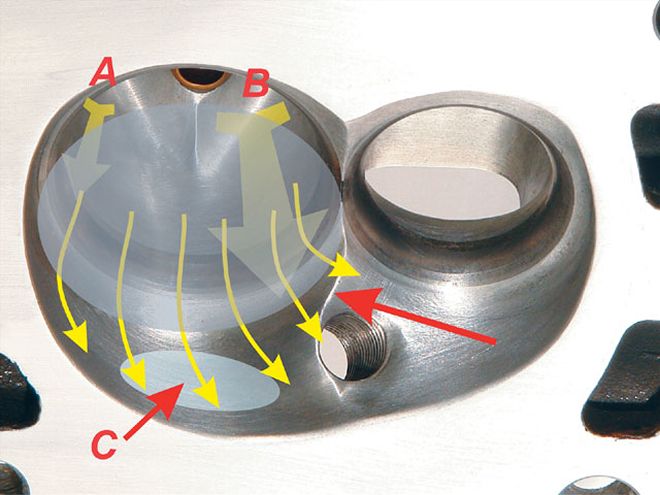

This is the finished chamber for our 425 Windsor with the valve "ghosted" in at .500-inch lift. In stock form, there are two main fuel streams. The smaller one (arrow "A") tends to wash the chamber wall area directly in line with the direction of the arrow. This, combined with a stronger fuel stream (arrow "B"), causes a large washout at area "C." After port and guide mods, the fuel stream is spread out more, as indicated by the solid yellow arrows. Also, by making the ridge (red arrow) more pronounced, fuel from the cylinder center side of the intake port is sheared into a finer state off the edge of this ridge.

The rockers were also from Crane. These nominally 1.6:1 rockers have a high off-the-seat ratio (about 1.72:1), which gets the valves open quicker-and that's important for success when a lot of cubes are involved. For pushrods and springs, we used COMP parts. The most important item in the valvetrain is the beehive spring. This allows us to moderate spring loads to counter lifter collapse without paying an rpm penalty.

Ignition! For an ignition system, we elected to use a Chevy HEI-style distributor made specifically for a Ford 351 Windsor by Performance Distributors. This has several advantages like low cost, high performance, and total simplicity. We told the guys there what the engine spec was in detail, and they built a unit with the appropriate mechanical curve built right in. Normally, we would also use a vacuum advance as well (for best mileage), and that too would be appropriately tailored for the job; however, our 425 was for all practical purposes a dyno mule, so we elected to use a Performance Distributors micro timing adjuster in place of the vacuum advance. This allows precise adjustment in small increments to get the very best from the engine in terms of WOT.

Intake & Carb If we were building a hopped-up 351 for the street, the carb size most recommended would probably be a 750. This would almost certainly be paired up with an air-gap-style two-plane or maybe a Victor Jr. single-plane, but we have 425 inches here. This engine is more like a big-block in terms of displacement, so some serious reevaluation of the carb cfm was needed. If we step up carburetion in proportion to the cubes, then this engine is going to need something along the lines of 920 cfm. Also, for any motor that can potentially pass the 550-570hp mark, a Super Victor intake is probably the best bet. The reality here is that if this 425-inch Windsor did not make at least 570 hp, our engine building skills would be seriously called into question.

The ultra-stiff Crane alloy-steel-body hydraulic lifter was a key factor in the building of our 425-inch valvetrain. By having a very low collapse rate, these lifters ensure the motion input by the cam profile actually reached the valves.

The ultra-stiff Crane alloy-steel-body hydraulic lifter was a key factor in the building of our 425-inch valvetrain. By having a very low collapse rate, these lifters ensure the motion input by the cam profile actually reached the valves.

For carburetion, Laz has a Cup Car carb builder that custom builds his highly functional carbs at a very nice price. The one built for our 425 was a custom piece with a booster design that had already established itself as optimal for this sort of application. Just as a reminder, the atomization produced by the booster/emulsion well/air bleed combo plays into our induction system's wet flow scenario. If the fuel droplets are too big, it counters most of the work we did refining the wet flow characteristics of the intake port. If the droplets are too small, too much fuel vaporizes in the intake manifold and cuts volumetric efficiency. Get things just right here, and it pays off. From previous testing, it has been established that booster selection and the appropriate detailing of a Holley HP 950 can, on a stroker motor such as ours, be worth 15 lb-ft and 15 hp.

The Rest Of The Gear We are now down to build details that relate to a dyno installation. Because it simplifies the dyno work, a Meziere electric water pump was used instead of a mechanical pump. These water pumps are typically good for 6-7 hp at 6,500 rpm, and as much as 12 hp at 8,000. For an exhaust system, dyno headers with a tuned secondary length were used. These headers had 1.75-inch primaries with an average length of 36 inches. These dumped into a secondary of 3.5 inches diameter, and a length of 14 inches from the end of the collector taper. Of the two, the secondary length is by far the most critical. Shorten this by 4 inches and the price can be a 20hp drop in output.

