The force on the pushrod can exceed 4,000 pounds. That's a lot of force on a slender metal tube.

The force on the pushrod can exceed 4,000 pounds. That's a lot of force on a slender metal tube.

When you think about it, everything in the valvetrain between the camshaft and the valve is little more than a high-tech telephone line. All the parts and pieces-the springs, the retainers, the rockers, the pushrods, and the lifters-are there simply to transmit the commands of the camshaft to the valves. Of course, each part adds a little to the equation: The springs help the valves close and accurately follow the back half of the cam lobe, and the rocker arms magnify the commands of the valve, allowing valve lift over 0.5 inch without requiring a lobe the size of your wrist. You get the idea. The pushrods, however, are often ignored and thought to be an extension to get from the lifters to the rocker arms.

If this is how you think of pushrods, you are missing out. Engineers at Competition Cams have spent countless hours studying every link in the valvetrain. They recently revealed that the desire of many engine builders for lightweight components was harming overall performance when it comes to pushrod selection. Given the trend of aggressive camshaft grinds coupled with ever-increasing rpm levels, the standard 51/416-inch diameter pushrod that was perfectly fine several years ago can now easily be the weakest link in the system.

It turns out, size does matter. Because racing engines are taking advantage of more aggressive camshaft profiles and pushing ever-higher rpm, many engine builders are finding the need to switch from 51/416-inch-diameter pushrods to the bigger 31/48-inch size. Despite the extra weight, the improved valve control is worth it.

It turns out, size does matter. Because racing engines are taking advantage of more aggressive camshaft profiles and pushing ever-higher rpm, many engine builders are finding the need to switch from 51/416-inch-diameter pushrods to the bigger 31/48-inch size. Despite the extra weight, the improved valve control is worth it.

"It's not the compression that's hurting these things," Thomas Griffin of Comp Cams explains. "It's the buckling loads, or the tendency of the pushrod to bend under pressure. Somebody might say, 'I've only got 500 pounds of spring pressure on the seat with a 1.8 rocker ratio,' which gives you 900 pounds on the pushrod over the nose. But that's cranking the engine over by hand. But when the engine is running, it is spinning much faster and inertial loads become a factor. And now that builders are pushing the rpm levels even higher, that just multiplies the load. We've had all kinds of valvetrain combos on our Spintron machine and put strain gauges on the pushrods, and we are seeing over 4,000 pounds of force exerted on the pushrods. That's a couple of Volkswagen Bugs balanced on the end of a slender metal tube."

It turns out that the pushrods are under the greatest loads at two of the worst possible times in the valve cycle: just as it opens and just before it closes. Why the pushrod is under load just as the valve opens is easy to understand. It is trying to accelerate the mass of the valve from a stationary position, which requires a great deal of energy. Radical opening ramps on racing camshafts make the load even greater.

To eliminate the chance of accidentally installing the wrong rods, the Comp Cams laser etches its racing pushrods with the length and wall thickness, so it's easy to see.

To eliminate the chance of accidentally installing the wrong rods, the Comp Cams laser etches its racing pushrods with the length and wall thickness, so it's easy to see.

It's a little more difficult to understand why a pushrod would be under its maximum load just before valve closing. After all, since the spring does the work of closing the valve, at this point, isn't the pushrod simply following the lifter back onto the cam's base circle? Not exactly.

In a perfect world, an engine would work most efficiently if the intake and exhaust valves popped open at the right time and were instantly at maximum lift. Then they would stay at maximum lift until time to close, and then drop back instantly against the seat. That, of course, isn't possible. So cam designers create steep opening and closing ramps to move the valves as quickly as possible when working on racing engines. They can't allow the valve to simply slam against the seat at maximum velocity. That would cause valve bounce, which reduces compression and destroys both the valve and the head.

New dual-taper pushrods use a larger barrel to provide even more strength, but they can still work with rockers and lifters designed for more conventional sizes.

New dual-taper pushrods use a larger barrel to provide even more strength, but they can still work with rockers and lifters designed for more conventional sizes.

Instead, they design the lobe to slow the valve back down in the last few degrees of camshaft rotation and gently drop the valve back onto the seat. As you can imagine, stopping the inertia of the quickly moving valve just before it slams into the seat places a great deal of stress on the pushrod. This is compounded by the fact that the entire system unloads at maximum lift and then comes back together somewhere on the closing cycle. It gets even worse if the valve lifts beyond maximum lift and the spring slams it back against the rocker arm, sending a shock wave through the system. In many cases, the load on the pushrod just before valve closing is even greater than it is when the valve opens.

