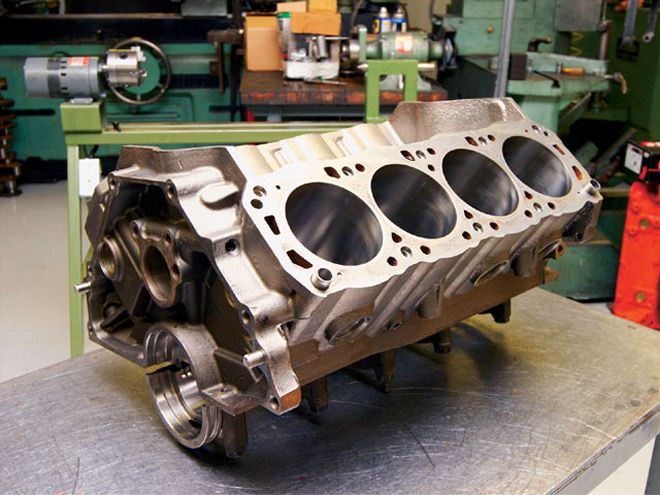

Developed by Raceparts Distribution and KT Engine Development for Ford Racing, this 351 Windsor block engine is the prototype for Ford's newest sealed crate racing motor.

Developed by Raceparts Distribution and KT Engine Development for Ford Racing, this 351 Windsor block engine is the prototype for Ford's newest sealed crate racing motor.

You have to give credit where credit is due: General Motors is largely responsible for the crate motor revolution in the beginning stages of sweeping through the stock car racing world. It was GM's Chevrolet brand that pushed the concept of spec V-8s in racing-going all the way back to the ASA's landmark decision to run warmed-over LS1s in the '99 racing season. Since then, Chevrolet has developed race-oriented small-blocks available for a good price and offered them as a cost-saving alternative to handbuilt racing engines.

Of course, everybody has an opinion as to whether this is the ultimate solution for declining car counts or the beginning of the end of circle track racing as we know it. The answer to that question is beyond the scope of this article, so we'll let sleeping dogs lie...for now. The news here is that Ford, which so far has largely been left out of the racing spec motor equation, is finally stepping up with an offering of its own. Now, at least if you are a die-hard Ford driver looking to run a spec motor series, you might not have to hide a Chevrolet motor in your car after all.

The project to develop this engine was spearheaded by Raceparts Distribution Inc. in Cornelius, North Carolina. RDI has long been Ford's primary distributor of hardware to its NASCAR Nextel Cup, Busch, and Truck teams, and the company is also expanding its reach into the Saturday night racing market. RDI's Preston Miller teamed with KT Engine Development to build a motor using almost exclusively parts available from the Ford catalog. The motor needed to be in line with Chevrolet's most popular sealed race motor (PN 88958601, GMR 350/400) both in terms of power production and price.

The foundation for this engine is Ford's 351ci Sportsman II wet sump block. It was chosen because it is an economical casting that still features a high-strength design perfect for medium-horsepower racing motors. It uses two-bolt mains with nodular iron caps. The bores are non-siamesed for better cooling, and the main journals are 3 inches.

The foundation for this engine is Ford's 351ci Sportsman II wet sump block. It was chosen because it is an economical casting that still features a high-strength design perfect for medium-horsepower racing motors. It uses two-bolt mains with nodular iron caps. The bores are non-siamesed for better cooling, and the main journals are 3 inches.

Circle Track was invited to check out this new powerplant while it was still in its late developmental stages. We were on hand for a final dyno run and teardown at KT Engine Development and got a first-hand look at the internals. The photos in this story are of the actual test engine, since it was the only version of this motor in existence at the time. That's also why the photos are of parts that have obviously been run.

The dyno run that we saw produced a peak torque number of 424.2 ft-lb at 4,600 rpm. Peak horsepower was 413.4 at 5,700 rpm. Optimum timing was found to be at 30 degrees. Like the Chevrolet, this motor is not a high-rpm screamer as most handbuilt race motors are. Although peak horsepower did fall off after 5,700, it didn't drop like a rock. The dyno run ended at 6,400 rpm, and horsepower was still at 387.4, while torque was at 317.9. Of course, it's also important to remember that this engine combo was built to exacting tolerances in a race shop, not a Ford assembly plant, so these numbers are probably 10 points higher than the final production motors will produce.

One thing we do like about this motor is that RDI and KT Engines have honestly tried to make it a fair match for what Chevrolet is already offering racing series as a sealed racing motor. Plus, all the mounting points for bolting the engine in the car, bolting up the bellhousing, and attaching the pulleys and other accessories are standard Ford. This means that most racers already racing with a 351W engine should be able to plug this one right into their cars if they choose to switch.

The crankshaft is cast and a direct replacement for 351W engines. Rod journals are 2.311 inches with 3-inch mains. It is designed for the stock 3.5-inch stroke.

The crankshaft is cast and a direct replacement for 351W engines. Rod journals are 2.311 inches with 3-inch mains. It is designed for the stock 3.5-inch stroke.

Part of the problem with putting together a Ford sealed crate motor is that there are almost no parts in Ford's current lineup of cars and trucks that use parts that will work in the 351W block-the basis for all of Ford's small-block race motors. Consequently, almost all of the hardware in this engine is from Ford's SVO line. The good news is that SVO parts are designed to stand up to the rigors of racing; the bad news is that they also usually cost more. While final pricing wasn't set at the time this issue of Circle Track went to press, you can expect the cost of this engine to be slightly more than Chevrolet's equivalent.

Right now, the working part number for Ford's new sealed race motor is SVOM6007Z351S. The "S" stands for sealed, although we're still not sure how Ford plans to do that or where the seals will be located. The target customers are tracks or racing series that are currently running NASCAR Late Model Stock-style engines and are looking into a crate program. By the time you read this, the motor should be available from both Ford and RDI. Ford will sell the motor less the Holley 650 carburetor and accessories. RDI plans to sell the motor along with a complete line of accessories, including its Nextel Cup fuel pump, carburetor, and a complete pulley/belt package.

RDI and KT considered several cam combinations before settling on a mild grind that brings the engine's power and torque curves in line with Chevrolet's. Ken Troutman, the owner of KT Engine Development, says that although many people will just compare the peak numbers, it was important to make sure the shape of the curves matched up well if the Ford and Chevrolet engines were going to be competitive on the racetrack. For maintenance-free longevity, a hydraulic roller cam was chosen. The grind specs call for 0.512 lift on both the intake and exhaust valves with 1.6-ratio rockers. Duration is 224 degrees on intake and 230 on exhaust at 0.05 lift, and the lobe separation angle is 110 degrees. Altogether, it's something an engine should be able to live with for quite some time.