When Detroit made the big switch to electronic fuel injection (EFI) about 15 years ago, most hot rodders retreated, assuming that this new technology would never be part of their world. Deeply immersed in the Carburetion Cult, they reacted to EFI in much the same way pilots of propeller-driven aircraft did to the very first jets in 1945. Wary skepticism, coupled with a natural fear of the unknown, caused many otherwise enlightened people to shun the wave of the future.

Fortunately, EFI has become standard equipment on virtu-ally every new car and light truck sold in the free world, and more than two decades of development has brought the OEM technology to the point of million-mile reliability. With routine maintenance (injector cleaning, oxygen-sensor replacement, and fresh fuel filters) many of these systems will outlast the cars they came in. And yes, EFI and factory high performance go hand in hand, as the owner of any Tuned Port IROC-Z, '86-up Mustang GT, Buick Grand National, or C4 Corvette (to name but a few) will happily confirm.

High-performance aftermarket EFI systems have been available for quite some time, but recently this technology and its benefits have really begun to take root with hot rodders. If you need any proof of the viability of EFI in a full-tilt performance application, check out our HOT ROD/NMCA World's Fastest Street Car drag-racing series. In those classes where EFI is legal, the racers are wondering how they ever got along without it. Pat Musi converted his Pro Street Camaro to EFI and picked up more than 4 mph to reset the Pro Street speed record at 205.88 mph. EFI is here to stay, so let's take full advantage of all it has to offer.

To expand our understanding of aftermarket EFI, we installed an ACCEL/DFI system on a big-inch Stage V Hemi Conversion-powered Dodge Dart in a quest for more power, better driveability, vastly enhanced fuel economy, and noticeably cleaner emissions. Our intention was to compare the performance of the dual-quad carburetion setup with the EFI in a before/after test, but as we made our first chassis dyno pull after installing the EFI, the TorqueFlite transmission and/or torque converter went south. For now, we will concentrate on the swap from carbs to electronic fuel injection.

The Test Car

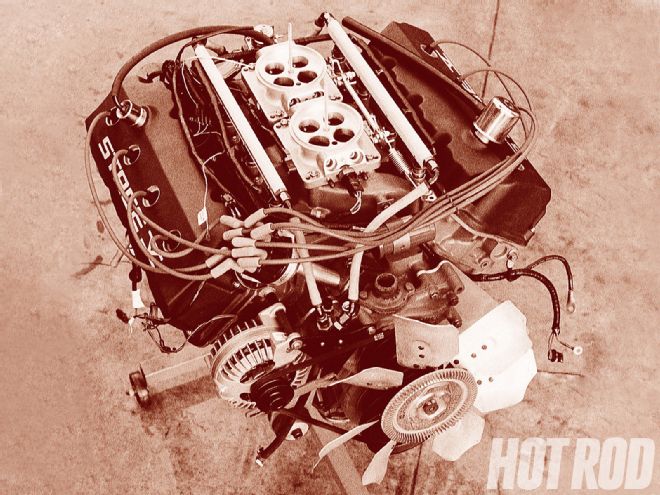

Although our '67 Dart test car isn't one of the original 72 units converted by Hurst Performance into Super Stock warriors, it is a clone...with a twist. While the Hurst cars were built specifically for drag racing, this Dart represents what a factory-built Street Hemi-powered version might have been like had market demand war-ranted such a package. Ford and Chevy lovers, try to imagine a Boss 429 Maverick or LS6 Nova, and you'll get the picture. Instead of a stock 426 Street Hemi, this never-built Street Hemi Dart clone is powered by a 520ci Stage V Hemi Conversion (see "What's a Stage V?" sidebar) packed with a Keith Black 5/8-inch stroker crank, Crower billet rods, Arias 10:1 forged pistons, Crower 0.626(I)/0.631(E) roller cam, and twin 750cfm Edelbrock carbs on a mildly reworked Street Hemi manifold.

On the Dynojet 248C chassis dyno at Harv's Performance Center, the Hemi produced 445 hp at 6,400 rpm and a calculated 616.7 lb-ft of torque at 2,300 rpm. Using the commonly accepted formula for horsepower based on chassis dyno numbers (rear wheel hp x 1.33), the Hemi was making 591 horsepower at the flywheel. Could we improve on those impressive numbers with the ACCEL/DFI EFI system? Craig Railsback of Blower Drive Service (BDS) said: "You will be amazed." But we'll have to wait until our wounded TorqueFlite is well again for those results. Judging from the results Railsback had tuning Frank Currie's 705-inch '32 Ford ("Shotgun Saltshaker," Nov. '97) for 205 mph Bonneville blasting and 18 mpg Power Tour Long Haul capability, the results should be impressive.