This results in a corruption of the valve timing events. If the pushrod flexes as the camshaft is trying to open the valve, it absorbs the energy from the cam and delays the opening. On the other side of the equation, if the pushrod flexes as the cam is trying to slow the valve just before it closes, it allows the valve to maintain too much velocity as it makes contact with the seat. In addition to the damage this does to the valve and seat, the extra speed can also cause the valve to bounce back open, reducing compression. You end up with a race engine that runs, but not to its full potential. All that money you spent on a state-of-the-art camshaft you have just flushed down the drain.

"The goal has gone from running as light a pushrod as you can, which you get with your 51/416-inch-diameter pushrod, to a more rigid piece with respect to bending," Griffin says. "Yes, a lighter pushrod is better, but if it is too light, it's too flimsy and it negates any advantage you gain from the lack of weight. A bigger pushrod with a thicker wall is much more resistant to buckling loads; the extra weight that comes from that is simply an unwanted-but unavoidable-by-product. Despite the added weight to the valvetrain system, the bigger pushrod almost always allows for greater rpm and more valve control."

Hi-Tech checker pushrods are threaded and can be easily expanded. Simply install one checker pushrod in the engine you are building and extend it to the correct size. Each revolution equals 0.05 inch, so all you have to do is count your revolutions and add that to the marked length on the checker to come up with the size you need in your engine.

Hi-Tech checker pushrods are threaded and can be easily expanded. Simply install one checker pushrod in the engine you are building and extend it to the correct size. Each revolution equals 0.05 inch, so all you have to do is count your revolutions and add that to the marked length on the checker to come up with the size you need in your engine.

Vibration

There is another factor to consider when it comes to pushrod size: the vibrations that are unavoidable in a valvetrain. Vibrations are generally worse at the higher rpm levels. Basically, vibration is the combined result of the components flexing and springing back to shape. Just like a spring, the metal components don't flex, spring back into shape, and then stop. They oscillate just like a spring. At certain rpm levels, the vibrations create a harmonic that throws everything into an out-of-control state. The problem is that this level is always changing, depending on components and conditions inside the engine, so it is impossible to predict where damaging harmonic conditions will show up.

One of the best ways Comp Cams engineers have found to control this is by using pushrods to essentially soak up the vibrations running through the valvetrain. "We are using the pushrod like a tuning fork," Griffin says. "When you run at any rpm level, the valvetrain becomes a vibrating system. What that means is it has frequencies where it likes to work and frequencies where it doesn't. What we've done with the pushrod by making it with a larger diameter and a thicker wall is allow it to have properties that are resistant to vibrations. As a result, your valve motion is a lot truer, and your valve is better controlled. It essentially protects the entire valvetrain."

Sized to Fit

No matter what diameter pushrod you are running, it's also critical to select the correct length. There are several factors that affect pushrod length. Deck height, rocker arm location, lifter size (roller lifters are typically longer), valve stem length, and cam base circle size are just a few of these factors. Because of this, pushrods generally aren't ordered until the engine is mocked up and the builder can see exactly what he needs.

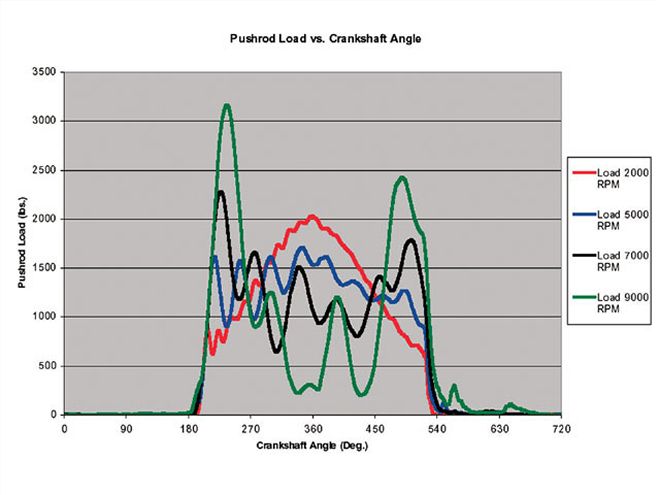

This is a chart showing pushrod load traces. The 2,000 rpm load is what you would expect to see. By 5,000 rpm, the load over the nose is still the maximum. Peak opening load is roughly twice what it was at 2,000 rpm. The 7,000 and 9,000 rpm traces show how the loading of the pushrod has changed significantly. This is due to the dynamics of the system. The time the cam spends opening and closing the valve at 9,000 rpm is a fraction of what it was at 2,000 rpm, so the load required must increase.