Dyno Time With our 425 on the dyno, expectations were running high. Eight degrees of initial timing proved to be a good starting point, and this fresh 425 Windsor lit off before the second revolution was even underway. It sounded good right from the start, and as soon as it had generated a little heat, it idled just fine at 825 rpm even before any carb idle adjustments had been made. After cycling the engine up and down from 1,000 to 2,500 rpm for about an hour, it was shut down and given a post break-in service that included an oil and filter change, and a head bolt torque check. The final phase of break-in involved cycling the engine from 2,500 to 4,000 for another 30 minutes.

By now, the engine was deemed ready for some exploratory pulls. The first was a 2,500-4,000 pull, and from this we learned that our 425 was making too much low-speed torque for the dyno to pull down much less than 2,900, where it was making close to 500 lb-ft. Since the mixture looked safe on the slightly rich side, runs were increased in rpm until we were seeing 6,000, where the motor was making a solid 590 hp.

Now was time to start fine-tuning. Dropping the jet sizes by two numbers all around saw a little more power. This netted 4-5 lb-ft more everywhere, and about 6 hp at the top end. Some steady-state pulls under full load were made and held a while. This showed we were about dead-on from the mixture standpoint. Now was time to dial in the timing. The 8 degrees initial we used as our starting point produced 30 degrees total, which was all in by 3,000. We used the distributor's thumb wheel micro timing feature to gradually dial in some more timing. After about 10 pulls, we had optimal timing at 33 degrees total. An optimal total advance this low is a good indication that the burn is taking place fast and effectively.

Using a Meziere electric water pump is typically worth 6-7 hp for engines peaking in the 6,000-6,500 rpm range. We used a pump like this one for the power advantage, and the convenience of dyno setup.

Using a Meziere electric water pump is typically worth 6-7 hp for engines peaking in the 6,000-6,500 rpm range. We used a pump like this one for the power advantage, and the convenience of dyno setup.

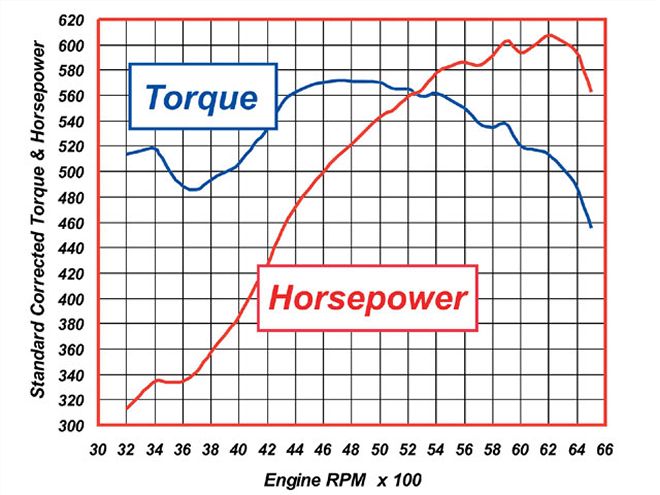

The lowest we could pull this 425 down to on the Mesa Balancing dyno was a shade under 3,200 rpm. At 3,200 rpm, it was cranking out a very impressive 517 lb-ft of torque. That's 17 lb-ft more than the peak torque of the Corvette LS7, which is virtually the same size as our stroker Windsor. From 3,500-3,900, the torque curve drops just below the 500 lb-ft mark in what can best be described as the intake manifold tuning hole. Here the length of the intake runners and the exhaust just don't coincide to do as much to assist cylinder filling as they could, but as 4,000 rpm comes around, things get wild. Here the engine comes on the cam; the intake, exhaust, and the big torque numbers reflect just how well this combination is working. We repeatedly saw peak numbers of 572 lb-ft, and on one run 575 lb-ft. That works out to a shade over 1.34 lb-ft per cube, and that (for a low-cost 10.5:1 pump-gas motor) is really good. As for horsepower, this Mesa-built stroker could hit the 607hp mark on every pull after the setup was perfected.

With this build we have shown once again the old adage that getting the right combination is the key to success, but that doesn't come as any surprise. What is more of a surprise is how cost-effective this build was. Sure, it's not at the bottom of the "budget barrel," but in terms of being reasonably priced, it's among the best budget-conscious builds we have done in a long time.

Dyno Test * 425CI Small-Block Windsor Peak HP: 607 at 6,200 rpm

Peak TQ: 572 lb-ft at 4,500 rpm These are the kind of results that can be expected when the combination is right. Other than the dip caused by the combined effect of the intake and exhaust tuning at 3,700 rpm, this 425 was good for 500 lb-ft plus from about 2,900-6,300 rpm.