We'll probably be criticized for this--pulling an engine out of the boneyard and running it on the dyno with different parts to try to make power. You've seen it before, but not with a Pontiac. Some say it's a waste of time, but we maintain this sort of exercise has value. Try not to focus on the junkyard aspect, and just think of it as a used Pontiac engine, perhaps like the one beneath your own car's hood. Not everyone wants or needs to rebuild an engine just because they're considering a few upgrades. As we've found, you can really breathe new life into an old dog with the right parts. This test actually wasn't our original intent for the 455. When we pulled it from the 'yard, we didn't have any definite plans for it, but knowing how scarce 455s have become, we had to yank it and stash it ... you know, just to have. Since the idea was to eventually rebuild the beast, it had to come apart anyway, but much to our surprise, after yanking the heads and oil pan, all indications were that this 455 had led a charmed life. The tops of the cylinder walls had nearly imperceptible wear ridges, the rod and main bearings still looked fresh, and even the valves showed almost no wear at the seats. These factors, coupled with the presence of flaky carbon on the pistons and crusty buildup on the backs of the valves seemed to imply that this engine probably hadn't seen much beyond 2,000 rpm in years, if ever.

So, after seeing how well-preserved the engine's internals were, we got to thinking that prior to actually rebuilding it, it might make a suitable test mule to show the effects of bolt-on upgrades to a stock, used engine that was still in good health.

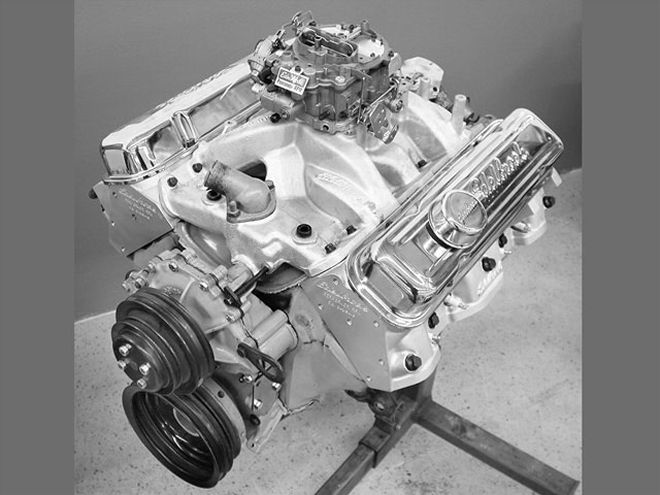

The Mule

Our engine came from a '76 Grand Prix, placing it among the last 455s produced, as 1976 was to be the swan song for the biggest Pontiac. All 455s produced that year, regardless of application, were identical, so the engine powering a '76 Grand Safari station wagon was the same as the one in a '76 Trans Am coupled to a four-speed trans. Smog regulations and concerns over fuel economy had effectively neutered the once-proud Pontiac, leaving it with 7.6:1 compression, a teeny little cam, and no guts. Even the intake manifold suffered, showing partially blocked secondary bores that were originally fed by a "detuned" Quadrajet. General Motors rated this particular version of the 455 at only 200 hp, peaking at a ridiculously low 3,500 rpm.

Despite the lame factory specs of our late 455, it still has tremendous potential. Obviously things like camshafts and intake manifolds are easy enough to improve, but since Pontiac built all 455s with fairly similar flat-top pistons, regaining compression is simply a matter of swapping cylinder heads. The Pontiac 455 debuted for the 1970 model year with 10.25:1 compression, which is obviously a bit high for an iron-headed pump-gas engine today. When compression ratios began to drop in 1971, the 455 H.O. plummeted all the way to 8.4:1. Despite this, performance remained strong on H.O. versions for the '71 and '72, and continued with the Super Duty for the '73 and '74, though these were fairly exotic "round-port" engines--referring to the shape of the exhaust ports found on most high-performance Pontiac engines from 19681/2-on. Standard "D-port" 455s for '71-'72 had even less squeeze at 8.2:1, and they dropped again to 8.0:1 for '73-'74 models. These were decent passenger-car engines, but the 7.6:1 engines in the '75-'76s were pretty pathetic.

Our plan was to run the 455 on an engine dyno in bone-stock form--junk heads, stock cam, restricted iron intake, even the stock iron "log"-style exhaust manifolds, and then upgrade it step-by-step, retesting at every interval along the way. Since we were dealing with a sound short-block and flat-top pistons, in theory, the potential to double the engine's output with bolt-on, or at least, bolt-in parts seemed somewhat feasible.

Check out the results in the sidebars below.