Why EFI?

Before we lay out the conversion process, let's outline the benefits of a dry-flow, multipoint EFI system and define the shortcomings of carburetion. Although carburetors have been with us for nearly 100 years, even the most highly evolved designs suffer from the flow restriction caused by the presence of a venturi cone and booster ring in each throttle bore. These necessary evils initiate a low-pressure siphon effect, which draws gasoline into the air path from the float bowls via the idle and main metering circuits. In a dry-flow system like the ACCEL/DFI setup we installed, carburetors are replaced by throttle bodies, or "air doors," which flow nothing but air through venturi-less throttle bores. Because the air is not saturated with fuel, it is lighter, more flexible, and can conform more readily to the necessary changes in direction and velocity as it travels toward the combustion chamber.

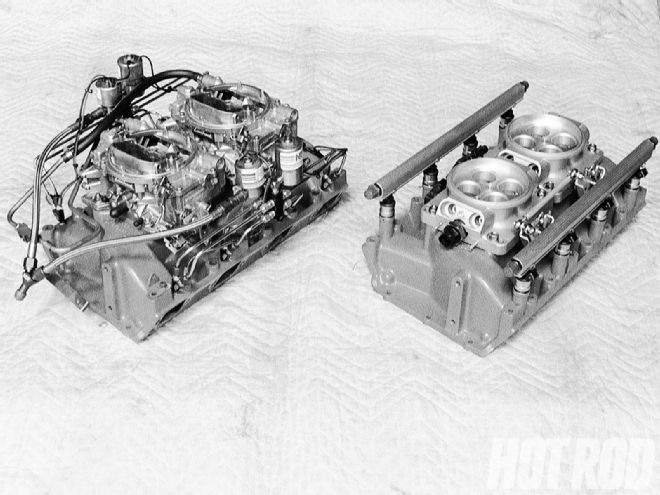

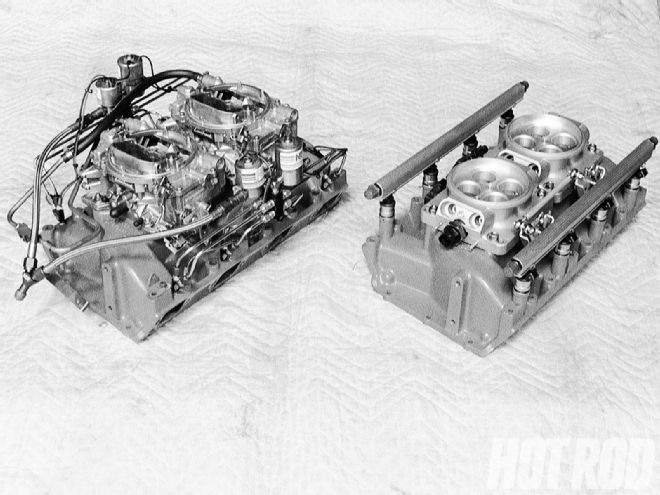

Chrysler Street Hemi intake manifolds are the basis of both fuel-delivery systems-ignore the nitrous-oxide plumbing on the carbureted intake; it was not used during testing. ACCEL/DFI throttle bodies are more than 1 inch lower than the carbs, boosting hood-to-air-cleaner clearance. The hood of the street-themed Dart is scoopless.

Chrysler Street Hemi intake manifolds are the basis of both fuel-delivery systems-ignore the nitrous-oxide plumbing on the carbureted intake; it was not used during testing. ACCEL/DFI throttle bodies are more than 1 inch lower than the carbs, boosting hood-to-air-cleaner clearance. The hood of the street-themed Dart is scoopless.

The dry-flow, multipoint system employs strategically positioned and electronically controlled fuel-injection solenoids, one per cylinder, which administer precisely timed, high-pressure streams of atomized gasoline into the air path in close proximity to the cylinder-head intake port. And therein lies the magic of the modern EFI system-because a carburetor administers the air/fuel mixture from atop the intake manifold, cylinder-to-cylinder fuel distribution can never be optimized, and there will always be some cylinders that run rich while others run lean. But thanks to the placement of a fuel injector in each intake runner (thus the term multipoint), and today's highly evolved electronic sensor/control technology, the ECM can actually tailor the pulse width of each fuel injector (the amount of time, measured in milliseconds, that each injector is firing) to the specific needs of each cylinder. The ECM also varies spark timing from cylinder to cylinder to control combustion, and it continuously makes corrections at a rate of 3,000 possible adjustments per second thanks to data feedback provided by the sensors in the system.

