The modern stock car racing engine is a product of two very interesting, and normally competing, dynamics. First, there are the rules. Aimed at providing safety, cost containment, and a level playing field (but not always in that order), it's the standard set of rules in stock car racing that have us still using the pushrod V-8 as the standard powerplant. Let's face it, we all know the pushrod V-8 doesn't deliver the best power per cubic inch ratio compared to more modern designs, nor is it very representative of "stock" these days. But, the design is fairly basic, easy to work on, and there are plenty of aftermarket parts manufacturers out there for it, so we are still racing it.

The other dynamic is that good old American need to win. It is what keeps many of you, and your engine builders, up at night trying to push the performance envelope just a little bit farther. That is what has helped take an engine design from the '50s and polish it to the near-perfect form it is today.

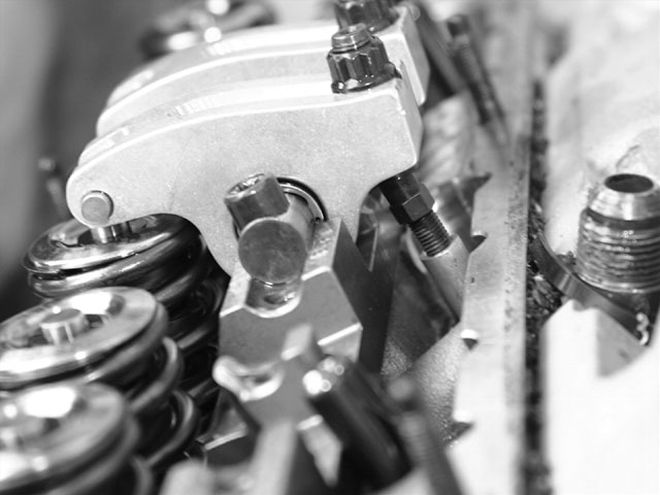

Today, Winston Cup engines are to the point that they are bumping up against the mythical 10,000 rpm barrier, and Saturday-night racing engines aren't far behind. The biggest weakness in these engines is the delicacy of the valvetrain components. At the upper-rpm limits, the allowable margin for error in an engine's valvetrain components becomes razor thin. Rocker arm/pushrod/valve combinations that seemed rock solid at 6,000 rpm suddenly feel the need to fly apart at 7,500. Shaft-mounted rocker arm systems have gone a long way toward stabilizing the valvetrain when compared to the old, stud-mounted rocker design, but both require proper installation for dependability.

Determining the proper pushrod length needed is a big part of that equation. Too much length and you may not have enough room to set the proper lash after the engine breaks in, or worse, the rocker may roll off the tip of the valve at full open. Too little and the opposite happens. Fortunately, calculating the proper pushrod length you need is fairly straightforward, and we're here to show you how.

The Toolbox Over the years, there have been as many methods of determining correct pushrod length as you care to imagine. But, fairly recently, different racing parts manufacturers have introduced tools that make it vastly easier. A critical component is centering the rocker over the tip of the valve stem. If the rocker isn't centered over the tip, you risk pressing the stem into the side of the bore, which vastly reduces the efficiency of the valve's actuation. If it is more extreme, the rocker can roll right off the top of the valve stem causing complete loss of valve control.

Normally, you would have to determine when the cam is at half lift before beginning any calculations, but that step is eliminated. With the proper tools to check pushrod length, all you need to do is have the lifter you are checking sitting on the pushrod of the cam.

Most pushrod checker tools will replicate the geometry of any ratio rocker arm for that manufacturer. With the tool positioned like you would a real rocker arm, you insert a valve all the way to the seat and make sure that the stem reaches the marked height (depends on type of tool). Then, insert an adjustable checking pushrod into place and run it out until it also makes contact with the checker.

Finally, remove the checking pushrod and get ready to do a little math. (To eliminate the possibility of accidentally changing the length of the checking pushrod when removing it, it's a good idea to first remove the rocker arm and get it out of the way.) Measure the length of the checking pushrod with a dial caliper. Now, take that length and subtract the lash you plan to run. This is the ideal length of your pushrod.

Of course, it's not exactly that easy. Pushrods are manufactured to lengths in 0.050-inch steps. When ordering your pushrods, you can generally round to the nearest 0.050 of an inch (for example, if your checking pushrod measures 8.515 inches, then the closest manufactured size is 8.500), but as engines break in, the lash usually reduces. If it is close, you might want to consider going to the next smaller size.