Though all but the number five cam bearings look the same size, each steps up slightly in diameter, and each will fit only in its assigned position. Notice the worn-out old bearing, right; an OEM production part with the dovetailed join.

Though all but the number five cam bearings look the same size, each steps up slightly in diameter, and each will fit only in its assigned position. Notice the worn-out old bearing, right; an OEM production part with the dovetailed join.

Some parts are high on the attention list when putting together a fresh mill, while others are just taken for granted. When it comes to engine bearings, what's hugging the crank and rods is given the priority. On the other hand, cam bearings are usually just knocked in by the machine shop charged with the block prep and forgotten about. After all, when was the last time you were bench racing and someone started talking about how sweet she was running until the cam bearings blew out? Probably not very often.

Though they don't generally cause much trouble when installed correctly, done wrong they cause a world of woes. Look at a set of cam bearings, and the first thing you'll notice are holes for oil passages. Each bearing has a hole that lines up with a passage from the mains, serving to lubricate that cam journal. Bearings two and four serve double duty, with a second hole to send oil over to the head, lubricating the valvetrain. No oil up top? Look for a misinstalled or spun cam bearing. While generally reliable in use, OE Mopar cam bearings often used a split-ring backing design. The backing actually joined, with the ends dovetailed together before the bearing material was laid in. In high-load use, the joint in the backing is the prime failure point. Most quality aftermarket cam bearings are manufactured with a seamless-ring backing, and are much less prone to failure. With even a quality set of cam bearings ringing the register for under twenty bucks, we see no reason to skimp.

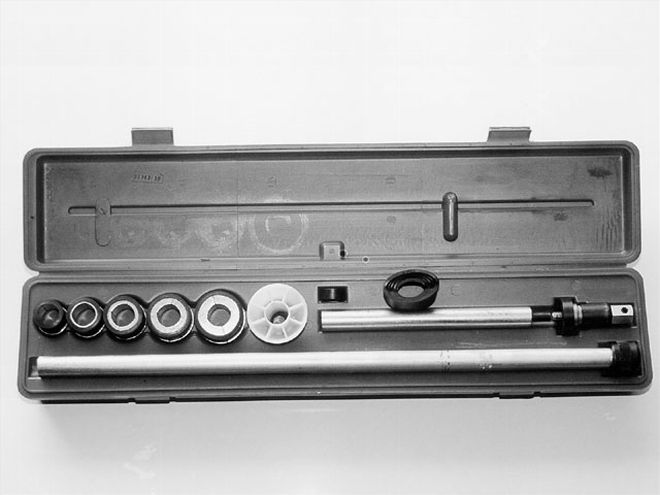

The Powerhouse #5312 universal cam-bearing installation kit can handle any Mopar cam bearing we've ever run across. If you build as many engines as we do, at $30-$40 a crack, the tool will eventually pay for itself, though the peace of mind from knowing the job is done right is priceless.

The Powerhouse #5312 universal cam-bearing installation kit can handle any Mopar cam bearing we've ever run across. If you build as many engines as we do, at $30-$40 a crack, the tool will eventually pay for itself, though the peace of mind from knowing the job is done right is priceless.

The fact is, at the average machine shop, installing cam bearings is usually the first step up the employment ladder for the guy unloading greasy cores from the back of your pickup truck. That's not to say that a professional installation is less than it should be-but it should be enough to convince the average wrenchman that it can be handled in his own garage with the right tools. The desire to do it ourselves came from bucks-down rebuilding, when the only machine-shop job in the budget was having the block hot tanked. The cleaned block came back for hand-honing to deglaze the bores and rebuilt with a $100 rebuild kit consisting of rings, bearings, and gaskets. The problem in this super-low-buck scenario was always in the cam bearings. Get the block hot tanked, and the cam bearings would be ruined, requiring new ones, plus 30-40 dollars to get them installed. If only we had the tool, we reasoned, we'd save big

Flipping through the Powerhouse Products catalog, we ordered a #5312 cam bearing installation set, and now we can do one more job ourselves in any rebuild. With the Powerhouse set, virtually any cam bearing can be installed or removed with its adjustable-diameter drivers, and we're certain the job is done right.