This is a chart showing pushrod load traces. The 2,000 rpm load is what you would expect to see. By 5,000 rpm, the load over the nose is still the maximum. Peak opening load is roughly twice what it was at 2,000 rpm. The 7,000 and 9,000 rpm traces show how the loading of the pushrod has changed significantly. This is due to the dynamics of the system. The time the cam spends opening and closing the valve at 9,000 rpm is a fraction of what it was at 2,000 rpm, so the load required must increase.

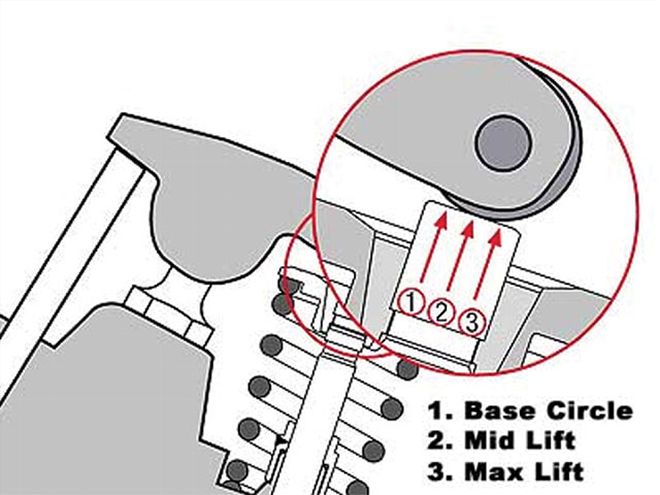

The ideal pushrod will center the rocker arm over the tip of the valve stem with the correct lash dialed in. This means the tip of the rocker arm will be contacting the inner third of the tip of the valve stem as soon as the lash is taken up and valve lift begins. It rolls across the middle of the stem at mid-lift and reaches as far as the outer third of the stem at maximum lift. If the pushrod causes the rocker to roll over the edge of the valve stem at either end, it will cause undue wear on the rocker, the valve, and even the valveguide.

The best way to determine the correct valve length is with a pushrod checker, which is essentially an expandable pushrod. Screw the pushrod checker to its minimum length and insert it in the engine just as you would a normal pushrod. Extend it until you get the correct valvetrain geometry (the tip of the rocker arm stays on the tip of the valve stem). This will require turning the engine over several times by hand, so it's best to mock up only a single valve. Once you find the correct length, pull the pushrod checker.

A good pushrod checker will make it easy to determine the expanded length. For example, Comp Cams' Hi-Tech checking pushrods come in a number of minimum sizes. The checker pushrod is expanded by unthreading one of the ends. Each revolution equals 0.05 inch. Simply count the revolutions, convert to inches, and add that to the checker pushrod's minimum size. For example, if we were using an 8-inch checker pushrod and extended it six revolutions, the final length would be 8.3 inches. (You can also double-check your calculations if you have an extra-long dial caliper.) Subtract your lash from that number and you have the correct length. For more information on checking pushrod length, see "Determining the Proper Push" in the December '03 issue of Circle Track.

Proper valvetrain geometry requires the end of the rocker arm to stay on the valve tip and be centered at mid-lift. Adjusting the pushrod length is the best way to achieve this.

Proper valvetrain geometry requires the end of the rocker arm to stay on the valve tip and be centered at mid-lift. Adjusting the pushrod length is the best way to achieve this.

Enter the Matrix

Just because the pushrod engine is nearly dead as far as over-the-road cars are concerned, don't think the performance aftermarket has forgotten about the racers. While working on this story, we heard whispers out of Comp Cams that the next generation of pushrod technology was on the table. Apparently, Comp Cams is working with other companies on a "graphite aluminum matrix pushrod."

No, we don't know what that means, either, but it sounds light and strong. The analogy for a graphite aluminum matrix pushrod is carbon fiber. Graphite strands are used much like carbon strands in carbon fiber, and aluminum is used as epoxy to form a bonding agent. The result is said to be an ultra-light material with incredible strength.

For the time being, there is no timetable to make these space-age pushrods a part of the catalog. Apparently, there is still plenty of R&D left to be done. Still, it's nice to know the future of racing technology is bright.