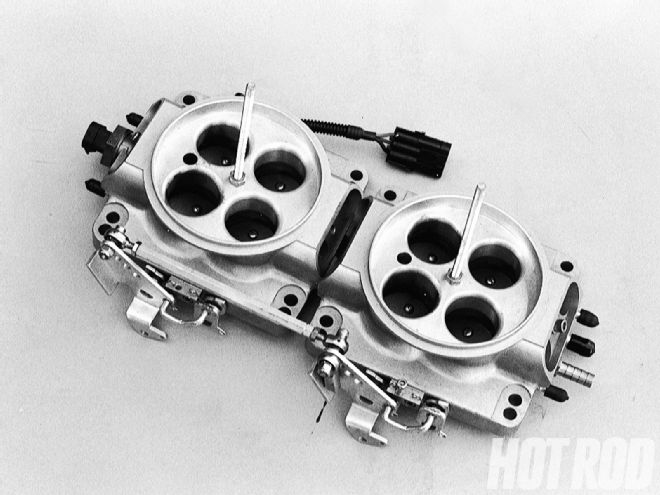

Enlarged throttle bores provide clearance for the dual 930cfm ACCEL/DFI throttle bodies (inset). The low-profile injector bung and fuel-rail installation does not interfere with the throttle linkage...

Enlarged throttle bores provide clearance for the dual 930cfm ACCEL/DFI throttle bodies (inset). The low-profile injector bung and fuel-rail installation does not interfere with the throttle linkage...

This is the key to maximizing efficiency and getting the most power from each cylinder. And it pays great dividends, not just in brute power, but in enhanced fuel economy, improved driveability, and reduced exhaust emissions.

The stars of the ACCEL/DFI show are the Coolant Temperature Sensor (CTS), which provides the ECM with data on whether the engine is hot or cold, so the fuel enrichment curve can be tailored accordingly; the Exhaust Gas Oxygen Sensor (02 Sensor), which measures the amount of oxygen present after combustion, an indication of whether the intake charge is rich or lean; the Throttle Position Sensor (TPS), which alerts the ECM to rapid acceleration or deceleration and whether the engine is at either idle or wide-open throttle; the Air Temperature Sensor (ATS), which provides the ECM with inlet-air temperature data, allowing the computer to adjust fuel-flow volume for changes in air density; the Manifold Absolute Pressure Sensor (MAPS), which measures changes in intake-manifold pressure as a result of engine speed and load and provides the ECM with data vital to proper fuel- and spark-delivery calculations for these varied conditions.

...When in place, the large-diameter Street Hemi air cleaner cloaks the EFI components if the competition starts snooping.

...When in place, the large-diameter Street Hemi air cleaner cloaks the EFI components if the competition starts snooping.

Induction

For our apples-to-apples comparison, Railsback modified a '66 Street Hemi dual-quad intake manifold for the multipoint EFI conversion. By using a common manifold design, we could post our findings against the dual Edelbrock 750cfm induction. Railsback milled the plenum bores oversize to accommodate the 1 11/16-inch butterflies in the new throttle bodies. Then, he bored holes into each runner as close to the terminus as possible and pressed threaded aluminum bungs into these holes in the manifold and secured them with a dab of heliarc welding. To eliminate vacuum leaks, Railsback flowed epoxy around each seam. When asked if the Street Hemi's dual-plane plenum and runner arrangement lent itself to conversion to dry-flow status, Railsback said that he preferred to work with single-plane designs but that the wide range of tunability with the ACCEL/DFI system would easily allow him to add or subtract fuel from each cylinder via injector-pulse-width manipulation to achieve the perfect balance. In short, Railsback can rework any existing manifold to operate successfully with EFI.

It is essential to mount the ECM in a cool, dry place. Moisture will induce internal shorts and failure. After confirming that the cowl and windshield gasket were sealed against leaks, we installed the ECM under the dashboard.

It is essential to mount the ECM in a cool, dry place. Moisture will induce internal shorts and failure. After confirming that the cowl and windshield gasket were sealed against leaks, we installed the ECM under the dashboard.

