Little can compare to the performance look of an RB-powered Mopar topped with a gleaming Six Pack induction. Legendary in its day, does the performance still stack up?

Little can compare to the performance look of an RB-powered Mopar topped with a gleaming Six Pack induction. Legendary in its day, does the performance still stack up?

Oh, the fabled Six Pack and the memories it brings. For me it harkens back to high school in the late '70s, when the local dealership mechanic flipped a complete aluminum-intake 440 Six Pack setup my way for a mere 75 bucks. Those fat six barrels running the length of the intake were pure visual candy-so much more than the plain-jane AVS four-barrel and iron intake they were replacing on my prized R/T. When they worked, it was sweet music, a rush of adrenaline that came with the surge of air pulled through those six gaping holes and into that mighty 440. It was addictive, and I came away bitten, another Six Pack junkie for life.

It lasted less than a month before fouled needles and seats had them overflowing with fuel, and the cheap parts-kit replacement cork gaskets of the day made them worthless for metering fuel. Numerous rebuilds and mods eventually took their toll, until stripped-out float bowls dealt the final deathblow. A boneyard yielded a complete replacement system-an iron intake setup marked "70 Charger" in that familiar wrecking-yard paint-pen yellow. Those carbs, too, were a constant effort to maintain, until, for the sake of reliability, the Six Pack was sacked in favor of a Holley 3310 750 on an old Edelbrock Torker intake. The surge of power, as I remember it, was never the same. While those old Six Pack carbs were problematic, the magic of how it ran when it was "on" remains with me to this day.

Were Six Packs really as good as we remember them? It's clear now that my carb's reliability problems were because of inexperienced hands and bogus cheapo parts. The memory of big power remains, but some of our non-Mopar buddies and coworkers scoff. When we jawboned around the office about an upcoming Six Pack tuning test, the cynics were out in force. We heard it all.

"Looks cool, but has no place on a performance engine today."

Our test engine is a .030-inch over 440 sporting 10.2:1 compression; Edelbrock heads; and a Comp XE285HL hydraulic cam working 1.6:1 rockers and exhaling through 2-inch Hooker headers. We bolted it to Westech's dyno to run the numbers on Six Pack performance.

Our test engine is a .030-inch over 440 sporting 10.2:1 compression; Edelbrock heads; and a Comp XE285HL hydraulic cam working 1.6:1 rockers and exhaling through 2-inch Hooker headers. We bolted it to Westech's dyno to run the numbers on Six Pack performance.

"Might have been better than stock 30 years ago, but no match for a modern induction."

"You're going to run that thing? Good luck."

It could just have been nostalgia, but we figured the 440 Six Pack induction would prove its worth. We were intent on running the system on the dyno and letting the numbers tell the story.

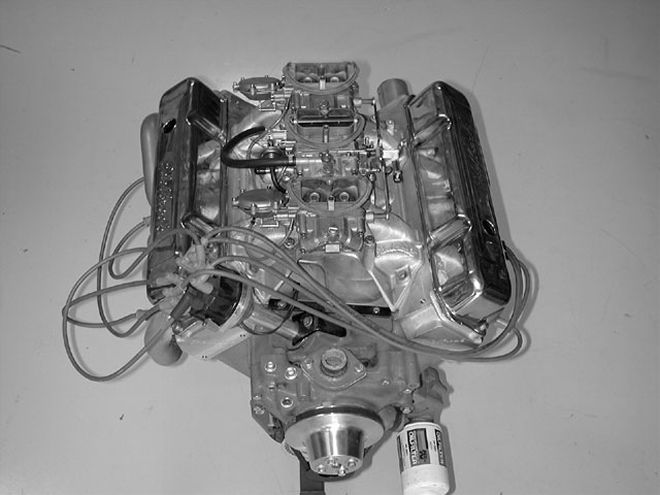

Our test Six Pack system is a far cry from the dusty and dried-out junkyard parts I remember from decades ago. That aluminum intake scored in the '70s had been brutalized with oversized drilled-out mounting holes to fit a set of milled heads, and barely held the carb fasteners with its war-worn threads. Twenty-plus years later I've finally assembled a Six Pack worthy of the legend. The test intake is a new Edelbrock piece, cast true to the original aluminum '69 version. Rather than ragged and rebuilt junkyard carbs, on hand is a fresh set of re-released Holley resto carbs, a #4670 center unit with a brace of #4672 outboards. Assembled from all-new components, the Six Pack induction is as much a work of art as a fuel system.