Each of the eight aluminum bungs was fitted with an ACCEL/DFI 55lb/hr low-impedance injector. Railsback computed this delivery rate-Max hp/# of injectors x 0.55=fuel requirement in lb/hr-based on his sense that the Hemi would jump from 591 to 650-plus horsepower after the EFI conversion. A pair of 930cfm four-barrel throttle bodies reside where the carbs once lived, and all applicable sensors and wiring harnesses were then installed.

Ignition System

In carbureted form, the Dart used an MSD 6A-L ignition control module, Pro Billet distributor, 8mm Heli Core secondary wires, and a Blaster 2 coil. The ACCEL/DFI engine-management system is designed to interface directly with these components (as well as several other popular aftermarket and OE ignition systems), and installation was a simple matter of following instructions and paying attention to the details. The expert crew at Harv's Performance Center handled this end of the conversion.

A mechanical Paxton fuel-pressure regulator (inset) mounted rearward of the fuel rails is set at 60 psi...

A mechanical Paxton fuel-pressure regulator (inset) mounted rearward of the fuel rails is set at 60 psi...

But because the ACCEL/DFI ECM is programmed to monitor all fuel- and spark-delivery functions, the mechanical-advance feature within the MSD distributor must be locked out. Conveniently, the MSD Pro Billet distributor quickly converts to no-advance, locked-out status by removing the advance springs, weights, and stop bushings from beneath the rotor; a small lock bolt immobilizes the advance plate. For our application, the distributor is set to provide a steady 35 degrees of total timing, but adjustment for advance and retard are subsequently handled by the ECM. Although the ECM is responsible for running the show when it comes to fuel- and timing-delivery curves, the MSD unit provides ignition voltage, and the engine-speed limiter remains active. Harv's technicians mounted the ECM under the dashboard to keep it cool and dry.

Fuel System

Electronic fuel injectors are far more sensitive to particulate contamination than are carburetors. If the gas tank has any internal surface corrosion, it must be replaced. Our Dart's tank was emptied, removed, and given a visual inspection to ensure that all was well. The next step was to ensure that the existing fuel-supply line would be capable of handling the increased fuel flow required by EFI. While carburetors are designed for fuel pressures between 4 and 7 psi, multipoint EFI systems require as much as 10 times that amount to ensure proper atomization and prevent fuel percolation. The preexisting 3/8-inch steel line on the Dart was deemed capable of handling the flow, but every bit of rubber hose connecting the steel sections was replaced with 250psi reinforced hose from Xtreme Racing Products (XRP). This may seem like overkill, but there is a world of difference between a 6psi leak and a 60psi leak!

...Excess fuel is routed back to the fuel-tank filler tube via the return line. We elected to have gasoline reenter the tank through a bung and fitting welded to a trunk-mounted filler tube because it was easier and safer than cutting and welding the gas tank.

...Excess fuel is routed back to the fuel-tank filler tube via the return line. We elected to have gasoline reenter the tank through a bung and fitting welded to a trunk-mounted filler tube because it was easier and safer than cutting and welding the gas tank.

The standard screw-type hose clamps were replaced with EFI-specific clamps and XRP press-on AN fittings. A copy of the supply line was fabricated and installed as a return line to route excess fuel flow from the Paxton pressure regulator back into the gas-tank filler tube. We replaced the Holley Blue pump with a high capacity Paxton 55lb/hr pump, which was mounted under the car near the gas tank. During the process, we were very cautious to ensure that all lines were flushed and blown clear prior to installation in order to prevent particulates from reaching an injector. Further, we plumbed two metal-body high-flow fuel filters-one between the tank and the pump, the other between the pump and the fuel rails. Finally, a fuel-pressure gauge was installed in-series with the fuel-supply line at the fuel-rail junction as an essential tuning aid. If the baseline fuel pressure is incorrect, tuning via the laptop computer will be impossible.

Testing 1, 2, 3

With the new equipment in place, Railsback tapped away on the keys of the laptop as the Hemi burbled to life. As he trimmed and tweaked the fuel and timing curves with each stroke of a key, the idle quality of the Hemi became crisp, and the throttle response was honed to perfection. After a quick systems-check testdrive, we rolled the Dart onto the chassis dyno. Straightaway, the motor refused to pull beyond 5,000 rpm. It wasn't anything to do with Railsback's tune-up; something inside the torque converter or transmission seemed to be dragging the engine down, so instead of forcing the issue, we elected to investigate the problem before proceeding with the test. As such, we will have a full drive, dyno, and drag report in an upcoming issue.