Our intention was to explore the performance potential of the Six Pack on a modern street/strip performance-built 440. We had a fresh Edelbrock-headed 440 at Westech's dyno shop, which had been built as part of Car Craft magazine's series on big-block performance engines. The 440 had been run in numerous dyno tests in various configurations, and produced righteous output. Build specs on the engine-a balanced and blueprinted stock bottom-end featuring .030 over TRW 2355 Six Pack pistons dialed in to yield 10.2:1 compression; a Comp XE285HL .904-inch tappet ramp hydraulic cam; 1.6:1 Harland Sharpe rockers; the aforementioned Edelbrock heads; and Hooker 2-inch Super Comp headers. In previous dyno work, the Edelbrock Performer RPM intake proved to be the best single four-barrel intake tested by a significant margin. It represents the state of the art in modern four-barrel dual-plane intake manifold design. We used the RPM intake as the baseline, to see how the Six Pack compares.

The Six Pack intake, like the Performer RPM, is a dual-plane design, cut with a unique plenum design to accommodate the three carbs that run the length of the engine.

The Six Pack intake, like the Performer RPM, is a dual-plane design, cut with a unique plenum design to accommodate the three carbs that run the length of the engine.

Crunching The Numbers

For the baseline test, the engine was fitted with a Performer RPM intake, topped with a Holley PN 0-80511-1 carb-an 830 cfm rated HP-series carburetor actually produced for Winston Cup competition. Both the carb and intake are modern designs, and some of the best equipment available. Our Six Pack arrangement was up against some stiff competition. We loaded the 440 onto Westech's SuperFlow 901 engine dyno and began optimizing the engine timing and the jetting on the Holley carb. The best output achieved came to the tune of 535 hp at 5,300 rpm, and an unreal 581 lb-ft at 3,900 rpm. The average output over the test range from 3,000-5,600 rpm worked out to be 553.3 lb-ft, and 450 hp. The Six Pack would have to work its proverbial tail off to meet the baseline figures of the single Holley.

We had the manifold swapped to the factory-calibrated Six Pack setup in short order. For our baseline run, the carbs were run out-of-the-box stock. The numbers were down on what we had seen with the previous induction, but not by much. We had peak numbers of 531 hp at 5,300 rpm, and 569.7 lb-ft at 4,000 rpm. The averages were also down, showing 545.7 lb-ft and 445 hp-a loss of nearly 8 lb-ft and 5 hp average over the pull.

Step one when setting up the Six Pack is to check and adjust the float levels. The sight plug in the float bowl is removed, and the centrally mounted needle and seat is adjusted until the fuel just trickles past the sight hole's threads.

Step one when setting up the Six Pack is to check and adjust the float levels. The sight plug in the float bowl is removed, and the centrally mounted needle and seat is adjusted until the fuel just trickles past the sight hole's threads.

Was there a reason to be disappointed? To us, things were looking pretty good. The Six Pack proved much closer to our engine's top-dog induction than did some of the other intakes run in past testing. We were still box-stock on calibration. As a side note, those who are familiar with the Six Pack induction know the outboard carbs are actuated by large vacuum diaphragms mounted to the carbs, rather than mechanically through the throttle linkage. To ensure that the outboard carbs were fully opening, a backup pull was performed as a test with the carbs' linkage pinned for mechanical operation. The result was a near perfect overlay of the output curve generated in the previous dyno pull. There was no question about the secondary carbs opening.

Quickfuel Plates

Since we were dealing with a well warmed-over 440, we had the issue of calibration to contend with. The stock Six Pack carbs come calibrated exactly as factory issued-designed to work on a mildly-cammed 390 hp 440 with iron exhaust manifolds and stock #906 or #346 heads. Extracting the potential of the Six Pack on our modified test engine would require jetting; however, the stock Six Pack carbs come with fixed-orifice metering plates in the outboard carbs. To facilitate making metering adjustments, a pair of QuickFuel's trick replacement metering plates were ordered. In lieu of jets, the factory-style metering plates use a drilled orifice for main-circuit fuel metering. Changing calibration can only be accomplished by drilling the metering orifices, or by installing plates with a different calibration. While it's possible to fine-tune a factory plate setup to razor sharp precision, the procedure is time-consuming and awkward, not to mention expensive, if a variety of differently calibrated stock-style plates are utilized. The clever QuickFuel plates replace the originals with a design that accepts standard Holley main jets. Once the carbs are converted to the QuickFuel plates, calibration changes are simply a matter of removing the float bowl and swapping jets.

Converting the carbs is a simple procedure. The float bowls are removed to access the stock metering plate, which is held in place with six clutch-head screws. Just unscrew the stock plates and replace with the QuickFuel plates and gaskets using the same fasteners. Regular Holley jets are then installed, and it's a done deal. Since the QuickFuel plates fit inside the float bowls like the originals, once the bowls are reinstalled there is no external evidence that the carbs have been modified. Jetting the outboard carbs requires removing the rear carb from the manifold for float bowl access, and the front carb bowl can be removed for jet replacement while the carb is bolted in place.

We made the conversion, installed a set of 72 jets, then ran a static test to see if we were in the ballpark. The dyno instrumentation showed we were lean. The bowls came off, and both outboard carbs were loaded with a pair of 80 jets. Another static pull showed the mixture to be close, and we were in business. Peak power output was up to nearly match the rpm, showing 534 hp at 5,600 rpm, but the peak torque was off the mark turned in by the box stock carbs, with 566 lb-ft at 4,000 rpm. The averages at 545.2 lb-ft and 444 hp showed that the 80 jets made virtually the identical output as the factory carb calibration. The Six Pack carbs seemed to be pretty close with jetting as delivered.

Next, we moved up to 82 jets in the outboard carbs. The engine liked the extra fuel, and output climbed to 573 lb-ft of torque at 4,100 rpm and 541 hp. Jetting up was definitely worth power on this combo over the factory carb calibration. The averages were also up handily, with the torque and horsepower numbers moving up to 551.4 and 450 respectively. The Six Pack was matching the average horsepower of the modern four-barrel induction and actually making more peak power up top. The edge in torque lower in the rpm range, however, went to the four-barrel by a small margin.

If some is good, more must be better, so we went back in a final time and stepped up the outboard carbs to 84 jets. We did see a slight gain in peak output with this change, posting 543 hp, our best number of the day, and a full 8 hp better than what was achieved with the single four-barrel. Torque was up a fraction at 573.1 lb-ft at 3,900 rpm. The averages were down just fractionally from the previous test-550.6 lb-ft of torque and 449 hp over the rpm range. The mixed results showed that the optimum jetting was somewhere between the two tests.

It was clear that we had reached a point of diminishing returns with further fattening of the carbs. With the QuickFuel metering plates, we were able to find 12 hp in our Six Pack induction with simple jet changes-a worthy gain by anyone's reckoning. We came away from the test more respectful than ever of the Six Pack's power-producing ability. The Performer RPM intake has proven itself in several of our tests as a spectacular power and torque producer on 440s at this power and rpm range. The tuned Six Pack, though not quite matching the torque numbers, edged it out in peak hp. Bear in mind that back in the day there was nothing in the league of the Six Pack. No wonder it stood head and shoulders above the crowd.

Dyno Results

Superflow 901 Engine Dyno

Tested At Westech Performance Group

HorsepowerRPM4 BBL6 BBL STK6 BBL JET 8430003223153143500376371373{{{4000}}}4414314354500477472475{{{5000}}}513506513530053553254355005335305385600531534543

TorqueRPM4 BBL6 BBL STK6 BBL JET 843000563.4552.1550.63500564.9556.3560.33900581.0564.8573.14000578.9566.0571.44500557.1551.3554.25000539.0531.1538.75500509.4506.4513.6

Average Power Output

3,000-5,600 RPM4 BBL6 BBLSTK6 BBL JET 846 BBL JET 82Torque553.3545.2550.6551.4Horsepower450444449450